Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SPE-68864-MS Modern Total Well Management - Sucker Rod Lift Case Study

Caricato da

Osmund MwangupiliTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SPE-68864-MS Modern Total Well Management - Sucker Rod Lift Case Study

Caricato da

Osmund MwangupiliCopyright:

Formati disponibili

SPE 68864

Modern Total Well Management - Sucker Rod Lift Case Study

J. N. McCoy, Echometer Company, A.L. Podio, University of Texas at Austin; Bill Drake, Echometer Company, Lynn

Rowlan, Echometer Company

Copyright 2001, Society of Petroleum Engineers Inc.

This paper was prepared for presentation at the SPE Western Regional Meeting held in

Bakersfield, California, 2630 March 2001.

This paper was selected for presentation by an SPE Program Committee following review of

information contained in an abstract submitted by the author(s). Contents of the paper, as

presented, have not been reviewed by the Society of Petroleum Engineers and are subject to

correction by the author(s). The material, as presented, does not necessarily reflect any

position of the Society of Petroleum Engineers, its officers, or members. Papers presented at

SPE meetings are subject to publication review by Editorial Committees of the Society of

Petroleum Engineers. Electronic reproduction, distribution, or storage of any part of this paper

for commercial purposes without the written consent of the Society of Petroleum Engineers is

prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300

words; illustrations may not be copied. The abstract must contain conspicuous

acknowledgment of where and by whom the paper was presented. Write Librarian, SPE, P.O.

Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

Abstract

Oilfield operators continually need to verify that their wells

are being produced at the optimum capacity and in a cost

effective manner. An integrated analysis of the pumping

system is required to reduce operating costs, increase oil

production and increase net income. The integrated analysis

of the pumping system must include the performance and

interaction of all the elements: the prime mover, surface

equipment, well bore equipment, down hole pump, down hole

gas separator and the reservoir. This integrated analysis

methodology is called Total Well Management, TWM. The

TWM analysis is made based on data obtained at the surface

without entering the well bore and yields an accurate

representation of the conditions existing on the surface, within

the well bore and within the reservoir. A field case study of a

sucker rod lifted well illustrates the procedure and benefits of

the Total Well Management methodology.

Introduction

The need to increase oil production and reduce operating costs

from wells requires an integrated analysis of the pumping

system including the performance and interaction of all the

elements: the surface equipment, the down hole equipment,

the well bore and the reservoir. The analysis is to be based on

data obtained at the surface without entering the well bore and

must yield an accurate representation of conditions that exist

at the surface, within the well bore, at the sand face and within

the reservoir.

Such system analysis can now be undertaken efficiently

using portable notebook computer data acquisition systems in

conjunction with appropriate sensors and a suite of analysis

software. The analysis can be undertaken on sucker rod lifted,

electrical submersible pumped, progressive cavity pumped,

plunger lift, gas lift, flowing and other types of wells to

determine the wells performance so the production rate can

be maximized and the operating expenses minimized.

Field experience undertaking such analysis in numerous

wells has resulted in the development of a methodology: Total

Well Management (or TWM) insures good results are

obtained with the minimum of effort. Operation of artificial

lift wells using the concept of TWM results in a more

complete understanding of the performance of a given well.

Implementation of this concept can result in significant

reductions in operating costs and increased oil production as

shown by results of numerous operators in a variety of

operating conditions.

TWM production optimization

methodology is a broad analysis and optimization concept, and

is applicable to sucker rod lifted wells, electrical submersible

pumped wells, progressive cavity pumped wells, plunger lift

wells, gas lift wells and other types of artificial lift. An

example of a sucker rod lifted field case study illustrates the

procedure and benefits of the Total Well Management

methodology.

Such procedure is greatly facilitated by the use of a fully

integrated portable instrument that includes all the necessary

sensors, precision analog to digital electronics, computer

hardware and software components. The integrated system

allows immediate analysis of the well performance at the well

site. The alternative is to use separate conventional fluid

level, dynamometer and power instruments for data

acquisition and then combine the results of each test using

various application programs. One of the cost-effective

advantages of an integrated analysis system is that the well

data is entered only once into a data file and the integrated

system uses the data to determine well performance.

Well Productivity and Inflow Performance

Most operators desire that wells be produced at or near their

maximum production rate. The maximum production rate

(potential) of a well is obtained when the producing bottom

hole pressure (PBHP) is low compared to the static bottom

hole pressure (SBHP). A well may be producing at 20%, 50%

or 80% of the maximum flow rate depending on the ratio

between the PBHP and the SBHP. If sufficient size equipment

exists on the well, the PBHP should be less than 10% of the

SBHP to insure maximum production. Most producing and

J.N. MCCOY, A. L. PODIO, BILL DRAKE, LYNN ROWLAN

static bottom hole pressures and analyses are obtained from

surface measurements by acoustically measuring the distance

to the liquid level in the well, measuring the casing pressure

and calculating the bottom hole pressure1, 2, 3.

Accurate knowledge of well productivity is lacking in

most oil fields. Very few operators have determined inflow

performance of their wells because static BHP surveys are

seldom undertaken, since few operating companies are willing

to shut-in wells for extended periods of time. Also, liquid

level measurements taken with strip chart acoustic instruments

are seldom converted to a calculated producing BHP. Every

effort should be made to obtain representative values of

producing and static bottom hole pressures that can be used in

determining Productivity Index or Inflow Performance

Relations (IPR). One way to obtain SBHP data is to institute a

policy to routinely make static fluid level measurements any

time that any well in a field is shut-in for any reason (work

over, repair, equipment failure) and to interpret these static

fluid level measurements in terms of static bottom hole

pressures. What is required is at least an estimate within 1015% of the actual stabilized SBHP. Operators should attempt

to periodically determine the static bottom hole pressures

when the wells are down for any reason, and then maintain the

producing bottom hole pressure at less than 10% of the SBHP,

when maximum inflow is desired.

Thus, it should be clear that in order to be able to make a

judgment about how efficiently we are producing a well we

must know BOTH the Static and the Producing bottom hole

pressures and have an accurate and up to date well production

test. If any one parameter is missing or is inaccurate (or

guessed) we may reach the wrong conclusion regarding the

potential of the well. Fig. 1 illustrates that the example well is

producing 99% of the maximum potential based on the 2000psi SBHP and the computed 58-psi PBHP. The PBHP is

obtained from an acoustic fluid level and casing pressure

measurement and then computed taking into account the effect

of annular gaseous liquid column if present. This test

indicates that the well is being produced at the formations

maximum producing efficiency. The operator is doing an

excellent job at maximizing the production from the well.

A well with a fluid level 1000 feet over the pump will

indicate the importance of determining both the producing and

static bottom hole pressures. Many operators may attempt to

correct the problem of an assumed 1000 feet of liquid column

over the pump, which would exert backpressure and restrict

production, by installing a larger pump. What if the 1000 feet

of liquid column over the pump is actually a mixture of

liquid aerated by gas flowing up the casing annulus and

discharging at the surface? The actual producing bottom hole

pressure may be only 150 PSI due to the liquid column being

aerated with gas bubbles flowing upward through the liquid

column. If the static bottom hole pressure is 2000 PSI, the

PBHP of 150 PSI is less than 10% of the SBHP and the

maximum production rate is being obtained. Installing a

larger pump would be a waste of time and money. In other

cases, a well may be produced with considerable liquid over

SPE 68864

the formation or a high casing pressure that does restricts fluid

flow from the reservoir.

Sucker Rod Lifted Wells

The TWM procedure for sucker rod lifted wells involves the

following steps:

1.

2.

3.

4.

5.

6.

7.

8.

Analyze the wells inflow performance to determine

if additional production is available.

Determine the overall efficiency to identify wells

that are candidates for improvement.

Analyze the performance of the pump.

Analyze the performance of the down hole gas

separator.

Analyze mechanical loading of rods and

pumping unit.

Analyze performance of prime mover.

Design modifications to existing system.

Implement changes and verify improvement.

Well Screening by Inflow Performance. All wells should be

tested to insure that the producing bottom hole pressure is low

compared to the static bottom hole pressure. This is the first

and most important step in optimizing a wells performance.

See Fig. 1 for an example of a well that is being operated at its

maximum potential to produce oil.

Well Screening by Energy Efficiency. Many different

parameters can be used to identify those wells that are the

most likely candidates for improvement. Experience has

shown that one method of identifying wells that need

improvement is to determine the overall efficiency of the

wells pumping system. This requires only the measurement

of input power to the prime mover, determination of the

producing bottom hole pressure (PBHP) and accurate

production test data.

Fig. 2 shows the results of a power survey on the case

study well illustrated in Fig. 1 obtained with power probes.

Both instantaneous motor power and motor current are plotted

for one complete pump stroke. The balanced RotaFlex

pumping unit in Fig. 2, shows the motor generates very little

power during the entire stroke and the overall efficiency is a

high 57.9%.

For comparision purposes data from a

counterweight-heavy conventional pumping unit, Fig. 3,

shows the motor generating power over a large portion of the

stroke, plus the overall efficiency is a low 30.4%. The

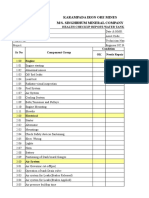

software, using the well data (partially shown in Fig. 4) and

acquired field data, performs a complete motor power and

current analysis. The overall efficiency4 of a sucker rod lifted

system should approximate 50%. In Fig. 3 the wells

performance could be improved, while in Fig. 2 the system is

being operated near peak efficiency.

The operating cost is calculated on the basis of a barrel of

fluid pumped and a stock tank barrel of oil produced. These

values are calculated from the production rates that were

SPE 68864

MODERN TOTAL WELL MANAGEMENT - SUCKER ROD LIFT CASE STUDY

entered in the well data file and based on the most recent well

test.

of the pumping units geometry, counterbalance effect or

counterbalance moment.

Pump Performance. Using an integrated data acquisition

system, motor power and dynamometer data can be obtained

simultaneously. The dynamometer measurement can be made

with a polished rod transducer (PRT) that is installed by a

single technician in a matter of minutes. Or the dynamometer

measurement can be made with a horseshoe loadcell

transducer (HT) installed between the pumping unit carrier bar

and the permanent polished rod clamp. Analysis of the down

hole pump operation is undertaken by calculation of the pump

dynamometer card from surface acquired load and position

data. Surface dynamometer and pump cards are immediately

available in the field so that a diagnosis can be made to

determine whether a pulling job needs to be scheduled. Fig. 5

shows that incomplete pump fillage is the main cause of this

wells inefficiency. The shape of the pump dynamometer card

gives a strong indication that gas interference due to an

inefficient down hole gas separator is the primary reason for

the problem. A down hole dynamometer card indicating

incomplete pump fillage coupled with an acoustic liquid level

test, Fig. 6, showing the presence of a gaseous liquid column

above the pump is conclusive evidence that an inefficient

separation of gas is occuring at the pump intake. Reference 5

gives detailed information on efficient down hole gas

separators.

Correct operation of the pump valves is mandatory to

achieve high efficiency. Although standing and traveling

valve tests are routinely made, proper interpretation depends

on the requirement that the tests are performed correctly. For

this reason, a series of valve measurements should be

performed in order to insure their reproducibility and validity.

Fig. 7 shows a series of three traveling valve tests followed by

two standing valve tests. These tests show that they are

reproducible (thus valid and well executed) and that the

measured values agree with the theoretical values (thus the rod

and pump data is correct and there is little rod-tubing friction)

and therefore we can conclude that the valves are operating

properly.

Performance of the prime mover. The primary objective of

acquiring power data is to determine the efficiency with which

the pumping unit is being operated from both standpoints of

energy utilization and of mechanical loading. In particular the

following can be studied:

How does the measured power usage compare to the

power billed?

Is the pumping unit operating at an acceptable electrical

efficiency (50% or more)?

Does changing the direction of rotation reduce power

cost or improve pumping unit balance?

Does excessive pumping off (pump pounding fluid)

cause inefficiency?

Is the motor the correct size for the unit? Or, is the

motor over or undersized?

What techniques are available for minimizing the

overall power consumption of a lease?

Experience has shown that the general tendency is to oversize

electrical motors installed on sucker rod lifted systems. The

reasoning varies but in general it can be said that most

operators are more concerned with providing abundant starting

torque than with the efficiency of the prime mover. In general,

if a motor is twice or more oversized for a given pumping

system it should be replaced with an appropriate size motor.

This will reduce the operating cost by reducing the

consumption, the electrical demand charge and the line losses.

See Reference 4 for additional information on power analysis.

Mechanical Loading of Rods, Gear Reducer and Pumping

Unit. It is important to maintain the loading of the rods within

the recommended guidelines for the well's service factors and

the corresponding rod's characteristics. The consistent overlay

of several dynamometer cards, Fig. 8, indicates the well is

pumping under steady state conditions and the measured loads

are within the allowable loads for the surface unit. In Fig. 8

the rod string loading is displayed in relation to the allowable

loads determined from the modified Goodman diagram and

the stresses at each rod diameter change. Proper loading of

the pumping unit and the gear reducer is equally important.

An under-loaded unit operates at low mechanical efficiency.

An overloaded unit requires excessive maintenance. Gearbox

torque loading is established more efficiently from an

instantaneous motor power survey rather than from

dynamometer measurements and does not require knowledge

Gearbox Balancing. An additional objective of power

measurement is the determination of the torque at the gearbox6

from direct conversion of the motor power to torque as shown

in Fig. 9. The downstroke torque peak exceeds the upstroke

peak indicating that the unit is overbalanced. This is partly

due to the fact that the pump is not full, Fig. 5. If the unit

operates continuously and this is the normal steady state mode

of operation, a significant reduction of peak torque could be

gained balancing the unit by moving the 5000-pound

counterweights inwards for a distance of 16 inches as shown

in Fig. 9. One advantage of this method of balancing based on

power measurement is that it does not require knowledge of

the geometry of the pumping unit nor the measurement of the

counterbalance effect at the polished rod nor calculation of the

counterweight moment.

Design Modifications to Existing System. The objective of

the TWM study is either to modify the pumping system to

reduce overloading of some production equipment (such as

torque or rod stress) or to modify the system to better match

its pumping capacity to the productivity of the well. In most

cases, the final criterion for selecting among various operating

modes will be the overall system efficiency.

Predictive programs for design of sucker rod lifted systems

based on wave equation modeling vary in complexity and

J.N. MCCOY, A. L. PODIO, BILL DRAKE, LYNN ROWLAN

flexibility. The best software should interface seamlessly with

the data acquisition software and should provide the necessary

design and analysis capability. Regardless of the model that is

used, the first step is to replicate with the predictive program,

the surface dynamometer that was measured on the well. A

reasonable match will indicate that the predictive model is

sufficiently complex and accurate to include the majority of

the parameters that influence the mechanical performance of

the system. The criteria for a match should include the

polished rod loads, power, plunger travel, and pump

displacement. Since the predictive software generates a

surface dynamometer card and the software is capable of

importing the measured dynamometer data, then the shape of

the predicted card should be matched to the measured card as

close as possible, in addition to matching the load levels. Fig.

10 shows a good match of the measured and computed

dynamometer cards. The matching procedure is generally by

trial and error. A good match gives confidence that the

predictive software can be used to investigate changes in the

operation and equipment that will result in improved

performance.

Generally the type of problem indicated by the measured

performance will give an indication of which parameters

should be varied. The starting point should always be those

parameters that can be changed with a minimum of

expenditure. For example if rod loads are excessive, then

direction of rotation, pumping speed and stroke length should

be varied in this order. If this does not produce the desired

reduction, then the rod string configuration and pump plunger

should be varied, and so on.

The cost effectiveness of the changes that would be

required in order to improve the efficiency of the system needs

to be evaluated. In this analysis, both increase in income and

reduction in expenses must be included. It has been observed

that reduction in power consumption on a lease-wide basis is

often accompanied by reduced overall power demand. This

may be translated into lower demand costs as well as possible

basis for rate negotiation with the Utility Company.

Implementation and Verification of Optimized Design. Is

perhaps the most important step in the process and is often

neglected. Adequate internal communications helps insure

and verify that the optimized design is implemented without

arbitrary modification.

Poor communication between

operating and design personnel is a problem that must be

resolved. Similarly feedback on the result of the changes must

be obtained, recorded in the appropriate database, and

analyzed by the operating and design personnel.

Pressure Transient Measurements in Pumping Wells.

Frequently the well's productivity is impaired by formation

damage in the vicinity of the well bore. A pressure transient

test gives the skin (or well bore damage) and the static

reservoir pressure along with other formation parameters.

The presence of the rods in a pumping well precludes using

SPE 68864

wire line-conveyed pressure recorders and thus pressure

transient tests are seldom undertaken.

This deficiency has been eliminated with the development

of systems for automatic measurement of casing head pressure

and annular fluid level that yields the data necessary to

analyze pressure buildup or draw down tests in pumping

wells7. This is done with a minimum of expenditure since it

does not require pulling the rods or tubing to install a down

hole pressure sensor or run a wire line pressure recorder.

The automatic pressure buildup system is programmed to

generate an acoustic pulse at periodic intervals (such as 30

shots per log cycle), record the casing pressure, determine the

fluid level and calculate the bottom hole pressure for as long

as it is necessary to obtain a representative pressure response.

Fig. 11 shows a plot of the Horner plot obtained in this

manner. The ability to analyze the data during the test gives

the user confidence that the test has run a sufficient length of

time to yield the desired data and thus limit the shut-in period

to a minimum. The data can be exported for analysis in other

programs if desired.

Technician Time Requirement. A production technician can

undertake the complete TWM survey including acquisition

and field processing of the acoustic, dynamometer and motor

power data in about 45 minutes per well. The same

measurements are then used to define the wells productivity,

the down hole pump performance, the down hole gas separator

performance, the rod and pumping unit loading and the motor

performance. The wells production rate can be maximized

and the operating costs minimized with this 45-minute well

analysis.

While at the well as the collected data is analyzed, the goal

for the production technician should be to answer the WELL

PERFORMANCE QUESTIONS listed in Table 1.

Recommendations to fix any problems discovered in the

analysis of the collected data should be typed as notes in the

comments text box. These notes recording the work necessary

to fix a problem are called the production technicians work

plan and the notes are called recommendations. When the

recommended changes to the well are completed, new data

should be collected in a few weeks once the well is operating

under stabilized conditions. The production technician should

re-read the recommendations from the previous analysis of the

wells data and notice if the well performance has changes as

planned. The analysis step to evaluate the recommended

changes is called the follow-up step of the analysis.

Following-up on recommendations is how production

technicians learn from their successes and failures; and their

role changes from a data collector to a knowledgeable well

analyst and problem solver.

Sucker Rod Lift Case Study

The Mallet Land & Cattle Co. well No. 50 is the RotaFlexequipped well tested. Chevron USA Inc operates the well.

Following is a description of the configuration of the

equipment installed on the well: The RotaFlex pumping unit,

Fig. 12, is a model 1100 with a 306-inch stroke. The API

SPE 68864

MODERN TOTAL WELL MANAGEMENT - SUCKER ROD LIFT CASE STUDY

designation is R-320-500-306. A 75 horsepower Nema D

motor, Corods and a long stroke pump are utilized. The 2 inch

pump is set below the formation, and the gas/liquid separation

capacity5 of the 2-7/8 tubing on the inside of 5-1/2 casing

exceeds the pump capacity of this high volume pump so that

gas interference in the pump is not a problem.

A complete well analysis was performed to fully evaluate

the wells performance8. An acoustic liquid level test is

shown in Fig. 13. The upward kicks occurring at 16 to 16.5

seconds on the acoustic trace identifies the depth of the casing

perforations (7669-8049 Feet). A downward kick on the

acoustic chart at 16.514 seconds indicates that the fluid level is

below the casing perforations. Liquid is flowing from the

casing perforations into the wellbore and falling to the pump

intake. The low (36.8 PSI) casing pressure and the low (57.7

PSI) PBHP cause negligible resistance to the fluid flow from

the high pressure (2000 PSI) formation into the wellbore. The

maximum liquid inflow into the wellbore is obtained. The

casing annulus gas flow rate is approximately 13 MCF per

day. Two vibration anomalies are shown on the acoustic

trace. One vibration anomaly is at 5.309 seconds, and the

second vibration anomaly is at 14.394 seconds.

The

anomalies (or vibrations) occur when the pumping unit

reverses direction at the top and bottom of each stroke. These

reversals vibrate the gas gun microphone and were noted when

viewing the acoustic trace before the gas gun generated the

acoustic pulse to determine liquid level depth. The pumping

unit is running at 3.3 SPM, so these vibrations are about 9.09

seconds apart (60 SEC / 3.3 SPM / 2).

The dynamometer surface cards, pump card, traveling

valve test and rod loadings are shown in Fig. 8. Since the

velocity of the polished rod on the upstroke and downstroke

are relatively constant, the surface card tends to exhibit a

rectangular shape. The pump card shows that the pump is

being filled with liquid.

The 2 pump and 2-7/8 seating nipple are set 52 feet

below the bottom of the casing perforations.

The

configuration forms a natural gas separator; allowing the free

gas from the formation to separate from the liquid and flow up

the casing annulus, while the liquid that flows downward and

enters the pump. The gas/liquid separation capacity8 of the 27/8 tubing on the inside of 5-1/2 casing is approximately

635 B/D which exceeds the pump capacity of 423 B/D. Gas

interference is not a problem even in this relatively highvolume, rod-pumped well. This gas separation technique of

setting the seating nipple below the producing interval results

in efficient separation of free gas from liquid and improves

pump efficiency when the gas/liquid separation capacity8 of

the tubing/casing combination exceeds the pump capacity.

A traveling valve test indicated that the pump leakage was

approximately 4 BPD. The standing valve did not leak and

the pump is operating properly.

Corods were installed in the well after problems occurred

with the use of conventional rods. The Corods have not failed

and are operating efficiently. The top Corod is 86% loaded at

a service factor of 0.85.

The power measurements shown in Fig. 14 were obtained

at the same time the dynamometer data was acquired. A 75

horsepower NEMA D motor is utilized as the prime mover. A

50 horsepower motor would operate this system, but the

additional horsepower may be desired during certain well

conditions. The overall system efficiency is 56.6%. That is,

the amount of power required to raise the liquid produced by

the well from the net liquid level depth is 56.6% of the power

supplied to the motor9. This is an efficient pumping system.

The torque analysis appears in the lower portion on the

same Fig. 15. The power or torque required on the upstroke is

less than the power or torque required on the downstroke.

Power can be converted to torque, Fig. 14 and Fig. 15, as

calculated from the instantaneous motor power measured

during one complete pump stroke using the following

equation:

Torque = 84.5 x Power x EFF / (SPM x CR x SV) ...(1)

The measured upstroke peak torque was 119,100 inchpounds, and the measured downstroke peak torque was

202,800 inch-pounds. Approximately 2,500 lbs. of the

auxiliary weights in the counterweight box should be removed

to reduce the counterbalance torque by 41,900 inch-pounds.

The software calculates all these numbers from the measured

power data and well file database.

The process of balancing the torque was undertaken in

stages over a one-hour period as shown in Table 2. Initially,

the unit was counterweight box heavy and more power and

torque were required raising the weight box than the rods.

The torque was more closely balanced after 782 lbs. of

weights were removed from the weight box. After another

1,058 lbs. of weights were removed from the weight box, the

pumping system was even more closely balanced. The second

and third dynamometer and power tests are not shown due to

space limitations, but are available upon request. Finally,

approximately 2760 lbs. of auxiliary weights were removed.

The resulting power and torque data is shown in Fig. 14. The

units upstroke and downstroke torques are balanced after

removal of the excess auxiliary weights and peak gearbox

torque is reduced from 202,800 inch-lbs. to 150,000 inch-lbs.

Fig. 14 also shows the power and torque usage after the

system was balanced. The average power consumption was

decreased from 27.5 KW to 27 KW. The overall system

efficiency increased from 56.6 to 57.5%, which is relatively

efficient.

This technique of balancing the unit is based on making

the peak torque on the upstroke equal the peak torque on the

downstroke. The motor will be more efficient if the average

power on the upstroke is balanced against the average power

on the downstroke so that the motor will be operating overall

at a higher efficiency. Motors operate more efficiently near

rated output. The operator has the option of balancing the

peak torques on the upstroke and downstroke, or balancing the

average power usage on the upstroke and the downstroke.

More efficient electrical operations will be obtained if average

power is balanced rather than peak torques. However, the

J.N. MCCOY, A. L. PODIO, BILL DRAKE, LYNN ROWLAN

peak torques on the upstroke and downstroke should be

balanced if the gearbox torque rating would be exceeded if

balancing by power usage.

The RotaFlex pumping system can also be balanced by

using the mechanical loadings of the system rather than the

electrical loadings on the motor. To balance the gearbox peak

torque loadings by mechanical means, the polished rod loads,

the polished rod positions, and the counterbalance weight of

the weight box and auxiliary weights must be known. In order

to determine the weight of the weight box plus auxiliary

weights, the counterbalance effect can be measured. On a

RotaFlex, the geometry of the polished rod load and the

counterweight box is symmetrical, and the load measured by

the horseshoe transducer is equal to the load in the belt that is

attached to the counterweight box. If the pumping unit is

stopped near the middle of the upstroke, the weight of the rods

plus the fluid load will exceed the weight of the counterweight

box plus auxiliary weights if the system is approximately

balanced during normal operation. If the brake is held until

some of the fluid load bleeds from the polished rod, the load

on the polished rod will decrease. The brake can be

momentarily released and reset, until a balanced condition

occurs when the load on the polished rod is equal to the

weight of the counterweight box. At this balanced condition,

the belt will not move because the loads are equal. This

weight can be measured accurately using the horseshoe load

cell transducer. If the brake is held longer, the load on the

polished rod will continue to bleed off and the counterweight

box and auxiliary weights will weigh more than the polished

rod. Fig. 16 shows the polished rod load while the system

was pumping and then stopped on the upstroke with the brake

set. Periodically releasing then resetting the brake showed that

at 46 seconds after data acquisition began, the belt did not

move when the brake was released. The load at 46 seconds

was 25,132 lbs. This polished rod load is equal to the weight

of the counterweight box plus auxiliary weights. After the

balanced condition was noted, the brake was reset, and the

dynamometer test shows a further decline in the polished rod

load.

The surface dynamometer cards and the pump cards after

the unit is balanced are shown in Fig. 17. The polished

rod/motor efficiency increased slightly since the motor is

operating in a more efficient range during the upstroke. The

polished rod horsepower, the polished rod peak loadings, and

the polished rod minimum loadings remained similar as

expected. Notice that 90% of the polished rod power of 29.4

HP is transferred to the pump power of 26.4 HP. The high

efficiency is probably due to the Corods having less metal-tometal sliding friction and the Corods having less resistance to

fluid flow from the pump to the surface up the tubing. A

summary of measured values is presented in Table 3.

all the liquids from the well bore. Removing approximately

2760 lbs. from the counterweight heavy box reduced excessive

power usage and gearbox load. After the unit was balanced,

the maximum gearbox load was reduced from 202,800 inchpounds to 150,000 inch-pounds, and the average power

requirement was reduced from 27.5 KW to 27 KW. The

relatively good system efficiency, when balanced, was 57.5%.

The cost of electricity was reduced approximately $14 per

month.

Summary and Conclusions

Table 1 lists a series of WELL PERFORMANCE

QUESTIONS that an operator must be able to answer to

efficiently produce a well. Oftentimes, an operator does not

know the answers to some of these questions, and hence, must

guess at the answer. An operator should know that the PBHP

is low compared to the SBHP so that the maximum production

is being obtained. An operator should know that the pump

traveling and standing valves are OK. An operator should

know whether the down hole gas separator is efficient or not,

and how to correct an inefficient gas separator problem. An

operator should know whether a pumping unit is out of

balance or not. An operator should know whether the rods are

overloaded or not. Analyzing a wells performance so that the

WELL PERFORMANCE QUESTIONS are answered allows

an operator to maximize oil production and minimize

operating costs.

Successful application of the TWM concept generally

includes some training of the operating personnel. Training is

especially necessary if effective application of modern data

acquisition hardware and software is to be introduced in an

operation that has been relying on limited computer resources.

Acknowledgments

The authors thank David Jennings from Chevron USA Inc for

the help provided in making the field measurements and

compiling all of the necessary data on the number 50 well on

the Mallet Land & Cattle Company lease.

Nomenclature

CR = pumping speed to gearbox sprocket rotational

speed ratio (chain ratio)

EFF = Motor to gearbox output shaft efficiency

Power = Instantaneous Input Motor Power (KW)

SPM = pumping speed, strokes per minute

SV = Speed Variation, minimum speed / average speed

References

1.

Analysis

After balancing, the RotaFlex system is producing all of the

liquid available efficiently from the well. The RotaFlex unit is

operated using a P-O-C that pumps the well approximately

19.7 hours per day, which is all of the time required to remove

SPE 68864

2.

McCoy, J.N., Podio, A.L. and Huddleston, K.L.: Analyzing

Well Performance XV, presented at the 1987 Artificial Lift

Workshop, Houston, TX, Apr. 22-24.

McCoy, J.N., Podio, A.L. and Huddleston, K.L.: Acoustic

Determination of Producing Bottomhole Pressure, paper SPE

SPE 68864

3.

4.

5.

6.

MODERN TOTAL WELL MANAGEMENT - SUCKER ROD LIFT CASE STUDY

14254 presented at the 1985 SPE Annual Technical Conference

and Exhibition, Las Vegas, NV, Sept. 22-25.

McCoy, J.N., Podio, A.L., Huddleston, K.L. and Drake, B.:

Acoustic Static Bottomhole Pressure, paper SPE 13810

presented at the SPE 1985 Production Operations Symposium,

Oklahoma City, OK, Mar. 10-12.

McCoy, J.N., Podio, A.L., Ott, R. and Woods, M.: Electrical

Motor Power Measurement as the Key for Optimized Rod

Pumping, paper SPE 36080 presented at the Fourth Latin

American and Caribbean Petroleum Engineering Conference,

Port-of-Spain, Trinidad & Tobago, Apr. 23-26, 1996.

McCoy, J.N. and Podio, A.L.: Improved Downhole Gas

Separators, presented at the Southwestern Petroleum Short

Course, Lubbock, TX, Apr. 7-8, 1998.

McCoy, J.N., Ott, R.E., Podio, A.L., Collier, F. and Becker, D.:

Beam Pump Balancing Based on Motor Power Utilization,

7.

8.

9.

paper SPE 29533 presented at the SPE 1995 Production

Operations Symposium, Oklahoma City, OK, Apr. 2-4.

McCoy, J.N., Podio, A.L. and Becker, D.: Pressure Transient

Digital Data Acquisition and Analysis From Acoustic

Echometer Surveys in Pumping Wells, paper SPE 23980

presented at the 1992 SPE Permian Basin Oil and Gas Recovery

Conference, Midland, TX, Mar. 18-20.

Podio, A.L., J.N. McCoy, B. Drake and D. Becker: "Total Well

Management-A Methodology for Minimizing Production Cost

of Beam Pumped Wells", The Petroleum Society of CIM, Paper

95-26, May, 1995.

Lea, J.F., Lynn Rowlan and Jim McCoy: "Artificial Lift Power

Efficiency," Southwestern Petroleum Short Course, Texas

Tech University, Lubbock, Texas, April 1999.

Table 1 - WELL PERFORMANCE QUESTIONS

From Acoustic Surveys:

Does liquid exist above the pump? At what depth is the top of the liquid column?

Does the liquid in the casing annulus restrict production from the well?

What is the maximum production rate available from the well?

What is the casing-head pressure? Does it restrict production?

What is the percentage of liquid in the annular fluid column?

Is gas flowing up the annulus? At what rate? What is the gas gravity?

Are there any restrictions or anomalies in the annulus above the liquid level?

From Dynamometer Surveys:

Is the well pumped off? What is the pump intake pressure? What is the pump fillage?

Is the traveling valve or standing valve leaking? What is the pump displacement?

What is the effective pump plunger travel? What is the current pumping speed?

Are the maximum and minimum rod loads within allowable limits?

What is the polished rod horsepower?

Is the gearbox overloaded?

Is the unit properly balanced? What movement of the counterweights is required to balance the unit?

Is the downhole gas separator operating effectively?

From Motor Power Surveys:

What is the overall electrical efficiency of the pumping system?

Is the overall electrical efficiency above 50%?

What is the power consumption, $/month, $/BBL, and power demand, KW?

What is the motor current? Does the motor overheat?

Does the motor generate electricity sometimes during the stroke? Is credit allowed for generation?

Is the gearbox overloaded?

Is the unit balanced? What movement of the counterweights is required to balance the unit?

From Transient Pressure Surveys:

What is the reservoir pressure? What is the producing bottom hole pressure?

What is the liquid/gas annular afterflow when the well is shut in?

Is there any wellbore damage? Does the formation need treatment? Is the well fractured?

From Predictive Dynamometer Design Programs:

Is the predicted dynamometer in agreement with accurately measured horseshoe dynamometer data?

Can the performance be improved by a change in pump size, polished rod stroke length, SPM, rod string configuration or other

factors?

J. N. MCCOY, A. L. PODIO, BILL DRAKE, LYNN ROWLAN

Table 2. Balancing of Rotaflex Pumping Unit Staged Over a One-Hour Period.

Peak

Peak

Calculated

Weights

Cumulative Cumulative CounterUpstroke Downstroke Balanced

To be

Weight

Weight

No. of

balance

Torque,

Torque,

Torque,

Removed, removed, removed,

weights Effect Test,

Time

Kin-lbs

Kin-lb

Kin-Lb

Lbs

Lbs

Lbs

removed

Lbs

12:30

119.1

202.8

161

2500

13:02

135.9

180.5

158.2

1300

782

782

17

13:19

134.5

162.2

148.4

800

1058

1847

40

13:29

147.2

150

148.6

100

923

2760

60

25132

Table 3. Summary of Measured Values.

Motor

Input

PPRL,

MPRL,

Power,

Time

Lbs

Lbs

HP

Polished

Rod

Power,

HP

Pump

Power,

HP

Polished

Rod/Motor

Efficiency,

%

Pump/

Motor

Efficiency,

%

Overall

System

Efficiency,

%

12:30

32,200

13,700

36.8

29.7

26.7

80.8

72.5

56.6

13:02

32,100

13,900

36.9

29.7

26.6

80.5

72.2

56.6

13:19

32,000

14,200

36.5

29.5

26.5

80.7

72.4

57.1

13:29

32,000

14,200

36.2

29.4

26.4

81.1

72.8

57.5

Fig. 1 Analysis Showing Well Inflow Performance

SPE 68864

SPE 68864

MODERN TOTAL WELL MANAGEMENT - SUCKER ROD LIFT CASE STUDY

Fig. 2 - Results of Power Survey (Operated Near Peak Efficiency)

Fig. 3 - Results of Power Survey (Efficiency Could be Improved)

10

J. N. MCCOY, A. L. PODIO, BILL DRAKE, LYNN ROWLAN

Fig. 4 Well Data

Fig. 6 Gaseous Liquid Column

Fig. 5 Incomplete Pump Fillage

Fig. 7 Standing and Traveling Valve Tests

SPE 68864

SPE 68864

MODERN TOTAL WELL MANAGEMENT - SUCKER ROD LIFT CASE STUDY

Fig. 8 Dynamometer Analysis

Fig. 9 Out of Balance Conventional Pumping Unit with Large Negative Torque

11

12

J. N. MCCOY, A. L. PODIO, BILL DRAKE, LYNN ROWLAN

SPE 68864

Fig. 10 Match of Measured and Computed Dynamometer Cards

Fig. 11 Pressure Transient Analysis Horner Plot

Fig. 12 Rotaflex Pumping Unit

SPE 68864

MODERN TOTAL WELL MANAGEMENT - SUCKER ROD LIFT CASE STUDY

Fig. 13 Complete Acoustic Liquid Level Test

Fig. 14 Power and Torque with System Balanced

Fig. 15 Power and Torque when Counterweight Box Heavy

13

14

J. N. MCCOY, A. L. PODIO, BILL DRAKE, LYNN ROWLAN

Fig. 16 Counter Balance Effect Load Test

Fig. 17 Dynamometer Cards After Unit Balanced

SPE 68864

Potrebbero piacerti anche

- Two Phase Beggs BrillDocumento4 pagineTwo Phase Beggs BrillOsmund MwangupiliNessuna valutazione finora

- Geothermal Two Phase Flow WellDocumento6 pagineGeothermal Two Phase Flow WellOsmund MwangupiliNessuna valutazione finora

- Pump Card Analysis Simplified and ImprovedDocumento14 paginePump Card Analysis Simplified and ImprovedOsmund MwangupiliNessuna valutazione finora

- The Role of Two-Speed Motors in Lifting Heavy Oil - : $xjcker Rod Pumping Aji!IlmDocumento4 pagineThe Role of Two-Speed Motors in Lifting Heavy Oil - : $xjcker Rod Pumping Aji!IlmOsmund MwangupiliNessuna valutazione finora

- SPE-23429 A Simple Method of Predicting The Performance of Sucker Rod Pumping SystemDocumento10 pagineSPE-23429 A Simple Method of Predicting The Performance of Sucker Rod Pumping SystemOsmund MwangupiliNessuna valutazione finora

- History of GISDocumento21 pagineHistory of GISOsmund MwangupiliNessuna valutazione finora

- Lecture3 Spatial Data AnalysisDocumento23 pagineLecture3 Spatial Data AnalysisOsmund MwangupiliNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- ARC-232, Material Construction 2Documento4 pagineARC-232, Material Construction 2danishali1090Nessuna valutazione finora

- Q4 Music 6 Module 2Documento15 pagineQ4 Music 6 Module 2Dan Paolo AlbintoNessuna valutazione finora

- Water Tanker Check ListDocumento8 pagineWater Tanker Check ListHariyanto oknesNessuna valutazione finora

- Specification Sheet: Case I Case Ii Operating ConditionsDocumento1 paginaSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarNessuna valutazione finora

- Meniere's Disease - Retinal Detatchment - GlaucomaDocumento3 pagineMeniere's Disease - Retinal Detatchment - Glaucomaybet03Nessuna valutazione finora

- #Angles Are in Degrees: EGR2313 HW SOLUTIONS (2021)Documento4 pagine#Angles Are in Degrees: EGR2313 HW SOLUTIONS (2021)SolomonNessuna valutazione finora

- College of Computer Science Software DepartmentDocumento4 pagineCollege of Computer Science Software DepartmentRommel L. DorinNessuna valutazione finora

- Hetal Patel: Team Leader - SalesDocumento2 pagineHetal Patel: Team Leader - SalesPrashant kumarNessuna valutazione finora

- Health and Safety For The Meat Industry: Guidance NotesDocumento198 pagineHealth and Safety For The Meat Industry: Guidance NotesPredrag AndjelkovicNessuna valutazione finora

- HAYAT - CLINIC BrandbookDocumento32 pagineHAYAT - CLINIC BrandbookBlankPointNessuna valutazione finora

- Land of PakistanDocumento23 pagineLand of PakistanAbdul Samad ShaikhNessuna valutazione finora

- Internet Bill FormatDocumento1 paginaInternet Bill FormatGopal Singh100% (1)

- Bigbazaar PDFDocumento14 pagineBigbazaar PDFazhagu sundaramNessuna valutazione finora

- Restaurant Report Card: February 9, 2023Documento4 pagineRestaurant Report Card: February 9, 2023KBTXNessuna valutazione finora

- SEC CS Spice Money LTDDocumento2 pagineSEC CS Spice Money LTDJulian SofiaNessuna valutazione finora

- Discovery and Integration Content Guide - General ReferenceDocumento37 pagineDiscovery and Integration Content Guide - General ReferencerhocuttNessuna valutazione finora

- Ae - Centuries Before 1400 Are Listed As Browsable DirectoriesDocumento3 pagineAe - Centuries Before 1400 Are Listed As Browsable DirectoriesPolNeimanNessuna valutazione finora

- MV Lec PDFDocumento102 pagineMV Lec PDFJonas Datu100% (1)

- 3M 309 MSDSDocumento6 pagine3M 309 MSDSLe Tan HoaNessuna valutazione finora

- 1 - Laminar and Turbulent Flow - MITWPU - HP - CDK PDFDocumento13 pagine1 - Laminar and Turbulent Flow - MITWPU - HP - CDK PDFAbhishek ChauhanNessuna valutazione finora

- TrellisDocumento1 paginaTrellisCayenne LightenNessuna valutazione finora

- CL RouterAndSwitches AE Kn1of3 AnswerDocumento19 pagineCL RouterAndSwitches AE Kn1of3 Answereugene ngNessuna valutazione finora

- Grade9 January Periodical ExamsDocumento3 pagineGrade9 January Periodical ExamsJose JeramieNessuna valutazione finora

- ArcGIS Shapefile Files Types & ExtensionsDocumento4 pagineArcGIS Shapefile Files Types & ExtensionsdanangNessuna valutazione finora

- CSEC SocStud CoverSheetForESBA Fillable Dec2019Documento1 paginaCSEC SocStud CoverSheetForESBA Fillable Dec2019chrissaineNessuna valutazione finora

- Sample Cross-Complaint For Indemnity For CaliforniaDocumento4 pagineSample Cross-Complaint For Indemnity For CaliforniaStan Burman75% (8)

- A Junk Project - An Income Generating ProjectDocumento2 pagineA Junk Project - An Income Generating ProjectHercules Verdeflor ValenzuelaNessuna valutazione finora

- Sistine Chapel Ceiling Lesson PlanDocumento28 pagineSistine Chapel Ceiling Lesson PlannivamNessuna valutazione finora

- Manual Samsung Galaxy S Duos GT-S7562Documento151 pagineManual Samsung Galaxy S Duos GT-S7562montesjjNessuna valutazione finora

- WinCC Control CenterDocumento300 pagineWinCC Control Centerwww.otomasyonegitimi.comNessuna valutazione finora