Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

InstallationInstructions RLK603

Caricato da

Shantanu DuttaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

InstallationInstructions RLK603

Caricato da

Shantanu DuttaCopyright:

Formati disponibili

Power Transmission

Installation and Operating Instructions for

Shrink Discs RLK 603

E 03.619e

Schaberweg 30-34

61348 Bad Homburg

Germany

Telephone +49 6172 275-0

Telefax +49 6172 275-275

www.ringspann.com

mailbox@ringspann.com

Installation and Operating Instructions

for Shrink Discs RLK 603

Issue: 27.05.2010

Version: 06

signed: Su

checked: Ei

E 3.619 e

Pages : 6

page: 2

IMPORTANT

Please read these instructions carefully before installing and operating the product. Your particular

attention is drawn to the notes on safety.

These installation and operating instructions are valid on condition that the product meets the

selection criteria for its proper use. Selection and design of the product is not the subject of these

installation and operating instructions.

Disregarding or misinterpreting these installation and operating instructions invalidates any product

liability or warranty by RINGSPANN; the same applies if the product is taken apart or changed.

These installation and operating instructions should be kept in a safe place and should accompany

the product if it is passed on to others -either on its own or as part of a machine- to make it

accessible to the user.

SAFETY NOTICE

Installation and operation of this product should only be carried out by skilled personnel.

Repairs may only be carried out by the manufacturer or accredited RINGSPANN agents.

If a malfunction is indicated, the product or the machine into which it is installed, should be

stopped immediately and either RINGSPANN or an accredited RINGSPANN agent should be

informed.

Switch off the power supply before commencing work on electrical components.

Rotating machine elements must be protected by the purchaser to prevent accidental contact.

Supplies abroad are subject to the safety laws prevailing in those countries.

Installation and Operating Instructions

for Shrink Discs RLK 603

Issue: 27.05.2010

1.

Version: 06

signed: Su

checked: Ei

E 3.619 e

Pages : 6

page: 3

General information

1.1 Function:

RLK 603 shrink discs are used to effect friction-tight, no-play connections between hollow shafts

and shaft ends for the purpose of transmitting torque, shear and axial forces.

1.2 General safety instructions:

Caution! Danger of injury!

The immediate vicinity of the rotating shrink disc must be kept clear of body

parts, hair, clothing and other objects at all times.

2.

Configuration and function

3.

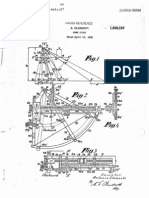

The RLK 603 shrink disc consists of a slotted inner ring, a pressure flange, a threaded flange and a

number of clamping screws. The threaded flange and the pressure flange are pulled together over

the inner ring by tightening the clamping screws. A radial clamping force is generated by the conical

surfaces which is dependent on the friction coefficients at the screws and the conical surfaces. The

radial clamping force presses the hollow shaft onto the shaft and creates a frictional connection at

the contact surfaces between the shaft and the hollow shaft. Thereby, torque and/or axial force can

be transmitted between the shaft and the hollow shaft.

During the clamping process, the position of the inner ring relative to the hollow shaft remains

unchanged. The connection is released simply by loosening the clamping screws, as the cone

angles are self-releasing.

.

Cross-sectional diagram and parts list

Installation and Operating Instructions

for Shrink Discs RLK 603

Issue: 27.05.2010

4.

Version: 06

signed: Su

checked: Ei

E 3.619 e

Pages : 6

page: 4

Purpose and proper use

RLK 603 shrink discs are external clamping elements. They are designed exclusively for rigid

hollow-to-solid shaft connections for the purpose of transmitting torque and axial forces through

friction-tight connection. Use for any other purpose is regarded as improper use. RINGSPANN

shall not be liable for damages resulting from improper use. All resulting risks shall be borne by

the user.

5.

Improper use

RLK 603 shrink discs are not suitable for use:

as torque-limiting safety devices.

6.

Condition on delivery

The shrink discs are delivered ready for installation. They have been sprayed with rust-proofing

oil and are wrapped in anti-corrosion paper.

7.

Technical requirements for safe operation

To ensure full transmission of torque and axial forces, the fitting tolerance for the outside

diameter of he hollow shaft must not exceed tolerance class f7. It is also important to ensure

compliance with the following clearance combinations between the hollow shaft bore and the

outside diameter of the shaft:

Other diameter of solid shaft dW

>

mm

mm

10

18

18

30

30

50

50

80

80

120

120

180

180

250

250

315

315

360

Hollow shaft

bore

ISO

Solid shaft

diameter

ISO

H6

j6

H6

H6

h6

g6

H7

g6

Joint clearence

min.

max.

mm

mm

0

0,014

0

0,017

0

0,032

0,029

0,048

0,012

0,069

0,014

0,079

0,015

0,090

0,017

0,101

0,018

0,111

Failure to adhere to these fitting tolerances may

cause changes in transmissible torques and/or axial forces and

render proper installation impossible.

In addition, the contact surfaces of the shaft ends and hollow shaft must have a mean

roughness depth of Ra 3,2 m.

Shaft and the hollow shaft must be manufactured from materials with the following mechanical

properties:

Yielt strength Re 340 N/mm2

E-module about 206 kN/mm2

The MoS2 paste between the tapered surfaces of the inner segment and outer segment, on the

threads and unter the head of the screws must not be removed. Proper installation is not

possible without this MoS2 paste.

Installation and Operating Instructions

for Shrink Discs RLK 603

Issue: 27.05.2010

8.

Version: 06

signed: Su

checked: Ei

E 3.619 e

Pages : 6

page: 5

Installation

8.1 Clean the hollow shaft bore and the shaft thoroughly to remove all dirt, oil and grease and

ensure a friction coefficient of 0,15 on all contact surfaces.

8.2 Apply a light coat of oil to the hollow shaft at the point at which the shrink disc is positioned

(diameter d).

8.3 Push the shrink disc onto the hollow shaft

8.4 Insert the shaft into the hollow shaft.

8.5 Tighten diametrically opposed clamping screws by hand whilst aligning the shaft coupling

so that the clamping flanges lie parallel to each other.

8.6 Tighten the clamping screws clockwise with full tightening torque

Ms with a torque wrench (see Section 12).

Tighten the clamping screws uniformly revolution

at a time. Repeat the process until no screw turns

at the full tightening torque of Ms.

Replace missing or damaged clamping screws with

equivalent screws of quality grade 10.9 only,

grease new screws like described under 10.2!

9.

Disassembly

9.1 Part-release the clamping screws evenly in stages in order to avoid any tilting of the

clamping flanges

Do not remove clamping screws completely from threaded bores under

any circumstances, as this poses the risk of injury.

9.2 Remove the shrink disc from the hollow shaft

10. Remounting removed shrink discs

Please observe the following instructions when reusing previously removed shrink discs:

10.1 Completely dismantle the shrink disc and clean thoroughly to remove residues of

lubricants applied to the tapered surfaces by the manufacture prior to delivery.

Shrink discs with damaged tapered surfaces may not be reused and must

be replaced with fully functional elements.

It is essential to ensure that the original pairing of pressure flange,

threaded flange and inner ring remains intact following cleaning and

lubrication.

Installation and Operating Instructions

for Shrink Discs RLK 603

Issue: 27.05.2010

Version: 06

signed: Su

checked: Ei

E 3.619 e

Pages : 6

page: 6

10.2 Lubricate the threads of the clamping screws and head contact surfaces thoroughly with

MoS2 paste gleitmo 100 from FUCHS LUBRITEC (www. fuchs-lubritec.de) or a

molybdenum-sulphide lubricant of equivalent quality.

11. Maintenance

RLK 603 shrink discs are maintenance-free. However, signs of settling may appear in

connections during operation. We therefore recommend checking the tightness of the clamping

screws each time maintenance is performed on the machine.

12. Tightening Torque Ms

Size

d

[mm]

Clamping screws

14

16

20

24

30

36

44

50

55

62

68

75

80

90

100

110

115

120

125

130

M 5

M 5

M 5

M 5

M 5

M 6

M 6

M 6

M 6

M 6

M 6

M 8

M 8

M 8

M 8

M 10

M 10

M 10

M 10

M 10

Tightening Torque Ms

[Nm]

4

4

4

4

6

12

12

12

12

12

12

30

30

30

30

59

59

59

59

59

Size

d

[mm]

140

155

160

165

170

175

180

185

190

195

200

220

240

260

280

300

320

340

360

Clamping screws

Tightening Torque Ms

[Nm]

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

12

12

12

16

16

16

16

16

16

16

16

16

20

20

20

20

20

20

20

100

100

100

250

250

250

250

250

250

250

250

250

490

490

490

490

490

490

490

Potrebbero piacerti anche

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingDa EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingValutazione: 4.5 su 5 stelle4.5/5 (9)

- 4HK1 & 6HK1 ManualDocumento352 pagine4HK1 & 6HK1 Manuallionkinghd94% (104)

- Programing PlanningDocumento93 paginePrograming PlanningShantanu DuttaNessuna valutazione finora

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDa EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNessuna valutazione finora

- Kawasaki ZX9R 98-99Documento307 pagineKawasaki ZX9R 98-99motomech100% (3)

- Overview CM, EstimationDocumento129 pagineOverview CM, EstimationShantanu Dutta100% (1)

- Foote-Jones Parallel Shaft Helical Reducer ManualDocumento18 pagineFoote-Jones Parallel Shaft Helical Reducer ManualbwelzNessuna valutazione finora

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Da EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Valutazione: 5 su 5 stelle5/5 (1)

- TSK EngDocumento7 pagineTSK EnguotefokNessuna valutazione finora

- To Find The Mechanical Advantage, Velocity Ratio and Efficiency of A Simple Screw JackDocumento12 pagineTo Find The Mechanical Advantage, Velocity Ratio and Efficiency of A Simple Screw Jackitsmeersaurabh69% (13)

- Kawasaki Zx400 h2Documento208 pagineKawasaki Zx400 h2Dheyvis LojdNessuna valutazione finora

- Specifications: 797F Off-Highway Truck Suspension CylinderDocumento12 pagineSpecifications: 797F Off-Highway Truck Suspension CylinderManuel Alejandro Silva VeraNessuna valutazione finora

- Rod Install PDFDocumento8 pagineRod Install PDFVeterano del Camino100% (1)

- Design and Fabrication of Power Scissor JackDocumento39 pagineDesign and Fabrication of Power Scissor Jackmohamedovic100% (4)

- Installation Instructions: BW Seals Q, QB SeriesDocumento8 pagineInstallation Instructions: BW Seals Q, QB Seriesaliihsan3461Nessuna valutazione finora

- Design and Construction of A Hydraulically Powered Scissors LiftDocumento61 pagineDesign and Construction of A Hydraulically Powered Scissors LiftJuan David Triana100% (2)

- SKF Bearing Handbook For Electric MotorsDocumento32 pagineSKF Bearing Handbook For Electric Motorskuruvillaj2217100% (2)

- Connecting Rod Bearings - Install: Table 1Documento3 pagineConnecting Rod Bearings - Install: Table 1David Apaza HurtadoNessuna valutazione finora

- HT Motor DatasheetDocumento62 pagineHT Motor DatasheetShantanu Dutta100% (2)

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionDa EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNessuna valutazione finora

- Tools Turbine PDFDocumento117 pagineTools Turbine PDFamjadNessuna valutazione finora

- SKF - Bearing Handbook - 140-430 - Dec08Documento32 pagineSKF - Bearing Handbook - 140-430 - Dec08ymsyaseen100% (1)

- Bolts and Power Screws - LongDocumento5 pagineBolts and Power Screws - LongAmeeh TorionNessuna valutazione finora

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- 1A Assignment 2 - IS 1200 Part 22Documento11 pagine1A Assignment 2 - IS 1200 Part 22Shantanu DuttaNessuna valutazione finora

- 1A Assignment 2 - IS 1200 Part 22Documento11 pagine1A Assignment 2 - IS 1200 Part 22Shantanu DuttaNessuna valutazione finora

- Fox Podium RC3 Service ManualDocumento22 pagineFox Podium RC3 Service ManualBrianCook100% (1)

- คู่มือบำรุงรักษา root blowerDocumento17 pagineคู่มือบำรุงรักษา root blowervarayutjNessuna valutazione finora

- Biomechanics of Locked Plates and ScrewsDocumento6 pagineBiomechanics of Locked Plates and Screwsd_muamer_116983894Nessuna valutazione finora

- Specs, BoQ, Drawings, Prelims SupervisionDocumento123 pagineSpecs, BoQ, Drawings, Prelims SupervisionShantanu DuttaNessuna valutazione finora

- Tech Specification 66kv 33kv Isolator - GetcoDocumento30 pagineTech Specification 66kv 33kv Isolator - GetcoManali Prajapati100% (1)

- Prensa Kurt D688Documento17 paginePrensa Kurt D688Arnulfo Larragoitia Martinez100% (1)

- Manual JASON SRG-255VK-2,5.Rev01 FifiDocumento34 pagineManual JASON SRG-255VK-2,5.Rev01 FifiMartin FrancoNessuna valutazione finora

- Method Statement of Textile Belt Splicing and LayingDocumento16 pagineMethod Statement of Textile Belt Splicing and LayingShantanu DuttaNessuna valutazione finora

- POM - Delrin Molding Guide-1Documento48 paginePOM - Delrin Molding Guide-1Ana Claudia Machado100% (1)

- Machine Design ExcelDocumento107 pagineMachine Design Excelmimi_chan_1767% (3)

- Racine Vane and Radial PumpsDocumento6 pagineRacine Vane and Radial Pumpssammar_10Nessuna valutazione finora

- 04 Applied Physical PrinciplesDocumento6 pagine04 Applied Physical PrinciplesRobles Mark100% (2)

- Power Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275Documento5 paginePower Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275barukomkssNessuna valutazione finora

- Power Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275Documento5 paginePower Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275barukomkssNessuna valutazione finora

- Power Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275Documento5 paginePower Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275barukomkssNessuna valutazione finora

- CARDAN MANUAL Installation - and Maintenance Manual Cardanshafts - 2012Documento6 pagineCARDAN MANUAL Installation - and Maintenance Manual Cardanshafts - 2012Edwin FontechaNessuna valutazione finora

- Ringspann ClampDocumento5 pagineRingspann ClamphamishjbadamsonNessuna valutazione finora

- Bielas Inspección PDFDocumento11 pagineBielas Inspección PDFhamilton mirandaNessuna valutazione finora

- RINGSPANN InstallationInstructions-RLK200Documento5 pagineRINGSPANN InstallationInstructions-RLK200Izzi Al-AkbarNessuna valutazione finora

- Cardan FuyDocumento7 pagineCardan FuyedwinNessuna valutazione finora

- Ba 42-06Documento16 pagineBa 42-06Thameemul BuhariNessuna valutazione finora

- SKF Supergrip BoltDocumento18 pagineSKF Supergrip Boltformech100% (1)

- 2008 Hollow Gram SL Crank Owners Manual Supplement enDocumento16 pagine2008 Hollow Gram SL Crank Owners Manual Supplement engregclimbsNessuna valutazione finora

- MR Bearing Conrod PDFDocumento11 pagineMR Bearing Conrod PDFbejoythomasNessuna valutazione finora

- 001-014 Connecting Rod: General InformationDocumento13 pagine001-014 Connecting Rod: General InformationWaad HarbNessuna valutazione finora

- 1.0 Maintenance (Worker Unit, Wh4)Documento13 pagine1.0 Maintenance (Worker Unit, Wh4)Mauricio PauloNessuna valutazione finora

- Remove & Install Connecting Rod BearingsDocumento4 pagineRemove & Install Connecting Rod BearingsRichard ChuaNessuna valutazione finora

- PDFDocumento10 paginePDFPaul HuaraychiriNessuna valutazione finora

- Remove RockerDocumento16 pagineRemove RockerjeremyNessuna valutazione finora

- Dodge DGF Gear Couplings: Instruction ManualDocumento2 pagineDodge DGF Gear Couplings: Instruction ManualTony_Black99Nessuna valutazione finora

- Roatary Actuators - Micromatic Repair Manual - SS-0.2A & SS-0.5ADocumento7 pagineRoatary Actuators - Micromatic Repair Manual - SS-0.2A & SS-0.5AtungNessuna valutazione finora

- Installation Instructions: BW Seals Q, QB SeriesDocumento8 pagineInstallation Instructions: BW Seals Q, QB SeriesJoseGarciaRNessuna valutazione finora

- HammerDocumento20 pagineHammerdatnguyen789jNessuna valutazione finora

- R999001185 2018 03 Gewindetriebe ENDocumento278 pagineR999001185 2018 03 Gewindetriebe ENMarco Manuel Ascensão SilvaNessuna valutazione finora

- FIS113eng Hi Temp BellowsDocumento8 pagineFIS113eng Hi Temp Bellowsandres castroNessuna valutazione finora

- Flex CouplingDocumento19 pagineFlex CouplingPradeep_VashistNessuna valutazione finora

- Foote-Jones Spiral Bevel Helical ReducerDocumento21 pagineFoote-Jones Spiral Bevel Helical Reducerbwelz100% (1)

- Lgf-432h-Emh-1025 - 490 - 4174 I+m ManualDocumento7 pagineLgf-432h-Emh-1025 - 490 - 4174 I+m ManualhansNessuna valutazione finora

- Lgf-432h-Emh-1025 - 490 - 4174 I+m ManualDocumento7 pagineLgf-432h-Emh-1025 - 490 - 4174 I+m ManualhansNessuna valutazione finora

- Repair Procedure HS14 - S7.4x2.5 - 26-10-7632Documento9 pagineRepair Procedure HS14 - S7.4x2.5 - 26-10-7632Cesar Camones100% (1)

- Coples Viva Type V, VS, VSX, Sizes 110-460Documento4 pagineCoples Viva Type V, VS, VSX, Sizes 110-460Andrés RamírezNessuna valutazione finora

- Repair Manual HS 1.5 Thru HS 015Documento12 pagineRepair Manual HS 1.5 Thru HS 015Mahesh NanayakkaraNessuna valutazione finora

- Annular Cutter Sharpening Machine HMCS100-2Documento19 pagineAnnular Cutter Sharpening Machine HMCS100-2Agustin AchioNessuna valutazione finora

- Connecting Rod Bearings - Install PDFDocumento3 pagineConnecting Rod Bearings - Install PDFGeorge GuerreroNessuna valutazione finora

- Assembly TECHLOK 3 Fold English v3 2013Documento2 pagineAssembly TECHLOK 3 Fold English v3 2013Chup AlaNessuna valutazione finora

- ATA70standard Practice EngineDocumento24 pagineATA70standard Practice EnginearunNessuna valutazione finora

- Brenco - CTRBMDocumento48 pagineBrenco - CTRBMDevendra SinghNessuna valutazione finora

- DX 6550Documento45 pagineDX 6550victorino2009Nessuna valutazione finora

- CCK - W33 - Mounting - Withdrawal Sleeve - Mechanical MountingDocumento14 pagineCCK - W33 - Mounting - Withdrawal Sleeve - Mechanical Mountingpmf engineering limitedNessuna valutazione finora

- Disclosure To Promote The Right To InformationDocumento21 pagineDisclosure To Promote The Right To InformationJaisree Balu PydiNessuna valutazione finora

- Vol 56 No 03 - Shaft and Hub Keyway and Key SizesDocumento4 pagineVol 56 No 03 - Shaft and Hub Keyway and Key SizesramsesluNessuna valutazione finora

- Pump Pressure - Head CharacteristicsDocumento4 paginePump Pressure - Head CharacteristicsShantanu DuttaNessuna valutazione finora

- 786A Spec (98692) E.2Documento1 pagina786A Spec (98692) E.2Shantanu DuttaNessuna valutazione finora

- Microsoft Project 2010 Step by Step-Chapter2Documento31 pagineMicrosoft Project 2010 Step by Step-Chapter2Arun HutabaratNessuna valutazione finora

- A Mechanical Engineer S Handbook by ONGC PDFDocumento303 pagineA Mechanical Engineer S Handbook by ONGC PDFshujad77Nessuna valutazione finora

- Brochure Call For Papers PDFDocumento8 pagineBrochure Call For Papers PDFShantanu DuttaNessuna valutazione finora

- ModuleDocumento26 pagineModuleSantosh KumarNessuna valutazione finora

- APY Subscriber Registration Form - NewDocumento1 paginaAPY Subscriber Registration Form - NewShantanu DuttaNessuna valutazione finora

- Procurement Management Procurement Management: FacultyDocumento21 pagineProcurement Management Procurement Management: FacultyShantanu DuttaNessuna valutazione finora

- Calculation of V-Belt LengthDocumento1 paginaCalculation of V-Belt LengthShantanu DuttaNessuna valutazione finora

- Grindability Index (HGI)Documento16 pagineGrindability Index (HGI)harishkumar.ravichandranNessuna valutazione finora

- InstallationInstructions RLK603 PDFDocumento6 pagineInstallationInstructions RLK603 PDFShantanu DuttaNessuna valutazione finora

- Particle Pal Doc2 PDFDocumento12 pagineParticle Pal Doc2 PDFShantanu DuttaNessuna valutazione finora

- IEI News August 2016 PDFDocumento12 pagineIEI News August 2016 PDFShantanu DuttaNessuna valutazione finora

- Dom Bobr Wagon PDFDocumento42 pagineDom Bobr Wagon PDFShantanu DuttaNessuna valutazione finora

- MSS SP 81 2000 Stainless Steel Bonnetless Flanged Knife Gate PDFDocumento9 pagineMSS SP 81 2000 Stainless Steel Bonnetless Flanged Knife Gate PDFShantanu DuttaNessuna valutazione finora

- E-Insurance Account Opening Form PDFDocumento1 paginaE-Insurance Account Opening Form PDFShantanu DuttaNessuna valutazione finora

- Cooling FanDocumento5 pagineCooling FanShantanu DuttaNessuna valutazione finora

- E-Insurance Account Opening FormDocumento1 paginaE-Insurance Account Opening Formmechanical_lecturerNessuna valutazione finora

- Electrical Shock - : Causes & ConsequencesDocumento1 paginaElectrical Shock - : Causes & ConsequencesShantanu DuttaNessuna valutazione finora

- Atlus Copco Compressor PDFDocumento24 pagineAtlus Copco Compressor PDFashish_pradhan75Nessuna valutazione finora

- 8 Power ScrewsDocumento57 pagine8 Power ScrewsKristian Marlowe Ole100% (1)

- 2tc TiafDocumento40 pagine2tc TiafNuno PiresNessuna valutazione finora

- Shigley Chapter 8Documento13 pagineShigley Chapter 8OLL OLLNessuna valutazione finora

- tài liệu vítme R999001185 - 2020 - 03 - EN - GewindetriebeDocumento272 paginetài liệu vítme R999001185 - 2020 - 03 - EN - GewindetriebevuthanhNessuna valutazione finora

- Design Guide - Stepper Motor Linear Actuators 101Documento16 pagineDesign Guide - Stepper Motor Linear Actuators 101DerekNessuna valutazione finora

- EME - Chapter IIDocumento23 pagineEME - Chapter IIChaitanya YengeNessuna valutazione finora

- Measurements & Metrology (English)Documento29 pagineMeasurements & Metrology (English)Kumar SubramanianNessuna valutazione finora

- Clementi Bombsight US1968127Documento4 pagineClementi Bombsight US1968127Dreamk990Nessuna valutazione finora

- Design and Fabrication of Toggle JackDocumento30 pagineDesign and Fabrication of Toggle JackJitendra Rout0% (1)

- Unit 2 and 3 Mechanics of MachinesDocumento21 pagineUnit 2 and 3 Mechanics of MachinesYogaraja JeyarajNessuna valutazione finora

- Edited Lesson Note Physics Sss2 First TermDocumento29 pagineEdited Lesson Note Physics Sss2 First TermadeyinkajamesgbolahanNessuna valutazione finora

- Motor Selection ExampleDocumento11 pagineMotor Selection ExampleMorena MoremoholoNessuna valutazione finora

- GE6253 Engineering MechanicsDocumento20 pagineGE6253 Engineering Mechanicssridevi73Nessuna valutazione finora

- Main Design of Ball ScrewDocumento6 pagineMain Design of Ball ScrewJigar M. UpadhyayNessuna valutazione finora

- Understanding Vernier Calliper Screw Gauge and SpherometerDocumento6 pagineUnderstanding Vernier Calliper Screw Gauge and SpherometerAnonymous vRpzQ2BLNessuna valutazione finora

- Simple Lifting Machine - NumericalsDocumento14 pagineSimple Lifting Machine - NumericalsHarsh ThakurNessuna valutazione finora

- Songin Kathleen 201708 MAScDocumento151 pagineSongin Kathleen 201708 MAScAthoriq Dias MuyasarNessuna valutazione finora

- Lecture 7 - Friction - NptelDocumento18 pagineLecture 7 - Friction - Nptels_murugan02Nessuna valutazione finora

- WhitePaper PBC Lead Screw EfficiencyDocumento4 pagineWhitePaper PBC Lead Screw EfficiencyBruno HulsmannNessuna valutazione finora

- Engineering CrosswordDocumento2 pagineEngineering CrosswordKelly Caldwell100% (1)

- Scisor Jack PresentationDocumento21 pagineScisor Jack Presentationgemechu mengistu100% (1)