Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Monolithic Structure Formwork System (For Submittal)

Caricato da

Haitham M A BecharaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Monolithic Structure Formwork System (For Submittal)

Caricato da

Haitham M A BecharaCopyright:

Formati disponibili

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

SUBMITTAL

FOR CONSTRUCTION SYSTEM APPROVAL

CAST IN PLACE MONOLITHIC CONCRETE STRUCTURE

IIntroduction

After assessing the project contents and required quality for the housing units, it is obvious

that the execution time is the most important criteria along with quality and occupants

comfort. For that we considered all options leading to the required results and we concluded

that the housing units should be executed using a modern chain production system able to

guaranty higher quality and comfort ratings in an exceptional shorter time than traditional

construction methods.

The above philosophy is considerably reinforced by the fact that the project is horizontally

spread (heavy equipment is not suitable) and the fact that the housing units are of only three

types which means a high repetition ratio of every single type.

IIObjective

In our approach, we had to fix our objectives in order to find the most suitable and optimal

answers. Thus the projects operations set the following objectives as being the constraints

for our assessment:

Rigidity, strength and integrity of the structure in addition to maximum durability.

Comfort of the occupants, knowing that the weather conditions at the project location

are among the most extreme conditions that can be faced.

Good finishing quality.

Exceptionally short execution time frame in order to satisfy the great needs &

demand in housing in the project area.

SEG international having a consistent experience in this type of projects, striving to fulfill its

clients satisfaction that overcomes all other profit considerations, guided our team to find

and recommend the optimal solution that will satisfy all the above constraints, by:

Building a whole unit shell entirely made of reinforced concrete which proved its

rigidity and durability for ages.

An external shell of the unit having very low thermal conductivity that means an

efficient thermal insulation.

Obtain fair faced concrete walls and ceilings completely avoiding irregularities of the

finish layers (plastering) that are common when using the traditional Tabouk bricks

and/or the cement blocks.

Page 1 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

A chain production system proven to deliver an average of two (2) housing units by

the end of every working day after the units construction launching period (estimated

to be shorter than four weeks).

Embedding all electrical conduits within the unit shell during construction, eliminating

chipping the walls.

Standardization of all openings dimensions (doors & windows) which allows a mass

production of those items in advance of construction, that means better quality,

shorter lead times and extremely faster installation.

Avoiding heavy lifting equipment (needed in some formwork or heavy precast

systems) since the project is a horizontal development.

III-

Recommended Construction System (Monolithic threedimensional light weight formwork)

The monolithic formwork system was introduced in early 60s and proved its efficiency

through many decades of time and adopted by many government and private housing firms

in all around the world mentioning the fast developed countries in East Asia, South America

and Middle East profiting from the fast production in construction and uniformity of products

in addition to the quality of the resulting product being a solid reinforced concrete structure

that provides the least maintenance cost over decades of use.

Monolithic Formwork Sample

The relevant concept of construction is to build in one shot a whole cast in place concrete

floor structure all together including but not limited to:

Columns

Bearing and non-bearing walls

Beams

Slabs

Page 2 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

Stairs and landings

Windows and door openings

Embedded insulation (when required)

Embedded conduits

The main characteristics of the monolithic formwork system:

A tailor made formwork especially fabricated for a given pre-engineered

repetitive structure.

A factory fabricated formwork that guaranties minimum tolerance in quality of

concrete.

Whole made of rigid but lightweight aluminum panels including the concrete

facing surface (smooth surface).

Easy handled and lightweight formwork that can cycle within the site easily.

The system is especially well suited for mass housing or multiple-unit housing

developments because of its quick erection and striking time.

Timely considerable fast production rate.

The benefits resulting from such method of construction are limitless structural wise,

durability, insulation and finishing.

IV-

The System Advantages

1- Structure rigidity, strength and integrity

The three aspects that affect the rigidity, strength & integrity of a structure can be grouped

as follows:

-

The tolerance in dimensions leading to proper installation.

The material compressive strength.

The material resistance to water, moist and other porous aspects.

Traditional Tabouk: yellow or reddish clay bricks of dimension 11.5*7.5*24 cm which are

commonly used in Iraq for internal and external walls. Rendered with (cement and sand) mix

plaster on both sides (interior and exterior). Starting in the 20th century, the use of brickwork

declined worldwide due to concerns with earthquakes. Earthquakes such as the San

Francisco earthquake of 1906 and the 1933 Long Beach earthquake revealed the

weaknesses of brick masonry in earthquake-prone areas. During seismic events, the mortar

cracks and crumbles, and the bricks are no longer held together. The mortar joints ratio =

17.28%

However the most optimal (Class A) traditional brick characteristics as being used in Iraq:

- Dimensional tolerance

: 3 %, means a 3cm tolerance for every one meter

long in all directions.

- Compressive strength

: 8.9 N/mm2,

- Water absorption

: 25-26%

Page 3 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

Traditional tabouk wall

Reinforced concrete: as known, reinforced concrete is used to build the core of any

structure worldwide, the concrete is consisted of mixing Ordinary Portland Cement (OPC) or

Sulfate Resistant Portland Cement (SRPC) with selected aggregates (20-25mm) and sand,

the reaction of the above mix with water will produce concrete product with optimal

compressive strength to be defined as per structural study recommendation.

Yet, the concrete mix, reinforced with appropriate steel rebar mesh, will be poured in the

designated formwork and will be kept to dry before submitting to curing phase till reaching

the desired strength.

However the most optimal reinforced concrete characteristics as being used in Iraq:

-

Dimensional tolerance

directions.

Compressive strength

Water absorption

: 0.5%; means 5mm for every one meter in all

: 20 N/mm2,

: 5%

By a simple comparison of the above data; we conclude that concrete walls are largely more

integer than the Tabouk constructed walls, they have more than two times strength and

less than one fifth absorption.

2- Thermal insulation

Page 4 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

Thermal conductivity is a critical constrain when developing in a location like South of Iraq,

since the weather condition may reach extreme levels of heat in summer and cold in winter

and it is a challenge to be able to build a weatherproof facility especially when it comes to

individual residential unit that:

-

Is energy-efficient, thus saving the owners money.

Provides more uniform temperatures throughout the space. There is less

temperature gradient both vertically (between ankle height and head height) and

horizontally from exterior walls, ceilings and windows to the interior walls, thus

producing a more comfortable occupant environment when outside temperatures are

extremely cold or hot.

Unlike heating and cooling equipment, insulation is permanent and does not require

maintenance, upkeep, or adjustment. Convenient insulation will largely reduce the

recurring expenses.

Lowers the Tripton rating of the carbon footprint produced by the house.

Thermal insulation is the act of reducing the thermal conductivity (k) of the building shell

which is inversely proportional to the thermal resistance value (R), resulting lower exchange

of heat through the building shell. Providing such system requires using materials with high

thermal resistance values along with avoiding non-preferred thermal bridges within the

entity.

Traditional Masonry Walls

Traditionally, builders seek to use thermal resistant masonry unit joined together using

mortar, where, besides the modest results in thermal resistance of the units (brick, cement

block) the mortar used to assemble the units all together creates thermal bridges.

Thermal bridges affect the thermal resistance which will increase thermal conductivity,

enabling additional heat exchange through the surface. Thus, the homogeneity of a surface

is a recommendation.

Graphic simulation of thermal bridges in a

traditional Tabouk wall. The red spots define the

higher thermal conductivity surfaces.

Page 5 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

Cast in Place Insulation System (CPI)

This solution combines the construction efficiency of our monolithic forming system with a

method to install high quality foam insulation within the structural walls. A continuous layer of

insulation foam is installed inside the formwork prior to the walls casting. The result is a

completely closed high performance thermal barrier with no thermal bridges.

For over 20 years the CIP System has been used extensively to insulate cast-in-place

concrete structures both above and below grade. It has been proven to be the most effective

method to incorporate a continuous foam insulation barrier within a concrete structure to

achieve high R-values, home comfort, and energy savings.

Continuous insulation system inside formwork

(Extruded Polystyrene panels placed at the centerline of walls)

Page 6 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

The CIP System utilizes the Thermal Mass Effect of concrete combined with the properties

of the foam insulation to achieve effective R values that are 2 to 3 times greater than the

material alone.

The CIP System is comprised of two main components, the Rigid Insulation made of

Extruded Polystyrene and the Fiber-Composite Connectors:

Rigid Insulation

- Extruded Polystyrene

- High long term R-Value 1.76 RSI/ 25mm thickness (of insulation).

- Protected within concrete.

- Readily available.

- Water, mold and pest resistant.

- Easily modified to fit around doors and windows.

- Can be ganged together and installed in the form in pre-prepared units.

Fiber Composite Connectors

-

Thermally non-conductive

Page 7 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

Ties the two layers of concrete together through the insulation barrier

Positions the insulation within the wall

Each Connector is comprised of a composite connector rod with toothed collar and a

retaining button to hold the insulation firmly in place in

either a balanced or unbalanced wall.

Connectors are made of 76,000 strands of EGlass

bonded with a Vinyl Resin. When embedded in the

concrete they form a structural bond between the two

layers of concrete on either side of the insulation.

Each Connector Assembly has a tested pull out

strength of 11kN and a shear capacity of 0.2kN

ensuring the structural integrity of the wall.

The combined material has the same expansion and contraction properties as

concrete to avoid cracking and spilling.

The materials are resistant to the high alkaline content of concrete and thus wont

degrade over time.

The connector is non-conductive and thus eliminates thermal bridging on either side

of the insulation through the connector.

The primary insulation component, the extruded polystyrene (XPS), combines with the ability

of concrete to store energy and dampen the effects of temperature change to considerably

increase the actual effective R-value for the constructed wall.

The effectiveness of the CIP System is also increased since the insulation barrier is

continuous throughout the wall as opposed to more traditional solutions which create thermal

bridging and reduce the effectiveness of the insulation.

As a result, the Interior temperature of a structure is stabilized against exterior temperature

changes much better than conventional insulation.

The effect of temperature change on heating and cooling systems is greatly reduced

resulting in significant energy savings and home comfort.

Page 8 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

Continuous Insulation without

thermal bridging

Very low resistance

Thermograph of wall with discontinuous

insulation and thermal bridging

Medium resistance

High resistance

Thermograph of wall using the

Thermomass CIP System

Page 9 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

3- Finishing quality

The desired finishing quality is high end fair face concrete surface, with the ability to receive

final finishing immediately after striking the formwork.

Fair Face finish: We adopted such solution to eliminate the defects that can be caused by

applying traditional plastering which must reach critical thickness when needed to align the

waviness of the subsurface caused by deformity of used bricks and/or cement blocks.

MEP Embedded Items: Mechanical and Electrical embedded items, will be installed in walls

and ceiling prior pouring concrete avoiding chipping the finished surface for installation.

Openings for doors and windows: the monolithic formwork system is a high precision

factory tailor made mold able to produce repetitive similar units with exactly same

dimensions openings. Therefore, the production doors and windows will start separately

without referring to site verification and measurements. That will allow installation right after

formwork striking.

Roof finishing: the roofing which is a critical issue regarding water proofing and insulation,

the monolithic system can provide a roof cast along with the walls avoiding joints at soffits

and leaning the concrete surface as per required slope during pouring stage then applying

protected waterproofing membrane and insulation on the top of concrete surface.

Fair face finished concrete surface

Installation of MEP embedded items

during formwork assembly.

Page 10 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

Standardization of openings allowing

easy production of doors, windows and

any required architectural details, in

one shot with the integral structure.

Page 11 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

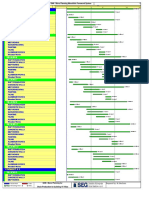

4- Time frame

The effectiveness of the monolithic Construction System relies on a unique and very efficient

daily repetitive work cycle. The other trades of reinforcing steel, concreting and mechanical

and electrical works also benefit from daily repetitive work. This efficiency also applies (to

a lesser degree) to the trades that follow such as tiling, plastering and painting.

The Monolithic System will result in the houses being constructed at the standard rate of one

house per day with one set of equipment. Each floor level of a particular house will be

concreted with a five day lag time between floor levels to allow for sufficient curing of the

concrete on the floor below. However, once the construction cycling is fully underway, one

ground floor, one first floor and one roof floor will be concreted every consecutive working

day with each set of equipment operating. The other trades such as steel reinforcement,

mechanical and electrical and the Monolithic System formwork itself follow along at the same

rate.

This justifies the time frame objective of producing a chain production which; after the

completion the very first unit; is able to produce one housing unit at the end of each

working day.

Page 12 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

5- Recapitulative Comparison

In reference to previous paragraphes and annexed sheets, we present here-after, a

comparison table recapitulating the advantages of the concrete (insulated) walls versus the

Tabouk walls.

Water

Absorption

Cement

Plaster

15 mm

R-1

Adobe

Brick

240 mm

R-2

Thermal Resistance (m2.k/W)

Gypsum

Reinforced

extruded

Plaster

Concrete

polystyrene

15 mm

80 mm

50 mm

R-3

R-4

R-5

Thickness

compressive

strength

Traditional

Tabouk

24 cm

8.9 N/mm2

25%

0.16

0.38

0.17

Concrete

wall with

insulation

24 cm

20 N/mm2

5%

4.5455

Reinforced

Concrete

110 mm

R-6

Wall

R

0.43

0.6369

3.8462

0.565

Trades involved in system

thickness

Traditional

Tabouk

Concrete

wall with

insulation

24 cm

24 cm

Finish

Quality

Clean fair

face with

clean angles

& lines

Irregular

angles, line

and surface

Needs

further

treatment

(plaster)

Production

Rate

Wall core

construction

Wall

Chipping

External

plaster

Internal

plaster

Openings

frame

installation

Material

Waste

2 m per

man hour

Yes

Yes

Yes

Yes

Yes

Yes

2 m per

day

complete

system

Yes

No

No

No

No

No

Page 13 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

6- How the system works

The complete construction and building envelope solution offers monolithic three

dimensional formwork system for cast-in-place concrete structures and requires only minor

considerations to the overall design of the building, erection of the formwork, and insulation

installation to maintain the benefits achieved through monolithic construction.

These considerations include:

- Structural wall design for insulated walls using the CIP System

- Insulation installation during form erection

- Concrete Casting

Page 14 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

A- Structural wall design for insulated walls using CIP

Exterior walls to be designed with insulation can either be balanced meaning equal

thicknesses of concrete on either side of the insulation; or unbalanced meaning a

thicker load bearing wall on one side of the insulation and a thinner nonstructural

layer on the other.

The choice of balanced vs. unbalanced is dictated by requirements of local

building codes, the attributes of the structure, and the preference of the builder. For

above grade structures an unbalanced wall is generally preferable as the load

bearing structural elements need no special consideration.

Minimum concrete coverage over the Insulation is 80 mm. typically, balanced walls

for residential uses are arranged in a 80/50/110 mm arrangement. Unbalanced walls

are arranged in a 120/50/80 arrangement. Insulation and concrete thickness can be

changed to any required thickness as specified by the structural engineer.

For both balanced and unbalanced walls a layer of rebar is required as specified by

the structural engineer on both sides of the insulation.

Interior walls of a structure do not need to be insulated and can be reduced in

thickness.

Any size of insulation sheet can be used and the orientation of the joints is

completely unhindered.

The foam core will be easily drilled though after the aluminum panels are in place (to

allow the taper ties to pass).

The taper ties will restrain the foam core in the form, eliminating uplift.

Page 15 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

B- Erection of the Form and Insulation

-

The erection of the formwork should follow the typical monolithic three dimensional

system erection guidelines set out by the manufacturer.

Form erection is begun on the interior and proceeds until all interior walls are

erected.

Once all interior wall formwork is installed the inside level of rebar for the insulated

exterior walls can be installed.

Rebar should have sufficient spacers installed

Insulation panels can also be integrated into pre-fabricated rebar cages.

Once interior walls are erected, slab erection and insulation erection can begin.

Once interior level of rebar is installed, the insulation pre-installed with connectors

should be erected over the interior level of rebar.

Insulation should be cut to fit around doors and windows.

Page 16 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

Once the insulation is installed, tie holes can be drilled through the insulation from

the interior form side. Interior walls and accessories can then be installed and taper

ties secured through the insulation.

Exterior level of rebar can be installed

Holes through the insulation created by the ties can be backfilled with insulation after

concrete is cured.

Once taper ties are installed through the insulation, and the exterior level of rebar is

in place the exterior form panel and walls can be installed and secured.

Form and insulation should be inspected prior to pour and once approved concrete

placement can begin

Page 17 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

C- Concrete Casting

The concrete casting shall take place once the checklist is completed, inspected and

approved:

1234-

Steel rebar is placed as per drawings and approved after inspection.

Insulation system is placed and approved after inspection.

Embedded MEP items placed and approved after inspection.

All the formwork is completed and inspected.

The formwork is integrally erected in one phase to include all the shell (walls, slabs, stairs,

parapets, etc).

The formwork is integrally

erected in one phase to

include all the shell (walls,

slabs, stairs, parapets, etc).

The concrete will be casted to the

whole structure (walls, slabs & stairs)

with the assistance of concrete pump.

Page 18 of 19

Prepared by:

SEG-IRAQ Operations / Dhe Qar Province

Bab Al Nasiriya Development Project

Monolithic construction System

Casting the complete structure in one shot

V-

Conclusion & Request

As shown in Section IV, there will be limitless advantages when adopting the monolithic

three dimensional formwork systems, to produce insulated concrete walls instead of Tabouk

walls, such advantages are as follows:

1234-

Assures a more than two times more strength than Tabouk walls.

Has more than five times less water absorption than Tabouk walls.

Assures around 4 times better insulation than Tabouk walls.

Is more than eight time faster in construction, it allows an average delivery of one unit

per working day.

5- Quality & Finishing:

a. Assures an excellent fair face finish with no need for further treatment

(plaster).

b. Avoids wall chipping for MEP embedding.

c. Gives precise doors and windows opening with no need to install pre-frames.

d. Has a great uniformity in production that allows excellent planning and

unforeseen elimination.

6- Eliminates material waste cost & management.

In reference to the above presentation of the system and advantages, based on our previous

experience in such projects and considering the projects interest (quality, time & occupants

comfort), we highly recommend the usage of the Monolithic Three-dimensional Formwork to

produce reinforced concrete walls in the housing units in replacement of the traditional

Tabouk Walls System.

Accordingly, we are seeking your appreciated eventual decision to kindly consider approving

the adoption of the Monolithic Three-dimensional Formwork system for the construction of

the housing units at Bab Al Nassiriya Project by an integrally cast in place reinforced

concrete shell for foundations, walls, slabs, stairs and parapets.

.

.

Page 19 of 19

Prepared by:

Potrebbero piacerti anche

- M3 CTM - Ktunotes - inDocumento11 pagineM3 CTM - Ktunotes - inFATHIMY RNessuna valutazione finora

- High Performance Buildings: Using Tunnel Form Concrete ConstructionDocumento8 pagineHigh Performance Buildings: Using Tunnel Form Concrete ConstructionDawit SolomonNessuna valutazione finora

- A Seminar On Affordable Rapid Mass Housing Using GFRG PanelsDocumento15 pagineA Seminar On Affordable Rapid Mass Housing Using GFRG PanelsSuman100% (10)

- Precast Concrete Component: Sub:-ABCMDocumento17 paginePrecast Concrete Component: Sub:-ABCMGauresh AmbulkarNessuna valutazione finora

- IKO BUFR Design Guide Feb 2012Documento40 pagineIKO BUFR Design Guide Feb 2012Deana WhiteNessuna valutazione finora

- Tunnel FormDocumento11 pagineTunnel Formscriptd_ozd3nNessuna valutazione finora

- Technology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemDocumento8 pagineTechnology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemQ8123Nessuna valutazione finora

- Low Cost ConstructionDocumento11 pagineLow Cost ConstructionSanjoli JainNessuna valutazione finora

- Low Cost School Building DesignDocumento29 pagineLow Cost School Building DesignDebashishParida0% (1)

- Kayson's Cast-in-Situ Monolithic Reinforced Concrete Construction System for High Performance, Cost-Effective BuildingsDocumento16 pagineKayson's Cast-in-Situ Monolithic Reinforced Concrete Construction System for High Performance, Cost-Effective Buildingssohail2006Nessuna valutazione finora

- Sustainable Construction: Moreton Lane Prison An Example of Fast ConstructionDocumento4 pagineSustainable Construction: Moreton Lane Prison An Example of Fast ConstructionmagdyamdbNessuna valutazione finora

- Ambo University Hachalu Hundessa Campus: School of Civil and Environmental EngineeringDocumento22 pagineAmbo University Hachalu Hundessa Campus: School of Civil and Environmental EngineeringTarekegnNessuna valutazione finora

- Prefabrication Unit I IntroductionDocumento30 paginePrefabrication Unit I Introductiondhanabal100% (2)

- Structural Systems in HousingDocumento9 pagineStructural Systems in HousingzuhaNessuna valutazione finora

- Cost Analysis in Low Cost Buildings: Submitted By:-Meenu Nashier Nancy NeerajDocumento32 pagineCost Analysis in Low Cost Buildings: Submitted By:-Meenu Nashier Nancy NeerajAditya VermaNessuna valutazione finora

- Design and Analysis of Low Cost Multi Stored Building Using Staad ProDocumento131 pagineDesign and Analysis of Low Cost Multi Stored Building Using Staad ProShaik ZuberNessuna valutazione finora

- BswallDocumento14 pagineBswallIdrus IsmailNessuna valutazione finora

- Low Cost HousingDocumento11 pagineLow Cost HousingSano SanojNessuna valutazione finora

- Masonry Structures LectureDocumento10 pagineMasonry Structures LecturemikramNessuna valutazione finora

- Speedy ConsDocumento11 pagineSpeedy ConsRemya R. Kumar100% (1)

- Precast ConcreteDocumento20 paginePrecast ConcreteMuhammadTareqRasyadJamallulailNessuna valutazione finora

- Untitled Presentation PDFDocumento13 pagineUntitled Presentation PDFFathima ZuhraNessuna valutazione finora

- Architecture Building ConstructionDocumento9 pagineArchitecture Building Construction08DALVI PRASHANINessuna valutazione finora

- Modern Construction TechniqueDocumento23 pagineModern Construction TechniquerizwanNessuna valutazione finora

- Capstone Project - Batch Vi (Aldep Class of 2019) Affordable Housing - Design, Cost & Time Optimization Using Rapid Wall Panels & PodsDocumento11 pagineCapstone Project - Batch Vi (Aldep Class of 2019) Affordable Housing - Design, Cost & Time Optimization Using Rapid Wall Panels & PodszuberNessuna valutazione finora

- BMC V - Unit-4-Advanced Construction Techniques and MaterialsDocumento13 pagineBMC V - Unit-4-Advanced Construction Techniques and Materialsaurora krishreddyNessuna valutazione finora

- Precast Concrete and Prefabricated TechnologyDocumento45 paginePrecast Concrete and Prefabricated TechnologyAzrina MadihiNessuna valutazione finora

- TUNNEL FORMWORK TECHNOLOGYDocumento93 pagineTUNNEL FORMWORK TECHNOLOGYP.K.MallickNessuna valutazione finora

- Review of Sustainable Building Materials for Wall ConstructionDocumento18 pagineReview of Sustainable Building Materials for Wall ConstructionMichael KiwingaNessuna valutazione finora

- 3d Panel SystemDocumento52 pagine3d Panel SystemVirat DesaiNessuna valutazione finora

- Lightweight cellular concrete for structural and non-structural applicationsDocumento4 pagineLightweight cellular concrete for structural and non-structural applicationsRanjan AnchanNessuna valutazione finora

- 2013 Ud Elective Ashok BhairiDocumento12 pagine2013 Ud Elective Ashok BhairivaishnaviNessuna valutazione finora

- Seminar Affordable Rapid Mass Housing Using GFRG PanelsDocumento17 pagineSeminar Affordable Rapid Mass Housing Using GFRG PanelsBasavaraj M PatilNessuna valutazione finora

- H+H Uk LTD Quinn Group Tarmac Topblock Limited Hanson Building ProductsDocumento12 pagineH+H Uk LTD Quinn Group Tarmac Topblock Limited Hanson Building ProductspseudosilNessuna valutazione finora

- Efficiency Vermont BBD Utilizing Insulated Concrete FormsDocumento59 pagineEfficiency Vermont BBD Utilizing Insulated Concrete FormsEd Carlo Rosa PaivaNessuna valutazione finora

- Introduction To Advanced R.C.C Roofing.: Group - 1Documento15 pagineIntroduction To Advanced R.C.C Roofing.: Group - 1Nidhi MehtaNessuna valutazione finora

- PrecastDocumento23 paginePrecastMohammadShahnawaz100% (2)

- Group 5 - Construction Methods and Operations-1Documento6 pagineGroup 5 - Construction Methods and Operations-1Donna Cece MelgarNessuna valutazione finora

- Abt 415 - Cobiax System, Steel Decks, PrecastDocumento6 pagineAbt 415 - Cobiax System, Steel Decks, PrecastLorraine JolbitadoNessuna valutazione finora

- Precast Cladding Panel BenefitsDocumento12 paginePrecast Cladding Panel BenefitsShreenidhi JoshiNessuna valutazione finora

- Design and Cost Analysis of Advanced Shuttering: NtroductionDocumento8 pagineDesign and Cost Analysis of Advanced Shuttering: Ntroductionsri projectssNessuna valutazione finora

- Unit 7 Modern Trends in Construction: StructureDocumento27 pagineUnit 7 Modern Trends in Construction: StructureRaj BakhtaniNessuna valutazione finora

- Advantages of Prefabricated ConstructionDocumento7 pagineAdvantages of Prefabricated ConstructionShubhaang GoelaNessuna valutazione finora

- Foam Concrete LiteratureDocumento14 pagineFoam Concrete LiteratureAnil Purohit100% (1)

- Cost Effective Concrete Construction Using Aluminium FormworkDocumento26 pagineCost Effective Concrete Construction Using Aluminium FormworkAditi SrivastavaNessuna valutazione finora

- CENTRION UNIVERSITY MULTI-STOREY BUILDING CONSTRUCTIONDocumento29 pagineCENTRION UNIVERSITY MULTI-STOREY BUILDING CONSTRUCTIONNihar RanjanNessuna valutazione finora

- S1Documento22 pagineS1AHMED SOHELNessuna valutazione finora

- Morterless Interlocking BlocksDocumento24 pagineMorterless Interlocking BlocksAHMED SOHEL67% (9)

- Why Hollow Core ENGDocumento24 pagineWhy Hollow Core ENGDario SmudNessuna valutazione finora

- FEHR Precast WallDocumento109 pagineFEHR Precast WallEduardo Depiné TarnowskiNessuna valutazione finora

- Tilt Up Construction PDFDocumento32 pagineTilt Up Construction PDFLauren Grant100% (2)

- Defination of High Rise BuildingDocumento14 pagineDefination of High Rise BuildingankitaNessuna valutazione finora

- Elegance 52 & Elegance 72 - Aluminium Curtain Walling and Facade Systems For UK - Sapa Building SystemDocumento40 pagineElegance 52 & Elegance 72 - Aluminium Curtain Walling and Facade Systems For UK - Sapa Building SystemSapa Building SystemNessuna valutazione finora

- Uses of Stabilized Mud Block, Hollow Concrete Block, Aerated Concrete BlockDocumento11 pagineUses of Stabilized Mud Block, Hollow Concrete Block, Aerated Concrete BlockAr Aditya SagarNessuna valutazione finora

- Precast Concrete ConstructionDocumento3 paginePrecast Concrete ConstructionHarendra SahrawatNessuna valutazione finora

- Pharos University in Alexandria's Tilt Up Structure SystemDocumento13 paginePharos University in Alexandria's Tilt Up Structure SystemAbir OsmanNessuna valutazione finora

- Nidhi Naik_2018060_pre-Cast Concrete and Hollow Core ReportDocumento17 pagineNidhi Naik_2018060_pre-Cast Concrete and Hollow Core Reportnetrararara14Nessuna valutazione finora

- Sustainable Renovation: Strategies for Commercial Building Systems and EnvelopeDa EverandSustainable Renovation: Strategies for Commercial Building Systems and EnvelopeNessuna valutazione finora

- Engineer's Report: Seismic Performance Evaluation and Tire Construction AnalysisDa EverandEngineer's Report: Seismic Performance Evaluation and Tire Construction AnalysisNessuna valutazione finora

- Reinforced Concrete Buildings: Behavior and DesignDa EverandReinforced Concrete Buildings: Behavior and DesignValutazione: 5 su 5 stelle5/5 (1)

- Risk ManagementDocumento9 pagineRisk ManagementMuhammad Guntur PamungkasNessuna valutazione finora

- Lebanon Planning ReportDocumento1 paginaLebanon Planning ReportHaitham M A BecharaNessuna valutazione finora

- Risk Identification ID DescriptionDocumento3 pagineRisk Identification ID DescriptionHaitham M A BecharaNessuna valutazione finora

- Risk ManagementDocumento9 pagineRisk ManagementMuhammad Guntur PamungkasNessuna valutazione finora

- Traffic Management Plan Template PDFDocumento18 pagineTraffic Management Plan Template PDFCarl Stien100% (1)

- DemolitionDocumento3 pagineDemolitionHaitham M A BecharaNessuna valutazione finora

- Al YOSR City 200 sqm units construction budget breakdownDocumento5 pagineAl YOSR City 200 sqm units construction budget breakdownHaitham M A BecharaNessuna valutazione finora

- Haitham Bechara TicketDocumento5 pagineHaitham Bechara TicketHaitham M A BecharaNessuna valutazione finora

- Cover LetterDocumento1 paginaCover LetterHaitham M A BecharaNessuna valutazione finora

- Lookahead of MarDocumento6 pagineLookahead of MarHaitham M A BecharaNessuna valutazione finora

- Method Statement: Scope of WorkDocumento8 pagineMethod Statement: Scope of WorkHaitham M A BecharaNessuna valutazione finora

- Budgeting Form ExcelDocumento142 pagineBudgeting Form ExcelHaitham M A BecharaNessuna valutazione finora

- Fanar Residential Complex: Block BDocumento1 paginaFanar Residential Complex: Block BHaitham M A BecharaNessuna valutazione finora

- Program Data (ALT1) Revision 1: Project Executive Summary Aley Commercial CenterDocumento2 pagineProgram Data (ALT1) Revision 1: Project Executive Summary Aley Commercial CenterHaitham M A BecharaNessuna valutazione finora

- Cahier Des Clauses Administratives GeneralesDocumento72 pagineCahier Des Clauses Administratives GeneralesHaitham M A BecharaNessuna valutazione finora

- Mystery BabylonDocumento20 pagineMystery BabylonHaitham M A BecharaNessuna valutazione finora

- Final PDF of Standard SpecificationDocumento179 pagineFinal PDF of Standard SpecificationabualamalNessuna valutazione finora

- Method Statement IFIDocumento17 pagineMethod Statement IFIHaitham M A Bechara0% (1)

- Summarized Schedule 14 VillasDocumento2 pagineSummarized Schedule 14 VillasHaitham M A BecharaNessuna valutazione finora

- Final PDF of Standard SpecificationDocumento179 pagineFinal PDF of Standard SpecificationabualamalNessuna valutazione finora

- Sum #Value! Count #Value!: Criteria Color Criteria ColorDocumento1 paginaSum #Value! Count #Value!: Criteria Color Criteria ColorHaitham M A BecharaNessuna valutazione finora

- Final Rate AnalysisDocumento235 pagineFinal Rate AnalysisSanjeev ShahNessuna valutazione finora

- CEng 3103 Building Construction Course OutlineDocumento52 pagineCEng 3103 Building Construction Course OutlineFitsum TadesseNessuna valutazione finora

- Concrete Aggregates: Standard Specification ForDocumento8 pagineConcrete Aggregates: Standard Specification ForHasanalmahmudNessuna valutazione finora

- Jazeera Anti-Carbonation ElastexDocumento3 pagineJazeera Anti-Carbonation ElastexAhmad BougeisNessuna valutazione finora

- Index: Life-Cycle Design, Assessment, and Maintenance of Structures and Infrastructure SystemsDocumento9 pagineIndex: Life-Cycle Design, Assessment, and Maintenance of Structures and Infrastructure Systemsاحمد علي احمدNessuna valutazione finora

- TDS Consol 71 EpDocumento4 pagineTDS Consol 71 EpPEP GUDANGNessuna valutazione finora

- Design Tension Piles Capacity CalculationsDocumento12 pagineDesign Tension Piles Capacity CalculationsAhmedKarimNessuna valutazione finora

- Molds For Forming Concrete Test Cylinders VerticallyDocumento5 pagineMolds For Forming Concrete Test Cylinders VerticallyAquinoNessuna valutazione finora

- WES-D series Digital Display Hydraulic Universal Testing Machine FeaturesDocumento14 pagineWES-D series Digital Display Hydraulic Universal Testing Machine FeaturesEduardo CruzNessuna valutazione finora

- Behaviour and Strength of Fully Encased Composite Columns PDFDocumento198 pagineBehaviour and Strength of Fully Encased Composite Columns PDFdxzaberNessuna valutazione finora

- Over Head ResevoirDocumento8 pagineOver Head ResevoirPoulomi BiswasNessuna valutazione finora

- Concrete Mix Design M-30 (Paver Block) Grade: Name of Work Client Authority Engineer ContractorDocumento23 pagineConcrete Mix Design M-30 (Paver Block) Grade: Name of Work Client Authority Engineer ContractorAshok amlapure75% (4)

- Khaadi Fabric Store at - Boq (r2) - Id Works - 24-12-2018Documento48 pagineKhaadi Fabric Store at - Boq (r2) - Id Works - 24-12-2018Kashan ShoukatNessuna valutazione finora

- E401-1001 Cooling TowersDocumento4 pagineE401-1001 Cooling TowersMehul BansalNessuna valutazione finora

- Project ReportDocumento47 pagineProject ReportMaheswariNessuna valutazione finora

- ACI 343R - 95 RC Bridge Design BookDocumento158 pagineACI 343R - 95 RC Bridge Design BookuttamNessuna valutazione finora

- Unit 528 Concrete Design Task 1Documento14 pagineUnit 528 Concrete Design Task 1Shine AungNessuna valutazione finora

- JPT Review Center Building Technology and Materials Multiple Choice ExamDocumento6 pagineJPT Review Center Building Technology and Materials Multiple Choice ExamdaydarasenganNessuna valutazione finora

- SPRAYED CONCRETE HISTORY AND APPLICATIONSDocumento27 pagineSPRAYED CONCRETE HISTORY AND APPLICATIONSSharanu PujariNessuna valutazione finora

- Flexural Strength ConcreteDocumento3 pagineFlexural Strength ConcreteShantanu DuttaNessuna valutazione finora

- Nitocote SN522: Constructive SolutionsDocumento2 pagineNitocote SN522: Constructive Solutionsمحمد عزتNessuna valutazione finora

- Job Mix FormulaDocumento12 pagineJob Mix FormulaAnonymous ptLRLiNN0% (1)

- Structural ReviewerDocumento71 pagineStructural ReviewerMark Anthony MalateNessuna valutazione finora

- ATENA Engineering 3D - Tutorial PDFDocumento94 pagineATENA Engineering 3D - Tutorial PDFLava HimawanNessuna valutazione finora

- Is-11682.1985 (Staging For Overhead Water Tanks)Documento27 pagineIs-11682.1985 (Staging For Overhead Water Tanks)amithcivil100% (2)

- Kodur Assessment of Fire Damaged StructuersDocumento6 pagineKodur Assessment of Fire Damaged StructuersKen Su100% (1)

- SikaAER-50-50 2011-10 - 1Documento2 pagineSikaAER-50-50 2011-10 - 1Amar WadoodNessuna valutazione finora

- G Writereaddata Eia 25042018sjwszk2mcp&empDocumento43 pagineG Writereaddata Eia 25042018sjwszk2mcp&empROHAN JHANDANessuna valutazione finora

- FINAL REPORT Coastal Markets PDFDocumento58 pagineFINAL REPORT Coastal Markets PDFVelina MilevaNessuna valutazione finora

- What Should You Consider When Choosing A Wet-Mix Shotcrete Pump?Documento3 pagineWhat Should You Consider When Choosing A Wet-Mix Shotcrete Pump?aeoiuNessuna valutazione finora

- Effect of Type, Size, and Dosage of Nanosilica and Microsilica On Properties of Cement Paste and MortarDocumento8 pagineEffect of Type, Size, and Dosage of Nanosilica and Microsilica On Properties of Cement Paste and MortarChan NovNessuna valutazione finora