Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Table Book Errata

Caricato da

Akshay GhodakeCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Table Book Errata

Caricato da

Akshay GhodakeCopyright:

Formati disponibili

Hazen-Williams Formula

In the absence of solid scientific data, engineers in the past have experimented with and used

empirical equations for determination of friction losses in pipe flow. Many of these equations

were developed over the early years but most have fallen into disuse. Due to the difficulty in

using the DArcy-Weisback equation for pipe flow one singular example still endures, which is

the Hazen-Williams formula. Hazen-Williams is simpler to use than DArcy-Weisbach where

you are solving for flowrate, pressure drop or velocity dependent on the flow.

The DArcy-Weisbach formula is generally considered more accurate and is valid for any liquid

or gas. The Hazen-Williams method is very popular, especially among civil engineers, because

of its ease of use and its friction coefficient C is not a function of velocity or pipe diameter.

Its validity depends on the successful selection of the constant friction loss coefficient C,

which is a function of pipe material, pipe linings and pipe age to indicate the roughness of a

pipe interior. The higher the C factor, the smoother the pipe. Typical values of the roughness

coefficient C is given in the table following this definition.

The Hazen-Williams equation has narrow applicable ranges for Reynolds numbers and pipe

sizes. The equation is generally valid for pipe sizes 3 in. (75 mm) and larger, for water flowing at

temperatures of between 40 to 75F (21 to 24C) and pressures up to 175 psi (1.2 MPa). The

level of error when the Hazen-Williams equation is used outside its data ranges is significant.

In this case, the DArcy-Weisbach formula must be used. The Hazen-Williams equation is commonly used for pressure drop calculations in American fire sprinkler systems, water distribution

systems, and irrigation systems where conditions are mostly constant.

Hazen-Williams Formula

Solving for psi pressure drop per 100 feet of pipe

Q1.85

Pd = 4.52

C1.85 d4.87

Solving for total psi pressure drop in system

1.85

1.85

Q1.8655

Td=0.002082 L 100

C

d

Solving for velocity

V=1.318 C R0.63 S0.54

Solving for flow rate

Q=0.849 C A R0.63 S0.54

Solving for friction head loss per 100 feet of type, SI units.

6.05 Q1.85

f=

C1.85 d 4.87

where

Q = quantity rate of flow, gpm (Lpm)

C = roughness coefficient, dimensionless

d = inside pipe diameter, in. (mm)

f = friction head loss in ft. hd./100 ft. of pipe (m per 100m)

Pd =pressure drop, psi/100 feet of pipe

R = hydraulic radius, feet (m)

V = Velocity, feet per second

A = cross section area, in (mm)

Td = Total drop in system, psi

L = Total length of pipe run, ft.

Plumbing Engineering and Design Handbook of Tables

73

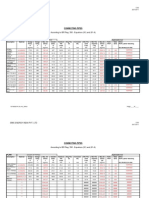

Sizing and Capacity (Natural Gas)

Gas): U.S./English

Maximum Capacity in Cubic Feet of Gas Per Hour (Natural Gas)

Material: Steel, ASTM A53 Schedule 40

Nominal

Actual OD

WT

Actual ID

Feet

1

0

10

20

30

40

50

60

70

80

90

100

125

150

175

200

250

300

350

400

450

500

550

600

650

700

750

800

850

900

950

1,000

1,100

1,200

1,300

1,400

1,500

1,600

1,700

1,800

1,900

2,000

1032

Inlet Pressure = 5.0 psi

Pressure Drop = 3.5 psi Specic Gravity 0.60 Temperature 70F

Pipe Size (inch)

1

1

1

2

0.840

1.050

1.315

1.660

1.900

2.375

0.109

0.113

0.133

0.140

0.145

0.154

0.622

0.824

1.049

1.380

1.610

2.067

Cubic Feet of Gas per Hour

3276

2251

1808

1547

1371

1243

1143

1064

998

943

835

757

696

648

574

520

479

445

418

395

375

358

342

329

317

306

296

287

279

271

258

246

235

226

218

210

204

197

192

186

6850

4708

3781

3236

2868

2598

2390

2224

2087

1971

1747

1583

1456

1355

1201

1088

1001

931

874

825

784

748

716

688

663

640

619

600

583

567

539

514

492

473

455

440

426

413

401

390

12903

8868

7121

6095

5402

4895

4503

4189

3930

3713

3291

2981

2743

2552

2262

2049

1885

1754

1646

1554

1476

1408

1349

1296

1248

1205

1166

1131

1098

1068

1015

968

927

891

858

828

802

777

755

734

26491

18207

14621

12514

11091

10049

9245

8601

8070

7623

6756

6121

5631

5239

4643

4207

3870

3601

3378

3191

3031

2891

2769

2660

2563

2475

2395

2322

2255

2193

2083

1987

1903

1828

1761

1701

1646

1596

1550

1507

39692

27280

21907

18749

16617

15056

13852

12886

12091

11421

10122

9171

8438

7850

6957

6303

5799

5395

5062

4781

4541

4332

4149

3986

3840

3708

3588

3479

3379

3286

3121

2978

2851

2739

2639

2548

2466

2391

2322

2259

76443

52539

42190

36110

32003

28997

26677

24818

23286

21996

19494

17663

16250

15117

13398

12140

11169

10390

9749

9209

8746

8344

7990

7676

7395

7141

6911

6700

6507

6329

6011

5735

5492

5276

5082

4908

4750

4605

4472

4350

2

2.875

0.203

2.469

121838

83738

67245

57553

51008

46217

42519

39556

37114

35058

31071

28152

25900

24095

21355

19349

17801

16560

15538

14677

13939

13298

12735

12234

11786

11382

11015

10679

10371

10087

9580

9140

8753

8409

8101

7823

7570

7340

7128

6933

American Society of Plumbing Engineers

Steel. ASTM A53 Schedule 40

Maximum Capacity in Cubic Feet of Gas Per Hour (Natural Gas)

Material: Steel, ASTM A53 Schedule 40 (Continued)

Nominal

Actual OD

WT

Actual ID

Feet

10

20

30

40

50

60

70

80

90

100

125

150

175

200

250

300

350

400

450

500

550

600

650

700

750

800

850

900

950

1,000

1,100

1,200

1,300

1,400

1,500

1,600

1,700

1,800

1,900

2,000

Inlet Pressure = 5.0 psi

Pressure Drop = 3.5 psi Specic Gravity 0.60 Temperature 70F

Pipe Size (inch)

3

4

5

6

8

10

3.500

4.500

5.563

6.625

8.625

10.750

0.216

0.237

0.258

0.280

0.322

0.365

3.068

4.026

5.047

6.065

7.981

10.020

Cubic Feet of Gas per Hour

215387

148035

118877

101743

90173

81703

75166

69928

65611

61976

54928

49769

45786

42595

37752

34206

31469

29276

27468

25946

24642

23509

22513

21628

20836

20121

19472

18879

18335

17833

16937

16158

15473

14865

14320

13829

13383

12975

12601

12256

439322

301943

242471

207524

183925

166649

153315

142630

133825

126410

112035

101512

93390

86881

77001

69769

64186

59713

56027

52922

50263

47952

45919

44115

42499

41040

39716

38507

37397

36373

34545

32957

31560

30320

29209

28207

27297

26466

25703

24999

794795

546258

438665

375440

332746

301492

277368

258038

242108

228694

202687

183649

168955

157180

139306

126221

116122

108029

101360

95744

90932

86751

83075

79810

76886

74248

71852

69664

67656

65804

62497

59624

57097

54853

52843

51030

49384

47880

46500

45227

1286957

884518

710299

607924

538792

488185

449124

417823

392030

370309

328198

297371

273577

254511

225568

204381

188028

174924

164125

155032

147241

140470

134517

129231

124496

120224

116345

112803

109551

106553

101198

96544

92453

88820

85565

82629

79963

77529

75294

73233

Plumbing Engineering and Design Handbook of Tables

2644205

1817347

1459394

1249052

1107012

1003033

922778

858467

805471

760843

674321

610984

562097

522923

463457

419926

386326

359402

337215

318531

302523

288613

276381

265520

255792

247015

239045

231766

225085

218925

207923

198362

189955

182490

175804

169772

164294

159292

154700

150466

4802582

3300787

2650649

2268613

2010629

1821776

1676011

1559205

1462950

1381894

1224747

1109710

1020919

949768

841762

762697

701672

652770

612473

578538

549463

524198

501983

482255

464587

448645

434169

420949

408815

397626

377643

360278

345010

331451

319308

308351

298402

289316

280976

273286

12

12.750

0.375

12.000

7707103

5297048

4253717

3640631

3226624

2923555

2689634

2502185

2347718

2217641

1965454

1780844

1638353

1524172

1350845

1223964

1126031

1047555

982886

928428

881769

841223

805573

773915

745561

719978

696748

675532

656059

638104

606035

578168

553666

531907

512420

494837

478871

464289

450905

438565

1033

1

0

Hazen-Williams Equation: PEX Tubing, ASTM F877

Flow Rate, Velocity, and Friction Loss (Water)

Material: PEX Tubing, ASTM F877

Coefficient of Friction, C=150

OD=Outside Diameter (in.) ID=Inside Diameter (in.) WT=Wall Thickness (in.)

" PEX

OD=0.625 ID=0.485 WT=0.070

Flow

Rate

(gpm)

Velocity

(ft/sec)

Pressure

Loss

(psi/100')

1.00

2.00

3.00

4.00

5.00

6.00

7.00

8.00

9.00

10.00

11.00

12.00

13.00

14.00

15.00

16.00

1.74

3.47

5.21

6.95

8.68

10.42

12.16

13.89

15.63

17.37

19.10

20.84

22.58

24.31

26.05

27.79

1.4448

5.2085

11.0276

18.7767

28.3728

39.7546

52.8736

67.6899

84.1697

102.2839

122.0067

143.3153

166.1891

190.6094

216.5590

244.0222

Plumbing Engineering and Design Handbook of Tables

" PEX

OD=0.875 ID=0.681 WT=0.097

Flow

Rate

(gpm)

1.00

2.00

3.00

4.00

5.00

6.00

7.00

8.00

9.00

10.00

11.00

12.00

13.00

14.00

15.00

16.00

17.00

18.00

19.00

20.00

21.00

22.00

23.00

24.00

25.00

26.00

27.00

28.00

29.00

30.00

31.00

32.00

33.00

Velocity

(ft/sec)

Pressure

Loss

(psi/100')

0.88

1.76

2.64

3.52

4.40

5.29

6.17

7.05

7.93

8.81

9.69

10.57

11.45

12.33

13.21

14.09

14.97

15.86

16.74

17.62

18.50

19.38

20.26

21.14

22.02

22.90

23.78

24.66

25.54

26.43

27.31

28.19

29.07

0.2767

0.9974

2.1116

3.5955

5.4330

7.6124

10.1245

12.9616

16.1173

19.5859

23.3625

27.4428

31.8228

36.4989

41.4679

46.7267

52.2725

58.1028

64.2151

70.6071

77.2768

84.2219

91.4407

98.9314

106.6921

114.7212

123.0173

131.5787

140.4040

149.4918

158.8409

168.4499

178.3175

255

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- API 526 - Spring Loaded Material TableDocumento1 paginaAPI 526 - Spring Loaded Material TableGanda SamosirNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Intake StructuresDocumento14 pagineIntake Structuresnimm1962100% (1)

- MS Concrete Works - Method StatementDocumento6 pagineMS Concrete Works - Method StatementmemekenyaNessuna valutazione finora

- SKF Bearing Installation and MaintenanceDocumento146 pagineSKF Bearing Installation and MaintenanceDefinal ChaniagoNessuna valutazione finora

- Behr Labor Technik Extraction En-1Documento28 pagineBehr Labor Technik Extraction En-1MilanVukic100% (1)

- 2010 enDocumento12 pagine2010 encristi_mt100% (1)

- Sulfidic Corrosion in Refineries - A ReviewDocumento13 pagineSulfidic Corrosion in Refineries - A Reviewrogerh44Nessuna valutazione finora

- 18.multistage Systems and Cascade SystemsDocumento9 pagine18.multistage Systems and Cascade SystemsericNessuna valutazione finora

- SSC Question PaperDocumento16 pagineSSC Question PaperAkshay GhodakeNessuna valutazione finora

- Notification Dissolution KonkanDocumento1 paginaNotification Dissolution KonkanAkshay GhodakeNessuna valutazione finora

- Library BooksDocumento13 pagineLibrary BooksAkshay GhodakeNessuna valutazione finora

- Exemption Engineering GraduatesDocumento1 paginaExemption Engineering GraduatesAkshay GhodakeNessuna valutazione finora

- Trigid PDFDocumento1 paginaTrigid PDFAkshay GhodakeNessuna valutazione finora

- The Institute of Cost Accountants of India (Statutory Body Under An Act of Parliament) 12, Sudder Street, Kolkata - 700 016Documento1 paginaThe Institute of Cost Accountants of India (Statutory Body Under An Act of Parliament) 12, Sudder Street, Kolkata - 700 016Akshay GhodakeNessuna valutazione finora

- Fee CollectionDocumento1 paginaFee CollectionAkshay GhodakeNessuna valutazione finora

- 01 Quality ControlDocumento3 pagine01 Quality ControlAkshay GhodakeNessuna valutazione finora

- CM Assignment2Documento30 pagineCM Assignment2Akshay GhodakeNessuna valutazione finora

- 02-Construction Equipment PDFDocumento17 pagine02-Construction Equipment PDFAkshay GhodakeNessuna valutazione finora

- Construction Management: Pravin S KolheDocumento3 pagineConstruction Management: Pravin S KolheAkshay GhodakeNessuna valutazione finora

- 08 Erection TechniquesDocumento8 pagine08 Erection TechniquesAkshay GhodakeNessuna valutazione finora

- Volume IDocumento214 pagineVolume IAkshay GhodakeNessuna valutazione finora

- Chapter-2 Population and Water Demand 2.1. Present PopulationDocumento10 pagineChapter-2 Population and Water Demand 2.1. Present PopulationAkshay GhodakeNessuna valutazione finora

- Reasoning 1Documento6 pagineReasoning 1Prasad Durga DNessuna valutazione finora

- Members Practice 2016Documento428 pagineMembers Practice 2016Akshay GhodakeNessuna valutazione finora

- Dear Sir/Madam,: Arvel Tructural OnsultantsDocumento1 paginaDear Sir/Madam,: Arvel Tructural OnsultantsAkshay GhodakeNessuna valutazione finora

- Request For Proposal (RFP) ForDocumento112 pagineRequest For Proposal (RFP) ForAkshay GhodakeNessuna valutazione finora

- Request For Proposal (RFP) ForDocumento112 pagineRequest For Proposal (RFP) ForAkshay GhodakeNessuna valutazione finora

- Mosfet: MOS FET) Is A Type of Field-Effect Transistor (FET), Most Commonly Fabricated byDocumento20 pagineMosfet: MOS FET) Is A Type of Field-Effect Transistor (FET), Most Commonly Fabricated byhahahaNessuna valutazione finora

- Safety Data Sheet Sodium GluconateDocumento4 pagineSafety Data Sheet Sodium GluconatemeNessuna valutazione finora

- Matter (Science Form 1 - Short Notes)Documento1 paginaMatter (Science Form 1 - Short Notes)jrpyroNessuna valutazione finora

- Installation Manual - Brazed Heat Exchangers - UK PDFDocumento2 pagineInstallation Manual - Brazed Heat Exchangers - UK PDFesteban vasquezNessuna valutazione finora

- Arc Detection in Electro-Discharge MachiningDocumento16 pagineArc Detection in Electro-Discharge MachiningMitu Leonard-GabrielNessuna valutazione finora

- Research Proposal Pleurotus FINALDocumento27 pagineResearch Proposal Pleurotus FINALSheena GagarinNessuna valutazione finora

- Experiment 1: Purification of Benzoic Acid Data and Results: Crude Benzoic Acid Purified Benzoic Acid Mass AppearanceDocumento2 pagineExperiment 1: Purification of Benzoic Acid Data and Results: Crude Benzoic Acid Purified Benzoic Acid Mass AppearanceLarry OngNessuna valutazione finora

- Me6402 mt2 Notes Rejinpaul PDFDocumento227 pagineMe6402 mt2 Notes Rejinpaul PDFRajeshNessuna valutazione finora

- Lead Removal Mechanism Using MgO NpsDocumento11 pagineLead Removal Mechanism Using MgO NpsKarthikeyan SNessuna valutazione finora

- T040032 00Documento17 pagineT040032 00Doanh HoangNessuna valutazione finora

- Revision Notes On Heat TransferDocumento11 pagineRevision Notes On Heat TransferAnonymous vRpzQ2BLNessuna valutazione finora

- History of Life On EarthDocumento10 pagineHistory of Life On Earthapi-355214789Nessuna valutazione finora

- Science Class7 PhysicalnChemicalChange RevisionNotes PDFDocumento5 pagineScience Class7 PhysicalnChemicalChange RevisionNotes PDFTestEmailForScribd TestEmailForScribdNessuna valutazione finora

- Materials Compatibility List: Chemicals For Processing Endoscopes and Endoscopic InstrumentsDocumento24 pagineMaterials Compatibility List: Chemicals For Processing Endoscopes and Endoscopic InstrumentsAlina AlinaNessuna valutazione finora

- Solutions To 7.012 Problem Set 1Documento4 pagineSolutions To 7.012 Problem Set 1attiqueNessuna valutazione finora

- Steatite Material Property Chart 1pageDocumento1 paginaSteatite Material Property Chart 1pageviksoniNessuna valutazione finora

- AllenDocumento40 pagineAllenDhanpat RaiNessuna valutazione finora

- Optimisation of Screw CompressorsDocumento29 pagineOptimisation of Screw CompressorsSaeedAkbarzadehNessuna valutazione finora

- MetallurgyDocumento2 pagineMetallurgygjabyNessuna valutazione finora

- Catalogo Medidores Rotativos para Gas NaturalDocumento8 pagineCatalogo Medidores Rotativos para Gas Naturalinglegs75Nessuna valutazione finora

- Connecting Piping IBRDocumento5 pagineConnecting Piping IBRgopaltryNessuna valutazione finora

- General Catalog en GrindingDocumento10 pagineGeneral Catalog en GrindingkarthikNessuna valutazione finora