Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Smart CNC

Caricato da

bngscribdTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Smart CNC

Caricato da

bngscribdCopyright:

Formati disponibili

High-Precision CNC EDM

Lead with the leader

smart cnc

for unlimited machining possibilities

www.ElectronicaEMT.com

Electronica Machine Tools Ltd.

and the EDM Technology have

been synonymous for more than

three decades.

High Speed Jump

High speed jump of 1500 mm/min.

creates a pumping action of dielectric,

resulting in good flushing conditions

always ensuring clean gap conditions.

In fact, Electronica pioneered

indigenous EDMs way back in

1973.

Now, Electronica presents

CNC EDMs with new features,

new applications and new

benefits. With, of course, the

proven economy in operation

and lower cost of ownership.

Our new, proud introduction

SMART CNC - the smart choice

for you to lead all the way.

High speed jump

Built-in GURU

Definable erosion axis

Canned orbiting cycles

Adaptive anti-arc and

flushing control

SAFE machining circuit

Ball screws on X,Y, Z

C axis (optional)

Built-in GURU

General User's

Recommended Utility

Simple 4-step programing

Enter basic information such as

electrode and workpiece material,

machining area, machining depth, and

type of machining ( low wear / optimum /

efficient ).

Select the cavity pattern viz. Single

cavity, Multi-cavity array, PCD,

assorted.

Select START & END machining

set up from the recipe generated by

GURU based on under-sizing of

the electrode and the surface finish

required.

Select orbiting pattern suitable for the

profile.

Adaptive Anti-arc and

Flushing Control

Gap discharges are monitored and

instant pulse-to-pulse corrective actions

are taken.

'Machining difficulty index' signal

is generated, based on which

pulse parameters are suitably

corrected.

Adaptive jump cycle control

based on the concentration

of debris in the machining gap.

Polygon

Circular

Vector

3D Orbital Cycles

3D circular

3D polygon

3D vector

SAFE Machining Circuit

Safe and stable, no-arc machining

Ultra-low

electrode wear even

on sharp corners and edges

resulting in:

l Longer electrode life

l Sharper machining details

High-efficiency rib machining

3D circular

3D taper circular

3D reverse taper circular

3D vector

3D taper vector

3D reverse taper

3D polygon

Advanced 3D Orbital Cycles

Spherical

CNC Applications

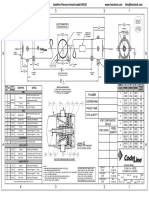

CNC Pulse Generator - S 50 CNC

CNC Controller

32-bit Pentium-based computer

for human-machine interface and

56-bit Digital Signal Processor

(DSP)

Multi-axes precise motion control

Independent programing for X, Y, Z

Background programing

and simulation

Part program edit

Programable multi-cavity operation

Orbiting in XY, XZ, YZ planes

Auto edge find and center find

(internal and external)

Selectable auto shut-off function

Auto power recovery

e

Insid

Programable jump to enhance

machining stability

Automatic frontal wear

compensation cycle (for Z axis)

Mirror image on X or Y axis

Display of electrode path during

machining

Pitch error and

backlash compensation

Menu-driven dialogue box

Built-in EDM technology data

for various materials to set

erosion conditions efficiently

(auto and user definable)

Self-diagnostics

smart cnc

Basic 2D Orbital Cycles

PCD with

3D orbital cycles

Assorted with

3D orbital cycles

Horizontal

machining

Countouring

xyz machining

3D machining

and orbiting

Groove machining

Circular threading

Corner sharpening

Rack machining

Internal threading

External threading

With optional C Axis

Threading

Indexing

Integrated C axis (optional)

is a registered trade mark of Delta Tau Data Systems, USA

High-Precision CNC EDM

Safety and Protections

For CPU, measuring circuit,

Servo overload, over traverse limits

and mains over and under voltage.

Dielectric over-temperature,

low level, overflow and fire detection.

Linear array with

3D orbital cycles

Data Input and Output

Keyboard ASCII

with 10 software keys

Isolated RS 232 C serial interface

1.44 MB, 3.5" floppy disk

LCD monitor

Unlimited machining possibilities

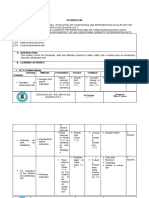

Polygon Cycle Orbiting

Workpiece : Stavax

Electrode : Copper

No. of electrodes : 1

Time : 3 hr. 40 min.

Surface Finish : 0.6 Ra

Good Quality Finish

with Single Electrode

Electrode : Copper

No. of electrodes : 1

Time : 5 hr. 20 min.

Surface Finish : 1.8 Ra

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Units and Symbols For Electrical EngineersDocumento38 pagineUnits and Symbols For Electrical EngineersWally Scharold100% (1)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Essentials For A Good Night'S Sleep: Mattresses, Duvets and PillowsDocumento4 pagineEssentials For A Good Night'S Sleep: Mattresses, Duvets and PillowselizondomaruNessuna valutazione finora

- Units and Conversion FactorsDocumento30 pagineUnits and Conversion FactorsBun YaminNessuna valutazione finora

- Units and Conversion FactorsDocumento30 pagineUnits and Conversion FactorsBun YaminNessuna valutazione finora

- Thief 2 The Metal Age ManualDocumento33 pagineThief 2 The Metal Age ManualMordenGreyNessuna valutazione finora

- SKF Hybrid BearingsDocumento4 pagineSKF Hybrid BearingsLLNessuna valutazione finora

- Tom Bearden - OdtDocumento68 pagineTom Bearden - OdtRoberto FernandesNessuna valutazione finora

- U.K.Singh Manufacturing ProcessesDocumento290 pagineU.K.Singh Manufacturing ProcessesGirish Dey100% (7)

- MagazineDocumento34 pagineMagazineAhmed Khalil100% (1)

- Protec SPD BrochureDocumento4 pagineProtec SPD BrochureCrestNessuna valutazione finora

- MVVNL RGGVY Approved Vendor List: S.NO. Name of Material Vendor Name AddressDocumento10 pagineMVVNL RGGVY Approved Vendor List: S.NO. Name of Material Vendor Name AddressELMEF LaboratoryNessuna valutazione finora

- Supor Operation Manual Dcy2 (1) .781.suporssv1.1b E - 131207Documento163 pagineSupor Operation Manual Dcy2 (1) .781.suporssv1.1b E - 131207Victor Sandoval50% (2)

- MRI Formulas ConversionsDocumento2 pagineMRI Formulas ConversionsarjmandquestNessuna valutazione finora

- 1 Stress Strain SMDocumento48 pagine1 Stress Strain SMappuanandhNessuna valutazione finora

- Codeline 80S30Documento3 pagineCodeline 80S30bngscribdNessuna valutazione finora

- Fundamentals of GD&T With The Background of GD&TDocumento50 pagineFundamentals of GD&T With The Background of GD&TRajasekaran VtNessuna valutazione finora

- ME 101 Engineering Mechanics SyllabusDocumento85 pagineME 101 Engineering Mechanics SyllabuseadaladarenuNessuna valutazione finora

- 1Documento211 pagine1Hari ShankarNessuna valutazione finora

- Wjchtscbrpq9fskyeeht Signature Poli 140918010418 Phpapp01 PDFDocumento50 pagineWjchtscbrpq9fskyeeht Signature Poli 140918010418 Phpapp01 PDFbngscribdNessuna valutazione finora

- Temperature Scales: Celsius, Fahrenheit ConversionDocumento1 paginaTemperature Scales: Celsius, Fahrenheit ConversionbngscribdNessuna valutazione finora

- GDand TDocumento0 pagineGDand TKaliya PerumalNessuna valutazione finora

- Tolerances, Limits, Fits and Surface FinishDocumento6 pagineTolerances, Limits, Fits and Surface FinishRap itttt100% (5)

- Rapid PrototypingDocumento18 pagineRapid PrototypingbngscribdNessuna valutazione finora

- Tolerances, Limits, Fits and Surface FinishDocumento6 pagineTolerances, Limits, Fits and Surface FinishRap itttt100% (5)

- Applications of Reverse Engineering and Rapid Prototyping Technology in Product Design DevelopmentDocumento6 pagineApplications of Reverse Engineering and Rapid Prototyping Technology in Product Design DevelopmentbngscribdNessuna valutazione finora

- Applications of Reverse Engineering and Rapid Prototyping Technology in Product Design DevelopmentDocumento6 pagineApplications of Reverse Engineering and Rapid Prototyping Technology in Product Design DevelopmentbngscribdNessuna valutazione finora

- Engineering PLTW CC 2014Documento50 pagineEngineering PLTW CC 2014bngscribdNessuna valutazione finora

- Geometric ModellingDocumento137 pagineGeometric ModellingintelchinoNessuna valutazione finora

- Applications of Reverse Engineering and Rapid Prototyping Technology in Product Design DevelopmentDocumento6 pagineApplications of Reverse Engineering and Rapid Prototyping Technology in Product Design DevelopmentbngscribdNessuna valutazione finora

- Applications of Reverse Engineering and Rapid Prototyping Technology in Product Design DevelopmentDocumento6 pagineApplications of Reverse Engineering and Rapid Prototyping Technology in Product Design DevelopmentbngscribdNessuna valutazione finora

- Big Data in High Performance Scientific ComputingDocumento10 pagineBig Data in High Performance Scientific ComputingbngscribdNessuna valutazione finora

- 5 Geometric ModelingDocumento38 pagine5 Geometric ModelingsmrajbeNessuna valutazione finora

- 2 Geometric ModellingDocumento22 pagine2 Geometric ModellingSravanthi SallaNessuna valutazione finora

- Radio Amateur's Software GuideDocumento251 pagineRadio Amateur's Software GuideZdenko NagyNessuna valutazione finora

- Tm500 Lte-A 3gpp Lte TestDocumento8 pagineTm500 Lte-A 3gpp Lte TestSmith KumarNessuna valutazione finora

- Suzuki 660 K6aDocumento88 pagineSuzuki 660 K6aJames Wayne BarkerNessuna valutazione finora

- Construction Quality Control Manager in Baltimore MD Resume Mary Kathleen WilsonDocumento3 pagineConstruction Quality Control Manager in Baltimore MD Resume Mary Kathleen WilsonMaryKathleenWilsonNessuna valutazione finora

- Medium Voltage Surge Arresters Catalog HG 31.1 2017 Low Resolution PDFDocumento79 pagineMedium Voltage Surge Arresters Catalog HG 31.1 2017 Low Resolution PDFAnkur_soniNessuna valutazione finora

- Industry 4.0 CourseDocumento49 pagineIndustry 4.0 CourseThiruvengadam CNessuna valutazione finora

- Bernstein ToolsDocumento138 pagineBernstein Toolsjoeblow56100% (1)

- BingDocumento5 pagineBingdheaNessuna valutazione finora

- List of Portmanteau Words: GeneralDocumento7 pagineList of Portmanteau Words: GeneraltarzanNessuna valutazione finora

- Business Functional Areas Functions ProcessesDocumento4 pagineBusiness Functional Areas Functions ProcessesDan MaliwatNessuna valutazione finora

- BPO Management System SoftwareDocumento22 pagineBPO Management System SoftwareSathyaaishuNessuna valutazione finora

- Amu Resume by KKMDocumento2 pagineAmu Resume by KKMapi-457874888Nessuna valutazione finora

- Limestone Problems & Redrilling A WellDocumento4 pagineLimestone Problems & Redrilling A WellGerald SimNessuna valutazione finora

- Session Plan (Julaps)Documento10 pagineSession Plan (Julaps)Wiljhon Espinola JulapongNessuna valutazione finora

- Preliminary Hazard Identification: Session 3Documento19 paginePreliminary Hazard Identification: Session 3Isabela AlvesNessuna valutazione finora

- Netsh Wlan Start HostednetworkDocumento3 pagineNetsh Wlan Start HostednetworkM Nanda KumarNessuna valutazione finora

- The Problem: Best!'Documento4 pagineThe Problem: Best!'HospitilioNessuna valutazione finora

- ActiveReports Allows You To Create Master Detail Reports With Grouping by Using The GroupHeader and Detail Sections To Contain Data From Master Files and Detail FilesDocumento3 pagineActiveReports Allows You To Create Master Detail Reports With Grouping by Using The GroupHeader and Detail Sections To Contain Data From Master Files and Detail FilesRyan AndrNessuna valutazione finora

- Ias Public Administration Mains Test 1 Vision IasDocumento2 pagineIas Public Administration Mains Test 1 Vision IasM Darshan UrsNessuna valutazione finora

- Sample Problems Newton's Laws and Applications PDFDocumento3 pagineSample Problems Newton's Laws and Applications PDFrussell valinoNessuna valutazione finora

- Sony MP3 NWZ B143F ManualDocumento82 pagineSony MP3 NWZ B143F ManualdummihaiNessuna valutazione finora

- Computer Architecture - Wikipedia, The Free EncyclopediaDocumento8 pagineComputer Architecture - Wikipedia, The Free EncyclopediaelcorinoNessuna valutazione finora