Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

High-Reliability Lead-Free Solder Paste: Senju Metal Industry Co., Ltd. Senju Manufacturing (Europe) LTD

Caricato da

zaizamTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

High-Reliability Lead-Free Solder Paste: Senju Metal Industry Co., Ltd. Senju Manufacturing (Europe) LTD

Caricato da

zaizamCopyright:

Formati disponibili

Senju Metal Industry Co.,LTD.

Senju Manufacturing (Europe) Ltd.

Senju Metal Industry Co., Ltd.

Senju Manufacturing (Europe) Ltd.

High-Reliability Lead-Free Solder Paste

M705-GRN360-K-V

Lead-Free solder paste ECOSOLDER M705-GRN360-K V-Type is a further development of

the GRN360 K-series especially designed to meet higher preheat temperatures. This means

users will not only benefit from very stable solder paste viscosity, but will see excellent

wettability, clear flux residue, reduced flux residue cracking and excellent joint cosmetics.

The GRN360-K solder paste series also covers a wide application range due to the

improved thermal properties. This includes high density applications with BGAs, CSPs etc.

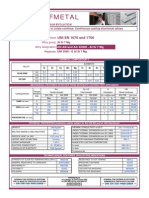

Characteristic of M705 alloy compared to eutectic tin-lead alloy

M705

63Sn-Pb

Alloy Composition(%)

Sn96.5-Ag3.0-Cu0.5

Sn63-Pb37

Specific gravity

7.4

8.4

Melting temperature

Solidus

217

Peak

219

Liquidus

220

183

Tensile strength (Mpa)

53.3

56.0

Elongation(%)

46

59

Youngs module (Gpa)

41.6

26.3

0.2% Yield point (Mpa)

39.4

45.8

Coefficient of linear expansion

(ppm/C)

21.7

23.5

Vickers Hardness (Hv)

17.9

16.6

Manufacturer

European Facility

Senju Metal Industry Co.,Ltd.

Senju Manufacturing (Europe) Ltd.

23 Senju Hashido-cho,

Adachi-Ku, Tokyo, Japan

Phone: +81-33888-5156

Fax: +81-33870-3032

Unit 5, The Gateway Centre, Coronation Road,

Cressex Business Park, High Wycombe,

Bucks HP12 3SU England

Phone:+44 (0) -1494-526000

Fax: +44 (0) -1494-526100

M705-GRN360-K-V

TC-P-40 2.0E Jan.2004

Senju Metal Industry Co.,LTD.

Senju Manufacturing (Europe) Ltd.

M705-GRN360-K V-Type characteristics

Items

M705-GRN360K-V (Type 4)

M705-GRN360-K

MK-V (Type 3)

Test method /Remarks

Solder Powder

Alloy Composition

Sn96.5-Ag3.0-Cu0.5

---

Melting Temperature

217 ~ 220 C

DSC

Powder Shape

Spherical

SEM

Powder size/distribution

25 ~ 36um

25-45 um

SEM & Laser method

FLUX

Type

RO

J-STD-004

Activity

L0

J-STD-004

Halide

0.0%/Flux

Titration method

Surface Insulation

Resistance

(40C90%RH,168hr)

Over 1.0E+12

ISO 9445-1/9454-1

Electro-migration Resistance

(85C85%RH

Bias DC45V, 1000hr)

Over 1.0E+9

No migration

ISO 9445-1/9454-1

Water resistance

750m

ISO 9455

Copper mirror test

PASS

ISO 9455

Fluoride Test

PASS

ISO 9455

Viscosity

K1:180 Pa.s

K2:200 Pa.s

ISO 9445-1/9454-1

Thixotropic Index

0.6

ISO 9455

Flux Content

11.5%

ISO 9445-1/9454-1

Hot Slump

0.4mm Max.

ISO 9445-1/9454-1

Tackiness

1.3N

ISO 9445-1/9454-1

Tackiness Time

Over 24h/1.0N

ISO 9445-1/9454-1

Spreading

77%

ISO 9455

Wetting and dewetting

Rank 1-2

ISO 9445-1/9454-1

Solder balls

Rank 1-2

ISO 9445-1/9454-1

Copper plate corrosion test

PASS

ISO 9455

Validity

(unopened, keep at 0 ~

10C)

6 months

---

Solder Paste

M705-GRN360-K-V

TC-P-40 2.0E Jan.2004

Senju Metal Industry Co.,LTD.

Senju Manufacturing (Europe) Ltd.

Recommended Reflow Temperature Profile M705-GRN360-K-V

Recommended reflow temperature profile for M705-GRN360-K-V is shown below.

During reflow not all temperatures on PCB are the same, there will be a variation due to the different

thermal mass.

However, all soldering points on the PCB showed go into the following recommendation for the thermal

profile.

TEMP ()

Heat resistance of present components

250

Heating rate

2-3

Reflow zone

C

220

200

Soak zone

150

Heating rate

2-4

B

A

100

Reflow oven

SAI-3808 atmosphere

SNR-725 N2

Recommendation

A: soak start:

B: soak end:

A - B: soak time:

M705-GRN360-K-V

TC-P-40 2.0E Jan.2004

150 - 180

170 - 200

90 30sec

C: Peak temp.:

D: time above 220;

(solidus line)

230 - 250

30 - 60sec

Potrebbero piacerti anche

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesDa EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNessuna valutazione finora

- 2017 Kynar Wire and Cable SolutionsDocumento8 pagine2017 Kynar Wire and Cable SolutionsKaarthicNatarajanNessuna valutazione finora

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDa EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsValutazione: 5 su 5 stelle5/5 (1)

- Datasheet-Sanmac-2205-En-V2021-10-07 13 - 03 Version 1Documento10 pagineDatasheet-Sanmac-2205-En-V2021-10-07 13 - 03 Version 1simone.mauriNessuna valutazione finora

- Elgacore DWA 55EDocumento2 pagineElgacore DWA 55Ecfyjdyu_684672809Nessuna valutazione finora

- Alloy 625 Spec SheetDocumento3 pagineAlloy 625 Spec SheetLinnie McleodNessuna valutazione finora

- URB25Documento4 pagineURB25malika_00Nessuna valutazione finora

- DS482Documento3 pagineDS482mariomatoNessuna valutazione finora

- Raffmetal: UNI EN 1676 and 1706Documento2 pagineRaffmetal: UNI EN 1676 and 1706Anshuman RoyNessuna valutazione finora

- Esab DublexDocumento8 pagineEsab DublexSuphi YükselNessuna valutazione finora

- Powder BrochureDocumento20 paginePowder Brochureatfrost4638Nessuna valutazione finora

- Zapp Precision Wire Inc Product CatalogueDocumento49 pagineZapp Precision Wire Inc Product CatalogueAyesha AleemNessuna valutazione finora

- Datasheet-Saf-2205-En-V2021-10-07 13 - 05 Version 1Documento8 pagineDatasheet-Saf-2205-En-V2021-10-07 13 - 05 Version 1simone.mauriNessuna valutazione finora

- Datasheet-Sandvik-254-Smo-En-V2021-04-22 18 - 35 Version 1Documento10 pagineDatasheet-Sandvik-254-Smo-En-V2021-04-22 18 - 35 Version 1darioNessuna valutazione finora

- Hysa9460 enDocumento3 pagineHysa9460 enengpontelliNessuna valutazione finora

- Specialty Materials Hastelloy C-276 ALLOY: Certified To Iso 9001Documento3 pagineSpecialty Materials Hastelloy C-276 ALLOY: Certified To Iso 9001Jarbas MoraesNessuna valutazione finora

- High Temperature Ceramic & Graphite Adhesives: Aremco Products, IncDocumento6 pagineHigh Temperature Ceramic & Graphite Adhesives: Aremco Products, IncHarshaNessuna valutazione finora

- Technical Data Sheet: Stainless Steel: SuperausteniticDocumento5 pagineTechnical Data Sheet: Stainless Steel: SuperausteniticSue EpicNessuna valutazione finora

- Castrol Molub Alloy 860Documento3 pagineCastrol Molub Alloy 860tribolasNessuna valutazione finora

- Shielding Gases ACM Vs CO2Documento34 pagineShielding Gases ACM Vs CO2ukavathekar100% (2)

- 275 287Documento14 pagine275 287Anonymous I7dJ0lmdNessuna valutazione finora

- Böhler Nibas 625 PW-FD: DescriptionDocumento1 paginaBöhler Nibas 625 PW-FD: DescriptionBBalopesabbNessuna valutazione finora

- 904LDocumento5 pagine904LManish542Nessuna valutazione finora

- Material Data Sheet NC 259 Sn100c Solder Paste Rev 1Documento3 pagineMaterial Data Sheet NC 259 Sn100c Solder Paste Rev 1vkmsNessuna valutazione finora

- Alpha SP Range: DescriptionDocumento3 pagineAlpha SP Range: Descriptionvicky kNessuna valutazione finora

- High Temperature Brazing AlloysDocumento0 pagineHigh Temperature Brazing AlloysvkmsNessuna valutazione finora

- Pamphlet (DW 2594)Documento1 paginaPamphlet (DW 2594)Irvansyah RazadinNessuna valutazione finora

- m705 grn360 Kv20series20flyDocumento2 paginem705 grn360 Kv20series20flyKek Siang MingNessuna valutazione finora

- HASTELLOY® C-22HS™alloyDocumento16 pagineHASTELLOY® C-22HS™alloyYudha SatriaNessuna valutazione finora

- Wall Colmonoy Surfacing Alloys Selector ChartDocumento3 pagineWall Colmonoy Surfacing Alloys Selector Chartmp87_ingNessuna valutazione finora

- Gii Turbine Oil 32 46 68 77 100Documento1 paginaGii Turbine Oil 32 46 68 77 100Thaer HamedeNessuna valutazione finora

- Data SAF2205 04Documento8 pagineData SAF2205 04il_yoo_1Nessuna valutazione finora

- 5 - Duplex Stainless Steels and Nickel AlloysDocumento44 pagine5 - Duplex Stainless Steels and Nickel AlloysdennykvgNessuna valutazione finora

- NC257 SN100C: Lead-Free Solder Paste FeaturesDocumento3 pagineNC257 SN100C: Lead-Free Solder Paste Featureshuynh thi y viNessuna valutazione finora

- 20Mncr5: Steel GradeDocumento4 pagine20Mncr5: Steel GradeAhmad ShujaNessuna valutazione finora

- Renolin CLPDocumento3 pagineRenolin CLPDANE80Nessuna valutazione finora

- MIP Bohler Welding Austria 63Documento1 paginaMIP Bohler Welding Austria 63thod3rNessuna valutazione finora

- Datasheet Sandvik Saf 2205 enDocumento15 pagineDatasheet Sandvik Saf 2205 enoctavioNessuna valutazione finora

- Alloy Data Sheet: Heat Resistant Alloy REVISION: 03/91Documento2 pagineAlloy Data Sheet: Heat Resistant Alloy REVISION: 03/91tetirichieNessuna valutazione finora

- Oring - Rubber GuidebookDocumento87 pagineOring - Rubber GuidebookThai KhangNessuna valutazione finora

- UR 65 310S y Su Comportamiento PDFDocumento4 pagineUR 65 310S y Su Comportamiento PDFhugo diazNessuna valutazione finora

- Al en Ab 42000 DatasheetDocumento2 pagineAl en Ab 42000 Datasheetc4pp3ll410_m4tt0Nessuna valutazione finora

- Alloy 276 Spec SheetDocumento3 pagineAlloy 276 Spec SheetermusatNessuna valutazione finora

- Microsoft Power Point - Deloro Stellite Advances in Wear Resistant Alloys and ProductsDocumento56 pagineMicrosoft Power Point - Deloro Stellite Advances in Wear Resistant Alloys and ProductsMilanWaNessuna valutazione finora

- Product Data Energol THB: DescriptionDocumento2 pagineProduct Data Energol THB: Descriptionkarim karimNessuna valutazione finora

- Av Catalogo Completo 2005Documento20 pagineAv Catalogo Completo 2005Marin LaurentiuNessuna valutazione finora

- BP Energrease Ls and Ls-Ep: DescriptionDocumento2 pagineBP Energrease Ls and Ls-Ep: DescriptionbenjaminNessuna valutazione finora

- Mechanical Engineering Design Presentation Bsme01183097Documento30 pagineMechanical Engineering Design Presentation Bsme01183097Waqar KhanNessuna valutazione finora

- Alloy Solution To Marine Fastener ProblemsDocumento10 pagineAlloy Solution To Marine Fastener ProblemsBackia LakshmiNessuna valutazione finora

- Nebula Igo Gear-OilDocumento1 paginaNebula Igo Gear-OilDidi KurniadiNessuna valutazione finora

- Sandvik SAF 2205: Duplex Stainless SteelDocumento8 pagineSandvik SAF 2205: Duplex Stainless SteelIuliu HurducaciNessuna valutazione finora

- Chemical CompositionDocumento6 pagineChemical CompositionAkbar DarmawansyahNessuna valutazione finora

- Unigear s3 Industrial Gear Oil SeriesDocumento2 pagineUnigear s3 Industrial Gear Oil SeriesAnya J PamungkasNessuna valutazione finora

- SAC ALLOY 305 MaterialDocumento2 pagineSAC ALLOY 305 Materialmuki10Nessuna valutazione finora

- Schaeffer # 229Documento3 pagineSchaeffer # 229Ingeniero aicNessuna valutazione finora

- Industeel Tableau Nuances Special Carbon and Low AlloyDocumento1 paginaIndusteel Tableau Nuances Special Carbon and Low AlloyPravin VisputeNessuna valutazione finora

- Solder Paste SC Blf03: Lead-FreeDocumento2 pagineSolder Paste SC Blf03: Lead-FreeluismcmcNessuna valutazione finora

- O Ring BrochureDocumento36 pagineO Ring BrochureJesus N RodriguezNessuna valutazione finora

- E 2209 AcdcDocumento2 pagineE 2209 AcdcLuis Alejandro Gonzalez SantanaNessuna valutazione finora

- Equipment Operating ProcedureDocumento5 pagineEquipment Operating ProcedurezaizamNessuna valutazione finora

- Equipment Operating ProcedureDocumento5 pagineEquipment Operating ProcedurezaizamNessuna valutazione finora

- Technical Description WSMB2015 ElectronicsDocumento49 pagineTechnical Description WSMB2015 ElectronicszaizamNessuna valutazione finora

- Jadual KursusDocumento1 paginaJadual KursuszaizamNessuna valutazione finora

- Manufacturing ProcessDocumento10 pagineManufacturing ProcesszaizamNessuna valutazione finora

- LG 22mp55d-hq Chassis Lm14a PDFDocumento25 pagineLG 22mp55d-hq Chassis Lm14a PDFWilliam Ariel de SouzaNessuna valutazione finora

- GrapheneDocumento22 pagineGrapheneDivyam Paliwal100% (2)

- Velocity Pressure Method Calculation SheetDocumento16 pagineVelocity Pressure Method Calculation SheetMahmud AnshoryNessuna valutazione finora

- TribologyDocumento28 pagineTribologyAmandeep Singh BansalNessuna valutazione finora

- 10 Pbed Reactor PDFDocumento16 pagine10 Pbed Reactor PDFAdrian García MoyanoNessuna valutazione finora

- Dr. Emilie Ringe Reveals Her Academic Achievements and Her Volunteering WorkDocumento1 paginaDr. Emilie Ringe Reveals Her Academic Achievements and Her Volunteering WorkEmilie Ringe Assistant ProfessorNessuna valutazione finora

- PHD Research ProposalDocumento5 paginePHD Research ProposalZeeshan AhmadNessuna valutazione finora

- Oil Tempered WireDocumento20 pagineOil Tempered WireGizem AkelNessuna valutazione finora

- Astm A255Documento26 pagineAstm A255amit gajbhiye100% (1)

- Comparative Process of Depolymerization of Pet: Continuous (Extrusion) and Batch Processes (Haake Mixer)Documento1 paginaComparative Process of Depolymerization of Pet: Continuous (Extrusion) and Batch Processes (Haake Mixer)Semana de Engenharia '2010Nessuna valutazione finora

- Stress: Tensile or Compressive Stress - Normal StressDocumento5 pagineStress: Tensile or Compressive Stress - Normal StressDenny1990100% (1)

- Microencapsulation TechnologyDocumento26 pagineMicroencapsulation TechnologyAnik MazumderNessuna valutazione finora

- Astm D695 23Documento7 pagineAstm D695 23Della MonicaNessuna valutazione finora

- Principles of CombustionDocumento14 paginePrinciples of CombustionJesus Garcia100% (1)

- Atomic Force MicrosDocumento29 pagineAtomic Force MicrosHitesh sharmaNessuna valutazione finora

- Shear Reinforcements in The Reinforced Concrete BeamsDocumento9 pagineShear Reinforcements in The Reinforced Concrete BeamsMD Meftahul AlamNessuna valutazione finora

- Photolithography: Innovative Products For Semiconductor ProcessesDocumento50 paginePhotolithography: Innovative Products For Semiconductor ProcessesGary Ryan DonovanNessuna valutazione finora

- Iec TS 61994-4-4-2005Documento18 pagineIec TS 61994-4-4-2005Francisco Ayancan AyancanNessuna valutazione finora

- Machine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01Documento10 pagineMachine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01The AIRS CreationsNessuna valutazione finora

- Cellulose Acetate AdhesionDocumento23 pagineCellulose Acetate AdhesionblackbutterflyNessuna valutazione finora

- RSPile - Laterally Loaded Pile TheoryDocumento32 pagineRSPile - Laterally Loaded Pile TheoryEmmanuel Garcia CarrascoNessuna valutazione finora

- Workbook Answers p2 Asal PhysicsDocumento4 pagineWorkbook Answers p2 Asal PhysicsSaw Lip Xuan JeffNessuna valutazione finora

- Me414 Lecture 1 Analysis of Simple StressesDocumento19 pagineMe414 Lecture 1 Analysis of Simple StressesILEENVIRUSNessuna valutazione finora

- Risk Assissment 1Documento12 pagineRisk Assissment 1Ibrahim BouzinaNessuna valutazione finora

- Blanking & Piercing (Handout)Documento50 pagineBlanking & Piercing (Handout)banana100% (1)

- HPC-00-06 - RedepositionDocumento5 pagineHPC-00-06 - Redepositionacoim100% (2)

- ASTM D 4014 3 BearingsDocumento7 pagineASTM D 4014 3 Bearingssruthi raniNessuna valutazione finora

- Material Characteristics Chart - of Duroplast and Technopolymer PlasticsDocumento4 pagineMaterial Characteristics Chart - of Duroplast and Technopolymer PlasticsManuel AcuñaNessuna valutazione finora