Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Us 3534011

Caricato da

ererDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Us 3534011

Caricato da

ererCopyright:

Formati disponibili

United States Patent 0 "ice

1

3,534,011

3,534,111 1

vPatented Oct. 13,- 1970

2

0.1% to about 5% phr., in an amount su?icient for cross-,

linking and heated. Mixtures of the above peroxides can

be used if desired. The compounding can be carried out

HEAT CURABLE COMPOSITION

David S. Breslow, Wilmington, Del., assignor to Hercules

Incorporated, Wilmington, Del., a corporation of

Delaware

by mixing on a two'roll mill or by use of any of the mix

5 ing devices known in the rubber compounding art. The

compounded compositions can contain the usual black

No Drawing. Filed May 29, 1968, Ser. No. 732,895

Int. Cl. (308i 27/00

US. Cl. 26094.9

or nonblack ?llers known in this art.

Advantages of curing with peroxides of the present in

6 Claims

vention lie in their stability at compounding temperatures

10 without scorch and their ability to cure at a cure tem

perature within the stability temperature range of the

ABSTRACT OF THE DISCLOSURE

polymers.

Disclosed is a heat curable composition comprised of

Compounding of compositions containing polymer com

a peroxide curable polymer, such as polyethylene, and a

pounded with 'the peroxides of this invention and sub

peroxydioxolanA-one.

15

sequent curing is exempli?ed by the following examples

wherein all parts and percentages are by weight and phr.

represents parts per hundred of polymer.

This invention relates to cross-linking of polymeric

materials with peroxides and more particularly to the

EXAMPLE 1

cross-linking of peroxide curable polymers with peroxy 20 Polyethylene (low density) is milled on a two-roll

dioxolan-4-ones.

mill at 240 C. and one phr. 2,5-dimethyl-5-hexyl-2-t

In accordance with this invention it has been found that

compositions of a peroxide curable polymer and a cross

butylperoxy-1,3-dioxolan - 4 - one (R1=C6H13, R2=CH3,

linking amount of a peroxide of the general formula

mer and mixed on the mill with cross-cutting and end roll

R3=CH3, R4=CH3, m=1) is spread on the warm poly.

25

ing with complete mixing accomplished in about 4 min

utes. The sheeted composition is cut into strips 11/2" x

3%" x 0.080" and placed in a mold and cured. Samples

are cured at 162 C., 177 0., 188 C., and 200 C. for

38, 10, 48, and 20 minutes respectively. The percent gel

30 and swell values are determined. The results are set forth

in Table I below.

EXAMPLE 2

where m is 1 or 2, R1 and R2 taken individually are

(Cl-C18) alkyl, (Cs-C14) 3W1, (Cr-C18) aralkyl, (Cr-C18)

Example 1 is repeated with peroxide used at the rate

alkaryl, and the sum of R1 and R2 does not exceed C2D; or

R1 and R2 taken together is CnH2n- where n=2, 3, 4,

or 5, R3 is (C1-C7) alkyl, phenyl, (C7Cm) alkaryl,

(Cr,C10) aralkyl, or methoxy (CT-Cm) aralkyl, and R4 is

(C1-C2) alkyl or phenyl when m=1, and phenylene or

(C2-C4) alkylene when m=2, are readily crosslinked by

heating the composition.

of 2 phr. The results are set forth in Table I below.

EXAMPLE 3

Example 1 is repeated using 2-isopropyl-5-methyl-5

40

ethyl-2-t-butylperoxy - 1,3 - dioxolan - 4 - one (R1=CH3,

R2=C2H5, R3=(CH3)ZCH, R4=CH3,

at the same

phr. rate and samples are similarly cured. The results are

set forth in Table I below.

The peroxides of the above general formula can be

prepared by the following reactions

EXAMPLE 4

45

Example 3 is repeated with peroxide used at the rate

of 2 phr. The results are set forth in Table I below.

TABLE I

Cure

Cure temp., C ...................... _.

Cure time, minutes ___________________ __

' Example 1, gel pereent_

Example 1, swell_ ___

55

162

38

177

10

188

48

200

20

None

None

74

3460

None

None

74

3700

Example 2, gel percen

None None

73

73

Example 2, swell- _ _ _

None

None

2640

2740

Example 3, gel percent-

None None

79

78

4350

76

3680

4450

74

4150

Example 3, swell ______________ _.

None

Example 4, gel percent ________ _.

.._ None

Example 4, swell _____________________ __ None

None

None

None

where R1, R2, R3, and R4 are as designated hereinabove

and m=l where R4 is monovalent and 2 where R4 is 60

The gel values set forth in Table I are determined in

divalent.

The preferred peroxides are those in which the R groups

xylene at 110 C. for 16 hours.

It is to be understood that the above description is illus

are C1-C4 alkyl.

It is well known that polyethylene, natural rubber,

trative of the invention and not in limitation thereof.

polystyrene, polyisoprene, cis-4-polybutadiene, poly(chlo 65 What I claim and desire to protect by Letters Patent is:

1. A composition capable of being crosslinked by heat

roprene), silicone rubber, ethylene-propylene copolymer,

terpolymers of ethylene, propylene and a diene, styrene

ing at a temperature above 177 C., comprising a curable

polymer of the group consisting of polyethylene, natural

butadiene rubbers, and nitrile-butadiene rubbers, are im~

proved by compounding with peroxides and heating to the

rubber, polystyrene, polyisoprene, cis-4-polybutadiene,

curing or cross-linking temperature.

70 poly(chloroprene), silicone, rubber, ethylene-propylene,

These polymers are compounded with a small per

copolymer, terpolymers of ethylene, propylene and a diene,

centage of peroxide, usually in the range of from about

styrene-butadiene rubber and nitrile-butadiene rubber and

3,534,011 .

4

a cross-linking amount of a peroxide of the general for

mula

the general formula in which R1 is CH3, R2 is C2H5, R3 is

(CH3)2CH, R4 is CH3, and-m is 1.

4. The heat cured composition of claim 1.

5. The heat cured composition of claim 2.

6. The heat cured composition of claim 3.

References Cited

UNITED STATES PATENTS

where m is 1 or 2, R1, R2 and R3 taken individually are

(C1-C5) alkyl and R4 is (C1-C2) alkyl or phenyl when

m=l or phenylene or (C2C4) alkylene when m=2.

_2. A composition of claim 1 in which the curable

polymer is polyethylene and the peroxide is a peroxide

of the general formula in which R1 is C6H13, R2 is CH3,

R3 is CH3, R4 is CH3 and m is 1.

3. A composition of claim 1 in which the curable

polymer is polyethylene and the peroxide is a peroxide of

3,079,370

3,296,184

3,372,139

2/1963

1/1967

3/1968

Precopio et al. ____ __ 260-94.9

Portolani et al. _____ __ 260'41

Behr et al. _________ __ 260-41

JOSEPH L. SCHOFER, Primary Examiner

R. A. GAITHER, Assistant Examiner

US. Cl. X.R.

26046.5, 80.7, 82.1, 82.3, 88.2, 93.5, 94.3, 97, 610

227350

UNITED STATES PATENT OFFICE

CERTIFICATE OF CORRECTION

Patent No.

2011.111.

Inventor(s)

Dated

October 131 1970

David S. Breslow (Case 44)

It is certified that error appears in the above-identified patent

and that said Letters Patent are hereby corrected as shown below:

Column 2 of the printed patent, In Column 4 of

Table I,

"

290

"

should read 200 -.

In the Claims

Claim 1, line 70 and 71,

" silicone, rubber,

ethylene-propylene, copolymer, " should read

- silicone rubber, ethylene-propylene copolymer, .

FEB. 2,1971

(SEAL)

Amen

mam?n?mh-

mm 1:. saaunm, m.

amen: 05"

manner or Patents

Potrebbero piacerti anche

- Two Step Aprotic Solvent Catalyzed Deikmann Condensation of Phenethylamine and MethylacrylateDocumento7 pagineTwo Step Aprotic Solvent Catalyzed Deikmann Condensation of Phenethylamine and MethylacrylateTravis BoltNessuna valutazione finora

- Two-Step Protic Solvent-Catalyzed Reaction of Phenylethylamine With Methyl Acrylate (Organic Preparations and Procedures International, 2005, 37, 6, 579-584 10.1080@00304940509354990)Documento7 pagineTwo-Step Protic Solvent-Catalyzed Reaction of Phenylethylamine With Methyl Acrylate (Organic Preparations and Procedures International, 2005, 37, 6, 579-584 10.1080@00304940509354990)DmitryNessuna valutazione finora

- Gas Turbine Blade Failures - Causes, Avoidance and Troubleshooting PDFDocumento48 pagineGas Turbine Blade Failures - Causes, Avoidance and Troubleshooting PDFTabiquera Guadalupe Victoria Texcoco De Mora100% (2)

- Polymers PPT PDFDocumento47 paginePolymers PPT PDFShivani RajeevNessuna valutazione finora

- Uec 3 & Uec3 MPC Manual440-12100Documento40 pagineUec 3 & Uec3 MPC Manual440-12100Periyasamy Chellaiah50% (2)

- A Fundamental Equation For The Calculation of The Thermodynamic Properties of EthanolDocumento17 pagineA Fundamental Equation For The Calculation of The Thermodynamic Properties of EthanolVlaicu AlexNessuna valutazione finora

- (Environmental Engineering Vol. 2) Santosh Kumar Garg - SEWAGE DISPOSAL and AIR POLLUTION ENGINEERING. 2-Khanna Publishers (2012)Documento1.016 pagine(Environmental Engineering Vol. 2) Santosh Kumar Garg - SEWAGE DISPOSAL and AIR POLLUTION ENGINEERING. 2-Khanna Publishers (2012)syed tabNessuna valutazione finora

- AFS, KanpurDocumento5 pagineAFS, Kanpurdipmoip2210Nessuna valutazione finora

- 10.1007 - s13202 013 0051 4Documento4 pagine10.1007 - s13202 013 0051 4Luis FloresNessuna valutazione finora

- Radiant Cooling Technology-InvensysDocumento8 pagineRadiant Cooling Technology-InvensysJavier BaronaNessuna valutazione finora

- TSPP9Documento90 pagineTSPP9Ian NaylorNessuna valutazione finora

- 5.dissolved Gas Analysis (DGA) of Alternative Fluids For Power TransformersDocumento10 pagine5.dissolved Gas Analysis (DGA) of Alternative Fluids For Power TransformersMuhamad FahrulNessuna valutazione finora

- Astm d1142 PDFDocumento11 pagineAstm d1142 PDFwahyu haryadiNessuna valutazione finora

- Exercises On Electric Motors.Documento11 pagineExercises On Electric Motors.Salman Muneer AhmedNessuna valutazione finora

- Tyre PyrolysisDocumento6 pagineTyre PyrolysisHande CambazNessuna valutazione finora

- 1,3-Dipolar Cycloaddition of Azomethine Ylides Generated From Aziridines in Supercritical Carbon DioxideDocumento5 pagine1,3-Dipolar Cycloaddition of Azomethine Ylides Generated From Aziridines in Supercritical Carbon DioxideLineth OyolaNessuna valutazione finora

- 08-3342AP Published Main ManuscriptDocumento8 pagine08-3342AP Published Main ManuscriptRon JohnsonNessuna valutazione finora

- Thermal Oligomerization of CardanolDocumento14 pagineThermal Oligomerization of Cardanolaurelio@moreiraNessuna valutazione finora

- Paracetamol Solubility in Pure SolventsDocumento6 pagineParacetamol Solubility in Pure SolventsValentino DhiyuNessuna valutazione finora

- The S T U D Y of The Copolymerization of Styrene A N D Acrylonitrile To High Conversion. Application of Low Conversion Reactivity RatiosDocumento8 pagineThe S T U D Y of The Copolymerization of Styrene A N D Acrylonitrile To High Conversion. Application of Low Conversion Reactivity RatiosPhilip ShihNessuna valutazione finora

- Analytical Sem 6, Practice MCQ'sDocumento9 pagineAnalytical Sem 6, Practice MCQ'sanooshNessuna valutazione finora

- The Melt&g Point of Polyethylene Terephthalate: TM (Ho + NH ) / (So + Ha1)Documento5 pagineThe Melt&g Point of Polyethylene Terephthalate: TM (Ho + NH ) / (So + Ha1)api-3733260Nessuna valutazione finora

- Resr LabDocumento12 pagineResr LabRenee GlodonNessuna valutazione finora

- Analysis of TriglyceridesDocumento8 pagineAnalysis of Triglyceridesdstar13Nessuna valutazione finora

- Mode of ChiralityDocumento8 pagineMode of ChiralitychemistNessuna valutazione finora

- Poster Expo Quim I A 2008Documento1 paginaPoster Expo Quim I A 2008Steven ObrienNessuna valutazione finora

- Spheatjaocsscc 2000Documento6 pagineSpheatjaocsscc 2000klpiNessuna valutazione finora

- PolymerDocumento14 paginePolymerTu Dao NgocNessuna valutazione finora

- Potenciometria Minoxidil PDFDocumento5 paginePotenciometria Minoxidil PDFJ C Torres FormalabNessuna valutazione finora

- Heterocyclization and Functionalization of 1,2-Bis - (4-Amino-5-Mercapto-1,2,4-Triazol-3-Yl) BenzeneDocumento14 pagineHeterocyclization and Functionalization of 1,2-Bis - (4-Amino-5-Mercapto-1,2,4-Triazol-3-Yl) BenzeneViviana TorresNessuna valutazione finora

- Molecules: Liquid-Phase Synthesis of Cyanuric Acid From UreaDocumento5 pagineMolecules: Liquid-Phase Synthesis of Cyanuric Acid From UreaSrujana BudheNessuna valutazione finora

- Cloud& Pour Points in Fuel BlendsDocumento5 pagineCloud& Pour Points in Fuel Blendsramy86Nessuna valutazione finora

- United States Patent (19) : Swearingen Et AlDocumento4 pagineUnited States Patent (19) : Swearingen Et AlLoren Lee SwearingenNessuna valutazione finora

- D 1555M - 00 - Rde1ntvnDocumento7 pagineD 1555M - 00 - Rde1ntvnMuhamad Firmansyah Hermana PutraNessuna valutazione finora

- Curing of Highly Loaded Ceramics Suspensions in AcrylatesDocumento33 pagineCuring of Highly Loaded Ceramics Suspensions in AcrylatesEllen Kay CacatianNessuna valutazione finora

- A GREEN APPROACH TO THE SYNTHESIS OF a-SUBSTITUTED CHLOROACETAMIDES FROM CHLOROACETYL CHLORIDE USING WATER AS A SOLVENT PDFDocumento7 pagineA GREEN APPROACH TO THE SYNTHESIS OF a-SUBSTITUTED CHLOROACETAMIDES FROM CHLOROACETYL CHLORIDE USING WATER AS A SOLVENT PDFReyzza Andia100% (1)

- US20100249366A1Documento5 pagineUS20100249366A1DenisNessuna valutazione finora

- Solubilidad Del CO2 en Agua-EtanolDocumento10 pagineSolubilidad Del CO2 en Agua-EtanolWladimir MosqueraNessuna valutazione finora

- Engine Fuel Derived From Waste Plastics by Thermal TreatmentDocumento9 pagineEngine Fuel Derived From Waste Plastics by Thermal TreatmentSiddharth SaxenaNessuna valutazione finora

- High-Temperature Continuous Bulk Copolymerization of Styrene and Acrylic Acid Determination of Monomer ConversionsDocumento11 pagineHigh-Temperature Continuous Bulk Copolymerization of Styrene and Acrylic Acid Determination of Monomer ConversionsKumaranNessuna valutazione finora

- Leucine SolubilityDocumento7 pagineLeucine SolubilityClarence AG YueNessuna valutazione finora

- 000422100-Meth Resolution Co2Documento5 pagine000422100-Meth Resolution Co2Rajesh KennyNessuna valutazione finora

- Science - Adh1853 SMDocumento44 pagineScience - Adh1853 SMgetahun esubalewNessuna valutazione finora

- Us2512649 PDFDocumento6 pagineUs2512649 PDFrushdiNessuna valutazione finora

- Extraction of Aromatics From Petroleum Naphtha Reformate by Solvent PDFDocumento6 pagineExtraction of Aromatics From Petroleum Naphtha Reformate by Solvent PDFmehul10941100% (1)

- Homoki Rutgers FinalDocumento14 pagineHomoki Rutgers Finalapi-307344946Nessuna valutazione finora

- DPS 2011 2 6 127 131Documento5 pagineDPS 2011 2 6 127 131anuradha.d.bhat9860Nessuna valutazione finora

- Liquid Phase Glycerol Hydrogenolysis Using Commercial and Laboratory Prepared Cu-Cr CatalystDocumento4 pagineLiquid Phase Glycerol Hydrogenolysis Using Commercial and Laboratory Prepared Cu-Cr CatalystEdidiong AsuquoNessuna valutazione finora

- Paper: Microwave Methods For The Synthesis of Paddlewheel Diruthenium Compounds With N, N-Donor LigandsDocumento6 paginePaper: Microwave Methods For The Synthesis of Paddlewheel Diruthenium Compounds With N, N-Donor LigandshttmaiNessuna valutazione finora

- Peroxide Crosslinking of PVC Foam FormulationsDocumento7 paginePeroxide Crosslinking of PVC Foam FormulationsSantiago RodriguesNessuna valutazione finora

- Rase - Chemical Reactor Design - Vol 2-Case 101Documento9 pagineRase - Chemical Reactor Design - Vol 2-Case 101Md.Faysal Ahamed Khan0% (1)

- Bull Soc Chim Belg 1992 - A Convenient Preparation of Pivalaldehyde-Some Remarks On The Bouveault SynthesisDocumento3 pagineBull Soc Chim Belg 1992 - A Convenient Preparation of Pivalaldehyde-Some Remarks On The Bouveault Synthesisjanina_nazarskaNessuna valutazione finora

- Study of The Aromatic Compounds Saturation Process in Middle DistillatesDocumento4 pagineStudy of The Aromatic Compounds Saturation Process in Middle DistillatesMarcelo Varejão CasarinNessuna valutazione finora

- Synthesis, Characterization and Application of O, O-Diethyl Acrylamide PhosphateDocumento5 pagineSynthesis, Characterization and Application of O, O-Diethyl Acrylamide Phosphateandi tiaNessuna valutazione finora

- Experiment 1Documento9 pagineExperiment 1Rizza Mae RaferNessuna valutazione finora

- PRP - Added 04 Practicals (30th Oct 2013)Documento6 paginePRP - Added 04 Practicals (30th Oct 2013)idyllic20Nessuna valutazione finora

- CSTR StartupDocumento7 pagineCSTR StartupIR Ika EtyEtyka DoraNessuna valutazione finora

- Chapter 6 Characterization of Eaps 2021Documento21 pagineChapter 6 Characterization of Eaps 2021Erick AcevesNessuna valutazione finora

- Process Optimization of Crude Palm Oil Biodiesel Production by Response Surface MethodologyDocumento8 pagineProcess Optimization of Crude Palm Oil Biodiesel Production by Response Surface MethodologyRuzi Falahi KautsarNessuna valutazione finora

- (Hmim) TFA PreparationDocumento4 pagine(Hmim) TFA PreparationjeminavalaniNessuna valutazione finora

- Study of The PP Pyrolysis KineticsDocumento6 pagineStudy of The PP Pyrolysis KineticsBabatunde Olawale AfeezNessuna valutazione finora

- Chemical Reactor Unit Operation Lab ReportDocumento18 pagineChemical Reactor Unit Operation Lab ReportLiudvikas LaunikonisNessuna valutazione finora

- Fatty Acid GC LabDocumento7 pagineFatty Acid GC LabDip MajumderNessuna valutazione finora

- United States Patent (19) : Acrylate Copolymer ThusDocumento6 pagineUnited States Patent (19) : Acrylate Copolymer Thusهیمن مNessuna valutazione finora

- A Novel and Green Route For Synthesis of Pyrazoline Derivatives in An Aqueous Media by Using Ionic Liquid at Reflux ConditionDocumento4 pagineA Novel and Green Route For Synthesis of Pyrazoline Derivatives in An Aqueous Media by Using Ionic Liquid at Reflux ConditioniaetsdiaetsdNessuna valutazione finora

- Transition Metal-Catalyzed Pyridine Synthesis: Transition Metal-Catalyzed Heterocycle Synthesis SeriesDa EverandTransition Metal-Catalyzed Pyridine Synthesis: Transition Metal-Catalyzed Heterocycle Synthesis SeriesNessuna valutazione finora

- Roll-to-Roll Manufacturing: Process Elements and Recent AdvancesDa EverandRoll-to-Roll Manufacturing: Process Elements and Recent AdvancesJehuda GreenerNessuna valutazione finora

- Comflor Composite Floor Deck Brochure UKDocumento32 pagineComflor Composite Floor Deck Brochure UKAma DavidescuNessuna valutazione finora

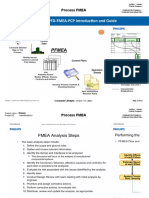

- CSR-05-074-15001 NDI D13 Dark Grey Sol Gel PFD-FMEA-PCP Rev 00Documento54 pagineCSR-05-074-15001 NDI D13 Dark Grey Sol Gel PFD-FMEA-PCP Rev 00Wahyu Jumain HayarullahNessuna valutazione finora

- Ecg524 - Term PaperDocumento11 pagineEcg524 - Term PaperamierulNessuna valutazione finora

- Nyloflex FTF enDocumento2 pagineNyloflex FTF enThe1LegendNessuna valutazione finora

- Guide Rope LubricationDocumento30 pagineGuide Rope LubricationRavi MahadeokarNessuna valutazione finora

- Jotun Facade New 21 - tcm132 91545Documento5 pagineJotun Facade New 21 - tcm132 91545dnytan12345Nessuna valutazione finora

- Lei 2011Documento8 pagineLei 2011Zakaria TabiaNessuna valutazione finora

- Extraction and Uses of Metals 3 MS PDFDocumento7 pagineExtraction and Uses of Metals 3 MS PDFAngus AnizNessuna valutazione finora

- Electric Sprayers: Graco's Complete Line of Professional Electric Airless SprayersDocumento24 pagineElectric Sprayers: Graco's Complete Line of Professional Electric Airless SprayersCalidad SteelexNessuna valutazione finora

- ASI Rhinophalt Technical and SafteyDocumento2 pagineASI Rhinophalt Technical and SafteyIndrajeet UpadhyayNessuna valutazione finora

- Gke10 Spirax SarcoDocumento2 pagineGke10 Spirax SarcoEMANessuna valutazione finora

- Alluvial Soil Paper PDFDocumento12 pagineAlluvial Soil Paper PDFawanishNessuna valutazione finora

- Cosmetic Material D023e7cfDocumento10 pagineCosmetic Material D023e7cfABDULRAHMAN ALSAHARNessuna valutazione finora

- CEBECO I LINE COST (As of July 2006)Documento24 pagineCEBECO I LINE COST (As of July 2006)Sugar RayNessuna valutazione finora

- Irr PD 1866 PDFDocumento33 pagineIrr PD 1866 PDFLeia VeracruzNessuna valutazione finora

- UMC 65nm FAQ 141103Documento56 pagineUMC 65nm FAQ 141103LoiLeVanNessuna valutazione finora

- DGT-eex Brochure Eng 2020Documento2 pagineDGT-eex Brochure Eng 2020Ali SadiqNessuna valutazione finora

- Waste To WealthDocumento33 pagineWaste To WealthrexNessuna valutazione finora

- Дизельные электростанции EMSADocumento52 pagineДизельные электростанции EMSABrizmotorsNessuna valutazione finora

- Notes 2. On Headloss - in Piping SystemsDocumento12 pagineNotes 2. On Headloss - in Piping SystemsAngel Lisette LaoNessuna valutazione finora

- PBL MTCP LabDocumento7 paginePBL MTCP LabAdarsh SinghNessuna valutazione finora