Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Liquid Soap Composition

Caricato da

Javier BecerraCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Liquid Soap Composition

Caricato da

Javier BecerraCopyright:

Formati disponibili

Patented May 8, 1951

UNIED STATE

AENT

2,551,634

LIQUID SOAP COMPOSITION

Robert Hamilton Price, Shelton, Wash.

N0 Drawing. Application December 17, 1945,

Serial No. 635,606

10 Claims. (01. 252-418)

1

This invention relates to surface active com- '

positions of matter. More particularly, the in

vention is especially concerned with providing

liquid soap compositions having new and greatly

improved properties.

- An object of the invention is to provide cleans

ing compositions which dissolve readily with

2

While the additives of this phase of the inven

tion are applicable to all types of customarily

used dry cleaning solvents, such as petroleum

distillates and chlorinated hydrocarbons, they

are especially suited as additives to Stoddard

solvent. Stoddard solvent in a petroleum distil

late widely used as a dry cleaning solvent. The

U. 5-. Bureau of Standards specifies that it is

a petroleum distillate conforming to a number of

warm water, which foam readily and which excel

because of their good washing and cleansing 10 standards including a flash point of not less than

100 F. In regard to distillation range it is

powers and more particularly to produce such

speci?ed that not less than 50% shall be re

results through the use of certain commonly used

covered in the receiver when the thermometer

soaps which do not now possess such combina

reads 350 F. The dry or end point shall be not

tions of properties.

A further object is to provide soap composi 15 higher than 410 F. No tolerance shall be al

lowed above l10 F.

tions which dissolve clearly in Water to furnish

The compositions of the invention have un

aqueous solutions which even when dilute will

usual properties making them very effective for

have a pH not substantially greater than 7, i. e.

grease dissolving properties even in cold or luke

substantially neutral.

general cleansing purposes as well as for more

provide soap compositions having the neutrality

emulsifying and detergent materials. Among the

important uses, they may be used as general

cleansing agents for such materials as painted

A still further object of the invention is to 20 specialized purposes, as wetting, penetrating,

and other desirable properties hitherto charac

teristic only of alkanolamine soaps, but without '

the use of any alkanolamines at all or by use

surfaces, linoleum, concrete, leather, glass, etc.

of much smaller quantities of alkanolamines 25 In addition they are valuable for such specialized

purposes as dry cleaning soaps, wet spotting

than would be required for ordinary alkanol

agents for use in conjunction with dry clean

amine soaps. This phase of the invention con

ing and as wetting, detergent and emulsifying

templates maintaining neutrality in aqueous

agents in industrial textile operations, as dyeing

solution while substituting either completely or

partially for expensive alkanolamines, relatively 30 assistants, etc. They may be used in place of

soap powder in washing clothes and in general

inexpensive alkali metal hydroxides, as for ex

used Where soap or soap-like compositions have

ample, sodium or potassium hydroxide.

been heretofore used or are capable of being

A still further object of the invention is to

used. The invention contemplates the pro

provide a clear liquid alkali metal soap composi

tion having the lathering properties hitherto as 35 vision of various preparations and compositions

comprising the materials for such uses.

sociated in liquid soaps only with coconut oil

I have found that by using soaps of a type

soaps but without the use of any coconut oil

hereinafter more fully speci?ed in conjunction

whatsoever. Such liquid soaps of the invention

with isopropanol and certain glycol ether modi

are blander and possess better detergent and

other properties than coconut oil liquid soaps. 40 fying agents strikingly new results obtain.

In this phase of the invention there is also con

Said glycol ether modifying agents which for

templated either partial or complete substitution

brevity I will refer to herein as glycol ether

of the potassium hydroxide alkali hitherto

modifying agents are compounds with the

deemed necessary for liquid soaps by the less ex

formula:

pensive sodium hydroxide.

P.-(OCH2CH2) IOH

In one of its most preferred aspects a further

object of the invention is to provide soap com

positions which are clearly soluble in both water

and organic solvents of the dry cleaning type,

c. g. petroleum solvents and chlorinated solvents

and which possess strong detergent properties in

either type of media. By the use of a composi

tion of this phase of the invention there is pro

vided in a single material (1) an additive ma

terial imparting detergent properties to dry

cleaning solvents and permitting the incorpora

tion in'them of substantial bene?cial amounts of.

water and (2) a water soluble soap for use in

aqueous solutions. Such a water soluble soap

where R is an alkyl radical with from 1 to 4 car

bon atoms and a: is an integer of from 1 to 2.

The soaps I use are all salts of oleic acid.

More speci?cally the soaps used are of four types:

1. Salts of a lower alkanolamine and oleic

acid.

2. Salts of a lower alkyl amine and oleic acid.

3. The salt of ammonia and oleic acid.

4. Salts of a caustic alkali and oleic acid.

As used herein the term alkanolamine, refers

to an ammonia molecule substituted by at least

one hydroxyalkyl group, any remaining valences

being satis?ed by hydrogen and/or alkyl radicals.

may be used by a dry cleaner for wet spotting

as well as for an additive to his dry cleaning

By lower alkanolamine is meant an alkanol

amine in which the carbon groups attached to

solvents.

the nitrogen have 1 to 7 carbon atoms.

2,551,634

Also as used herein the term alkyl amine re

fers to an ammonia molecule substituted by at

least one alkyl group, any remaining valences be

ing satis?ed by hydrogen radicals.

The alkyl

amines used may be either primary, secondary or

tertiary.

Further by lower alkyl amine is

meant an alkylamine in which the carbon groups

attached to the nitrogen have from 1 to 7 carbon

atoms.

By caustic alkali as used herein is meant the

hydroxide bases of the monovalent elements of

group IA of the periodic table. Most practically

there will be used the more readily available

bases, potassium and sodium hydroxide.

solved by glycol ethers or isopropanol, water is

added for the practical purpose of preventing

attack by the organic solvents. For such purposes

the additions of water are relatively large, i. e.,

at least 1 to 2 volumes of water per volume of the

anhydrous or substantially anhydrous soap com

positions. In most cases of actual use by the con

sumer the soap composition of my invention will

be diluted down with many volumes of water but

even with only 1 to 2 volumes of water there will

be no attack on paint. Even in dilute solutions,

however, the organic solvents will impart grease

dissolving or dispersing properties to the solu

tions. Obviously the soap compositions could be

To secure the advantages of the invention the

manufactured and sold in a substantially anhy

drous condition and diluted down to quite dilute

solutions by the ultimate user. To render use

tions of substantially one mole or more of glycol

foolproof and more convenient, however, and to

ether modifying agent per mole of oleic acid.

avoid any possibility of attack upon paint by mis

More speci?cally by substantially one mole or -_ use I prefer to manufacture a product with at

more of glycol ether modifying agent is meant

least 1 to 2 volumes of water per volume of an

at least 0.90 mole of glycol ether modifying agent

hydrous soap composition. Such a soap compo

per mole of oleic acid. While there is no upper

sition is safe for all uses but for most purposes

limit for the proportion of glycol ether modify

may be further greatly diluted with water at the

ing agent the most preferred range is 1.20-2.40

time of use by the consumer.

moles of glycol ether modifying agent per mole

Some of the soap compositions of my discovery,

of oleic acid.

as will be later more fully described, are soluble

Conjointly with the glycol ether modifying

in solvents of the petroleum type and are useful

agent there must be used at least 1.5 moles and

as additives to dry cleaning solvents. I also

preferably at least 2.0 moles of isopropanol per

prefer to add water to these soap compositions in

mole of oleic acid.

order to increase the detergent properties of the

Soaps of nitrogenous bases such as lower al

dry cleaning solutions. To soap compositions in

kanolamines, lower amines and ammonia have

tended for use in dry cleaning I add appreciable

in the past been known to have considerable de

smaller amounts of water than the products in

tergent power and to yield relatively neutral aque

tended for use in aqueous solutions. For use in

ous solutions. Such soaps in water, however, are

dry cleaning solvents there is an upper limit

very largely hydrolyzed so that their aqueous

for the water additions in that the soap compo

solutions are extremely turbid.

sition must remain soluble in the organic sol~

Soaps of the caustic alkalies on the other hand,

vent. In practice I can readily use amounts of

while yielding much less turbid aqueous solu :10 water up to 2.25 moles per mole of fatty acid

tions than soaps of nitrogenous bases, neverthe

though I prefer to add about l.'75-2.0 moles per

mole of fatty acid.

less have an alkaline reaction in aqueous solu

tion. Thus even though a caustic alkali (such

The novel soap compositions of my invention

as sodium or potassium hydroxide) be com

yield aqueous solutions which are completely

pounded with a soap forming fatty acid in theo

clear and which have a pH of almost exactly '7

retical proportions, in dilute aqueous solution the

or i_n some cases even slightly less than '7.

soap, due to hydrolysis will react quite de?

A stock solution in which the anhydrous soap

nitely alkaline.

solution of my invention or discovery has already

Stating broadly and generally but briefly and

been diluted with two parts of water for use in

therefore incompletely, my novel discovery con 60 general cleaning may be further greatly diluted

glycol ether modifying agents must be used in

conjunction with the speci?ed soaps in propor

cerns the use of soaps of oleic acid and a cation

derived from one of four types of bases (lower

alkanolamines, lower amines, ammonia and caus

tic alkalies), said soaps being used in conjunc

tion with per mole of fatty acid, (1) at least 1.5

moles and preferably at least 2.0 moles of iso

propanol and (2) at least 0.90 and more prefer

ably at least 1.20 moles of glycol ether modifying

agent of the formula:

with water for many purposes.

These concen

trated stock solutions or greatly diluted solutions

are ideal for cleaning painted and varnished sur

faces, upholstery, clothing, rugs, linoleum, tile,

porcelain, bath tub rings, shoes, automobiles,

comforters, quilts, dishes, greasy pots and pans,

grease, tar and pitch from hands, and anything

which requires a grease removing solvent. The

soap compositions are also ideal for spotting

R(OCH2CH2)OH

60 grease, oil, pitch, tar, chewing gum, lipstick, grass

where R is an alkyl radical with 1 to 4 carbon

stains, also some inks on textile fabrics.

atoms and m is an integer from 1 to 2.

Other speci?c procedures for use which have

In general there is no upper limit for the

given especially good results are given below:

amounts of isopropanol and glycol ether modi

For general cZeaning.Mix eight ounces stock

fying agents. Additional amounts of either of 65 solution to one gallon of water. Saturate a clean

isopropanol or glycol ether modifying agents over

cloth, brush, or wool sponge in the solution, wash

the actual minimum or preferred lower limits

surface, then rinse with clean water.

may be added as diluents.

Spotting textile fabrics.Saturate spot or soiled

In addition to the above enumerated essential

area with water, apply concentrated stock so

ingredients I generally add, for bene?cial or im 70 lution full strength. or a solution of one part

proved results, water in variable quantities ac

stock solution and one part water. Tap with

cording to the purpose for which the soap com

spotting brush or work the spot or soiled area

position is to be used and as is more fully ex

with blunt object to loosen foreign material.

plained later. Where the soap composition is to

Rinse with clear water. For this procedure best

be used to clean paint or other materials dis 76 results are obtained by ?rst placing a towel or

2,551,684

loss of neutrality or the other advantages. This

cheese cloth under the soiled area to take up the

water. Then absorb surplus water on top with

another clean cloth-~thus avoid a deposit of soil

is of great value from the standpoint of cost and

from such other standpoints as those of stability

and a ring on material.

and color of the soaps and non-volatility of the

caustic alkalies as compared to lower amines

Washing machine cleaning-Fill washer with

the required amount of water, add enough stock

solution to create a lasting suds (approximately

one pint) and wash in usual manner.

Most unusual results will be obtained by soak

ing the most soiled garments several hours or

over-night before running in machine.

The extreme neutrality of the novel soap com

positions when caustic alkali soaps are used as

whole or partial soap components is particularly

surprising. It is well known of course that ordi~

nary soaps do not hydrolyze when in solution in

organic solvents as for example in alcohol solu

and

ammonia.

'

Again in the past, in order to make clear, high

lathering liquid soaps it has generally been neces

sary to use coconut oil fatty acids for at least

part of the fatty acid components. The soap

compositions of the invention, however, contain

no coconut oil fatty acids but are clearly soluble

in water, lather readily and form stable lathers.

Again with liquid alkali metal soap compost

tions it has generally been considered necessary

to use as the alkali, potassium hydroxide vrather

sodium hydroxide. In the liquid soap com

Thus any soap which is free from excess

positions of the invention, however, potassium

alkali over the theoretical will react neutral when

dissolved in alcohol.

hydroxide may be partially or wholly substituted

It is a wholly novel and unpredictable result,

however, that the soap compositions of the in

vention would react neutral in dilute aqueous

solution where the amount of glycol ether modi

fying agent would be present in only a very mi~

nute proportion in relation to the water present.

clarity and other desirable features. This .is ob

viously of considerable economic advantage.v

As heretofore stated, the glycol ether modify

ing agents used in the soap compositions of the

invention are compounds with the formula:

tion.

Sodium and potassium soaps have been the

most generally used of all detergents. As re

gards use for a number of purposes, however,

by sodium hydroxide while maintaining the

where R is an alkyl radical with from 1 to 4 car

bon atoms and at is an integer of from 1 to 2. In

these materials have had the drawback that they

the most preferred cases, however, R will have 4

react alkaline in aqueous. To avoid such alka

linity, in some cases nitrogenous bases have been

carbon atoms, 1. e., will be a butyl radical.

used in place of sodium and potassium hydroxide

in making soaps. The use of nitrogenous bases,

In

other words the most preferred glycol ethermodi

fying agents will be compounds having the

formula:

however, has been accompanied by other disad

vantages. For example, with ammonium soaps

where cc is an integer of from 1 to 2.

there is the objection that they tend to lose am

By the use of these preferred glycol ether

monia due to hydrolysis and the voltatile nature

modifying agents together with isopropanol, the

of the base. The alkanolamines on the other

hand, are substantially non-volatile and produce 40 soap compositions have all the hitherto men

tioned advantages enumerated for the soap com

relatively neutral soaps. Such soaps, however,

positions using with the isopropanol the more

are expensive and in the case of the use of the

general class of glycol ether modifying agents.

more readily available alkanolamines such as

With the use of these preferred glycol ether

triethanolamine, the soaps formed tend to be

come dark colored on standing. By using cer 45 modifying agents, however, the soaps have the

additional advantage of being not onlyclearly

tain other alkanolamines instead of triethanola

soluble in water but also being clearly soluble in

mine the soaps formed show less tendency to

petroleum solvents or other dry cleaning type

darken on ageing. Such soaps, however, are

solvents. By their presence they also permit the

even more expensive than triethanolamine soaps.

incorporation in the dry cleaning solvents of sub

Also, soaps formed from nitrogenous bases,

stantial amounts of water and impart to the dry

whether lower alkanolamines, lower amines or

cleaning solvents marked detergent properties in

ammonia all largely hydrolyze in water and yield

regard to removal of dirt, stains, etc., from

very turbid solutions.

In many cases where e?ective detergent action

fabrics.

The ingredients of my preferred soap compo

has been reduired along with absolute neutrality 55

sitions which I may use either as dry cleaning

it has been necessary to forego the use of soaps

soaps in organic solvents or in aqueous solutions

entirely. in such scaes it has been necessary to

resort to the use of synthetic detergents built

are described in more detail below.

up by complicated reactions.

,1 ESSENTIAL INGREDIENTS OF PREFERRED

By the methods of the invention, however, it is

SOAP COMPOSITIONS USABLE EITHER IN

possible to provide by very simple procedures,

DRY CLEANING SOLVENTS OR IN WATER

soap compositions which dissolve absolutely

1. One mole of oleic acid.

clearly in water and which react almost abso

2. A total of substantially one mole of base

lutely neutral in water solution. These soap com

positions, moreover, even in cold dilute aqueous 65 which may be either a single base or a mixture

of bases selected from lower alkanolamines, low

solution, lather readily, form stable lathers and

er amines, ammonia and caustic alkalies.

readily disperse even heavy greases without the

3. At least 1.5 and preferably at least 2.0 moles

use of heat.

'

of isopropanol per mole of oleic acid.

.

The advantages of the invention enumerated

4. At least 0.90 and preferably at least 1.20

above may be obtained when using as the soap 70

moles, per mole of oleic acid, of a glycol ether

forming bases, nitrogenous bases, i. e., lower alka~

modifying agent having the formula:

nolamines, lower amines and ammonia. The in~

vention also, however, comprises the discovery

C4H9- (OCH2CH2) @OH

that these bases may be wholly or partially sub

stituted by caustic potash or caustic soda without 75 where x is an integer of from 1 to 2.

2,561,634

7

aminoethanol,

triisopropylamine,

2-amino-1

In addition to the above. enumerated essential

ingredients. I prefer to add water in amounts up

butanol, 2 - amino - 2 -methyl - 1 - propanol, 2

to. 2.25 moles per mole of oleic acid and more

preferably from 1.75 to 2.0v moles per mole of

oleic acid. This added Water greatly increases

methyl-1, 3-propanediol, tris (hydroxymethyl)

aminomethane dibutylethanolamine, diethanol

amino - 2 - ethyl-1,

2-amino-2

ethylamine, cyclohexylethanolamine, diethanol

cyclohexylamine, diethylethanolamine, isobu

tanolamine, mixtures of monoisopropanolamine,

the detergency when the soap compositions are

added to dry cleaning solvents and markedly

aids the removal of stains particularly those hav

ing. as a base water soluble or dispersible mate-v

dii'sopropanolamine and triisopropanolamine.

H)

rials-such as sugars or starches.

B-propanediol,

Instead of, or in addition to,. adding Water to

the dry cleaning soap composition, water may

be added to the dry cleaning solvent at the time

of use in the dry cleaning, machine. Such wa

ter additions may be either made as such or in

the form of aqueous ammonia which aids in the

detergency. When Water is added While the

clothes are actually being cleaned it may be

added in surprisingly large amounts without vis

ible-separation of water.

I amof course well aware that oleic acid soaps,

B. Lower amines

Methylamine, ethylamine, diethylamine, tri

ethylamine, n-dibutylamine, n-tributylamine,

triamylamine-morpholine, dimethylcyclohexyl

amine, diethylcyclohex,lamine, n-butylamine,

n-amylamine, isopropylamine.

C. Ammonia

Ammonia.

D. Caustic alkalies

Potassium hydroxide, sodium hydroxide.

both of potash and of triethanolamine, have

been used before as dry cleaning soaps. Such

previously used dry cleaning soaps, however,

The glycol ether modifying agents which are

used in the invention may be divided into two

classes:

have been superfatted soaps, i. e., contained "

1. Glycol ether modifying agents used in liqud

soap compositions soluble in water only

a large excess of fatty acid. This large excess

of fatty acid was necessary in order to secure

solubility in the dry cleaning solvents. While

previously used superfatted soaps did impart

some detergent properties to the dry cleaning

solvents their use was accompanied by certain

marked. disadvantages. In particular the con

tent of free fatty acid was objectionable in that

in practice, small amounts of fatty acid Would

usually be retained by the fabric after solvent

Washing with the result that disagreeable ran

cidity odors would tend to develop.

The dry cleaning soap compositions of myiin

vention'onthe other hand do not contain super

fatted soaps. My novel dry cleaning soap com

positions contain theoretically neutral soaps,

i: e';, soaps in which there is substantially one

mole-of base per mole of fatty acid. According

ly-' even if traces of these soaps should not be

removed by the solvents from the fabrics there

will be substantially no tendency for any ran

cidity odors to develop.

Also,. the previously used superfatted soaps

were strictly dry cleaning soaps'in that they were

not- substantially soluble in water except as

emulsions. My preferred soap compositions are

completely soluble in both petroleum solvents

and in water, forming completely neutral solu

tions in the latter. When added to dry clean

in'g solvents in particular they aid the'removal

of water soluble or'water dispersible materials.

When added to water they particularly aid'the

removal of greases and other materials soluble

in organic solvents. This double action in a

single material is strikingly novel.

While. ity is to be understood that the. inven

tion is not to be construed as being limited to

any speci?c examples of compounds set forth,

some of the bases which are especially suitable

Glycol monomethyl ether, glycol monoethyl

ether, glycol monopropyl ether, diethylene glycol

monomethyl ether, diethylene glycol monethyl

ether, diethylene glycol monopropyl ether.

2. Glycol ether modifying agents used in liquid

soap compositions soluble in both Stoddard

solvent and water

These compounds which represent a special

subclass under the general formula are glycol

mcnobutyl ether and diethylene glycol mono

butyl ether.

Ten examples of preferred liquid soap composi

tions of my invention soluble both in Stoddard

solvent and in water are given in the table fol

lowing:

Examples of liquid soap compositions soluble in

both Stoddard solvent and water

Chemicals ___________________ __

2'

Olcic Acid (gms) ___________ __ G7. '5

Glycol

Monobuiyl

34.1

diethanolamine,

trieth

anolamine, mixtures of monoethanolamine, di

ethanolamine, and triet'nanolamine, methyl

67. 75

67. 75

[)7 7)

(57. 75

34. l

34. l

25. (i

34. l

99% Isopropanol (gIIlS.) _____ _. 29.7

29.7

29.7

29.7

22.2

Hydroxide

(531115.) _____________________ __

89

98% Sodium Hydroxide (gins) . _____ __

26% Ammonia (gl'llS.)__

__

3. 42

Tricthauolaminc (glllS.)

_.__

10.66

Water (gills) ________________ _- 30. 3

_____ __

3. Si;

3. 42

10.66

30. 3

_

_____ ..

33

.

26.0

31-;

.... ._

17

Examples of liquid soap compositions soluble in

both Stoddard solvent and water~Continued

Chemicals ___________________ . _

Olcic Acid (gins)... . .__

Glycol

Monobutyl

ms __________________ ._

Diclhylenc Glycol \lonobi

'

Ethcr(gms.) _______ _.

____ 35.01

46.7

46.7

fbrusein the soap compositions of the invention

99% lsopropanol (gms) _ _ _ _ _ ._ 29.7

29.7

29.7

are given below. These bases fall under four

90% Potassium Hydroxid

(gins) __________________________________________ __

classes, i. e., lower alkanolamines, lower amines,

20% Ammonia (gins

_

ammonia and caustic alkalies, all of which

2-nrninor-2~mcthyl l

(liol

(gins).

_

classes have been found to be operative.

70 2-umino-2-nletl ~

(gins-Luna"

v

A. Lower allcanolamines

Isopropylnmlne (gms.)_.___.__ ________ ..._.__

1-1.2

Monoethanolamine,

Ether

(gins) _____________________ __

Potassium

Water (gins) ________________ __

33

33

3:;

46.7

.... .i

29.7

29 7

14.95

5. 89

', -

........... ..

3:;

30.3

Where the solutions of the compositions shown

ethanolamine, morpholine'r- ethanol, dieth-yl 75 in the preceding table. are to be used solely in

2,551,684

10

aqueous solutions, I prefer as hereinabove ex

plained to prepare stock solutions which are

tial proportion of the reaction product of oleic

still relatively concentrated but which have been

ing of solium hydroxide and potassium hydroxide,

diluted with at least one volume (and more gen

said soap consisting of substantially theoretical

equivalents of oleic acid and total base, (2) at

least 1.5 moles of isopropanol per mole of oleic

acid, and (3) at least 0.9 mole per mole of oleic

acid of a glycol ether modifying agent having the

acid and a base selected from the group consist

erally one to two volumes) of water. This water

addition is not only convenient but also pre

eludes any possibility of attack when used on

sensitive painted surfaces. Also as heretofore de

scribed these concentrated stock solutions may

formula

be greatly diluted with water by the consumer 10

for actual use in most cleansing operations.

Also where the liquid soap compositions are

to be used solely in aqueous solutions the glycol

ether modifying agents are not limited to the

R(OCH2CH2) mOH

Where R is an alkyl radical with l to 4 carbon

atoms and a," is an integer from 1 to 2.

2. A non-superfatted liquid soap composition

soluble

in both Stoddard solvent and water to

glycol monobutyl ether and diethylene glycol 15

produce optically clear substantially neutral so

monobutyl ether illustrated in the table. While

lutions having marked detergent properties, said

these compounds are preferred there may be

composition comprising (1) a mixed soap com

used for aqueous cleaning solutions instead:

prising (a) the reaction product of oleic acid and

Glycol monomethyl ether, glycol monoethyl

ether, glycol monopropyl ether, diethylene glycol 20 a base selected from the group consisting of the

lower alkanolamines, the lower amines, and am

monomethyl ether, diethylene glycol monoethylr

monia, and (b) a substantial proportion of the re

ether, diethylene glycol monopropyl ether.

action product of oleic acid and a base selected

Obviously also instead of a single glycol ether

from the group consisting of sodium hydroxide

more than one glycol ether modifying agent. 25 and potassium hydroxide, said soap consisting of

substantially theoretical equivalents of oleic acid

Where, however, the liquid soap compositions

and total base, (2) at least 1.5 moles of isopro

are to be soluble in both Stoddard solvent and

panol per mole of oleic acid, and (3) at least 0.9

water, such mixtures would be limited to mix

mole per mole of oleic acid of a glycol ether modi

tures of glycol monobutyl ether and diethylene

fying agent having the formula

glycol monobutyl ether.

Also obviously in place of neutralizing the

i iodifying agent there may be used a mixture of

oleic acid with a single base, the oleic acid may

if desired be neutralized with one equivalent of

a mixture of bases. I have obtained especially

good results by using a mixture of potassium hy

droxide, a lower alkanolamine and ammonia.

where as is an integer from 1 to 2.

3. A non-superfatted liquid soap composition

soluble in both Stoddard solvent and water to

(One preferred mixture would contain potassium

produce optically clear substantially neutral solu

tions having marked detergent properties, said

hydroxide, a lower alkanolamine and ammonia

composition comprising (1) a mixed soap com

prising (a) the reaction product of oleic acid and

in approximate molar ratios of 0.40, 0.35 and 0.25,

respectively.)

Preferred alkanolamines very 40 a base selected from the group consisting of the

lower alkanolamines, the lower amines, and am

monia, and (b) a substantial proportion of the

reaction product of oleic acid and a base selected

from the group consisting of sodium hydroxide

very light colored liquid soap solutions are de

and potassium hydroxide, said soap consisting of

sired.

substantially theoretical equivalents of oleic acid

The soap compositions of the invention are

and total base, (2) at least 1.5 moles of isopro

not to be construed as being limited to any par

panol per mole of oleic acid, and (3) at least 0.9

ticular order of adding the materials. Practi~

mole per mole of oleic acid of ethylene glycol

cally, however, I prefer to add the isopropanol

and glycol ether modifying agent to the oleic acid 50 monobutyl ether.

4. A non-superfatted liquid soap composition

prior to adding the base or mixture of bases. In

soluble

in both Stoddard solvent and water to

this way the formation of a solid soap composi

produce optically clear substantially neutral so

tion is avoided and the preparation much simpli

lutions having marked detergent properties, said

?ed. If a solid soap is ?rst formed it usually re

composition comprising (1) a mixed soap com

quires considerable agitation and/or heating to

prising the reaction products of oleic acid and a

dissolve it in the isopropanol and glycol ether

mixture of bases consisting of potassium hydrox

suitable for such mixtures are triethanolamine,

and 2-amino-2-methyl-l, B-propanediol. The lat

ter alkanolamine is especially preferred where

modifying agent.

'

Generally, I prefer to incorporate during the

mixing of the ingredients water in the propor

tions heretofore described. Where solid bases

such as potassium hydroxide, sodium hydroxide

or 2-amino-2-methyl-1, 3-propanediol are used

it is most convenient to dissolve these in all or a

ide, triethanolamine and ammonia, said potas

sium hydroxide constituting a substantial pro

portion of the total base, and said soap consisting

of substantially theoretical equivalents of oleic

acid and total base, (2) at least 1.5 moles of iso~

propanol per mole of oleic acid, and (3) at least

0.9 mole per mole of oleic acid of a glycol ether

portion of the water to be incorporated in the 65 modifying agent having the formula

liquid soap composition.

C4319 (OCH2CI-Iz) 10H

I claim:

1. A non-superfatted liquid soap composition

where a: is an integer from 1 to 2.

soluble in water to produce optically clear sub

5. A non-superfatted liquid soap composition

stantially neutral solutions having marked deter 70 soluble in both Stoddard solvent and water to

gent properties, said composition comprising (1)

a mixed soap comprising (a) the reaction prod

not of oleic acid and a base selected from the

group consisting of the lower alkanolamines, the

lower amines, and ammonia, and (b) a substan

produce optically clear substantially neutral

solutions having marked detergent properties,

said composition comprising (1) a soap consisting

of the reaction products of oleic acid and a mix

. ture of bases consisting of triethanolamine, am

2,551,634

11

12

mania and a substantial proportion of potassium

hydroxide, said soap consisting of substantially

theoretical equivalents of oleic acid and total

base, (2) at least 1.5 moles of isopropanol per mole

of oleic acid, and (3) at least 0.9 mole per mole

of oleic acid of ethylene glycol monobutyl ether.

6. A non-superfatted liquid soap composition

least one volume of water per volume of an

hydrous liquid soap composition.

9. A non-superfatted aqueous liquid soap com

position harmless to painted surfaces and textile

fabrics and characterized by being soluble in

water to produce clear neutral solutions having

marked detergent properties, said composition

comprising (1) a soap consisting of the reaction

products of oleic acid and a mixture of bases con

10 sisting of triethanolamine, ammonia and a sub

soluble in both Stoddard solvent and water to

produce optically clear substantially neutral solu

tions having marked detergent properties, said

stantial proportion of potassium hydroxide, said

soap consisting of substantially theoretical

equivalents of oleic acid and total base, (2) at

composition comprising (1) a soap consisting of

the reaction products of oleic acid and a mixture

of bases consisting of triethanolamine, ammonia

and a substantial proportion of potassium hy

droxide, said soap consisting of substantially

theoretical equivalents of oleic acid and total

base, (2) at least 1.5 moles of iscpropanol per mole

of oleic acid, (3) at least 0.9 mole per mole of

least 1.5 moles of isopropanol per mole of oleic

acid, (3) at least 0.90 mole per mole of oleic

acid of a glycol ether modifying agent having the

formula

oleic acid of ethylene glycol monobutyl ether, and

where R is an alkyl radical with 1 to 4 carbon

atoms and .r is an integer from 1 to 2, and (4) at

least one volume of water per volume of an

(4) water not exceeding 2.25 moles per mole of

oleic acid.

'7. A non-superfatted liquid soap composition

soluble in both Stoddard solvent and water to

produce optically clear substantially neutral

hydrous liquid soap composition.

10. The method of making a non-superfatted

liquid soap composition soluble in water to pro

duce clear substantially neutral solutions having

solutions having marked detergent properties,

said composition comprising (1) a mixed soap

comprising (a) the reaction product of oleic acid

marked detergent properties, comprising mixing

and a base selected from the group consisting of

the lower allianolamines, the lower amines and

ammonia, and (b) a substantial proportion of

the reaction product of oleic acid and a base

selected from the group consisting of sodium hy

one mole of oleic acid with at least 1.5 moles of

iscpropanol per mole of oleic acid, and at least

0.90 mol per mole of oleic acid of a glycol ether

droxide and potassium hydroxide, said soap con

sisting of substantially theoretical equivalents

of oleic acid and total base, (2) at least 1.5 moles

of iscpropanol per mole oi oleic acid, (3) at least

0.9 mole per mole of oleic acid of a glycol ether

modifying agent having the formula

.'

modifying agent having the formula

R(OCH2CH2) rOH

where R is an alkyl radical with l to 4 carbon

atoms and a: is an integer from 1 to 2, and adding

to said mixture one equivalent based on said oleic

acid. of total base consisting of a base selected

from the group consisting of the lower alkanol~

amines, the lower amines and ammonia, and a

4 D substantial proportion of a base selected from the

where x is an integer from 1 to 2, and (4) water

not exceeding 2.25 moles per mole of oleic acid.

8. A non-superfatted aqueous liquid soap com

position harmless to painted surfaces and textile

fabrics and characterized by being soluble in

water to produce clear neutral solutions having

marked detergent properties, said composition

comprising (1) a mixed soap comprising (a) the

reaction product of oleic acid and a base selected

from the group consisting of the lower allzanol- '

amines, the lower amines and ammonia, and

(b) a substantial proportion of the reaction prod

uct of oleic acid and a base selected from the

group consisting of sodium hydroxide

potas

sium hydroxide, said soap consisting of substan~

tially theoretical equivalents of oleic acid and

total base, (2) at least 1.5 moles of iscpropanol

per mole of oleic acid, (3) at least {3.9 mole per

mole of oleic acid of a glycol ether modifying

agent having the formula

(50

where R is an alkyl radical with l to 4 carbon

atoms and x is an integer from 1 to 2, and (4) at

group consisting of potassium hydroxide and

sodium hydroxide.

ROBERT HAMILTON PRICE.

REFERENCES CITED

The following references are of record in the

file of this patent:

UNITED STATES PATENTS

Number

Name

Date

1,847,437

Moscowitz ________ __ Mar. 1, 1932

OTHER REFERENCES

Ind. and Eng. Chem., July 1929, pages 685-687,

article by Trusler entitled Ethanolamine Soaps.

Emulsions, Booklet published by Carbide and

Carbon Chem. Corp, New York (1934), 4th ed.,

pages 6, 7, 51, 52, and 53.

Synthetic Organic Chemicals, Carbide and

Carbon Chem. Corp., New York, 11th ed., 1942,

pages 25 and 28.

Potrebbero piacerti anche

- Soap-Making Manual A Practical Handbook on the Raw Materials, Their Manipulation, Analysis and Control in the Modern Soap Plant.Da EverandSoap-Making Manual A Practical Handbook on the Raw Materials, Their Manipulation, Analysis and Control in the Modern Soap Plant.Valutazione: 4 su 5 stelle4/5 (2)

- Bio Surfactants and Synthetic Variants Used in Herbal Face Wash A ReviewDocumento6 pagineBio Surfactants and Synthetic Variants Used in Herbal Face Wash A ReviewP. SathammaiNessuna valutazione finora

- ACD Guidelines For Product Information File (PIF)Documento7 pagineACD Guidelines For Product Information File (PIF)NukiAdelaNessuna valutazione finora

- VIETNAM. PROCESSING OF AROMA CHEMICALS AND FRAGRANCE MATERIALS. TECHNICAL REPORT - AROMA CHEMICALS AND PERFUME BLENDING (20598.en) PDFDocumento83 pagineVIETNAM. PROCESSING OF AROMA CHEMICALS AND FRAGRANCE MATERIALS. TECHNICAL REPORT - AROMA CHEMICALS AND PERFUME BLENDING (20598.en) PDFOsamaAliMoussaNessuna valutazione finora

- MSDS Liquid Shoe PolishDocumento4 pagineMSDS Liquid Shoe PolishAhmAd GhAziNessuna valutazione finora

- Enactus Liquid Soap ProjectDocumento40 pagineEnactus Liquid Soap ProjectWendellReeceFrank100% (1)

- Oils and Fats Glossary TermsDocumento19 pagineOils and Fats Glossary TermsThais Soraluz HidalgoNessuna valutazione finora

- Sodium Lauryl Ether Sulfate Production Process OverviewDocumento28 pagineSodium Lauryl Ether Sulfate Production Process OverviewSalihin FhooziNessuna valutazione finora

- Manufacturing Process, Environmental Impacts, and Manufacturer RolesDocumento9 pagineManufacturing Process, Environmental Impacts, and Manufacturer RolesSyauqi Subri100% (1)

- Dial Liquid Soap RedesignDocumento6 pagineDial Liquid Soap RedesignHailey LewisNessuna valutazione finora

- Soaps & Detergents: ManufacturingDocumento4 pagineSoaps & Detergents: ManufacturingAnis HafizahNessuna valutazione finora

- COSMOS Standard V3.0 Including Editorial Changes 0101 2019Documento47 pagineCOSMOS Standard V3.0 Including Editorial Changes 0101 2019Suresh KumarNessuna valutazione finora

- Test Residues pH Meters Indicators KitsDocumento3 pagineTest Residues pH Meters Indicators Kitsat_sehly2458Nessuna valutazione finora

- SALERM Catalogue (En) 2015Documento75 pagineSALERM Catalogue (En) 2015spainyepNessuna valutazione finora

- IFRA-RIFM QRA Information Booklet V7.1 (July 9, 2015)Documento37 pagineIFRA-RIFM QRA Information Booklet V7.1 (July 9, 2015)Carlos-Ivan TlatoaniNessuna valutazione finora

- Stability Testing-Basic Theory and Concept AplicationDocumento16 pagineStability Testing-Basic Theory and Concept AplicationSham Saja100% (1)

- SoapsDocumento13 pagineSoapsIrah Lokman100% (1)

- Castor Oil & Its Derivatives Oleoresin, Turkey Red Oil, Dco, Hco, Sebacic Acid, 12-Hydroxy Stearic AcidDocumento5 pagineCastor Oil & Its Derivatives Oleoresin, Turkey Red Oil, Dco, Hco, Sebacic Acid, 12-Hydroxy Stearic Acidkunal agiwaleNessuna valutazione finora

- PerfumeDocumento13 paginePerfumePaul Michael Joules Salise100% (1)

- Flowsheet LabsDocumento10 pagineFlowsheet LabsNisaMardiyahNessuna valutazione finora

- MWE-9501 - Manual de Serviço (EN) (2004.10)Documento72 pagineMWE-9501 - Manual de Serviço (EN) (2004.10)Thiago AzevedoNessuna valutazione finora

- ShampooDocumento31 pagineShampooMohamed LaghyatiNessuna valutazione finora

- Surfactants in DetailDocumento6 pagineSurfactants in DetailArvind Tandon100% (1)

- BCI0711Documento1 paginaBCI0711franciscocampoverde8224Nessuna valutazione finora

- Room Perfume Aerosol Spray Free ExampleDocumento7 pagineRoom Perfume Aerosol Spray Free ExampleKhan SajjadNessuna valutazione finora

- Liquid DetergentDocumento7 pagineLiquid Detergentmagdy100% (1)

- Surfactant BrochureDocumento8 pagineSurfactant BrochureRaj Aryan YadavNessuna valutazione finora

- 3 - Shortenings - Science and TechnologyDocumento41 pagine3 - Shortenings - Science and TechnologyJulesNessuna valutazione finora

- Soap Noodles Methodology 1 December 2015Documento17 pagineSoap Noodles Methodology 1 December 2015Luis BejaranoNessuna valutazione finora

- GMP Guild For Cosmetic IngredientDocumento48 pagineGMP Guild For Cosmetic IngredientLennon Tan Qin JiNessuna valutazione finora

- PIF Requirements for Cosmetic ProductsDocumento27 paginePIF Requirements for Cosmetic ProductsKim SablayanNessuna valutazione finora

- ShampooDocumento24 pagineShampooHenry GohNessuna valutazione finora

- Preservatives in Cosmetic ProductsDocumento35 paginePreservatives in Cosmetic Productsketchito100% (2)

- Manage Distribution Operations & FulfillmentDocumento34 pagineManage Distribution Operations & FulfillmentMaroa Al HabsiNessuna valutazione finora

- Swot R&DDocumento2 pagineSwot R&Dcrismg1Nessuna valutazione finora

- CosmeticDocumento6 pagineCosmeticArjun M NairNessuna valutazione finora

- Who Recommended Hand-Rub FormulationDocumento9 pagineWho Recommended Hand-Rub FormulationSaeed Mohammed100% (2)

- Biariq SLES 70% TDSDocumento2 pagineBiariq SLES 70% TDSAbdullah AzzamNessuna valutazione finora

- Dishwashing LiquidDocumento1 paginaDishwashing Liquidmagdy100% (1)

- 2 ShampoosDocumento22 pagine2 ShampoosRatih PramintariNessuna valutazione finora

- Formulations Ot Toilet SoapDocumento3 pagineFormulations Ot Toilet SoapER. INDERAMAR SINGH100% (1)

- Foam Car - Shampoo - FormulationDocumento9 pagineFoam Car - Shampoo - FormulationBejoyNessuna valutazione finora

- Method For Measuring Degreasing On Different SubstratesDocumento42 pagineMethod For Measuring Degreasing On Different SubstratesFra FraNessuna valutazione finora

- Product Safety Data Sheet: Section 1: IDocumento17 pagineProduct Safety Data Sheet: Section 1: ILiemar EstayNessuna valutazione finora

- Natural Liquid to Matte Lipstick FormulaDocumento2 pagineNatural Liquid to Matte Lipstick FormulaFelix Martin GutierrezNessuna valutazione finora

- Deo Spray SamplesDocumento8 pagineDeo Spray SamplesVaibhav KaushikNessuna valutazione finora

- Pif GuidelinesDocumento27 paginePif GuidelinesKim SablayanNessuna valutazione finora

- Soap and Detergent Manufacturing Processes ExplainedDocumento40 pagineSoap and Detergent Manufacturing Processes ExplainedShahzil RehmanNessuna valutazione finora

- Evaluation of ShampoosDocumento13 pagineEvaluation of ShampoosPraneeth Reddy100% (1)

- How To Produce Laundry Soap in NigeriaDocumento18 pagineHow To Produce Laundry Soap in NigeriaDemelash GebreNessuna valutazione finora

- Life Cycle Assessment of Soap and DetergentsDocumento14 pagineLife Cycle Assessment of Soap and Detergentstewegeb5100% (3)

- FRAME FORMULATION Oznamenie Ramcovych Zlozeni A Vzory Oznameni V AnglictineDocumento50 pagineFRAME FORMULATION Oznamenie Ramcovych Zlozeni A Vzory Oznameni V AnglictineRajesh Kumar100% (1)

- Europass CV 101130 135735Documento3 pagineEuropass CV 101130 135735razvanNessuna valutazione finora

- Homemade Hand Sanitizer - Learn How to Make Your Own Natural Hand Sanitizer Recipes for a Healthier LifestyleDa EverandHomemade Hand Sanitizer - Learn How to Make Your Own Natural Hand Sanitizer Recipes for a Healthier LifestyleNessuna valutazione finora

- Colloidal Surfactants: Some Physicochemical PropertiesDa EverandColloidal Surfactants: Some Physicochemical PropertiesNessuna valutazione finora

- Emulsion-based Systems for Delivery of Food Active Compounds: Formation, Application, Health and SafetyDa EverandEmulsion-based Systems for Delivery of Food Active Compounds: Formation, Application, Health and SafetyShahin RoohinejadNessuna valutazione finora

- Organic Food Certification and Marketing StrategiesDa EverandOrganic Food Certification and Marketing StrategiesNessuna valutazione finora

- Waste Paper ReceptableDocumento3 pagineWaste Paper ReceptableJavier BecerraNessuna valutazione finora

- Viscous Liquid SoapDocumento8 pagineViscous Liquid SoapJavier BecerraNessuna valutazione finora

- Fairy Ring ControlDocumento5 pagineFairy Ring ControlJavier BecerraNessuna valutazione finora

- Extraction PDFDocumento18 pagineExtraction PDFJavier BecerraNessuna valutazione finora

- Anti-Fog Resin Sheet Enhances Low-Temp EffectsDocumento14 pagineAnti-Fog Resin Sheet Enhances Low-Temp EffectsJavier BecerraNessuna valutazione finora

- Fog DispersalDocumento5 pagineFog DispersalJavier BecerraNessuna valutazione finora

- Hairy RootDocumento39 pagineHairy RootJavier BecerraNessuna valutazione finora

- Hairy Cell LeukemiaDocumento34 pagineHairy Cell LeukemiaJavier BecerraNessuna valutazione finora

- Method and Apparatus FogDocumento5 pagineMethod and Apparatus FogJavier BecerraNessuna valutazione finora

- Hairy Cell LeukemiaDocumento34 pagineHairy Cell LeukemiaJavier BecerraNessuna valutazione finora

- Machine Learning ServiceDocumento65 pagineMachine Learning ServiceJavier BecerraNessuna valutazione finora

- Transformation of Animal Cells PDFDocumento8 pagineTransformation of Animal Cells PDFJavier BecerraNessuna valutazione finora

- Soap Bar Containing Hydrogel Phase ParticlesDocumento19 pagineSoap Bar Containing Hydrogel Phase ParticlesJavier BecerraNessuna valutazione finora

- Soap Bar Containing Hydrogel Phase ParticlesDocumento19 pagineSoap Bar Containing Hydrogel Phase ParticlesJavier BecerraNessuna valutazione finora

- Insert MachineDocumento31 pagineInsert MachineJavier BecerraNessuna valutazione finora

- Anti-fog coating for optical devicesDocumento11 pagineAnti-fog coating for optical devicesJavier BecerraNessuna valutazione finora

- Dispensing MachineDocumento12 pagineDispensing MachineJavier BecerraNessuna valutazione finora

- Liquis SoapDocumento4 pagineLiquis SoapJavier BecerraNessuna valutazione finora

- Lava Petr IsDocumento8 pagineLava Petr IsJavier BecerraNessuna valutazione finora

- Machine Learning ServiceDocumento65 pagineMachine Learning ServiceJavier BecerraNessuna valutazione finora

- Antifreeze ProteinDocumento18 pagineAntifreeze ProteinJavier BecerraNessuna valutazione finora

- Multi-purpose dishwasher rack for storing dishwareDocumento5 pagineMulti-purpose dishwasher rack for storing dishwareJavier BecerraNessuna valutazione finora

- Dish Washer DecalcifierDocumento8 pagineDish Washer DecalcifierJavier BecerraNessuna valutazione finora

- Dispositivo AntiempañanteDocumento11 pagineDispositivo AntiempañanteJavier BecerraNessuna valutazione finora

- Printed AntifogDocumento15 paginePrinted AntifogJavier BecerraNessuna valutazione finora

- Antifog 2Documento19 pagineAntifog 2Javier BecerraNessuna valutazione finora

- List of New Arrival Books in Applied MechanicsDocumento69 pagineList of New Arrival Books in Applied MechanicsKESHAV SINGHALNessuna valutazione finora

- EPA Corrosion ManualDocumento141 pagineEPA Corrosion Manualnert100% (1)

- Zumdahl Chapter 9Documento24 pagineZumdahl Chapter 9Master NistroNessuna valutazione finora

- 2017 CSEC Integ. Sci P1Documento10 pagine2017 CSEC Integ. Sci P1Ameer PersaudNessuna valutazione finora

- STABILITYDocumento11 pagineSTABILITYNandyNessuna valutazione finora

- New VARTA Power Trio batteries for commercial vehiclesDocumento68 pagineNew VARTA Power Trio batteries for commercial vehiclesJosh DuplooyNessuna valutazione finora

- Piping & Instrumentation DiagramDocumento1 paginaPiping & Instrumentation DiagramSearch45Nessuna valutazione finora

- Closed System Energy AnalysisDocumento1 paginaClosed System Energy AnalysisKousak TDNessuna valutazione finora

- Chemistry Investigatory ProjectDocumento14 pagineChemistry Investigatory ProjectV P SomeshwarNessuna valutazione finora

- CM5241 Literature Review Project TopicsDocumento3 pagineCM5241 Literature Review Project TopicsCheryldine LimNessuna valutazione finora

- AC Transformer LectureDocumento4 pagineAC Transformer LectureDE VERA, KENNETH GABRIEL D.Nessuna valutazione finora

- Resazurin Cell Viability Assay - Orzel (Full)Documento5 pagineResazurin Cell Viability Assay - Orzel (Full)ShawnNessuna valutazione finora

- Local Treatment of Electron Correlation-Svein SaeboDocumento24 pagineLocal Treatment of Electron Correlation-Svein SaeboAndré RojasNessuna valutazione finora

- Carbon Dioxide: Pressure - Enthalpy Diagram: R 90 0 Sity 7 00 KG/MDocumento1 paginaCarbon Dioxide: Pressure - Enthalpy Diagram: R 90 0 Sity 7 00 KG/MJackNessuna valutazione finora

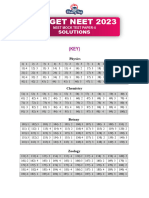

- Mock Test 4 Paper Neet SolDocumento16 pagineMock Test 4 Paper Neet Solspamhater566Nessuna valutazione finora

- Asam Mefenamat EmulgelDocumento5 pagineAsam Mefenamat EmulgelVi Vian HiuNessuna valutazione finora

- JIS G3466 - Thailand - CONTENT1011579693989745Documento1 paginaJIS G3466 - Thailand - CONTENT1011579693989745Nguyễn Tiến TùngNessuna valutazione finora

- Design Basis Report-Nh208Documento19 pagineDesign Basis Report-Nh208Atanu AdhiakryNessuna valutazione finora

- Condensation of Acetophenone To (Dypnone) Over Solid Acid CatalystsDocumento9 pagineCondensation of Acetophenone To (Dypnone) Over Solid Acid CatalystsLutfiah Nur HidayatiNessuna valutazione finora

- IV (M) QM Gamma Ray MicroscopeDocumento2 pagineIV (M) QM Gamma Ray MicroscopeAbhigyan HazarikaNessuna valutazione finora

- Reactor Design Sample ExamDocumento7 pagineReactor Design Sample ExamAugustine BrockNessuna valutazione finora

- Dyes and Pigments: SciencedirectDocumento9 pagineDyes and Pigments: SciencedirectrishabhNessuna valutazione finora

- Nature of Adherence of Porcelain Enamels To MetalsDocumento22 pagineNature of Adherence of Porcelain Enamels To MetalsFernando BarreraNessuna valutazione finora

- Scince (Assement-1)Documento4 pagineScince (Assement-1)ARAF ABDULLAHNessuna valutazione finora

- GUI PWR Sim Using Python DTU ThesisDocumento56 pagineGUI PWR Sim Using Python DTU ThesisAnkit RajNessuna valutazione finora

- Studiesonsomeaspectsofconveyordrivepulleydesign PDFDocumento7 pagineStudiesonsomeaspectsofconveyordrivepulleydesign PDFjoaquin fuentealba moralesNessuna valutazione finora

- Practical Training Presentation on Thermal Power Plant ComponentsDocumento26 paginePractical Training Presentation on Thermal Power Plant ComponentsDivyansh ChaturvediNessuna valutazione finora

- M1 January 2012 Question PaperDocumento28 pagineM1 January 2012 Question PapergerikaalhuNessuna valutazione finora

- Hadighi AliDocumento66 pagineHadighi AliMousaNessuna valutazione finora

- SUB: Heat & Mass Transfer (EME 504) : Assignment-IDocumento2 pagineSUB: Heat & Mass Transfer (EME 504) : Assignment-IdearsaswatNessuna valutazione finora