Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Understanding Paper Brightness PDF

Caricato da

SappiETCTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Understanding Paper Brightness PDF

Caricato da

SappiETCCopyright:

Formati disponibili

Printer Technical Service

Understanding Paper

Brightness

Introduction

Brightness quantifies the percentage of blue light reflected from the surface of

paper as measured at a specific effective wavelength of 457 nanometers (with a

1

half-peak bandwidth of 44 nm).

Brightness does not indicate the color or relative shade of the paper since a

single number reflective value measured at 457 nm ignores all other wavelengths

of light reflected across the visible spectrum. A brighter paper, therefore, reflects

a greater amount of blue light than does the surface of a less bright paper.

Three different brightness measurement methodologies are used worldwide.

Each of these methods will produce a different brightness number when used to

measure the same paper sample. It is, therefore, important to understand basic

concepts of each of the three testing methods, including photometric principles,

characteristics of the illuminants, and illumination/observerreflected light

measurement geometries.

Due to differences in illuminants and illumination/reflected light measurement

geometries, there are no direct correlations between brightness measurements

produced by the three methods.

Monitoring the photometric curve response throughout the pulp bleaching cycle shows

that changes are greatest in the short wavelength area (the violet/blue region of the

visible spectrum). Therefore, 457 nanometers has been determined to be an appropriate

wavelength for optimal measurement of light reflection to monitor pulp and paper

brightness.

1

Sappi North America

2017 Sappi North America. All Rights Reserved.

Printer Technical Service

The three paper brightness standards are briefly described as follows.

TAPPI (T 452) / GE Brightness

The Technical Association of the Pulp and Paper Industry (TAPPI) has authorized

method T 452 for use in determining the brightness of paper. TAPPI T 452

brightness is often referred to as GE brightness since General Electric invented

one of the first paper brightness testing machines which became the industry

standard for decades. The GE brightness measurement scale has been in place

since the 1930s. Considering there are two TAPPI standards for brightness, we

will hereafter refer to the T 452 method as GE brightness.

GE brightness is used for specification of paper brightness primarily in North

America.

The International Commission on Illuminationalso known as the CIE from its

French name, the Commission Internationale de lEclairage, has defined the

spectral power distributions of several illuminants which are divided into three

categories: tungsten, daylight, and fluorescent.

When measuring GE brightness, the paper sample is illuminated with a CIE

2

illuminant C defined light source; a simulated daylight illuminant containing a

3

certain amount of U.V. energy. In-line brightness filters are also applied which

modify the spectral characteristics of the reflected illuminant.

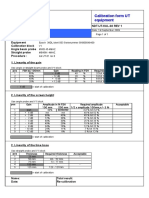

TAPPI T 452 specifies directional illumination/measurement geometry of 45

illumination, 0 observation (i.e., 45/0). In other words, the test instrument emits

light which strikes the surface of the paper at a 45 angle of incidence. A

photocell receptor is positioned at the N or 0 position, perpendicular to the paper

sample. The directional illumination/reflected light measurement geometry is

illustrated in figure 1.

CIE illuminant C is no longer a CIE standard illuminant. However, the International

Commission on Illumination publishes a spectral power distribution, tristimulus values,

and chromaticity coordinates for illuminant C. Illuminant C is used by many spectral and

colorimetric measurement systems.

3

ISO 2470-2 states that the UV content of CIE illuminant C approximates levels of UV

energy present in certain indoor viewing conditionssignificantly less than the UV

content of CIE standard illuminant D65.

Sappi North America

2017 Sappi North America. All Rights Reserved.

Printer Technical Service

Photocell Detector

Light Source

0

45

Brightness filters

Paper Sample

Directional Geometry (45/0)

Figure 1

A focused beam of light strikes the paper sample at 45 and, after passing

through a series of filters, the reflected light is received by the photocell.

The quantity of reflected light received by the photocell is measured and

expressed based on a scale relative to the amount of light that would be reflected

from a 100% reflective magnesium oxide standard. Therefore, the expressed

brightness measurement mandated by the GE methodology is not an exact

percentage of light actually reflected from the paper.

There are advantages and disadvantages to the directional geometry method

4

specified by the TAPPI T 452/GE brightness standard. One of the challenges of

directional illumination and measurement is that the focused illumination

geometry makes the system sensitive to non-uniformities in the paper. Different

test results may be obtained when measuring in the machine and cross-machine

directions (i.e., parallel to paper grain and across paper grain direction

respectively). The industry typically measures the directional brightness of paper

samples with orientation parallel to grain direction.

Technidyne Corporation Technical Bulletin No: 101: Diffuse vs. Directional Brightness

Measurement, provides an excellent overview of the advantages and disadvantages

associated with the directional and diffuse measurement systems.

Sappi North America

2017 Sappi North America. All Rights Reserved.

Printer Technical Service

ISO Brightness (ISO 2470-1)

The ISO paper brightness measurement system, as defined by ISO 2470-1 and

TAPPI T 525, is used for specification of paper brightness throughout Europe and

in many other parts of the world.

When measuring ISO brightness, the paper sample is illuminated with a CIE

illuminant C light source; a daylight illuminant containing a certain amount of U.V.

energy. This is the same illuminant used by the TAPPI T452/GE paper brightness

measurement system (see footnotes 2 and 3).

ISO 2470-1 specifies an illumination/reflected light measurement system which

utilizes diffuse optical geometry (diffuse illumination, 0 observation; i.e., d/0).

The instrument used to measure ISO brightness illuminates the samples with

light projected by two lamps into an integrating sphere. The interior wall of the

sphere is coated with a highly reflective non-glossy material which allows the light

to inter-reflect and illuminates the paper sample from all directions; i.e., diffusely.

Photocells or diode receptors are positioned at the 0 position, perpendicular to

the plane of the paper sample, and record the amount of light reflected from the

papers surface. The computer analyzes the spectral power distribution of the

reflected light and quantifies the energy response at 457 nanometers. Figure 2

illustrates the diffuse illumination/observation system.

Diffuse measurement geometry integrates the light reflected across nonuniformities of the sample and averages the effects of reflective differences due

to paper directionality. Therefore, ISO brightness measurements are less

sensitive to paper surface and directional orientation irregularities.

Unlike the TAPPI T 452/GE method, the ISO brightness measurement system

quantifies the actual percentage of light reflected from the sample at 457 nm

rather than relating measurements to a scale correlated to the percentage of light

reflected by an external standard.

The ISO brightness methodology typically produces a higher brightness number

than the TAPPI T 452/GE method when measuring the same paper sample due

to slightly greater fluorescence stimulation, the illumination/light measurement

geometry, and the brightness scales used.

Sappi North America

2017 Sappi North America. All Rights Reserved.

Printer Technical Service

Photocell Detector

Gloss Trap

Integrating

Sphere

0

Light Source

Light Source

Paper Sample

Diffuse Geometry (d/0)

Figure 2

D65 Brightness (ISO 2470-2)

The D65 brightness measurement system (ISO 2470-2) is essentially the same

as the previously described ISO system (ISO 2470-1) with the exception of the

specified illuminant.

D65 brightness uses the CIE standard illuminant D65, an outdoor (average north

sky) daylight illuminant containing a significantly greater amount of UV energy

than CIE illuminant C (as specified for ISO brightness measurement). Therefore,

the additional UV energy emitted by the D65 standard illuminant will produce a

greater fluorescence response when the paper contains optical brightening

agents. Consequently, D65 brightness measurements will be significantly higher

(when paper contains optical brightening agents) than those produced by the

TAPPI T 452/GE or the ISO brightness methods which specify an illuminant with

less UV content.

The following provides a comparison of key elements for each brightness

measurement standard:

Standard

Illumination/Viewing Geometry

TAPPI T 452 / GE Brightness

Directional (45/0)

ISO Brightness (ISO 2470-1)

D65 Brightness (ISO 2470-2)

Diffuse (d/0)

Diffuse (d/0)

Sappi North America

2017 Sappi North America. All Rights Reserved.

Illuminant

CIE illuminant C (filtered

response)

CIE illuminant C

CIE standard illuminant D65

Printer Technical Service

If a paper contains optical brightening agents, the GE brightness methodology will

produce the lowest brightness number while D65 brightness will produce the

highest.

Note regarding fluorescence and brightness measurements

in excess of 100%

In response to the design community and the graphic arts industrys demand for

brighter blue white papers, fine paper manufacturers commonly add chemical

compounds called optical brightening agents or fluorescent whitening agents

(OBAs/FWAs) to commercial printing papers. These chemicals have the unique

ability to absorb ultraviolet radiation and then transform and re-emit invisible UV

wavelengths as high energy photons of light in the violet/blue area of the visible

spectruma phenomenon called fluorescence. Invisible UV wavelengths such

as contained in sunlight, ISO 3664:2009 standard lighting, and, to varying

degrees in many artificial light sources, are therefore absorbed by optical

brightening agents in fine printing papers and transformed into wavelengths of

energy perceptible to human viewing. This transformed UV energy becomes

visible light radiating from the papers surface.

When illuminated by a light source containing a significant amount of U.V. energy,

the energy transference process (from invisible to visible wavelengths) is

activated and an optical brightener enhanced paper may actually reflect more

total light than it receives from the light source (i.e., visible light reflected from the

light source plus re-emitted blue light transferred from the invisible realm of the

electromagnetic spectrum).

Since paper brightness is measured in the blue area of the visible spectrum (457

nm), the very region where the process of fluorescence redirects UV energy to

become visible light, illuminants with high UV energy content (e.g., D65) can

produce brightness measurements in excess of 100%.

Fluorescence may be quantified with both directional and diffuse measurement

systems. Measurements are made with and without the use of a UV-cut filter. A

fluorescence value is then calculated from the mathematical difference between

the UV included and UV excluded measurements. Note that the measurement

system must utilize a controlled, spectrally defined illuminant since the spectral

power distribution characteristics and UV energy content of the light source will

significantly affect the balance of reflected light and the degree of fluorescence.

Sappi North America

2017 Sappi North America. All Rights Reserved.

Printer Technical Service

Comparative brightness measurements

As previously pointed out, each of these brightness measurement methods will

produce a different brightness number when used to measure the same paper

sample.

Due to slight modification of the illuminant, measurement geometries, and the GE

standard brightness scale, TAPPI T 452/GE brightness will yield the lowest

brightness number of the three methods. TAPPI T 452/GE brightness numbers

will rarely exceed 100. When measuring the same paper sample, ISO brightness

numbers will be slightly higher than those produced by the GE brightness method.

The D65 brightness measurement methodology will return the highest readings

often in excess of 100% for papers containing fluorescent components. This is

due to the high UV energy content of the CIE standard illuminant D65.

The three methods may produce similar brightness numbers when measuring a

common paper with low fluorescence. However, as fluorescence increases, the

measurements produced by the three different methods will become

progressively dissimilar.

References

TAPPI T 452 om-08; Brightness of pulp, paper, and paperboard.

ISO 2470-1, Second edition 2016-09-15; Paper, board and pulpsMeasurement

of diffuse blue reflectance factor; Part 1: Indoor daylight conditions (ISO

brightness).

ISO 2470-2, First edition 2008-11-01; Paper, board and pulpsMeasurement of

diffuse blue reflectance factor; Part 2: Outdoor daylight conditions (D65

brightness).

Sappi North America

2017 Sappi North America. All Rights Reserved.

Potrebbero piacerti anche

- Gray Scale For Color Change and Gray Scale For Staining: or ISO Test Method 105-X12Documento4 pagineGray Scale For Color Change and Gray Scale For Staining: or ISO Test Method 105-X12郭哲宏Nessuna valutazione finora

- Is Iso 105 A05 1996Documento12 pagineIs Iso 105 A05 1996tramy1413Nessuna valutazione finora

- Test Methods For Textile Fibres With Textile LabDocumento5 pagineTest Methods For Textile Fibres With Textile LabRezaul Karim TutulNessuna valutazione finora

- L1050109 - Spectrum 3 IR Dual-Range Spectrometer User's Guide en-USDocumento108 pagineL1050109 - Spectrum 3 IR Dual-Range Spectrometer User's Guide en-USFrizki88Nessuna valutazione finora

- TiN Coating of Tool SteelDocumento13 pagineTiN Coating of Tool Steelvitet412759Nessuna valutazione finora

- Mil STD 1501bDocumento12 pagineMil STD 1501bJuan Pablo ToroNessuna valutazione finora

- CVD 1 PDFDocumento11 pagineCVD 1 PDFpichonsisimoNessuna valutazione finora

- BS en Iso 00105-E04-2009Documento12 pagineBS en Iso 00105-E04-2009batataNessuna valutazione finora

- Iso 105.a03.1993Documento10 pagineIso 105.a03.1993Muthukumaar GanapathisamyNessuna valutazione finora

- Free Chlorine Test MethodDocumento8 pagineFree Chlorine Test MethodarjunanpnNessuna valutazione finora

- UOP952Documento12 pagineUOP952goodcharacter1Nessuna valutazione finora

- Is Iso 105-C10Documento17 pagineIs Iso 105-C10JGD123100% (1)

- BS en Iso 00105-B07-2009Documento12 pagineBS en Iso 00105-B07-2009amer0% (1)

- Holographic Projection - SahadDocumento23 pagineHolographic Projection - SahadSahad MkNessuna valutazione finora

- Fluorescent Light Source Color ChartsDocumento1 paginaFluorescent Light Source Color Chartsninadpujara2007Nessuna valutazione finora

- End of Waste - Scrap Metal Case Study: Working DocumentDocumento25 pagineEnd of Waste - Scrap Metal Case Study: Working Documentsuresh693sNessuna valutazione finora

- Categories of HologramsDocumento2 pagineCategories of HologramsChanNessuna valutazione finora

- Durometro - Time - th130 PDFDocumento2 pagineDurometro - Time - th130 PDFjoseperezosoNessuna valutazione finora

- Principle of HolographyDocumento36 paginePrinciple of HolographySumanth BodduNessuna valutazione finora

- Tool Wear MechanismDocumento8 pagineTool Wear Mechanismnduvu1050% (2)

- AISI Type 430Documento3 pagineAISI Type 430Agus MulyadiNessuna valutazione finora

- Physic Holograms PaperDocumento8 paginePhysic Holograms PaperWesley ShippNessuna valutazione finora

- Colour Fastness Report For LabDocumento3 pagineColour Fastness Report For LabGhazanfar Gul Bhutto100% (1)

- Fowler Instructions Report EditDocumento5 pagineFowler Instructions Report Editapi-550048875Nessuna valutazione finora

- About Folded and Crumpled Models in NatureDocumento8 pagineAbout Folded and Crumpled Models in NatureWilliam DriepuntnulNessuna valutazione finora

- Laundering - Aatcc 124.1996Documento5 pagineLaundering - Aatcc 124.1996Zubair ShafqatNessuna valutazione finora

- Holography HistoryDocumento27 pagineHolography HistoryasduraiNessuna valutazione finora

- B703 Standard Test For Apparent Density by Arnold MeterDocumento3 pagineB703 Standard Test For Apparent Density by Arnold MeterakjeevananthamNessuna valutazione finora

- CH-24-Stainless Steel Notes PDFDocumento7 pagineCH-24-Stainless Steel Notes PDFArvind RaguNessuna valutazione finora

- AATCC - 89 - Mercerization in CottonDocumento2 pagineAATCC - 89 - Mercerization in CottonNguyễn Công Thoại100% (1)

- Different Fastness TestDocumento13 pagineDifferent Fastness TestadeelNessuna valutazione finora

- CF To PrespirationDocumento6 pagineCF To Prespirationdr tamerNessuna valutazione finora

- ISO 105 E03-1997 Textiles. Tests For Colour Fastness. Colour Fastness To Chlorinated Water (Swimming Bath Water)Documento12 pagineISO 105 E03-1997 Textiles. Tests For Colour Fastness. Colour Fastness To Chlorinated Water (Swimming Bath Water)Sumanto100% (1)

- FTIR (Things We Need To Know)Documento3 pagineFTIR (Things We Need To Know)Keith Jaszer AgarradoNessuna valutazione finora

- DyStar Product Selection Guidance Nike 2014101Documento54 pagineDyStar Product Selection Guidance Nike 2014101Dewan Ajuad Hossain RifatNessuna valutazione finora

- Nato Reaction-To-Fire Tests For Materials Smoke Generation: Afap - 2 (Edition 3)Documento31 pagineNato Reaction-To-Fire Tests For Materials Smoke Generation: Afap - 2 (Edition 3)PAWANSVPNessuna valutazione finora

- GLIMMDocumento22 pagineGLIMMJou RazoNessuna valutazione finora

- Testing Textile Color Fastness To WaterDocumento6 pagineTesting Textile Color Fastness To WaterMajor SaahabNessuna valutazione finora

- Drimarene Blue CL-BRDocumento3 pagineDrimarene Blue CL-BRDaneyel MoreiraNessuna valutazione finora

- Improving Tapping Performance & Increasing Tapping Tool LifeDocumento10 pagineImproving Tapping Performance & Increasing Tapping Tool LifeSrikar ShenoyNessuna valutazione finora

- HolographyDocumento17 pagineHolographymanoj kumar rout100% (2)

- --Documento70 pagine--The TinyStrikerNessuna valutazione finora

- ISO 105-E01:2013 Textiles - Tests For Colour Fastness - Part E01: Colour Fastness To WaterDocumento1 paginaISO 105-E01:2013 Textiles - Tests For Colour Fastness - Part E01: Colour Fastness To WaterKushagradhi DebnathNessuna valutazione finora

- BS 3424 - 5 PDFDocumento12 pagineBS 3424 - 5 PDFshobhit2310100% (1)

- Modeling Flank Wear of Carbide Tool Insert in Metal CuttingDocumento12 pagineModeling Flank Wear of Carbide Tool Insert in Metal CuttingBasarabeanuNessuna valutazione finora

- Banknotes and Coins March 2015Documento11 pagineBanknotes and Coins March 2015Jolina EsmandeNessuna valutazione finora

- Feature Advantage Benefit (CelCulture CO2 Incubator Range)Documento4 pagineFeature Advantage Benefit (CelCulture CO2 Incubator Range)Michael G. BasaNessuna valutazione finora

- Cash Sorting Cell Stat Bank of PakistanDocumento12 pagineCash Sorting Cell Stat Bank of PakistangreathigreatNessuna valutazione finora

- FTIR Technical PaperDocumento24 pagineFTIR Technical PaperBalqis yasinNessuna valutazione finora

- Semi Automatic Polarimeter: MODEL NO. - ACM-SAP-2644Documento4 pagineSemi Automatic Polarimeter: MODEL NO. - ACM-SAP-2644saurabh_acmasNessuna valutazione finora

- What Is KaolinDocumento12 pagineWhat Is KaolinMekiya DefarNessuna valutazione finora

- Brightness in Paper IndustryDocumento2 pagineBrightness in Paper IndustryKazi ShorifNessuna valutazione finora

- Gomes 2016 J. Phys. Conf. Ser. 733 012025 PDFDocumento6 pagineGomes 2016 J. Phys. Conf. Ser. 733 012025 PDFZ-xentaNessuna valutazione finora

- Diffuse Ys. Directional Brightness Measurement: by S. J. Popson President, Technidyne Corporation, New Albany, In. U.S.ADocumento6 pagineDiffuse Ys. Directional Brightness Measurement: by S. J. Popson President, Technidyne Corporation, New Albany, In. U.S.ADiego Fernado AvendañoNessuna valutazione finora

- Phase Contrast Microscopy: Figure 1 - Schematic of A Phase Contrast Microscope. FromDocumento4 paginePhase Contrast Microscopy: Figure 1 - Schematic of A Phase Contrast Microscope. FromTrevon BadloeNessuna valutazione finora

- Optics and Optical Instruments: An IntroductionDa EverandOptics and Optical Instruments: An IntroductionValutazione: 4 su 5 stelle4/5 (5)

- Use of Optical Fibre in Spectrometry and ColorimetDocumento9 pagineUse of Optical Fibre in Spectrometry and ColorimetFitra AsyifaNessuna valutazione finora

- Schlieren Image Velocimetry of Swirl SpraysDocumento25 pagineSchlieren Image Velocimetry of Swirl Sprayslokesh14Nessuna valutazione finora

- Refractive Index MeasurementsDocumento6 pagineRefractive Index MeasurementsPınar ULUDAĞNessuna valutazione finora

- AimDocumento4 pagineAimIchi Berry0% (1)

- TRW 1915 Promotion Printone Demobook PDFDocumento10 pagineTRW 1915 Promotion Printone Demobook PDFSappiETCNessuna valutazione finora

- Understanding Paper Whiteness PDFDocumento2 pagineUnderstanding Paper Whiteness PDFSappiETCNessuna valutazione finora

- FAQs - G7, GRACoL, ISO 12647-2 PDFDocumento5 pagineFAQs - G7, GRACoL, ISO 12647-2 PDFSappiETC50% (2)

- Introduction To The G7 Methodology PDFDocumento5 pagineIntroduction To The G7 Methodology PDFSappiETCNessuna valutazione finora

- TRW 1917 Promotion Suggestion PDFDocumento69 pagineTRW 1917 Promotion Suggestion PDFSappiETCNessuna valutazione finora

- Selecting A Paper For G7 Calibration PDFDocumento3 pagineSelecting A Paper For G7 Calibration PDFSappiETCNessuna valutazione finora

- TRW 1925 Education Letsbemisers PDFDocumento63 pagineTRW 1925 Education Letsbemisers PDFSappiETCNessuna valutazione finora

- TRW 1910 Promotion Newideas PDFDocumento11 pagineTRW 1910 Promotion Newideas PDFSappiETCNessuna valutazione finora

- TRW 1915 Promotion Lustro CTD Demobook PDFDocumento11 pagineTRW 1915 Promotion Lustro CTD Demobook PDFSappiETCNessuna valutazione finora

- TRW 1927 Education Standardno5 PDFDocumento44 pagineTRW 1927 Education Standardno5 PDFSappiETCNessuna valutazione finora

- TRW 1951 Education Printingaid PDFDocumento29 pagineTRW 1951 Education Printingaid PDFSappiETCNessuna valutazione finora

- TRW 1955-1964 Advertising Fotoplate PDFDocumento20 pagineTRW 1955-1964 Advertising Fotoplate PDFSappiETCNessuna valutazione finora

- TRW 1915 Promotion Cameo PLT Demobook PDFDocumento11 pagineTRW 1915 Promotion Cameo PLT Demobook PDFSappiETCNessuna valutazione finora

- TRW 1925 Education Standardno3 PDFDocumento32 pagineTRW 1925 Education Standardno3 PDFSappiETCNessuna valutazione finora

- TRW 1961-1962 Advertising Bookpaper PDFDocumento8 pagineTRW 1961-1962 Advertising Bookpaper PDFSappiETCNessuna valutazione finora

- TRW 1924 Education Standardno1 PDFDocumento43 pagineTRW 1924 Education Standardno1 PDFSappiETCNessuna valutazione finora

- TRW 1924 Education Standardno2 PDFDocumento43 pagineTRW 1924 Education Standardno2 PDFSappiETCNessuna valutazione finora

- TRW 1922 Education Warren Monthly Jan PDFDocumento21 pagineTRW 1922 Education Warren Monthly Jan PDFSappiETCNessuna valutazione finora

- TRW 1923 Education Chemistry PDFDocumento12 pagineTRW 1923 Education Chemistry PDFSappiETCNessuna valutazione finora

- TRW 1923 Education Warren Monthly Febmarch PDFDocumento35 pagineTRW 1923 Education Warren Monthly Febmarch PDFSappiETCNessuna valutazione finora

- TRW 1959-1961 Advertising Sdwarren PDFDocumento29 pagineTRW 1959-1961 Advertising Sdwarren PDFSappiETCNessuna valutazione finora

- TRW 1957-1964 Advertising Yearbook PDFDocumento22 pagineTRW 1957-1964 Advertising Yearbook PDFSappiETCNessuna valutazione finora

- TRW 1962-1964 Advertising Sdwarren PDFDocumento18 pagineTRW 1962-1964 Advertising Sdwarren PDFSappiETCNessuna valutazione finora

- TRW 1923 Education Warren Monthly Junejuly PDFDocumento45 pagineTRW 1923 Education Warren Monthly Junejuly PDFSappiETCNessuna valutazione finora

- TRW 1946-1956 Advertising Sdwarren PDFDocumento19 pagineTRW 1946-1956 Advertising Sdwarren PDFSappiETCNessuna valutazione finora

- TRW 1943-1945 Advertising Sdwarren PDFDocumento25 pagineTRW 1943-1945 Advertising Sdwarren PDFSappiETCNessuna valutazione finora

- TRW 1941 Advertising Cumberland PDFDocumento12 pagineTRW 1941 Advertising Cumberland PDFSappiETCNessuna valutazione finora

- TRW 1939-1942 Advertising Sdwarren PDFDocumento32 pagineTRW 1939-1942 Advertising Sdwarren PDFSappiETCNessuna valutazione finora

- TRW 1940-1956 Advertising Yearbook PDFDocumento23 pagineTRW 1940-1956 Advertising Yearbook PDFSappiETCNessuna valutazione finora

- Chapter 35 Interference PDFDocumento10 pagineChapter 35 Interference PDFAttabik AwanNessuna valutazione finora

- Ufh951xm V.1.1 01012020Documento2 pagineUfh951xm V.1.1 01012020Rang DechNessuna valutazione finora

- 206 A PhysicsDocumento817 pagine206 A PhysicsRK SinghNessuna valutazione finora

- 3) Dialux Simulation-DROWO-40m P2P-2Lanes (R2)Documento19 pagine3) Dialux Simulation-DROWO-40m P2P-2Lanes (R2)Raffique HazimNessuna valutazione finora

- Calibration Sheet Ultrasonic Test EquipmentDocumento1 paginaCalibration Sheet Ultrasonic Test EquipmentjohnNessuna valutazione finora

- Konica Big Mini Bm-201Documento29 pagineKonica Big Mini Bm-201n vNessuna valutazione finora

- 9637 Chap01Documento30 pagine9637 Chap01gurjarNessuna valutazione finora

- Gemological Study Blue Sapphires Baw Mar Mine Mogok Myanmar GIADocumento87 pagineGemological Study Blue Sapphires Baw Mar Mine Mogok Myanmar GIAjoniman9Nessuna valutazione finora

- Physics 2Documento39 paginePhysics 2AlmiraNessuna valutazione finora

- Year 11 Prelim Exams PhysicsDocumento22 pagineYear 11 Prelim Exams PhysicsTimothy KurbyNessuna valutazione finora

- Basic Manual Control of A SLR Camera: Photographers Don't Just Take Photographs - They Make Them !Documento16 pagineBasic Manual Control of A SLR Camera: Photographers Don't Just Take Photographs - They Make Them !Sairam EdupugantiNessuna valutazione finora

- Testing: Performance For Precision 500D Classical R/F SystemDocumento25 pagineTesting: Performance For Precision 500D Classical R/F SystemIzah NasirNessuna valutazione finora

- Subtractive and Additive TheoryDocumento22 pagineSubtractive and Additive TheoryRemyaNessuna valutazione finora

- OSRAM - LEDVANCE Luminaires BrochureDocumento36 pagineOSRAM - LEDVANCE Luminaires BrochureZvonko DamnjanovicNessuna valutazione finora

- Diploma in Photography: Light and ExposureDocumento52 pagineDiploma in Photography: Light and ExposuregullipalliNessuna valutazione finora

- Glossary of Terms Related To T Audiovisual Materials - Copia 1Documento1 paginaGlossary of Terms Related To T Audiovisual Materials - Copia 1aitor camieraNessuna valutazione finora

- Study Material: Free Master Class SeriesDocumento21 pagineStudy Material: Free Master Class SeriesTinku SinglaNessuna valutazione finora

- 001 Xii Phy Study Materials Minimum Learning MaterialDocumento192 pagine001 Xii Phy Study Materials Minimum Learning Materialnaveen kumarNessuna valutazione finora

- Double Cavity-Backed Dual-Band Crossed DipoleDocumento3 pagineDouble Cavity-Backed Dual-Band Crossed DipolerehanNessuna valutazione finora

- Romanian NAAO 2014 ProblemsDocumento25 pagineRomanian NAAO 2014 ProblemsScience Olympiad Blog100% (4)

- VersaDoc MP 4000 Sole Source SpecificationsDocumento3 pagineVersaDoc MP 4000 Sole Source SpecificationsdnajenNessuna valutazione finora

- Bell Ringer: Explain One of The Stations From Yesterday in DetailDocumento77 pagineBell Ringer: Explain One of The Stations From Yesterday in DetailMark Jay BongolanNessuna valutazione finora

- Wall Light WLXD18Documento1 paginaWall Light WLXD18EliasNessuna valutazione finora

- Prob Set QMDocumento31 pagineProb Set QMStephanie Palomares LevitaNessuna valutazione finora

- Variocam® High Definition: Thermographic Solution For Universal UseDocumento2 pagineVariocam® High Definition: Thermographic Solution For Universal Usedanny buiNessuna valutazione finora

- GunnarDocumento4 pagineGunnargiacomoNessuna valutazione finora

- BE (E&TC) BCS (404190) Credits: 04 UNIT-II: Light Wave SystemDocumento12 pagineBE (E&TC) BCS (404190) Credits: 04 UNIT-II: Light Wave SystemGaurav MunjewarNessuna valutazione finora

- AM-4000 Plus Series Surgical MicroscopeDocumento12 pagineAM-4000 Plus Series Surgical MicroscopeМоднейший СтоматологNessuna valutazione finora

- 897N102435ADocumento64 pagine897N102435ADPTO TECNICO OFICINANessuna valutazione finora

- Principles of Signal Transmission and ReceptionDocumento5 paginePrinciples of Signal Transmission and ReceptionbrysonNessuna valutazione finora