Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Din en Iso 8501-3 2007

Caricato da

Técnico XXXTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Din en Iso 8501-3 2007

Caricato da

Técnico XXXCopyright:

Formati disponibili

DEUTSCHE NORM

October 2007

DIN EN ISO 8501-3

ICS 25.220.10

Preparation of steel substrates before application of paints and related

products

Visual assessment of surface cleanliness

Part 3: Preparation grades of welds, edges and other areas with surface

imperfections (ISO 8501-3:2006)

English version of DIN EN ISO 8501-3:2007-10

Document comprises 11 pages

No part of this standard may be reproduced without prior permission of

DIN Deutsches Institut fr Normung e. V., Berlin. Beuth Verlag GmbH, 10772 Berlin, Germany,

Copyright Deutsches Institut

Normung

E.V. right of sale for German Standards (DIN-Normen).

hasFurthe

exclusive

Provided by IHS under license with DIN

No reproduction or networking permitted without license from IHS

English price group 8

www.din.de

www.beuth.de

Not for Resale

//^:^^#^~^^""~:@":^*^~$~"#:*~"*:~:*~@"~~*^~:^"$:#:^:"\\

--`,,```,,,,````-`-`,,`,,`,`,,`---

Vorbereitung von Stahloberflchen vor dem Auftragen von Beschichtungsstoffen

Visuelle Beurteilung der Oberflchenreinheit

Teil 3: Vorbereitungsgrade von Schweinhten, Kanten und anderen Flchen mit

Oberflchenunregelmigkeiten (ISO 8501-3:2006)

Englische Fassung DIN EN ISO 8501-3:2007-10

!$J)b"

1390663

DIN EN ISO 8501-3:2007-10

National foreword

This standard falls within the responsibility of Technical Committee CEN/TC 139 Paints and varnishes

(Secretariat: DIN, Germany). It is identical with International Standard ISO 8501-3 which was prepared by

Technical Committee ISO/TC 35 Paints and varnishes, Subcommittee SC 12 Preparation of steel substrates

before application of paints and related products (Secretariat: BSI, United Kingdom).

The responsible German bodies involved in its preparation were the Normenausschuss Beschichtungsstoffe

und Beschichtungen (Coatings and Coating Materials Standards Committee) and the Normenausschuss Bauwesen (Building and Civil Engineering Standards Committee), Technical Committees NA 002-00-10-04 GUA

Oberflchenvorbereitung und -prfung and NA 002-00-10 GA Korrosionsschutz von Stahlbauten.

DIN EN ISO 8501 consists of the following parts, under the general title Preparation of steel substrates before

application of paints and related products Visual assessment of surface cleanliness:

Part 1: Rust grades and preparation grades of uncoated steel substrates and of steel substrates after

overall removal of previous coatings

Part 2: Preparation grades of previously coated steel substrates after localized removal of previous

coatings

Part 3: Preparation grades of welds, edges and other areas with surface imperfections

Part 4: Initial surface conditions, preparation grades and flash rust grades in connection with high-pressure

water jetting

The DIN Standards corresponding to the International Standards referred to in clause 2 and in the Bibliography

of the EN are as follows:

ISO 8504-3

ISO 12944-2

ISO 12944-3

DIN EN ISO 8504-3

DIN EN ISO 12944-2

DIN EN ISO 12944-3

National Annex NA

(informative)

DIN EN ISO 8504-3, Preparation of steel substrates before application of paints and related products

Surface preparation methods Part 3: Hand- and power-tool cleaning

DIN EN ISO 12944-2, Paints and varnishes Corrosion protection of steel structures by protective paint

systems Part 2: Classification of environments

DIN EN ISO 12944-3, Paints and varnishes Corrosion protection of steel structures by protective paint

systems Part 3: Design considerations

2

Copyright Deutsches Institut Fur Normung E.V.

Provided by IHS under license with DIN

No reproduction or networking permitted without license from IHS

Not for Resale

//^:^^#^~^^""~:@":^*^~$~"#:*~"*:~:*~@"~~*^~:^"$:#:^:"\\

--`,,```,,,,````-`-`,,`,,`,`,,`---

Bibliography

EUROPEAN STANDARD

EN ISO 8501-3

NORME EUROPENNE

EUROPISCHE NORM

July 2007

ICS 25.220.10

English Version

Preparation of steel substrates before application of paints and

related products - Visual assessment of surface cleanliness Part 3: Preparation grades of welds, edges and other areas with

surface imperfections (ISO 8501-3:2006)

Vorbereitung von Stahloberflchen vor dem Auftragen von

Beschichtungsstoffen - Visuelle Beurteilung der

Oberflchenreinheit - Teil 3: Vorbereitungsgrade von

Schweinhten, Kanten und anderen Flchen mit

Oberflchenunregelmigkeiten (ISO 8501-3:2006)

Prparation des subjectiles d'acier avant application de

peintures et de produits assimils - valuation visuelle de

la propret d'un subjectile - Partie 3: Degrs de prparation

des soudures, artes et autres zones prsentant des

imperfections (ISO 8501-3:2006)

This European Standard was approved by CEN on 11 July 2007.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the

official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,

Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

--`,,```,,,,````-`-`,,`,,`,`,,`---

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the CEN Management Centre or to any CEN member.

//^:^^#^~^^""~:@":^*^~$~"#:*~"*:~:*~@"~~*^~:^"$:#:^:"\\

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMIT EUROPEN DE NORMALISATION

EUROPISCHES KOMITEE FR NORMUNG

Management Centre: rue de Stassart, 36

2007 CEN

All rights of exploitation in any form and by any means reserved

worldwide for CEN national Members.

Copyright Deutsches Institut Fur Normung E.V.

Provided by IHS under license with DIN

No reproduction or networking permitted without license from IHS

Not for Resale

B-1050 Brussels

Ref. No. EN ISO 8501-3:2007: E

EN ISO 8501-3:2007 (E)

Foreword

The text of ISO 8501-3:2006 has been prepared by Technical Committee ISO/TC 35 "Paints and

varnishes of the International Organization for Standardization (ISO) and has been taken over

as EN ISO 8501-3:2007 by Technical Committee CEN/TC 139 "Paints and varnishes", the

secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of

an identical text or by endorsement, at the latest by January 2008, and conflicting national

standards shall be withdrawn at the latest by January 2008.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of

the following countries are bound to implement this European Standard: Austria, Belgium,

Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece,

Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United

Kingdom.

--`,,```,,,,````-`-`,,`,,`,`,,`---

Endorsement notice

The text of ISO 8501-3:2006 has been approved by CEN as EN ISO 8501-3:2007 without any

modifications.

Copyright Deutsches Institut Fur Normung E.V.

Provided by IHS under license with DIN

No reproduction or networking permitted without license from IHS

Not for Resale

//^:^^#^~^^""~:@":^*^~$~"#:*~"*:~:*~@"~~*^~:^"$:#:^:"\\

EN ISO 8501-3:2007 (E)

Introduction

The performance of protective coatings of paint and related products applied to steel is significantly affected

by the state of the steel surface immediately prior to painting. The principal factors that are known to influence

this performance are:

a)

the presence of rust and mill scale;

b)

the presence of surface contaminants, including salts, dust, oils and greases;

c)

the surface profile.

International Standards ISO 8501, ISO 8502 and ISO 8503 have been prepared to provide methods of

assessing these factors, while ISO 8504 provides guidance on the preparation methods that are available for

cleaning steel substrates, indicating the capabilities of each in attaining specified levels of cleanliness.

compatible and appropriate both for the environmental conditions to which the steel will be exposed and

for the protective coating system to be used;

within the capability of the cleaning procedure specified.

The four International Standards referred to above deal with the following aspects of preparation of steel

substrates:

ISO 8501

Visual assessment of surface cleanliness;

ISO 8502

Tests for the assessment of surface cleanliness;

ISO 8503

Surface roughness characteristics of blast-cleaned steel substrates;

ISO 8504

Surface preparation methods.

Each of these International Standards is in turn divided into separate parts.

Imperfections at welds, edges and other areas of steel substrates are generally starting points for corrosion.

Such areas are also difficult to protect by application of paints and related products. To assist in achieving

efficient corrosion protection, this part of ISO 8501 defines certain imperfections and preparation grades for

such areas.

Copyright Deutsches Institut Fur Normung E.V.

Provided by IHS under license with DIN

No reproduction or networking permitted without license from IHS

3

Not for Resale

//^:^^#^~^^""~:@":^*^~$~"#:*~"*:~:*~@"~~*^~:^"$:#:^:"\\

--`,,```,,,,````-`-`,,`,,`,`,,`---

These International Standards do not contain recommendations for the protective coating system to be

applied to the steel surface. Neither do they contain recommendations for the surface quality requirements for

specific situations even though surface quality can have a direct influence on the choice of protective coating

to be applied and on its performance. Such recommendations are given in other documents such as national

standards and codes of practice. Users of these International Standards should ensure the qualities specified

are:

EN ISO 8501-3:2007 (E)

Scope

This part of ISO 8501 describes preparation grades of welds, edges and other areas, on steel surfaces with

imperfections. Such imperfections can become visible before and/or after an abrasive blast-cleaning process.

The preparation grades given in this part of ISO 8501 are to make steel surfaces with imperfections, including

welded and fabricated surfaces, suitable for the application of paints and related products.

Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 12944-2, Paints and varnishes Corrosion protection of steel structures by protective paint systems

Part 2: Classification of environments

ISO 12944-3, Paints and varnishes Corrosion protection of steel structures by protective paint systems

Part 3: Design considerations

Types of imperfection

This part of ISO 8501 deals with imperfections on:

welds;

edges;

steel surfaces generally.

The various types of imperfection are illustrated and described in Table 1.

--`,,```,,,,````-`-`,,`,,`,`,,`---

4

Copyright Deutsches Institut Fur Normung E.V.

Provided by IHS under license with DIN

No reproduction or networking permitted without license from IHS

Not for Resale

//^:^^#^~^^""~:@":^*^~$~"#:*~"*:~:*~@"~~*^~:^"$:#:^:"\\

EN ISO 8501-3:2007 (E)

Preparation grades

Three preparation grades for making steel surfaces with visible imperfections suitable for the application of

paints and related products are as follows:

P1 Light preparation: no preparation or only minimum preparation needs to be carried out before

application of paint;

P2 Thorough preparation: most imperfections are remedied;

P3 Very thorough preparation: surface is free of significant visible imperfections.

The significance of visible imperfections should preferably be agreed between all relevant parties, depending

on the specific application.

Requirements for the preparation grades are given in Table 1.

NOTE 1

It is important that the preparation methods used to achieve these preparation grades are not deleterious to

the integrity of the steel surface or welded areas. For example, strong grinding pressure can result in the formation of

heat-affected areas on a steel surface, and removal of defects by grinding can leave sharp edges at the edges of the grind

pattern.

NOTE 2

It is possible that different imperfections on a structure will require different preparation grades. For example,

undercut (Table 1, 1.4) might require P3 preparation while all other imperfections might require P2 preparation. This can,

in particular, be the case when there are requirements for the aesthetic appearance of the finish. In such cases, P3 could

be specified even if there were no apparent corrosivity requirements (see ISO 12944-2).

--`,,```,,,,````-`-`,,`,,`,`,,`---

NOTE 3

A replica, known as NACE standard RP 0178, showing examples of weld imperfections and certain levels of

preparation, can be obtained from NACE International, PO Box 218340, Houston, Texas 77218-8340, USA.

//^:^^#^~^^""~:@":^

Copyright Deutsches Institut Fur Normung E.V.

Provided by IHS under license with DIN

No reproduction or networking permitted without license from IHS

5

Not for Resale

EN ISO 8501-3:2007 (E)

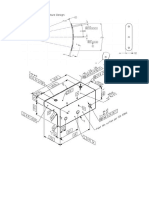

Table 1 Imperfections and preparation grades

Type of imperfection

Description

1

Illustration

Preparation grades

P1

P2

P3

Welds

1.1 Welding spatter

Surface shall be

free of all loose

welding spatter

[see a)]

Surface shall be free Surface shall be

of all loose and lightly free of all welding

spatter

adhering welding

spatter [see a) and b)]

Welding spatter

shown in c) may

remain

No preparation

1.3 Welding slag

Surface shall be Surface shall be free

free from welding from welding slag

slag

Surface shall be

free from welding

slag

1.4 Undercut

No preparation

Surface shall be free

from sharp or deep

undercuts

Surface shall be

free from

undercuts

1.5 Weld porosity

No preparation

Surface pores shall be Surface shall be

sufficiently open to

free from visible

allow penetration of

pores

paint, or dressed out

No preparation

End craters shall be

Surface shall be

free from sharp edges free from visible

end craters

Key

1

visible

invisible (might open after abrasive

blast cleaning)

1.6 End craters

Copyright Deutsches Institut Fur Normung E.V.

Provided by IHS under license with DIN

No reproduction or networking permitted without license from IHS

Not for Resale

--`,,```,,,,````-`-`,,`,,`,`,,`---

//^:^^#^~^^""~:@":^*^~$~"#:*~"*:~:*~@"~~*^~:^"$:#:^:"\\

Surface shall be

dressed (e.g. by

grinding) to remove

irregular and sharpedged profiles

Surface shall be

fully dressed, i.e.

smooth

1.2 Weld

ripple/profile

EN ISO 8501-3:2007 (E)

Table 1 (continued)

Type of imperfection

Description

2

Preparation grades

Illustration

P1

P2

P3

Edges

2.1 Rolled edges

No preparation

No preparation

Edges shall be

rounded with a

radius of not less

than 2 mm

2.2 Edges made

by punching,

shearing, sawing

or drilling

//^:^^#^~^^""~:@":^*^~$~"#:*~"*:~:*~@"~~*^~:^"$:#:^:"\\

(see ISO 12944-3)

Edges shall be

rounded with a

radius of not less

than 2 mm

No part of the

edge shall be

sharp; the edge

shall be free from

fins

No part of the

edge shall be

sharp; the edge

shall be free from

fins

Surface shall be

free of slag and

loose scale

No part of the

Cut face shall be

edge shall have

removed and

an irregular profile edges shall be

rounded with a

radius of not less

than 2 mm

(see ISO 12944-3)

Key

1

punching

shearing

2.3 Thermally

cut edges

(see ISO 12944-3)

3

Surfaces generally

3.1 Pits and

craters

Pits and craters

shall be

sufficiently open

to allow

penetration of

paint

Pits and craters

shall be

sufficiently open

to allow

penetration of

paint

Surface shall be

free of pits and

craters

3.2 Shelling

Surface shall be

free from lifted

material

Surface shall be

free from visible

shelling

Surface shall be

free from visible

shelling

Surface shall be

free from lifted

material

Surface shall be

free from visible

roll-overs/

laminations

Surface shall be

free from visible

roll-overs/

laminations

NOTE

In

English-language

usage, the terms

slivers and

hackles are also

used to describe

this type of

imperfection.

3.3 Roll

overs/roll

laminations/cut

laminations

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright Deutsches Institut Fur Normung E.V.

Provided by IHS under license with DIN

No reproduction or networking permitted without license from IHS

7

Not for Resale

EN ISO 8501-3:2007 (E)

Table 1 (continued)

Type of imperfection

Description

Illustration

Preparation grades

P1

P2

P3

3.4 Rolled-in

extraneous matter

Surface shall be

Surface shall be

Surface shall be

free from rolled-in free from rolled-in free from rolled-in

extraneous matter extraneous matter extraneous matter

3.5 Grooves and

gouges formed by

mechanical action

No preparation

The radius of

grooves and

gouges shall be

not less than

2 mm

3.6 Indentations

and roll marks

No preparation

Indentations and Surface shall be

roll marks shall be free from

smooth

indentations and

roll marks

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright Deutsches Institut Fur Normung E.V.

Provided by IHS under license with DIN

No reproduction or networking permitted without license from IHS

Surface shall be

free from grooves,

and the radius of

gouges shall be

greater than 4 mm

Not for Resale

//^:^^#^~^^""~:@":^*^~$~"#:*~"*:~:*~@"~~*^~:^"$:#:^:"\\

EN ISO 8501-3:2007 (E)

Bibliography

[1]

ISO 8504-3, Preparation of steel substrates before application of paints and related products

Surface preparation methods Part 3: Hand- and power-tool cleaning

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright Deutsches Institut Fur Normung E.V.

Provided by IHS under license with DIN

No reproduction or networking permitted without license from IHS

9

Not for Resale

//^:^^#^~^^""~:@":^*^~$~"#:*~"*:~:*~@"~~*^~:^"$:#:^:"\\

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- MAZDA Tribute - Instrukcja Obslugi (2003) ENGDocumento245 pagineMAZDA Tribute - Instrukcja Obslugi (2003) ENGjszbpNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- BRC Packaging Document KitDocumento8 pagineBRC Packaging Document KitRiky Hadi WibawaNessuna valutazione finora

- ISO - IEC 27001 Standard - Information Security Management SystemsDocumento3 pagineISO - IEC 27001 Standard - Information Security Management SystemsPiiseth KarPearNessuna valutazione finora

- PU SystemsDocumento18 paginePU SystemsVicente CarmonaNessuna valutazione finora

- 7740612Documento164 pagine7740612Halit Yalçınkaya100% (3)

- Functional Gage and Fixture DesignDocumento8 pagineFunctional Gage and Fixture DesignAnonymous 7ZTcBn0% (1)

- SITXHRM006Documento10 pagineSITXHRM006ajay80% (5)

- BS en 12390-6 2000 (En)Documento14 pagineBS en 12390-6 2000 (En)msohaibazizNessuna valutazione finora

- Msds Aluminium FoilDocumento7 pagineMsds Aluminium FoillatifahNessuna valutazione finora

- NAV 04 Calibration and Use of Measuring and Test EquipmentDocumento5 pagineNAV 04 Calibration and Use of Measuring and Test EquipmentaaqipaperNessuna valutazione finora

- BPMN, CMMN and DMN Specifications at OmgDocumento2 pagineBPMN, CMMN and DMN Specifications at OmgRodrigo Ignacio SalinasNessuna valutazione finora

- MAS-38 Submachine Gun (France)Documento4 pagineMAS-38 Submachine Gun (France)blowmeasshole1911Nessuna valutazione finora

- Manual de Utilizare Concasor BB300Documento20 pagineManual de Utilizare Concasor BB300lucianchiritaNessuna valutazione finora

- Gen 7 ICL QSFP For X7 DirectorDocumento2 pagineGen 7 ICL QSFP For X7 DirectorNguyễn Văn GiangNessuna valutazione finora

- Surgelogic NQPanelboards PDFDocumento6 pagineSurgelogic NQPanelboards PDFgramirezsalazar@yahoo.com.mxNessuna valutazione finora

- 1 62F North Wing Electrical Load ScheduleDocumento1 pagina1 62F North Wing Electrical Load ScheduleJoyce RoaNessuna valutazione finora

- NNR 45-150 - NNR 45-150-Crew - ARK0963 - v04Documento4 pagineNNR 45-150 - NNR 45-150-Crew - ARK0963 - v04Harold ReveloNessuna valutazione finora

- AGFA Drystar - 5302Documento222 pagineAGFA Drystar - 5302ClaudiaNessuna valutazione finora

- FM5300 User Manual V2.7Documento105 pagineFM5300 User Manual V2.7Alex CanNessuna valutazione finora

- Controlador Llama Siemens Lga PDFDocumento12 pagineControlador Llama Siemens Lga PDFPaolo CruzNessuna valutazione finora

- EEPROM - m24c64-w PDFDocumento38 pagineEEPROM - m24c64-w PDFLodewyk KleynhansNessuna valutazione finora

- Engineering Management & Ethics Lecture Notes 4. Production & Operations Management (Quality Management) (20.03.17)Documento36 pagineEngineering Management & Ethics Lecture Notes 4. Production & Operations Management (Quality Management) (20.03.17)Afranur ErenNessuna valutazione finora

- 1391939938+megger S1 568 S1 1068 Insulation Resistance MegohmmeterDocumento3 pagine1391939938+megger S1 568 S1 1068 Insulation Resistance MegohmmetervasileNessuna valutazione finora

- KY5 MNTP 3 RNDocumento40 pagineKY5 MNTP 3 RNJuan Carlos Trucios MitmaNessuna valutazione finora

- Realestate Measurement Conversion in Andhra IndiaDocumento1 paginaRealestate Measurement Conversion in Andhra Indiatvjagan100% (3)

- 1sdh000999r0002 Emax1.2Documento108 pagine1sdh000999r0002 Emax1.2AnandNessuna valutazione finora

- The 186 Range of Portable Diesel Air CompressorsDocumento4 pagineThe 186 Range of Portable Diesel Air CompressorsGuptaNessuna valutazione finora

- CC ProjDocumento280 pagineCC ProjsidlaskarNessuna valutazione finora

- 1105 & 06 Samsung MagazineDocumento60 pagine1105 & 06 Samsung Magazinemiksan1975Nessuna valutazione finora

- Installation Guide Hebel Slab Panel 08.20lDocumento18 pagineInstallation Guide Hebel Slab Panel 08.20lmuchlis prayogaNessuna valutazione finora