Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PLC and Control Panel Up-Gradation From Messung To Mitsubishi

Caricato da

IJSTETitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PLC and Control Panel Up-Gradation From Messung To Mitsubishi

Caricato da

IJSTECopyright:

Formati disponibili

IJSTE - International Journal of Science Technology & Engineering | Volume 3 | Issue 06 | December 2016

ISSN (online): 2349-784X

PLC and Control Panel Up-Gradation from

Messung to Mitsubishi

Mr. Vijay Patil

Assistant Professor

Department of Electronics & Telecommunication Engineering

Sandip Foundations, Sandip Institute of Technology and

Research Centre, Nasik, India

Antara Mhatre

Student

Department of Electronics & Telecommunication Engineering

Sandip Foundations, Sandip Institute of Technology and

Research Centre, Nasik, India

Sayli Borade

Student

Department of Electronics & Telecommunication Engineering

Sandip Foundations, Sandip Institute of Technology and

Research Centre, Nasik, India

Kamini Jadhav

Student

Department of Electronics & Telecommunication Engineering

Sandip Foundations, Sandip Institute of Technology and

Research Centre, Nasik, India

Abstract

This research paper is based on the electronic refitting of control unit from older PLC that is Messung PLC to new PLC that is

Mitsubishi PLC and using HMI. The system previously used was with the Messung PLC but now it is replaced to Mitsubishi

PLC .Due to this the productivity has increased, better and good quality have made by Mitsubishi PLC.

Keywords: HMI, Messung PLC, Mitsubishi PLC, Variable Frequency Drive

________________________________________________________________________________________________________

I.

INTRODUCTION

Automation is a controlling process and reducing the use human intervention. PLC is used for controlling function of system and

provides easy reprogramming, proper control and error free work. There are different programming languages that used in PLC

that are Ladder language, Functional block diagram, Sequential Functional chart, Structural Text, Instruction List. When PLC

program is run it will be continually in indefinite loop .An HMI machine is interface between human and machine. Here we have

replaced the Messung PLC with Mitsubishi PLC.

II. LITERATURE SURVEY

1) In [1] According to author of PLC Controlled Low Cost Automatic Packing Machine. In this paper proposed work were

done by using Messung PLC. In this Messung PLC for controlling action of the system effectively action using messung

results in increased production, less time consumption and better safety the employees. But there are some disadvantages of

the Messung PLC that are the modification is more, Scan time is more, Time consuming etc.

2) In [2] According to author of HONING MACHINE SYSTEM WITH PLC. In this paper proposed work were done by

using Honing Machine System. Honing is the process that improves the surface texture and provides proper surface

appearance to look better. This honing operation is one of the most important steps in the production of ball bearing which

is used in car,

3) In [3] According to author of PLC based Control System for Hardening and Tempering Furnace in Heat Treatment Plant.

In this paper proposed work were done by using PLC based Control System for Hardening and Tempering Furnace in Heat

Treatment Plant. The automated process efficiently reduces the Human intervention required and also increases the

efficiency of hardening and tempering raw steel bits. This paper gives very detailed information each of the components

used in this project. This system is controlled with the Messung PLC.

III. EXISTING SYSTEM

Before we have used the Messung PLC that have some disadvantage that are MTTR (Mean time to repair) is more, Modification

is difficult, Scan time is more ,Production is less to overcome all this disadvantages we used Mitsubishi PLC.

IV. PROBLEM STATEMENT

In previous project, we have used Messung PLC. The disadvantages were MTTR (Mean time to repair is more, Modification is

difficult, Production rate is less and Scan time is more. So to avoid this overcome we used Mitsubishi PLC. The Mitsubishi PLC

All rights reserved by www.ijste.org

245

PLC and Control Panel Up-Gradation from Messung to Mitsubishi

(IJSTE/ Volume 3 / Issue 06 / 043)

has the following advantages MTTR (Mean time to repair) is less, Optically isolated input are present, Modification is easy,

Scan time present is less, Production rate present is more, So we have used Mitsubishi PLC for this advantage.

V. PROPOSED OF SYSTEM

Automation is a reducing the human intervention control function to machine for: increasing productivity, reduced time, easily

reprogrammed. This up gradation ensures higher production rate and will minimizes the disadvantages that are occur in Messung

PLC. Also the quality of the product will increase.

VI. OVERVIEW OF SYSTEM

The PLC based automated system controls mainly three types of control functions namely Hydraulic control, Pneumatic control

and Motor control. The aim of PLC and Control panel up-gradation from Messung to Mitsubishi PLC. This is to make a project

which would remove the redundancy of continuously manual work with less efficiency, so with more efficiency the automatic

automation can be produced.

Fig. 1: Block Diagram of the system

VII. MITSUBISHI PLC ON TO A SINGLE SYSTEM

With unique multiple CPU functionality, each process area of different application can be used to controlled by different CPU.

Multiple CPU create an even wider boundaries for the PLC operations which combines up to 4 CPUs on to a single Q series

system, which are dedicated CPUs for Process, Redundant, Motion.

Fig. 2: MITSUBISHI PLC

Comprehensive Range of I/O

Q series includes a comprehensive range of inputs and outputs and intelligent function modules to meet the needs of wide range

of applications. In addition to standard digital and analog input and output types, serial communications, Motion bus, Modbus,

Profibus commutation modules are available to build a robust and ultra-fast network.

All rights reserved by www.ijste.org

246

PLC and Control Panel Up-Gradation from Messung to Mitsubishi

(IJSTE/ Volume 3 / Issue 06 / 043)

VIII. FLOW CHART

Fig. 3: Flowchart of system

IX. APPLICATION

The purpose of PLC in this system is to control and implement the nozzle which is further used as part in bearings which

are used in car.

Pairs of tapered PLC are used in car to simultaneously tolerate the vertical and horizontal force.

X. CHALLENGES TO OVERCOME

After numerous studies have been done based on PLC. Before we have used Messung PLC which has some disadvantages that

are MTTR (Mean time to repair is more, Modification is difficult, Production rate is less and Scan time is more. So to avoid this

overcome we used Mitsubishi PLC.

XI. CONCLUSION

The purpose of the PLC used in this system is to create holes in nozzle using the AGIE machine and removing the water from the

nozzle using the Air blowing unit. This nozzle is used in bearings which are further used in car.

ACKNOWLEDGMENT

The work procedure in this report would not have been completed without the encouragement and support of many people who

gave their precious time and encouragement throughout this period. We would like to sincerely thank our project guide Prof.

Vijay Patil for his guidance and for the patience he showed us during the process of preparation of project from initial conception

of final design and implementation. We would also like to extend our gratefulness to the Head of Department E&TC Prof. Dr.

G.M. Phade. Lab and library in charge for kindly granting us access to lab. We would also like to thank to the teaching and nonteaching staff that helped us from time to time with their own experience and also we would like to express our gratitude to the

core of our heart, principal Prof. Dr. S.T. Gandhe Sir for being supportive and always encouraging.

REFERENCES

[1]

[2]

[3]

Aargau Ganguly1, Naveen Kumar Kumbhare2, Pooja Shinde3, Jayashri P. Joshi4``PLC based Control System for Hardening and Tempering Furnace in

Heat Treatment Plant, International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering Vol. 3, Issue 4, April 2014.

Dipesh Topkhanewalea ,Krithika Raoband Sonal Pawar`` HONING MACHINE SYSTEM WITH PLC, International Journal of Innovative and Emerging

Research in Engineering ,Volume 3, Issue 3, 2016

Shashank Lingappa M.1, Vijayavithal Bongale2, Sreerajendra3 PLC Controlled Low Cost Automatic Packing Machine, International Journal of

Advanced Mechanical Engineering ISSN 2250-3234 Volume 4, November 7 (2014), pp. 803-811.

All rights reserved by www.ijste.org

247

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- 1893 Shadow RunDocumento6 pagine1893 Shadow RungibbamonNessuna valutazione finora

- CCTV Camera Hack With Google Dork ListDocumento3 pagineCCTV Camera Hack With Google Dork ListsarahdianewhalenNessuna valutazione finora

- 21st Bomber Command Tactical Mission Report 146, OcrDocumento54 pagine21st Bomber Command Tactical Mission Report 146, OcrJapanAirRaidsNessuna valutazione finora

- Learning Resource Management Made SimpleDocumento12 pagineLearning Resource Management Made SimpleJosenia ConstantinoNessuna valutazione finora

- MCQ in Services MarketingDocumento83 pagineMCQ in Services Marketingbatuerem0% (1)

- Optimization of Overall Efficiency Using Facilities Planning in Ropp Cap Making IndustryDocumento8 pagineOptimization of Overall Efficiency Using Facilities Planning in Ropp Cap Making IndustryIJSTENessuna valutazione finora

- Design and Analysis of Magneto Repulsive Wind TurbineDocumento7 pagineDesign and Analysis of Magneto Repulsive Wind TurbineIJSTENessuna valutazione finora

- Optimization of Treatability by FACCO For Treatment of Chemical Industry EffluentDocumento9 pagineOptimization of Treatability by FACCO For Treatment of Chemical Industry EffluentIJSTENessuna valutazione finora

- A Mixture of Experts Model For ExtubationDocumento4 pagineA Mixture of Experts Model For ExtubationIJSTENessuna valutazione finora

- Partial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderDocumento7 paginePartial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderIJSTENessuna valutazione finora

- A Cloud Based Healthcare Services For Remote PlacesDocumento4 pagineA Cloud Based Healthcare Services For Remote PlacesIJSTENessuna valutazione finora

- Multipurpose Scheme of Workshop Exhaust System For Ventilation and Electrical Power GenerationDocumento9 pagineMultipurpose Scheme of Workshop Exhaust System For Ventilation and Electrical Power GenerationIJSTENessuna valutazione finora

- FPGA Implementation of High Speed Floating Point Mutliplier Using Log Based DesignDocumento4 pagineFPGA Implementation of High Speed Floating Point Mutliplier Using Log Based DesignIJSTENessuna valutazione finora

- Automatic Generation Control in Three-Area Power System Operation by Using "Particle Swarm Optimization Technique"Documento8 pagineAutomatic Generation Control in Three-Area Power System Operation by Using "Particle Swarm Optimization Technique"IJSTENessuna valutazione finora

- RFID Based Toll Gate AccessDocumento5 pagineRFID Based Toll Gate AccessIJSTENessuna valutazione finora

- Development of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityDocumento6 pagineDevelopment of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityIJSTENessuna valutazione finora

- Effect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsDocumento9 pagineEffect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsIJSTENessuna valutazione finora

- The Bicycle As A Mode Choice - A Gendered ApproachDocumento4 pagineThe Bicycle As A Mode Choice - A Gendered ApproachIJSTENessuna valutazione finora

- A Comprehensive Survey of Techniques/Methods For Content Based Image Retrieval SystemDocumento6 pagineA Comprehensive Survey of Techniques/Methods For Content Based Image Retrieval SystemIJSTENessuna valutazione finora

- A Radar Target Generator For Airborne TargetsDocumento8 pagineA Radar Target Generator For Airborne TargetsIJSTENessuna valutazione finora

- Optimum Placement of DG Units Using CPF MethodDocumento6 pagineOptimum Placement of DG Units Using CPF MethodIJSTENessuna valutazione finora

- An Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabDocumento5 pagineAn Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabIJSTENessuna valutazione finora

- Enriching Gum Disease Prediction Using Machine LearningDocumento6 pagineEnriching Gum Disease Prediction Using Machine LearningIJSTENessuna valutazione finora

- Comparative Study and Analysis of PCC Beam and Reinforced Concrete Beam Using GeogridDocumento7 pagineComparative Study and Analysis of PCC Beam and Reinforced Concrete Beam Using GeogridIJSTENessuna valutazione finora

- Onerider The Bike TaxiDocumento3 pagineOnerider The Bike TaxiIJSTENessuna valutazione finora

- Interstage Construction Techniques For Mass Gain: An OverviewDocumento5 pagineInterstage Construction Techniques For Mass Gain: An OverviewIJSTENessuna valutazione finora

- App-Based Water Tanker Booking, Monitoring & Controlling SystemDocumento6 pagineApp-Based Water Tanker Booking, Monitoring & Controlling SystemIJSTENessuna valutazione finora

- Technology Advancement For Abled PersonDocumento9 pagineTechnology Advancement For Abled PersonIJSTENessuna valutazione finora

- Using The Touch-Screen Images For Password-Based Authentication of IlliteratesDocumento6 pagineUsing The Touch-Screen Images For Password-Based Authentication of IlliteratesIJSTENessuna valutazione finora

- An Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemDocumento5 pagineAn Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemIJSTENessuna valutazione finora

- Wireless Information Process and Power Transfer in Single-User OFDM SystemDocumento6 pagineWireless Information Process and Power Transfer in Single-User OFDM SystemIJSTENessuna valutazione finora

- Optimizing Turning Process For EN43 by Taguchi Method Under Various Machining ParametersDocumento4 pagineOptimizing Turning Process For EN43 by Taguchi Method Under Various Machining ParametersIJSTENessuna valutazione finora

- Research On Storage Privacy Via Black Box and Sanitizable SignatureDocumento6 pagineResearch On Storage Privacy Via Black Box and Sanitizable SignatureIJSTENessuna valutazione finora

- Duplicate Detection Using AlgorithmsDocumento3 pagineDuplicate Detection Using AlgorithmsIJSTENessuna valutazione finora

- Adhokshaj Mishra: Thwarting The Surveillance in Online CommunicationDocumento24 pagineAdhokshaj Mishra: Thwarting The Surveillance in Online CommunicationGauravRajNessuna valutazione finora

- 4PL Supply Chain Transformation SolutionsDocumento2 pagine4PL Supply Chain Transformation SolutionsGourav HegdeNessuna valutazione finora

- Testing concrete and brick strengthDocumento2 pagineTesting concrete and brick strengthlolenlennNessuna valutazione finora

- Artikel Jurnal - Fundamental Differences of Transition To Industry 4.0 From Previous Industrial RevolutionsDocumento9 pagineArtikel Jurnal - Fundamental Differences of Transition To Industry 4.0 From Previous Industrial RevolutionsJohny DoelNessuna valutazione finora

- SEO ProposalDocumento5 pagineSEO ProposalShivdev SaiNessuna valutazione finora

- Galaxy Service ManualDocumento100 pagineGalaxy Service ManualGovind RajNessuna valutazione finora

- College Report of Optical Burst SwitchingDocumento21 pagineCollege Report of Optical Burst Switchingimcoolsha999Nessuna valutazione finora

- Jotafloor SL UniversalDocumento6 pagineJotafloor SL UniversalrogandatambunanNessuna valutazione finora

- Results Part III - Part III-March 2017 - ElectricalDocumento3 pagineResults Part III - Part III-March 2017 - ElectricalTharaka MunasingheNessuna valutazione finora

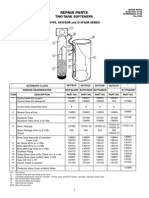

- Star S07FS32DR Water Softener Repair PartsDocumento1 paginaStar S07FS32DR Water Softener Repair PartsBillNessuna valutazione finora

- ICT PresentationDocumento13 pagineICT PresentationThe Leo LoverNessuna valutazione finora

- Designing The Marketing Channels 13Documento13 pagineDesigning The Marketing Channels 13Gajender SinghNessuna valutazione finora

- Seb ProjectDocumento32 pagineSeb ProjectperthlingNessuna valutazione finora

- Audio (Amplifier) - Electrical DiagnosticsDocumento195 pagineAudio (Amplifier) - Electrical DiagnosticsRafael CherechesNessuna valutazione finora

- Sample Style GuideDocumento5 pagineSample Style Guideapi-282547722Nessuna valutazione finora

- Scope of Work Project Sahastradhara Road (GYAN CONSTRUCTIONS)Documento4 pagineScope of Work Project Sahastradhara Road (GYAN CONSTRUCTIONS)Hotel Central palaceNessuna valutazione finora

- PDF Saa6d140e 2 Seriespdf CompressDocumento8 paginePDF Saa6d140e 2 Seriespdf CompressNathawatNessuna valutazione finora

- Astm D-2361Documento4 pagineAstm D-2361Claudia Da Rolt0% (1)

- Managing ImapDocumento408 pagineManaging ImapPriya RaoNessuna valutazione finora

- Engineering Data, Summary of Productivity 2022Documento2 pagineEngineering Data, Summary of Productivity 2022Listya AnggrainiNessuna valutazione finora

- Indus Water Treaty & Emerging Water IssuesDocumento24 pagineIndus Water Treaty & Emerging Water Issuesu1umarNessuna valutazione finora

- Tyre ManufacturingDocumento18 pagineTyre ManufacturingniteshkrisNessuna valutazione finora

- Phase Locked LoopDocumento4 paginePhase Locked LoopsagarduttaNessuna valutazione finora

- BSC Prospectus 2019-20Documento37 pagineBSC Prospectus 2019-20Gaurav VamjaNessuna valutazione finora

- GPT 1-15 LineBackerDocumento4 pagineGPT 1-15 LineBackerazadeazNessuna valutazione finora