Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Safe Work Method Statement (SWMS) - : Incorporating Job Safety Analysis

Caricato da

Khuda BukshTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Safe Work Method Statement (SWMS) - : Incorporating Job Safety Analysis

Caricato da

Khuda BukshCopyright:

Formati disponibili

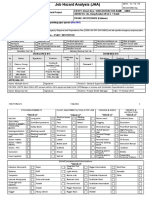

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Description of Activity to be carried out:

Work Location:

Above Ground External Surface protection by

Painting of Piping, Equipment & Structure.

MC3

Corridors of Ras Laffan, Tank form area, B110,

B120, B130, B140, B150, B160, B310, C110,

C120, C130, C140, C160, C300, D100, D200

Risk Assessment Log Section:

Step

Critical Steps in this Activity:

1.0

Loading of Erection Material on Trailer (using

Trailer, Crane, Forklift etc.)

JGC approve the use of this MSJSA :

Name:

Position: JGC HSE Manager

Signature:

Date:

Activity Guidelines used:

Potential Hazards:

Improper loading of material.

Falling material

Personnel Injury

HSE Controls to be Implemented:

2.0

Shifting of material to Site

- Off loading by Trailer, Crane, etc

Road Traffic Accidents

Material fall during transportation

Accident due to improper loading

Improper Off-loading

Loading of material will be under proper

supervision.

Only Third party certified and color coded

lifting gears will be used

Only Banksman with High visibility Vest

will give signals to crane operator.

Barricade the loading area.

Approved operator will operate the crane.

Tag line to be used.

Access to be provided in case of

requirement

Secure all material

Ensure that overloading is prevented

For the lifting of load wind speed should

be less than 25 knots confirmed by JGC

All drivers / operators will be oriented for

safe access to site. Only approved trailer

to be used

No standing at the back of Trailor.

Road traffic signs to be followed.

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

3.0

Critical Steps in this Activity:

Shifting of Tools and Plant /

Equipment at site.

Potential Hazards:

Defective / unserviceable machines

Source of Ignition / Fire

Earth / Cables etc.

HSE Controls to be Implemented:

4.0

Grit blasting by using Garnet

Occupational Health problem due to Grit

Blasting dust.

Irritation on Skin

Personnel Injury due to

Improper containment of area

Inadequate / Defective PPEs

Unfiller / Improper Air Suction and quality

Inadequate coupling / Hose connection

Poor Communication

Poor House Keeping

Slips / Trips

Ensure all compressor checked prior to

shifting to site

All blasting accessories like blasting parts

nozzles blasting hoods filters and tools

are approved / certified / inspected prior

to use.

Compressors with Fire extinguisher

Trained personnel will be involved in

shifting of tools and plant / equipment

Tool Box talk will be conducted regarding

hazards of Garnet being used for blasting

material, MSDS attached.

The Grit Blast Operator will wear an airsupplied hood approved for Grit Blasting.

Adequate periphery protection will be

done.

Other workers in or around the area will

wear dust masks approved for Blasting

Area.

Grit Blast nozzle will be with dead man

control that will shut off the flow if nozzle

is dropped, Control Switch will be in

reach of the blaster.

Hose nozzle, coupling, fittings will be

checked visually to be well in place. Hose

joint will be provided with safety chain /

pin

Grit blast operator will wear Shot resistant apron, Safety boots, Gauntlet gloves,

heavy shirt and trouser.

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

Critical Steps in this Activity:

Potential Hazards:

HSE Controls to be Implemented:

No one will be allowed within range of

Grit jet while work is in progress. Workers

attending equipment will not leave the

equipment un-attended and wear all

PPEs (having proper with blaster.

Supply rate of Air to Blasting hood will be

6 cfm per hood without vortex tube and

25 cfm with vortex tube.

Approved Blasting material will be used.

Work area will be barricaded and sign

posted as "NO ENTRY GRIT

BLASTING IN PROGRESS"

Site Supervisor will be responsible for

observing distance of rebound and for

moving ropes and barricades and signs

clear of rebound.

A proper bonded or electrically conductor

hose will

be used to prevent

accumulation of static electricity in the

operator's body.

Maintain working area clean and tidy.

Only experienced personnel to do this

activity.

Waste from blasting yard will be disposed

off as per JGC / Dolphin waste

management system.

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

Critical Steps in this Activity:

Potential Hazards:

HSE Controls to be Implemented:

5.0

Use of Air compressor

Occupational Health problem due to noisy

atmosphere

Compressed air leakage due to improper

hose connection or damaged hose

Skin injury due

compressed air.

to

improper

Slip / Trip Hazard

Improper grounding

No / improper guard on moving parts

Use of defective equipment

use

of

-

All air compressor, Air receivers and

other equipment will be JGC Inspected,

color coded.

Perform regular inspection on daily basis

to identify defects

Periodic maintenance to be done

Immediately

report

any

defect/damage/malfunction or missing

part to supervisor

Ensure all safety gadgets and gauges

working properly

Wear hearing protection in noisy

environment.

Ensure drip tray to avoid any spill due to

leakage

Provision of fire extinguisher with the air

compressor.

Air Quality to be checked regularly and

moisture drained. This will be done by

checking the air using personal gas

monitor periodically as described in Air

Quality Procedure.

Compressed air not to be used for

cleaning purpose

Inspection of air hose assembly and hose

connections before each use.

Wire checks will be used on hose joints

Hoses to be routed properly to prevent

slip / trip hazard

Proper earthing of the air compressor to

be done

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

Critical Steps in this Activity:

Potential Hazards:

HSE Controls to be Implemented:

6.0

Storage of chemicals

Occupational Health hazard due to exposure

to toxic chemicals

Environmental Hazard due to spillage

Fire hazard due to flammable chemicals

Improper handling and disposal of waste

Improper housekeeping

Ignition source / hot work near flammable

material

The design and specification of chemical

storage areas will be in compliance with

JGC Procedure.

Waste storage areas will comply with the

requirements stated within the JGC

Waste Management Procedure RLO0000-FPR-50126.

Management of spills of chemicals will

comply with the measures stated in the

Spill Contingency, Procedure RLO-0000FPR-50128.

Disposal

procedures

and

control

measures for chemical waste will comply

with the procedure and measures stated

in the Waste Management Procedure

RLO-0000-FPR-50126.

Ensure the availability of MSDS of

chemicals being used.

Use of drip trays to avoid spillage

Ensure availability of Fire extinguisher at

chemical storage area.

Control measures and emergency

contacts are provided in case of any spill

or fire.

Good housekeeping to be maintained at

all the times at chemical storage area.

Labeling of all chemical containers

Ensure that all containers are tightly

packed

List of emergency contact numbers is

provided.

No smoking in or around chemical

storage area.

No hot work/ignition source nearby to

chemical storage area

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

Critical Steps in this Activity:

Potential Hazards:

HSE Controls to be Implemented:

No accumulation of chemicals in work

area / walkways where it poses a health

hazard/fire hazard.

All spills to be cleaned immediately.

Flammable liquids to be dispensed over

drip trays in a safe area away from an

ignition source

Flammable liquids not to be used for

cleaning machinery or its parts

Suitable signs to be posted

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

Critical Steps in this Activity:

Potential Hazards:

7.0

Painting Works

Occupational Health problem due to

inhalation of paint fumes.

Trips / Slips / Falls

Inadequate storage / disposal of paint and

empty container

Non-availability of eye wash kit

Sign boards

Over spray in adjacent areas

Use of defective paint spray equipment

Eye Injury

Fire Hazard

Environmental hazard due to spillage of paint

HSE Controls to be Implemented:

TBT to be conducted on the hazards and

risk to health by paint materials MSDS

attached.

Proper planning before starting activity to

minimize the risk to human health, safety

and environment

PPES to be used as an extra protection

or where other control measures are not

practicable

Ensure that all containers are tightly

packed when not in use.

List of emergency contact numbers is

provided.

Use of paint will be performed on open

areas as for possible.

The Quantity of paint brought into the

work area will be controlled and restricted

to the anticipated or intended amount to

be used.

Only trained personnel will be allowed to

use and handle paint.

Consumption of food and smoking will be

prohibited when working with paint.

Supervisor to ensure that workforce is

aware of all precautions given in the

MSDS of paint and follow these fully.

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

Critical Steps in this Activity:

Potential Hazards:

HSE Controls to be Implemented:

Respiratory protection will be used as per

MSDS.

Paint will be stored in a safe manner,

material will be segregated in accordance

with good practice keeping oxidizing and

reducing apart.

Paint will be stored in well ventilated and

cool place.

No Hot work, in and around the painting

area.

Use proper access work plat

Use adequate rope to lift / lower the paint

containers / brush while working at

height.

Maintain area clean and tidy at all times.

In case of any paint spillage, it will be

cleaned immediately.

Left out paint will be kept in separate

container and disposed as per JGC /

Dolphin waste management system.

Fire extinguisher will be kept as required

in the area.

"NO NAKED FLAME" or "HOT WORK"

sign boards will be placed.

All area nearby will be masked prior to

spray.

All tools / equipment will be inspected,

approved and color coded.

Emergency eye wash kit will be placed in

the painting area.

Safety glasses will be worn at all time,

especially during the paint spray and

mixing.

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

Critical Steps in this Activity:

8.0

Refueling of Equipments e.g. Air Compressor

etc

Potential Hazards:

Environmental hazard due to Spillage of oil

during refueling.

Fire Hazards during refueling.

Personal injury due to slip / trip

Inadequate hose connection

Struck against / Struck by

Over fueling

HSE Controls to be Implemented:

Stay near your equipments fueling point

when refueling.

Ensure a safe access to the equipment to

be refueled

Wearing of appropriate PPES at all time

during refueling

Switch off equipment before starting

refueling

Never overstretch refueling hose

Never overfill or top the fuel tank

Refueling to be done at slow rate to

reduce the potential for spillage and static

ignition buildup

Let the fuel dispenser shut off

automatically and leave the nozzle in the

tank for six to eight seconds so the fuel

can settle down and any fuel in the

nozzle can drip down into fuel tank

Ensure drip tray under the equipment to

be refueled.

Hose and refueling assembly should be

in good condition

Refueling to be done only by refueling

vehicle and trained person.

If fuel is needed to be taken on site in

cane, use the recommended jerry cane

Ensure the availability of fire extinguisher

near refueling point

No ignition source /smoking near

refueling point

Switch off mobile phone before starting

refueling

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

Critical Steps in this Activity:

9.0

Mandatory & / or Recommended Personal

Protective Equipment (Tick Appropriate PPE)

------- Hard Hat

------- Safety Glasses, Goggles, Face Shield

------- Safety Shoes

------- Coverall Long Sleeve Nomex

------- Air Supplied Blasting Hood

------- Hearing Protection

------- Hand Gloves (Cotton, Leather, Rubber

Others)

------- Full Body Harness & Lifeline

------- Respiratory Protective Equipment

------- H2S Gas Alert clip

------- SCBA on stand-by

------- Others

Potential Hazards:

1. This JSA, including all relevant checklists, will

be used in conducting Tool Box Talks (TBT)

with all concerned workers.

2. Only diesel equipment / tools inspected and

approved by JGC are allowed in the work

area.

3. Heat Stress prevention will always be

emphasized in TBT.

4. Provided that all the necessary PPE are

used, relevant PTW requirements are

followed and all the control measures stated

above are adhered to, the activity can

proceed.

Note:

Any worker has the right to refuse to work due to

safety and environmental concern. Such concern

will at once be reported to his supervisor /

foreman or to the operation and EHS personnel

at site.

HSE Controls to be Implemented:

Prepared By :________________

(Painting Subcontractor)

Reviewed By :________________

(Subcontractor - Safety)

Approved By :_______________

(JGC - Discipline & Safety)

Date :____________

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

HSE Information / Requirements

Resources and Competency

Does the Work Team have the necessary capacity, capability, experience & authority to avoid, minimize, monitor and control the risks (Training / Awareness / Equipment, etc.)?

Detail minimum expected requirements:

Peoples have been trained by Descon HSES Training Manager. Tool box Talk has been delivered to the crew by their Supervisor,

Equipment has been inspected and certified by JGC

Communications / Workforce Consultation

Have all members of the Work Party attended the Toolbox Talk, and have they been made fully aware of the risks that they are taking (Residual risks)?

TBT Record No.

Yes

External Risk

Has an assessment been conducted to identify all external (to the activity) hazards and potential risks (3rd parties such as other workforce teams or other adjacent parties)? What is the

result?

Risk Assess. No.

Job Safety Analysis has been carried out keeping in view all external Risks / Hazards. No simultaneous activities are carried out by

Other Parties in the vicinity of job area. Area will be barricaded and signboards will be posted.

H&S Training

Employees should be trained in the proper interaction with equipment, and the proper response to incidents involving this equipment. List the training your employee(s) has received.

All employees attended JGC induction training.

Specialist Training

Will the workforce require any specialist training?

YES / NO (IF YES, list the specialist training required for the job):

No, because employees are already trained for painting job.

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

High Potential Risks

Does the task require special access / egress / heavy lifting / entry into confined spaces or work at height / in excavations?

(IF YES, a separate Risk Assessment needs to be completed).

YES / NO

Risk Assess. No.

No

Where practicable - Attach supporting Risk Assessment

Other Impacts

Are there any other ways in which the work will be affecting and/or protecting the Health and Safety of the team members?

YES / NO (If so, please describe below):

No

PTW / Isolations: Other Certificates / Permits

What other precautions (e.g. electrical isolation, permits to work) are required and who will authorize them?

PTW / Cert. Nos.

No

Contingency / Emergency Response

Should special emergency procedures be instituted, e.g. Emergency Drill, providing Fire Wardens, extra First Aid cover, etc.?

YES / NO (If so, please describe below):

No

Air Emissions

Will the work you perform produce or cause the release of any air emissions?

No

YES / NO

(If YES, list air emissions and method for preventing impact to the environment):

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Water Discharges

Will the work you perform produce or cause the release of any wastewater?

YES / NO (IF YES, how will the wastewater be handled?):

No

Materials

What materials (chemicals, oils, etc.) and/or equipment will you be handling or bringing on-site to perform the contracted work?

Paint and related Material will be handled

Environmental Training

Have employees been trained in the proper handling of materials and equipment, and the proper response to incidents involving these materials? List the training your task employees

have received.

Environmental aspects are already covered in Job Safety Analysis training

Waste Generation

Will the work you perform result in any wastes? YES / NO (IF YES, list the disposal location, as well as amounts and types of wastes expected and the proposed disposal method):

Waste generated will be disposed off as per JGC Waste Management Procedure RLO-0000-FPR-50126.

Energy

Will the work you perform consume energy (electricity, compressed air, natural gas, steam, etc.)? YES / NO (IF YES, explain what type of energy will be consumed, and how you will

minimize consumption):

Yes, Diesel fuel will be used in cranes, generators, air compressors etc. Equipment will be stopped if it is not needed to reduce fuel consumption

Other Impacts

Are there any other ways in which the work will be affecting and/or protecting the environment?

No

YES / NO (If YES, please describe below):

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Environmental Monitoring

Describe any environmental monitoring to be performed, including sampling methods, frequency, analytical requirements and laboratory to be used:

Not Applicable

Legal requirements

Identify environmental legal requirements applicable to the work that has not already been addressed by the Project.

Not Applicable

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Training modules required to complete Activity:

List Codes of Practice, Legislation, Standards which apply to this Activity:

JSA will be used as a training module

Standard

Codes

ASTM-1599

ASME B31.3

ASME B16.5

List Plant / Equipment / PPE required for this Activity:

Crane, power generator, welding machines,

compressor.

PPEs:

List Equipment / Maintenance

Checks required for this Activity:

Pre job equipment check

will be done before starting

the job

Safety Helmet

Engineering Certificates / Permits / Approvals required for this Activity

(e.g. RLC Permit Road closure, Utility isolation, Special Waste license, etc.)

No

Type

Reference/Documents

Safety Shoes

Safety Goggles

Safety Gloves

Dust Masks

Person(s) Responsible for Supervising / Inspecting Work:

Person(s) responsible for supervising the work, inspecting and approving work areas, work methods, protective measures, plant equipment and power / other tools:

NB: List of qualifications/experience is held in local JGC files see JGC HSE Group for details.

Name: .

Ray

Name: .

Meeran

Position:

Position:

Supervisor (GRP)

Supervisor (DESCON)

Signature: .................................................................

Signature: .................................................................

For a list of names and signatures of staff instructed in this Safe Work Method Statement and JSA, see JGC training records.

Copy 1 - To be posted at the Worksite / Supervisor at the Worksite

Copy 2 - To be retained by JGC HSE Group (24 months)

Copy 3 - To be held by the subcontractor (24 months)

SAFE ACTIVITY PRE-CHECK (SAP) SHEET

Company:

Date:

Foreman (print

name):

Location:

Task Description:

MUSTER / ASSEMBLY POINT LOCATION:

IS YOUR DESIGNATED PLACE OF WORK TIDY? - YES or NO (If "NO" housekeeping must be performed prior to work commencing).

PERMIT TO WORK REQUIREMENTS

YES

Key Task Related Hazards

(tick box)

NO

N/A

Excavations

Access Only

Plant & Equipment

Electrical

Key Preventative Control Measures

Confined Spaces

Isolations

Lock Out / Tag Out

Hot work

Instrumentation

Pre / Commissioning / START-UP

EXCAVATION

YES

NO

N/A

HOTWORK (Non PTW controlled)

SHORED / SLOPED / BENCHED

FIRE EXTINGUISHER

LADDERS PROVIDED

FIRE BLANKET

BURIED SERVICES IDENTIFIED

CYLINDERS UPRIGHT & SECURED

VEHICLE STOP BARRIERS / BOARDS

COMBUSTIBLES REMOVED

EXCAVATION INSPECTED

CONFINED SPACES

NO

N/A

EMERGENCY COMMUNICATIONS

WORK BELOW RESTRICTED

PERMIT to WORK

BARRIERS / SIGNS POSTED

GAS TEST COMPLETED

FLAME ARRESTORS FITTED

TALLY BOARD or similar

WELDING CABLES IN GOOD CONDITION

EMERGENCY ACCESS

CHEMICALS

COMMUNICATIONS

MSDS REVIEWED / AVAILABLE

SAFETY HARNESSES

SKIN / EYE / THROAT IRRITANT

SUITABLE (Ex.) LIGHTING

SHOWER or EYEWASH AVAILABLE

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

SPECIAL PPE AVAILABLE AS PER MSDS

SCAFFOLD INSPECTED

CONTAINERS LABELLED PROPERLY

INSPECTION SCAFTAG POSITIONED & IN DATE

SIGNS POSTED

SAFE ACCESS / EGRESS PROVIDED

RISK ASSESSMENT CONDUCTED

TOEBOARDS, KICKPLATES IN ORDER

HAZARDS COMMUNICATED

HANDRAILS SECURED

GROUNDING

HARNESS & LANYARDS INSPECTED

CONTAINMENT REQUIRED / PROVIDED

STATIC LINES - TIE OFF POINTS

ABSORBENT AVAILABLE IN SITU.

YES

NO

N/A

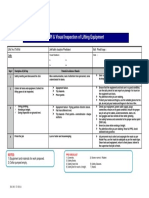

PORTABLE TOOLS

PLANT & EQUIPMENT INSPECTED

TOOLS, APPLIANCES INSPECTED

LIFTING GEAR, RIGGING INSPECTED & CERTS.

BANKSMAN / COMPETENT PERSON

IDENTIFIED

LIFTING PLAN / CALCS & M/S CHECKED

DEFECTS REPORTED

OPERATOR CERTIFIED

OPERATORS CERTIFIED

CABLES, HOSES INSPECTED

PPE REQUIREMENTS IDENTIFIED

PORTABLE APPLIANCES INSPECTED

EXTENSION CABLE CHECKED & TAGGED

FLAGMEN TRAINED / POSITIONED

OCCUPATIONAL HEALTH

N/A

SPECIAL PPE (VISORS, GLOVES, etc)

VENTILATION

PLANT & EQUIPMENT

NO

FIRE WATCH (Safety Passport check)

YES

STANDBY MAN

SCAFFOLDING

YES

GUARDS POSITIONED

YES

NO

N/A

PPE

SAFE ACTIVITY PRE-CHECK (SAP) SHEET

FIRST AIDER / FIRST AID KIT

HARD HAT

HEAT STRESS

BOOTS

DUST

GLASSES

HYGIENE (FOOD / WATER) CONTAINERS

COVERALLS / HIGH-VISIBILITY VESTS

NOISE

FACE MASKS

VIBRATION

GENERAL WORK GLOVES

YES

ELECTRICITY

NO

N/A

SPECIALIST PPE

PTW REVIEWED (COMPETENT PERSON)

WELDERS, FIRE RETARDANT GLOVES

SYSTEM LOCK OUT

ELECTRICAL RUBBER GLOVES

SYSTEM TAGGED OUT

EAR DEFENDERS / PLUGS

JSA / METHOD STATEMENT IN PLACE

HARNESSES / LANYARDS

SYSTEM DISCONNECTED

WELDERS SCREEN

SYSTEM TESTED

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

FACE MASK (DUST - FUMES)

MANUAL HANDLING

YES

NO

N/A

RESPIRATORS

WORKER(S) TRAINED (Safety Passport check)

SELF CONTAINED BREATHING APPARATUS

LIFTING, PULLING

FIRE RETARDENT CLOTHING

STRETCHING

ENVIRONMENTAL CONSTRAINTS

SHARP OBJECTS, PINCH POINTS

ENV. STUDY REPORT COMPLETED

(TROLLEYS, FORKLIFTS, etc) available

ENV. HAZARDS IDENTIFIED IN MS

SOUND GROUND / UNDERFOOT CONDITIONS

WORK AREA CHECKED (R&E SPECIES)

GENERAL

YES

NO

N/A

WASTE CONTAINERS / AREA IDENTIFIED

FLYING PARTICLES

SPILL CONTAINMENT

CABLES SECURED ABOVE HEAD HEIGHT

ENV. MONITOR INFORMED / AVAILABLE

VOIDS / HOLES COVERED & SECURED

SITE PLANT & VEHICLES

BARRIERS & TAPE PROVIDED

SAFE DISTANCE - VEHICLES & PEDESTRIANS

ALL HAZARDS COMMUNICATED

SIGNS ERECTED AND VISIBLE

OTHER WORKERS SAFETY CONSIDERED

NOISE / EXHAUST HAZARDS IDENTIFIED

Foreman / Supervisor: I have discussed the above potential hazards involved in the task, reviewed the SAP Card with

the employees under my control, and implemented suitable and sufficient controls to minimize the risks involved.

Name (print)

Signature

Employees: I / WE ACCEPT THE RESPONSIBILITY FOR THE SAFE BEHAVIOUR OF MYSELF AND MY CO-WORKERS

DURING THE TASKS IDENTIFIED ABOVE:

EMPLOYEE NAME

SIGNATURE

EMPLOYEE NAME

1.

10.

2.

11.

3.

12.

4.

13.

5.

14.

6.

15.

7.

16.

8.

17.

9.

18.

SIGNATURE

Potrebbero piacerti anche

- JSA - Sand Blasting & PaintingDocumento4 pagineJSA - Sand Blasting & Paintingsurendra behera100% (4)

- JSA Blasting and Coating KP 69.4Documento5 pagineJSA Blasting and Coating KP 69.4shinto Lawrence100% (6)

- Civil JSA Form Block WorkDocumento3 pagineCivil JSA Form Block Workdrmuhsin86% (7)

- JSA - Fire Proofing WorksDocumento5 pagineJSA - Fire Proofing WorksAnis Uddin100% (3)

- Jobs Safety Analysis (JSA)Documento8 pagineJobs Safety Analysis (JSA)uttam mishra100% (1)

- Jsa For HydrotestDocumento10 pagineJsa For HydrotestAnonymous CcGYhZb080% (5)

- SGD SAIPEM CAMP LOADING AND UNLOADINGDocumento2 pagineSGD SAIPEM CAMP LOADING AND UNLOADINGsubhanmusadiq82% (55)

- Job Safety Analysis Sheet: FacilityDocumento1 paginaJob Safety Analysis Sheet: Facilitywahyu nugrohoNessuna valutazione finora

- What Are The Two Major Forms of Workplace DiversityDocumento2 pagineWhat Are The Two Major Forms of Workplace DiversityThắng Thông100% (1)

- Jsa For Civil Confined Space EntryDocumento11 pagineJsa For Civil Confined Space EntryKhuda BukshNessuna valutazione finora

- Jsa Grit BlastingDocumento2 pagineJsa Grit BlastingHenryOdoh100% (3)

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocumento9 pagineHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- JSA for Painting Works on Storage TanksDocumento6 pagineJSA for Painting Works on Storage TanksHaseeb Nouman Abbasi100% (2)

- 7 - Civil WorkDocumento12 pagine7 - Civil WorkPerwez21100% (1)

- Job Safety Analysis: 1 Confined Space Entry JSA ExampleDocumento7 pagineJob Safety Analysis: 1 Confined Space Entry JSA Examplerashid zamanNessuna valutazione finora

- JSA-009a Drilling and Mon Well Construction-SonicDocumento4 pagineJSA-009a Drilling and Mon Well Construction-SonicDedi Apriadi83% (6)

- Jsa For Piping and Erection RevisedDocumento1 paginaJsa For Piping and Erection RevisedAlvin Smith77% (26)

- Monthly HSE Performance ReportDocumento17 pagineMonthly HSE Performance ReportKhuda BukshNessuna valutazione finora

- Concrete Surface Coating JSA-027Documento5 pagineConcrete Surface Coating JSA-027shivgovind pal100% (1)

- JSA For Cutting, Grinding and WeldingDocumento4 pagineJSA For Cutting, Grinding and Weldingyc safety100% (3)

- Coating and Painting Work.Documento9 pagineCoating and Painting Work.MOHNISHKUMARJHANessuna valutazione finora

- JSA For Coating and Raping Activity in TankDocumento7 pagineJSA For Coating and Raping Activity in TankEslam lotfy- Eslam elsadatNessuna valutazione finora

- Welding, Cutting and GrindingDocumento6 pagineWelding, Cutting and GrindingMohammed MinhajNessuna valutazione finora

- Blasting & Painting JHADocumento8 pagineBlasting & Painting JHADedy Kurniawan100% (1)

- Jsa For Tie in of Fuel Gas LineDocumento3 pagineJsa For Tie in of Fuel Gas LineMohammed Minhaj100% (1)

- JSA For Painting Works-Hazards ControlDocumento4 pagineJSA For Painting Works-Hazards Controlkaleem0% (2)

- Manual Tig Welding (RRC) - Job ProcedureDocumento3 pagineManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- HSE Docs 186 HSE Checklists Hseprof ComDocumento57 pagineHSE Docs 186 HSE Checklists Hseprof ComMansoor BabbarNessuna valutazione finora

- Permit To Work ProcedureDocumento42 paginePermit To Work ProcedureKhuda Buksh100% (1)

- ISO 45001 Gap Analysis ChecklistDocumento7 pagineISO 45001 Gap Analysis ChecklistKhuda Buksh75% (12)

- Quality PlanDocumento21 pagineQuality PlanTAHER AMMAR86% (7)

- UKZN SCMA301 2008 Past PaperDocumento5 pagineUKZN SCMA301 2008 Past Papertr1ckyNessuna valutazione finora

- 3 - Sample Company Rules and PolicyDocumento6 pagine3 - Sample Company Rules and PolicyRonalyn Claire Singson100% (1)

- SMETA Pilot Terms of Reference for Private Employment Agency AuditsDocumento2 pagineSMETA Pilot Terms of Reference for Private Employment Agency AuditsChrisa KargiotouNessuna valutazione finora

- 8 Case StudiesDocumento3 pagine8 Case StudiesSwarup PradhanNessuna valutazione finora

- Jsa For Steel Structure For Off PlotDocumento13 pagineJsa For Steel Structure For Off PlotKhuda BukshNessuna valutazione finora

- JSA - Dismantling CM ShedDocumento4 pagineJSA - Dismantling CM ShedvivekaramanaNessuna valutazione finora

- MEGHA ENGINEERING JSA FOR CONFINED SPACE ENTRYDocumento5 pagineMEGHA ENGINEERING JSA FOR CONFINED SPACE ENTRYjithin shankar100% (3)

- JSA G17 Lift Container With CraneDocumento4 pagineJSA G17 Lift Container With CraneYosep Sapto Rahyudi100% (3)

- JSA For Painting Inside TankDocumento2 pagineJSA For Painting Inside TankDilshad aliNessuna valutazione finora

- Method Statement For Painting of All Metallic Piping: Form 000.653.F0100Documento9 pagineMethod Statement For Painting of All Metallic Piping: Form 000.653.F0100narmathaNessuna valutazione finora

- Ultratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSADocumento5 pagineUltratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSATFattah100% (1)

- GRP PIPING INSTALLATION SWMSDocumento13 pagineGRP PIPING INSTALLATION SWMSKhuda Buksh100% (1)

- JSA For Material ShiftingDocumento3 pagineJSA For Material ShiftingMohammed Minhaj100% (1)

- JSA Shut Down and Tie in Work PDFDocumento6 pagineJSA Shut Down and Tie in Work PDFpjosesm80% (5)

- Jsa For Ut TestDocumento2 pagineJsa For Ut Testnasar_mahsood50% (2)

- Civil Works Construction Confined Space JSADocumento5 pagineCivil Works Construction Confined Space JSAkosoko100% (1)

- Lifting Operatio in Progress PDFDocumento1 paginaLifting Operatio in Progress PDFsubhanmusadiq100% (1)

- Jsa Grinding Welding Gas CuttingDocumento3 pagineJsa Grinding Welding Gas CuttingQomarudin Comenk100% (2)

- Jsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsDocumento7 pagineJsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsMohammed Minhaj100% (1)

- 0 JsaDocumento54 pagine0 JsaRavi AmarlapudiNessuna valutazione finora

- JSa For Operation of Jack HammeringDocumento3 pagineJSa For Operation of Jack Hammeringyc safety0% (1)

- Refueling JSA 4 08 2019 Rev.03 Near WaterDocumento9 pagineRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariNessuna valutazione finora

- JSA For Lifting of RebarsDocumento5 pagineJSA For Lifting of RebarsNiraNessuna valutazione finora

- JSA of MPI InspectionDocumento1 paginaJSA of MPI Inspectionengmuhmud100% (1)

- JSA For Welding of HVACDocumento4 pagineJSA For Welding of HVACMohammed Minhaj100% (1)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocumento2 pagineJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNessuna valutazione finora

- JSA - Repair-Coating and Finition WorkDocumento3 pagineJSA - Repair-Coating and Finition WorkAMIN100% (1)

- Job Safety Analysis for Blasting and Painting WorkDocumento11 pagineJob Safety Analysis for Blasting and Painting WorkRajuNessuna valutazione finora

- CPF-JSA-022 Welding Cutting and Drilling of Underground and Above Pipes Night ShiftDocumento3 pagineCPF-JSA-022 Welding Cutting and Drilling of Underground and Above Pipes Night Shiftaioudi100% (1)

- Job Hazard Analysis Welding Operations: Attachment 4Documento3 pagineJob Hazard Analysis Welding Operations: Attachment 4mujahed.ahmed4253063Nessuna valutazione finora

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Documento4 pagine0017 JS A Hot Job (Welding, Grinding & Cutting)Positivesolution100% (2)

- Jsa For Air Flushin & Mech. Cleaning of PipesDocumento17 pagineJsa For Air Flushin & Mech. Cleaning of PipesKhuda Buksh100% (2)

- JSA - Chemical CleaningDocumento4 pagineJSA - Chemical CleaningkrshhNessuna valutazione finora

- Use of Master Builders Generic Safe Work Method StatementsDocumento7 pagineUse of Master Builders Generic Safe Work Method StatementsJonasNessuna valutazione finora

- RA, COSHH, MSDS Screed & Waterproofing PDFDocumento27 pagineRA, COSHH, MSDS Screed & Waterproofing PDFテレブリコ ジェファーソン60% (5)

- Doosan Heavy Industries Vietnam Grounding and Cad Welding Method StatementDocumento34 pagineDoosan Heavy Industries Vietnam Grounding and Cad Welding Method StatementGanga Daran100% (2)

- Zamil HVAC safety proceduresDocumento4 pagineZamil HVAC safety proceduresHazrat AminNessuna valutazione finora

- Method Statement FormatDocumento11 pagineMethod Statement FormatPrem Preetham Dsouza100% (1)

- Safety ProcedureDocumento9 pagineSafety ProcedurezoewongshNessuna valutazione finora

- HSE Procedure For Planning & AuditingDocumento4 pagineHSE Procedure For Planning & AuditingKhuda Buksh100% (1)

- Toxic Gas Fact SheetDocumento15 pagineToxic Gas Fact SheetKhuda BukshNessuna valutazione finora

- Work at Heigh at Night SafetyDocumento49 pagineWork at Heigh at Night SafetyKhuda BukshNessuna valutazione finora

- HSE Procedure For Garbage DisposalDocumento4 pagineHSE Procedure For Garbage DisposalKhuda BukshNessuna valutazione finora

- Stamp: Copy No. HolderDocumento266 pagineStamp: Copy No. HolderMd EnaamAzharNessuna valutazione finora

- Work at Height Safety Question & AnswersDocumento34 pagineWork at Height Safety Question & AnswersKhuda BukshNessuna valutazione finora

- Safety GuideDocumento53 pagineSafety GuideKhuda BukshNessuna valutazione finora

- Checklist For Heavy Equipment - 1Documento15 pagineChecklist For Heavy Equipment - 1Katita ChascaNessuna valutazione finora

- 1691582034614Documento16 pagine1691582034614Joseph NNessuna valutazione finora

- HSE Drilling and Well Control ProcedureDocumento5 pagineHSE Drilling and Well Control ProcedureKhuda Buksh100% (2)

- Short Note For Safety OfficerDocumento24 pagineShort Note For Safety OfficerKhuda BukshNessuna valutazione finora

- 500 Technical Questions Safety&Fire-1Documento26 pagine500 Technical Questions Safety&Fire-1Saad GhouriNessuna valutazione finora

- HSE PLAN by HTTPSDocumento52 pagineHSE PLAN by HTTPSKhuda BukshNessuna valutazione finora

- 3S Technical Proposal OHSAS ISO Implementation PDFDocumento38 pagine3S Technical Proposal OHSAS ISO Implementation PDFKhuda BukshNessuna valutazione finora

- HSE-BMS-010 Permit To WorkDocumento24 pagineHSE-BMS-010 Permit To WorkKhuda BukshNessuna valutazione finora

- Weekly Safety InspDocumento4 pagineWeekly Safety InspKhuda BukshNessuna valutazione finora

- 02 Abrasive WheelsDocumento2 pagine02 Abrasive WheelsKhuda BukshNessuna valutazione finora

- NFPAP Member Registration Form - WordDocumento1 paginaNFPAP Member Registration Form - WordKhuda BukshNessuna valutazione finora

- HSE (Trainor Et Al) - 2006 - HSE Report No 426 ACUTEXDocumento106 pagineHSE (Trainor Et Al) - 2006 - HSE Report No 426 ACUTEXKhuda Buksh100% (1)

- 06 Power Tools OperationDocumento2 pagine06 Power Tools OperationKhuda BukshNessuna valutazione finora

- 03 Wood CuttingDocumento1 pagina03 Wood CuttingKhuda BukshNessuna valutazione finora

- Emergency ProceduresDocumento23 pagineEmergency ProceduresKhuda BukshNessuna valutazione finora

- PPE PROTECTIONDocumento3 paginePPE PROTECTIONKhuda BukshNessuna valutazione finora

- CV Zafar Ul Haq KhokharDocumento1 paginaCV Zafar Ul Haq KhokharKhuda BukshNessuna valutazione finora

- Carbon MonoxideDocumento17 pagineCarbon MonoxideKhuda BukshNessuna valutazione finora

- THE CAREER PLAYBOOK Parent's GuideDocumento45 pagineTHE CAREER PLAYBOOK Parent's GuideRandomHouseAcademicNessuna valutazione finora

- Enigma - HR CrosswordDocumento4 pagineEnigma - HR CrosswordAishwary KoulNessuna valutazione finora

- Quiz 1Documento2 pagineQuiz 1Kurt Morin CantorNessuna valutazione finora

- MANALO et. al. v TNS PHILIPPINES INC. AND OCAMPO (40Documento2 pagineMANALO et. al. v TNS PHILIPPINES INC. AND OCAMPO (40MichaelJohnF.BorjaNessuna valutazione finora

- GRI Reporting - StakeholdersDocumento4 pagineGRI Reporting - StakeholdersdavehidNessuna valutazione finora

- Income Tax on Salary, Allowances & BenefitsDocumento2 pagineIncome Tax on Salary, Allowances & BenefitsBhava Nath DahalNessuna valutazione finora

- Plant Engineering Sep14Documento88 paginePlant Engineering Sep14Marian GresoiuNessuna valutazione finora

- PHARMACIA AND UPJOHN Vs AlbayadaDocumento2 paginePHARMACIA AND UPJOHN Vs Albayadagregoriomanueldon.patrocinioNessuna valutazione finora

- The Benefits of Employee Training & DevelopmentDocumento20 pagineThe Benefits of Employee Training & DevelopmentAcornNessuna valutazione finora

- Chapter 16, Employees Safety and HealthDocumento65 pagineChapter 16, Employees Safety and HealthAbeera100% (1)

- Training and DevelopmentDocumento17 pagineTraining and Developmentankit161019893980Nessuna valutazione finora

- Sa8000 2014 RevisionDocumento63 pagineSa8000 2014 RevisionJohn RajeshNessuna valutazione finora

- Stadium WHS PLANDocumento53 pagineStadium WHS PLANsaher iqbalNessuna valutazione finora

- Bridget Wisnewski ResumeDocumento2 pagineBridget Wisnewski Resumeapi-425692010Nessuna valutazione finora

- Talent Acquisition Assistant Manager - Sheila Pradesia SantosoDocumento2 pagineTalent Acquisition Assistant Manager - Sheila Pradesia SantosoDyah FanniNessuna valutazione finora

- Separation PayDocumento9 pagineSeparation PaylofrancocaNessuna valutazione finora

- F&B Staff Organization GuideDocumento7 pagineF&B Staff Organization GuidebhuvaneswariNessuna valutazione finora

- CV CorectatDocumento3 pagineCV Corectatileana_marzaNessuna valutazione finora

- PeopleSoft HCM PERSON MODELDocumento83 paginePeopleSoft HCM PERSON MODELGanesh.am100% (17)

- CVTemplateDocumento2 pagineCVTemplateClayzingoNessuna valutazione finora

- Labor Relations Final Exam ReviewerDocumento7 pagineLabor Relations Final Exam ReviewershaneivygNessuna valutazione finora

- Hudson Meridian Defects and Due Diligence. Fact Sheet On Letterhead 1-9-16Documento4 pagineHudson Meridian Defects and Due Diligence. Fact Sheet On Letterhead 1-9-16John CarterNessuna valutazione finora

- Case Study - Organizational PoliticsDocumento4 pagineCase Study - Organizational PoliticsDr. Harshada MulayNessuna valutazione finora

- Induction Program Performance and MoraleDocumento107 pagineInduction Program Performance and MoralePaul John BerdanNessuna valutazione finora

- Week 6 & 7Documento29 pagineWeek 6 & 7Vandana MohanNessuna valutazione finora