Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Asa Reinforcement India 2 PDF

Caricato da

Bang JoyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Asa Reinforcement India 2 PDF

Caricato da

Bang JoyCopyright:

Formati disponibili

R EINFORCEMENT S TEEL S OFTWARE

Save money by reducing

reinforcement scrap

Contact us today:

aSa India +91.9870284190 irfan@asaHQ.com

U.S. Headquarters +1.724.733.8700 websales@asaHQ.com

Save money by dramatically

reducing reinforcement

scrap

Make the best use of your

machinery and employees

Eliminate fabrication errors

and mistakes

Create comprehensive,

easy-to-read bar bending

schedules, bundle tags, and

management reports

About aSa. aSa is the worlds leading provider

of software for the reinforcing steel industry. aSa

automates nearly every step of the reinforcing

steel process from estimating and bar

bend schedule creation, to tagging, computer

optimized shearing, and material tracking.

Small and large rebar fabricators, contract rebar

estimators and rebar detailers, engineering firms,

and placing firms all benefit from aSa software

solutions.

Modular, integrated system grows with

your companys needs

Experience weve been developing rebar

software since 1969

Complete solution provider hardware, IT

services, training, and support

Worldwide service office in India to serve

your needs; additional locations in the U.S.,

Australia, Latin America, and the Middle East

Automate all phases of reinforcement fabrication

without wasting time, material, or manpower.

Our core modules

Bar List

B

C

aSas built-in error-checking, advanced editing features, and

automatic engineering calculations make listing material fast

and simple. From a single list of material, you can generate a

wealth of comprehensive, professional documents, including a

comprehensive bar bending schedule.

Tagging

aSa Production creates tags, fabrication reports, and load checkoff lists for each order that you produce. aSa-generated equipment

interfaces automate your machinery with electronic instructions,

nearly eliminating setup time and greatly reducing the chance of

human error.

Computer Shearing

aSa Computer Shearing saves time and material by giving your shop

crew specific instructions for cutting, packaging, and handling each

bundle of steel with maximum efficiency. The program optimizes

your material lists and calculates the most effective cutting

combinations so you can eliminate costly scrap.

We have seen a big difference in our scrap rates since we

implemented aSa. Also, aSa software helps us track and

make better use of our offcuts.

J. Emmanuel Oliver

Detailing Engineer

Steel Fab Tech Limited

United Arab Emirates

List material faster and with greater accuracy

Time-saving features and built-in error-checking help you create mistake-free material lists

faster.

Never enter the same information twice

Previously entered customer and job information is automatically available to Bar List. Bar

List Split, Get Bar List Data, and Save As tools allow you to easily move and copy takeoff

from one list to another.

Eliminate hand-drawn shapes

All industry standard shapes are built into the system, plus you can draw and define your

own custom special bends using aSa Shape Manager. Shape illustrations automatically

display on tags and reports.

Automate all calculations

Quantities, hook lengths, slope dimensions, and radius dimensions are automatically

calculated and filled in for you even for user-defined shapes.

Generate multiple reports from a single source

Enter details once. A multitude of management, fabrication, and placing reports are

generated from a single material list.

Keep office, shop, and field crews informed

Messages and special notations entered in Bar List allow you to communicate effectively via

the bar bend schedule and other aSa-generated reports.

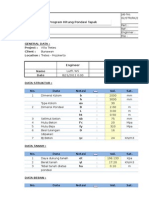

Sample Production Results:

Typical Manual Calculations

Sample Production Results:

aSa Computer Shearing

Produced Material

90%

When shop employees calculate cutting

combinations manually, you can lose 5% or

more of your material on unusable scrap.

Scrap

0.6%

Offcuts

1.1%

Scrap

5%

Offcuts

5%

Produced Material

98.3%

aSa Shearing automatically calculates the

most efficient cutting combinations, so very

little material goes to waste. This savings

provides a huge return on your investment.

Results will vary based on stock lengths, cut lengths, quantities, machinery, job requirements, and other factors.

Achieve total shop management

Easy-to-read schedules, tags, and reports guide your crew through the entire fabrication process,

from shake-out, to cutting, tagging, crane calls, bending, end preparation, material movement, and

trailer loading.

Boost production rates and reduce scrap

Material yield, shop environment, and time are all considered in aSas computer-generated shearing

instructions.

Prevent shortages

aSa creates handy check-off sheets to verify that each required bundle of steel is loaded for

shipment and nothing gets left behind. aSas Material Tracking module can be added to automate

this process even further.

Get more from your machinery

By automating your equipment with aSa-generated instructions, you eliminate the need for an

operator to manually enter details, saving time and reducing the chance of errors. For the ultimate

in productivity, connect to the aSa Opto-Shear Console.

Take the guesswork out of material handling

Based on parameters that you define, the system automatically assigns items to the appropriate

shearline or off-coil machine. Easy-to-apply production options let you override the default

assignment when a machine is down or over-capacity.

aSa Reinforcement Steel Software Modules

B

C

Estimating

Bundle Inventory

Estimate material and labor costs for your

projects.

Track on-hand material and heat

information.

ProRebarTM

Material Tracking

Model concrete and rebar: Building

Information Modeling (BIM).

Record fabrication steps; see employee and

machine productivity rates.

CAD/Detailing

Load Tracking

Create high-quality reinforcement placing

drawings.

Validate bundles as they are loaded onto

trucks for shipment.

Bar List

Delivery Ticket

Quickly list material and generate helpful

reports.

Create professional-quality shipping

documentation.

Scheduling / Planning

Field Placing

Plan fabrication dates, delivery dates, and

trailer loads.

Manage reinforcement placing information

from the estimate to the jobsite.

Production

Rebar Financials

Automate fabrication: Tagging, Computer

Shearing, and Equipment Interfaces.

Automate contract management and

accounting tasks for reinforcement projects.

About aSa software

aSas fully integrated suite of software products automates all aspects of reinforcing steel fabrication. The

system is modular, allowing you to install only the components you need today with the option to expand as

your needs grow. Our products are backed by a large team of trained experts who will help you with all phases

of implementation, training, and support.

Ask us for a free no-obligation quote

We work closely with you to determine the needs of your operation and your project. Well discuss your

options and provide a comprehensive quote right from the start. You can count on competitive pricing with no

surprise extra costs. Youll always know exactly what youre paying for with aSa rebar software.

Contact us today!

World Headquarters

aSa India

5270 Logan Ferry Road

Murrysville, PA 15668 USA

1.800.CALL.ASA

+1.724.733.8700

www.asarebar.com

P.O. Box 8388

Jogeshwari (West)

Mumbai - 400102 India

+91.9870284190

irfan@asaHO.com

aSa Australia

+61.429.227.891

ben.mead@asaHO.com

The Complete Rebar Solution

Copyright 2013. All rights reserved. aSa is a registered trademark and service mark of Applied Systems Associates, Inc. All other names and company names are the property and/or trademarks of their respective owners.

Potrebbero piacerti anche

- CNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingDa EverandCNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingNessuna valutazione finora

- AdamsCar DSDocumento0 pagineAdamsCar DSOvidiu DanielNessuna valutazione finora

- CimatronDocumento20 pagineCimatronsagarbolisettiNessuna valutazione finora

- 2013 Garant Machining HandbookDocumento1.096 pagine2013 Garant Machining HandbookLouis Ting-An Liu86% (14)

- Jupyter Notebooks Advanced TutorialDocumento40 pagineJupyter Notebooks Advanced Tutorialuda100% (1)

- Design of Reinforced Concrete Column FootingDocumento41 pagineDesign of Reinforced Concrete Column FootingBang JoyNessuna valutazione finora

- DBS - V2 HalliburtonDocumento70 pagineDBS - V2 HalliburtonMohamed Khaled Fadl DahabNessuna valutazione finora

- Halliburton - Drill Bits and Services - Catalog PDFDocumento66 pagineHalliburton - Drill Bits and Services - Catalog PDFandrzema100% (6)

- AutoCAD Mechanical 2015 Overview Brochure - A4Documento4 pagineAutoCAD Mechanical 2015 Overview Brochure - A4Raul ReynosoNessuna valutazione finora

- Combined Strap FootingDocumento12 pagineCombined Strap FootingBang Joy100% (1)

- Shop Drawing Prequalification Very ImpDocumento29 pagineShop Drawing Prequalification Very ImpAshish SawantNessuna valutazione finora

- RCC Design Sheets 1Documento437 pagineRCC Design Sheets 1Bang JoyNessuna valutazione finora

- Autocadmechanicaloverviewbrochureus 100324114523 Phpapp02 PDFDocumento4 pagineAutocadmechanicaloverviewbrochureus 100324114523 Phpapp02 PDFSonja ŠtefanacNessuna valutazione finora

- BOX CULVERT Spread SheetDocumento20 pagineBOX CULVERT Spread Sheetdsananda0% (1)

- Introductory CourseDocumento10 pagineIntroductory Coursesantisal11Nessuna valutazione finora

- SAS Catalog 2013 PartsDocumento136 pagineSAS Catalog 2013 PartsAri Ercilio Farias FereirraNessuna valutazione finora

- AWS Overview Part 1Documento34 pagineAWS Overview Part 1Vinu3012Nessuna valutazione finora

- RCC Design SheetsDocumento69 pagineRCC Design SheetsFahim H bepari100% (1)

- RCC Design SheetsDocumento69 pagineRCC Design SheetsFahim H bepari100% (1)

- RCC Design SheetsDocumento69 pagineRCC Design SheetsFahim H bepari100% (1)

- Inventor Pro 2010Documento32 pagineInventor Pro 2010bdi_ro100% (1)

- MySep Software Brochure PDFDocumento7 pagineMySep Software Brochure PDFoverlord5555Nessuna valutazione finora

- Excel Perhitungan AbutmentDocumento15 pagineExcel Perhitungan AbutmentKrismanto MahendraNessuna valutazione finora

- Payroll Element HDL Template Generator - Kaushik - v0 - 1Documento8 paginePayroll Element HDL Template Generator - Kaushik - v0 - 1Sachiin ShiirkeNessuna valutazione finora

- Catia v5 Machining BrochureDocumento4 pagineCatia v5 Machining BrochureMiguel PittaNessuna valutazione finora

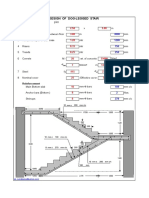

- Dog Legged Stair Case SheetDocumento11 pagineDog Legged Stair Case SheetWaqas AnjumNessuna valutazione finora

- IT in Education, Business, Infrastructure, Food Industry and BankingDocumento38 pagineIT in Education, Business, Infrastructure, Food Industry and BankingShiela Mae SagaNessuna valutazione finora

- Perhitungan Struktur Baja Cinnection BearingDocumento26 paginePerhitungan Struktur Baja Cinnection BearingBang Joy100% (2)

- 118144974-Perhitungan-Pondasi-FullDocumento20 pagine118144974-Perhitungan-Pondasi-FullBang JoyNessuna valutazione finora

- 118144974-Perhitungan-Pondasi-FullDocumento20 pagine118144974-Perhitungan-Pondasi-FullBang JoyNessuna valutazione finora

- Increase Efficiency With The Catia V5-to-VERICUT InterfaceDocumento4 pagineIncrease Efficiency With The Catia V5-to-VERICUT InterfaceTRUNG QUOC LENessuna valutazione finora

- Mold&dieDocumento2 pagineMold&dieTRUNG QUOC LENessuna valutazione finora

- Fast Cam SystemsDocumento4 pagineFast Cam Systemsfarhan_82Nessuna valutazione finora

- Express Alignment - WorldwideDocumento9 pagineExpress Alignment - WorldwideCarlos LaoNessuna valutazione finora

- Folleto X8Product GuideDocumento28 pagineFolleto X8Product Guideespeci@lNessuna valutazione finora

- Stampack: Technology For Cost Reduction, Quality Improvement and Productivity GainsDocumento2 pagineStampack: Technology For Cost Reduction, Quality Improvement and Productivity GainsBG2012Nessuna valutazione finora

- Vericut Brochure 70Documento16 pagineVericut Brochure 70sivakumarsambandamNessuna valutazione finora

- Flyer Sheet MetalDocumento8 pagineFlyer Sheet MetalBG2012Nessuna valutazione finora

- Auto ConDocumento9 pagineAuto ConkiranhujareNessuna valutazione finora

- OEM CostimatorDocumento6 pagineOEM CostimatorSuryakant GideNessuna valutazione finora

- Apparel Software Suite Manages Entire Production ProcessDocumento12 pagineApparel Software Suite Manages Entire Production ProcessartadecorativaNessuna valutazione finora

- Systems & Robotic IntegrationDocumento15 pagineSystems & Robotic IntegrationpressroomautomationNessuna valutazione finora

- Express Alignment: by FixturlaserDocumento16 pagineExpress Alignment: by FixturlaserVishal DesaiNessuna valutazione finora

- NC Programming For Molds, Dies, Plates & Discrete ManufacturingDocumento2 pagineNC Programming For Molds, Dies, Plates & Discrete ManufacturingKhang NguyenNessuna valutazione finora

- Gangam Style 24Documento20 pagineGangam Style 24Light WorkerNessuna valutazione finora

- ShopData Quickduct CAD 2009Documento2 pagineShopData Quickduct CAD 2009Daniel AustinNessuna valutazione finora

- Adams Tracked Vehicle (ATV) SolutionDocumento8 pagineAdams Tracked Vehicle (ATV) SolutionIroshana Thushara KiriwattuduwaNessuna valutazione finora

- Gangam Style 6Documento31 pagineGangam Style 6Light WorkerNessuna valutazione finora

- Fixturlaser Segment Brochure Ship BuildingDocumento4 pagineFixturlaser Segment Brochure Ship BuildingManh PhamNessuna valutazione finora

- NX CAD CAM AutomationDocumento12 pagineNX CAD CAM AutomationfalexgcNessuna valutazione finora

- The Challenge With Reverse Engineering-1 1Documento5 pagineThe Challenge With Reverse Engineering-1 1gfdczxNessuna valutazione finora

- Tanner Manual - HydDocumento65 pagineTanner Manual - Hydkarthikp207Nessuna valutazione finora

- Simufact Welding: Simulations Software For Welding ProcessesDocumento8 pagineSimufact Welding: Simulations Software For Welding ProcessesDarioNessuna valutazione finora

- Factsheet Automated SolutionsDocumento1 paginaFactsheet Automated SolutionsMatthew BrinkmanNessuna valutazione finora

- CATIA PLM Express: CATIA - Lathe & Prismatic MachiningDocumento2 pagineCATIA PLM Express: CATIA - Lathe & Prismatic MachiningjcetmechanicalNessuna valutazione finora

- AM CE: Advanced MachiningDocumento4 pagineAM CE: Advanced MachiningDESIGNER WORLDNessuna valutazione finora

- MetaCAM EnterpriseDocumento8 pagineMetaCAM EnterpriseMetamation IncNessuna valutazione finora

- Software For DiesDocumento4 pagineSoftware For DiesJoselo HRNessuna valutazione finora

- HyperForm SAB CSDocumento2 pagineHyperForm SAB CSElaine JohnsonNessuna valutazione finora

- Pa Drill t78Documento2 paginePa Drill t78Carlos ArenasNessuna valutazione finora

- Adams 2008r1 Doc ReleaseDocumento68 pagineAdams 2008r1 Doc ReleaseVivek_subzeroNessuna valutazione finora

- Reduce Waste & Maximize Utilization with SSODocumento8 pagineReduce Waste & Maximize Utilization with SSONarendra TomarNessuna valutazione finora

- Comcast Smart ResumeDocumento8 pagineComcast Smart Resumewajhnzwhf100% (1)

- RS Consultancy IT automation energy monitoringDocumento4 pagineRS Consultancy IT automation energy monitoringbabai_2007Nessuna valutazione finora

- Simplify Asset Management with AMSDocumento2 pagineSimplify Asset Management with AMSShaham FarrukhNessuna valutazione finora

- Delcam - PowerMILL 2014 R1 Whats New EN - 2013Documento137 pagineDelcam - PowerMILL 2014 R1 Whats New EN - 2013phạm minh hùngNessuna valutazione finora

- Increase Efficiency With The NX-to-VERICUT InterfaceDocumento4 pagineIncrease Efficiency With The NX-to-VERICUT InterfaceTRUNG QUOC LENessuna valutazione finora

- CHX - Theta RodStar SoftwareDocumento2 pagineCHX - Theta RodStar Softwaretomas.a.sierraNessuna valutazione finora

- High Speed DATA-Optimize: The Future of High Speed Machining Has Arrived .Documento4 pagineHigh Speed DATA-Optimize: The Future of High Speed Machining Has Arrived .Poghos PetrosNessuna valutazione finora

- Plant Simulation: Simulation and Optimization of Production Systems and ProcessesDocumento2 paginePlant Simulation: Simulation and Optimization of Production Systems and ProcessesMateo QuispeNessuna valutazione finora

- Analysis Guide For Machine Designers EnglishDocumento9 pagineAnalysis Guide For Machine Designers EnglishNurul HudaNessuna valutazione finora

- IBM IndustryView For Semiconductor Standard (SiView)Documento2 pagineIBM IndustryView For Semiconductor Standard (SiView)Immanuel HenneNessuna valutazione finora

- Camworks 2.5-Axis Milling: For Pocketing, Contouring, and DrillingDocumento2 pagineCamworks 2.5-Axis Milling: For Pocketing, Contouring, and DrillingAxel DominiqueNessuna valutazione finora

- Delcam - PowerMILL 2012R2 Whats New EN - 2012Documento82 pagineDelcam - PowerMILL 2012R2 Whats New EN - 2012phạm minh hùngNessuna valutazione finora

- Mine Planning Solutions: Accurate Mine Plans. On TimeDocumento8 pagineMine Planning Solutions: Accurate Mine Plans. On Timejhon_hendrik01Nessuna valutazione finora

- Impact CAD Brochure - EnglishDocumento6 pagineImpact CAD Brochure - EnglishardensoftwareNessuna valutazione finora

- Application Performance Measurement and Analysis Made Easier and More AutomaticDocumento4 pagineApplication Performance Measurement and Analysis Made Easier and More Automaticscribd-itNessuna valutazione finora

- Material PDFDocumento4 pagineMaterial PDFBang Joy100% (1)

- Perbandingan Harga Satuan Material Distribusi Anggaran Investasi Tahun 2010 - 2015Documento3 paginePerbandingan Harga Satuan Material Distribusi Anggaran Investasi Tahun 2010 - 2015Bang JoyNessuna valutazione finora

- Single Line Diagram-2Documento1 paginaSingle Line Diagram-2asmt25hainamNessuna valutazione finora

- For More Structural Engineering Spreadsheets Go To:: EmailDocumento2 pagineFor More Structural Engineering Spreadsheets Go To:: EmailBang JoyNessuna valutazione finora

- Rivas Filter DesignDocumento6 pagineRivas Filter DesignBang JoyNessuna valutazione finora

- Blue Fields Indicate User Input.: Note: This Is The D50 Stone Used For Rock SizeDocumento5 pagineBlue Fields Indicate User Input.: Note: This Is The D50 Stone Used For Rock SizeBang JoyNessuna valutazione finora

- Steel Structural Design Bolted Welded Connections PDFDocumento52 pagineSteel Structural Design Bolted Welded Connections PDFBang JoyNessuna valutazione finora

- BarBeQueIntroduction PDFDocumento19 pagineBarBeQueIntroduction PDFBang JoyNessuna valutazione finora

- EstimatingDocumento30 pagineEstimatinguud87Nessuna valutazione finora

- Scaner Portable PDFDocumento2 pagineScaner Portable PDFIhwan AsrulNessuna valutazione finora

- Sludge Dewatering Building Working Drawings PDFDocumento11 pagineSludge Dewatering Building Working Drawings PDFBang JoyNessuna valutazione finora

- Retaining WallDocumento15 pagineRetaining WallMarija DojcinovskaNessuna valutazione finora

- Sludge Dewatering Building Working Drawings PDFDocumento11 pagineSludge Dewatering Building Working Drawings PDFBang JoyNessuna valutazione finora

- Canopy SampleDocumento10 pagineCanopy SampleBang JoyNessuna valutazione finora

- Scaner Portable PDFDocumento2 pagineScaner Portable PDFIhwan AsrulNessuna valutazione finora

- 219815782-Footing-Design-AciDocumento6 pagine219815782-Footing-Design-AciBang JoyNessuna valutazione finora

- OPTIMASI PONDASIDocumento95 pagineOPTIMASI PONDASIMiftakhul Tafri MukhtarNessuna valutazione finora

- Assessment Task Notification Year 10 Ist Task 1Documento3 pagineAssessment Task Notification Year 10 Ist Task 1api-205401545100% (1)

- Polling: RUGGEDCOM NMS™ FeaturesDocumento11 paginePolling: RUGGEDCOM NMS™ Featuresraul alcaNessuna valutazione finora

- Automated Mobile Testing with AppiumDocumento68 pagineAutomated Mobile Testing with Appiumvaditya2005Nessuna valutazione finora

- ActiveModels krm10Documento11 pagineActiveModels krm10m_michael_cNessuna valutazione finora

- Suricata User Guide: Release 4.1.0-DevDocumento272 pagineSuricata User Guide: Release 4.1.0-DevDavid Simon Hoyos GonzalezNessuna valutazione finora

- 2nd Unit Test 2018-2019Documento2 pagine2nd Unit Test 2018-2019Puche MaraNessuna valutazione finora

- Pega Csa 7.4 Certification Training PDFDocumento2 paginePega Csa 7.4 Certification Training PDFScott DanielNessuna valutazione finora

- Video System Management Software GuideDocumento129 pagineVideo System Management Software GuideIdrusNessuna valutazione finora

- Term Paper About Microsoft AccessDocumento7 pagineTerm Paper About Microsoft Accessea20cqytNessuna valutazione finora

- SF EC Position Management enDocumento148 pagineSF EC Position Management enKizze SilvaNessuna valutazione finora

- Explore (Ict Concepts)Documento17 pagineExplore (Ict Concepts)rose dela cruzNessuna valutazione finora

- Symbian Platform+OverviewDocumento19 pagineSymbian Platform+OverviewFahad_Mudassar100% (1)

- IVR Dev GuideDocumento60 pagineIVR Dev GuideNaveen Reddy0% (2)

- Aindump2go Javascript-Developer-I Vce 2022-Mar-25 by Lawrence 103q VceDocumento12 pagineAindump2go Javascript-Developer-I Vce 2022-Mar-25 by Lawrence 103q VceJonathan Alejandro ZambranoNessuna valutazione finora

- PR Oracle TraceDocumento4 paginePR Oracle TraceRavi ChandarNessuna valutazione finora

- Making Sense of The Semantic Web: Nova Spivack CEO & Founder Radar NetworksDocumento36 pagineMaking Sense of The Semantic Web: Nova Spivack CEO & Founder Radar NetworksRocelle UriarteNessuna valutazione finora

- Context Driven Merchandising ModuleDocumento25 pagineContext Driven Merchandising ModuleRajib BoseNessuna valutazione finora

- Masm 2Documento16 pagineMasm 2Supraja RamanNessuna valutazione finora

- CourseDocumento12 pagineCourseTrue PracticeNessuna valutazione finora

- Intro To SQADocumento42 pagineIntro To SQAcharu322Nessuna valutazione finora

- Simple Calculator - JavaDocumento12 pagineSimple Calculator - JavaMichelin FernandezNessuna valutazione finora

- Cogging Lab Simulation SetupDocumento12 pagineCogging Lab Simulation SetupK Srinivasa SagarNessuna valutazione finora

- Creating Form Buttons and ActionsDocumento64 pagineCreating Form Buttons and ActionsJason HallNessuna valutazione finora

- Basic Software Modeling: ECE 417/617: Elements of Software Engineering Stan Birchfield Clemson UniversityDocumento29 pagineBasic Software Modeling: ECE 417/617: Elements of Software Engineering Stan Birchfield Clemson Universitydoy0176Nessuna valutazione finora