Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tipe NGR

Caricato da

Ade Y SaputraTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tipe NGR

Caricato da

Ade Y SaputraCopyright:

Formati disponibili

NR Neutral Grounding Resistors

APPLICATION

Neutral Grounding Resistor

Powerohm Type NR Neutral Grounding Resistors are used

in industrial power systems for resistance grounding of wyeconnected generators and transformers. A neutral grounding resistor limits the fault current to a value which is

sufficient enough to operate protective relays, yet prevent

unwanted fault damage.

Neutral Grounding Resistor Schematic

Transformer or Generator

Secondary

N

To Protective

Relay

CT

R

Neutral Grounding

Resistor

G

DESIGN REQUIREMENTS

Neutral grounding resistors are rated in line-to-neutral

voltage (system voltage divided by 1.732), initial fault

current and maximum time on. Powerohm neutral grounding resistors are designed to dissipate the required amount

of energy and not exceed the temperature limitations of

IEEE Standard 32-1972. As defined in this publication,

the time and temperature ratings for neutral grounding

resistors are as follows:

Short time: Short time ratings are 10 and 60 seconds.

Since short time rated resistors can only withstand rated

current for short periods of time, they are usually used with

fault clearing relays. The short time temperature rise for

the resistive element is 760C.

Extended time: A time on rating greater than ten minutes

which permits temperature rise of resistive elements to

become constant, but limited to an average not more than

90 days per year. The extended temperature rise for the

resistive element is 610C.

Continuous: Capable of withstanding rated current for

an indefinite period of time. The continuous temperature

rise for the resistive element is 385C.

POWEROHM

RESISTORS, INC.

BASIC CONSTRUCTION

Resistor Assembly: The resistor coils consist of a stainless

steel edgewound element wound around a ceramic core

supported on a through-rod. Glazed insulators are attached

to each end of the coils and fastened to a heavy gage,

corrosion resistant frame. The unit is designed to permit the

expansion of supporting rods when submitted to high operating temperatures. Resistor elements are joined by stainless steel connectors, which are welded in place, to form a

positive electrical path.

Safety Enclosure: Our resistor assemblies are available

with grounded safety enclosures to protect personnel and

wildlife from harm. Screened and louvered enclosures are

available in a variety of finishes including painted, powder

coated, mill galvanized, hot-dipped galvanized, aluminum

and stainless steel.

Options: A number of additional options are available

including entrance bushings, current transformers, elevating stands and disconnect switches.

ELECTRICAL TESTS

All units are factory tested in accordance with IEEE Standard 32-1972, specifically Sections 10.1.4 and 10.3.2. The

procedure includes a resistance measurement test to verify

that the tolerance is within + 10%, and an applied potential

test. A copy of the test report is included with each shipped

unit.

5713 13th Street

Katy, Texas 77493

Phone: (281) 391-6800, Fax: (281) 391-6810

Please visit our website at www.powerohm.com

Ratings & Dimensions of Standard Size Units

RATINGS: The following table contains information on the most

common size units, other variations are available.

10 SECOND TIME RATINGS

CATALOG

NUMBER

INITIAL

AMPS

RESISTANCE

1390 VOLTS LINE-TO-NEUTRAL (2400 VOLT SYSTEM)

13.90

NR1390-100-10

100

38

38

6.95

NR1390-200-10

200

38

38

4.63

NR1390-300-10

300

38

38

3.48

NR1390-400-10

400

38

38

2.78

NR1390-500-10

500

38

38

2.32

NR1390-600-10

600

38

38

1.74

NR1390-800-10

800

38

38

1.39

NR1390-1000-10

1000

38

38

APPROX.

WEIGHT

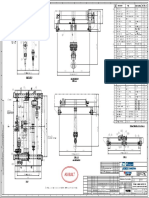

DIMENSIONS: The dimensions listed in the

table are in inches. Information subject to

change without notice.

FRONT VIEW

Neutral Bushing

30

30

30

30

30

30

30

30

280

290

300

310

320

340

350

360

30

30

30

30

30

30

36

36

380

390

400

410

420

430

490

500

Ground

Terminal

2400 VOLTS LINE-TO-NEUTRAL (4160 VOLT SYSTEM)

NR2400-100-10

NR2400-200-10

NR2400-300-10

NR2400-400-10

NR2400-500-10

NR2400-600-10

NR2400-800-10

NR2400-1000-10

100

200

300

400

500

600

800

1000

24.00

12.00

8.00

6.00

4.80

4.00

3.00

2.40

38

38

38

38

38

38

38

38

38

38

38

38

38

38

38

38

RIGHT SIDE VIEW

4160 VOLTS LINE-TO-NEUTRAL (7200 VOLT SYSTEM)

NR4160-100-10

NR4160-200-10

NR4160-300-10

NR4160-400-10

NR4160-500-10

NR4160-600-10

NR4160-800-10

NR4160-1000-10

100

200

300

400

500

600

800

1000

41.60

20.80

13.87

10.40

8.32

6.93

5.20

4.16

38

38

38

38

38

38

44

44

38

38

38

38

38

38

54

54

36

36

36

36

36

36

54

54

550

560

570

580

590

600

680

700

8000 VOLTS LINE-TO-NEUTRAL (13800 VOLT SYSTEM)

NR8000-100-10

NR8000-200-10

NR8000-300-10

NR8000-400-10

NR8000-500-10

NR8000-600-10

NR8000-800-10

NR8000-1000-10

100

200

300

400

500

600

800

1000

80.00

40.00

26.70

20.00

16.00

13.30

10.00

8.00

44

44

44

44

44

44

44

44

54

54

54

54

54

54

54

54

54

54

54

54

54

54

84

84

820

830

840

850

870

880

950

990

30

30

36

320

370

420

36

36

54

450

550

850

54

54

54

900

950

1400

EXTENDED TIME RATINGS

1390 VOLTS LINE-TO-NEUTRAL (2400 VOLT SYSTEM)

NR1390-15-E

NR1390-25-E

NR1390-50-E

15

25

50

92.7

55.6

27.8

38

38

38

38

38

38

2400 VOLTS LINE-TO-NEUTRAL (4160 VOLT SYSTEM)

NR2400-15-E

NR2400-25-E

NR2400-50-E

15

25

50

160.0

96.0

48.0

38

38

44

38

38

54

4160 VOLTS LINE-TO-NEUTRAL (7200 VOLT SYSTEM)

NR4160-15-E

NR4160-25-E

NR4160-50-E

15

25

50

227.3

166.4

83.2

44

44

84

54

54

54

The above drawing details a typical neutral

grounding resistor with enclosure. Units are

available with screened or louvered covers

on front and back. All units normally have

solid tops and sides and a perforated bottom.

TO ORDER A NEUTRAL GROUNDING RESISTOR NOT LISTED IN THE TABLE,

SPECIFY THE FOLLOWING:

1. Line-to-neutral voltage.

2. Initial fault current.

3. Maximum time on.

4. Special requirements or options.

Generator Neutral Grounding Resistors

APPLICATION

Generator Neutral Grounding Resistor

Powerohm offers high resistance grounding equipment for

wye connected generators. Our equipment is normally

designed to limit the line-to-ground fault current to below 15

amps for generators rated up to 14,400 volts. These units will

provide a high resistance neutral during a fault condition,

while allowing the system to operate as an ungrounded

system during normal operating conditions. The configuration basically consists of a dry-type single-phase transformer with a resistor connected across the secondary. The

primary of the transformer is then connected between the

wye point of the generator and ground.

Powerohm generator grounding equipment is normally supplied with the transformer and resistor installed in a common

enclosure. Continuous rated units are usually compartmentalized to separate the resistor assembly from the transformer which is subject to overheating. Units do not normally

include any relaying or control circuitry, but do offer the

transformer secondary wired to a terminal block installed in

an external junction box.

WYE-CONNECTED

GENERATOR

N

R

TO PROTECTIVE

RELAY

GROUNDING

TRANSFORMER

G

BASIC CONSTRUCTION

Transformer: For continuous time ratings, the transformer

must be capable of withstanding rated current for an indefinite period of time; therefore, the KVA rating of the grounding

transformer is equal to the rated line-to-neutral voltage times

the desired neutral current. For a short-time rating, the KVA

rating of a grounding transformer will be smaller because the

unit is designed to carry its rated current for a limited time.

Resistor Assembly: The resistance value is calculated by

dividing the secondary voltage by the rated current necessary to obtain the desired fault current on the primary.

Resistor elements are selected to best meet the current and

voltage requirements of the system. A typical assembly

includes all stainless steel elements, bus bars and

terminals.

Safety Enclosure: Our grounding assemblies are available

in grounded NEMA 1 or NEMA 3R safety enclosures,

complete with nearly any finish including mill galvanized,

power coated, hot dipped galvanized after fabrication, aluminum or stainless steel.

Options: A number of additional options are available,

including entrance bushings, current transformers, elevating stands, and disconnect switches.

ELECTRICAL TESTS

All units are factory tested in accordance with IEEE Standard 32-1972, specifically Sections 10.1.4 and 10.3.2. The

procedure includes a resistance measurement test to verify

that the tolerance is within + 10%, and an applied potential

test. A copy of the test report is included with each shipped

unit.

Resistance Grounding with a Zigzag Transformer

Zigzag Grounding Transformer with Resistor

APPLICATION

The best way to resistance ground a power system is to

obtain the system neutral through a generator or transformer with a wye-connected winding. However, a system

neutral may not be available, particularly in many older low

voltage systems and a significant number of existing

medium voltage systems. To avoid the high cost of replacing

a source transformer, an existing delta-connected system

can be grounded using a zigzag transformer to form an

artificial neutral, then connecting a resistor between the

newly created wye-point and ground.

A zigzag transformer has no secondary winding, and is

designed to provide a low-impedance path for the zerosequence currents to flow. During a line-to-ground fault

condition, the zero sequence currents can flow into the

ground at the point of the fault, and back through the neutral

of the grounding transformer. The impedance of the zigzag

transformer to balanced three-phase voltages is relatively

high, therefore, when there is no fault on the system, only a

small magnetizing current flows in the windings. A zigzag

grounding transformer provides a stable neutral point which

makes possible its use for grounding an otherwise isolated

neutral system.

A zigzag transformer with a resistance ground is normally

designed for a short time rating of 10 to 60 seconds.

Consequently, the grounding transformer is much smaller in

size than an ordinary continuously rated transformer with

the same rating. For short time ratings, the short time

temperature rise for the resistive element is 760C.

TO UNGROUNDED

3-PHASE VOLTAGE

SOURCE

TO UNGROUNDED

3-PHASE LOAD

ZIGZAG

TRANSFORMER

BASIC CONSTRUCTION

Transformer: For a short time rating, the grounding

transformer is designed to carry its rated current for a limited

time, consequently the unit is ordinarily much smaller,

physically, than an ordinary three-phase transformer for the

same rated kVA.

Resistor Assembly: The resistance value is calculated by

dividing the line-to-neutral voltage by the rated neutral

current. Resistor elements are selected to best meet the

short time current rating and voltage requirements of the

system. A typical assembly includes all stainless steel

elements, bus bars and terminals.

Safety Enclosure: Our grounding assemblies are available

in grounded NEMA 1 or NEMA 3R safety enclosures,

complete with nearly any finish, including mill galvanized,

power coated, hot dipped galvanized after fabrication, aluminum, or stainless steel.

Options: A number of additional options are available

including entrance bushings, current transformers, elevating stands and disconnect switches.

ELECTRICAL TESTS

R

RESISTOR

All units are factory tested in accordance with IEEE Standard 32-1972, specifically Sections 10.1.4 and 10.3.2. The

procedure includes a resistance measurement test to verify

that the tolerance is within + 10%, and an applied potential

test. A copy of the test report is included with each shipped

unit.

Potrebbero piacerti anche

- NGRDocumento4 pagineNGRrakeshshinganeNessuna valutazione finora

- Ngcat00 PDFDocumento4 pagineNgcat00 PDFK.RamachandranNessuna valutazione finora

- NGR Guide PDFDocumento4 pagineNGR Guide PDFajaymannNessuna valutazione finora

- Cag14 PDFDocumento5 pagineCag14 PDFnchandru84850% (1)

- Design EngineeringDocumento6 pagineDesign EngineeringNoel JenningsNessuna valutazione finora

- Neutral Grounding ResistorsDocumento5 pagineNeutral Grounding Resistorsnhan209a100% (1)

- Resistance Grounded Systems: PurposeDocumento6 pagineResistance Grounded Systems: Purposerenjithas2005Nessuna valutazione finora

- Gt110-08 NGR TransDocumento2 pagineGt110-08 NGR TransRaviteja NowduruNessuna valutazione finora

- Earthing TransformerDocumento7 pagineEarthing Transformerabhi_akNessuna valutazione finora

- Resistance GroundingDocumento4 pagineResistance Groundingjawad_13Nessuna valutazione finora

- NGR PDFDocumento4 pagineNGR PDFmanicheNessuna valutazione finora

- NGRDocumento2 pagineNGRAchint RajputNessuna valutazione finora

- VTT 11 12Documento6 pagineVTT 11 12rajabharath12Nessuna valutazione finora

- Otn, Otr, Otf TransformersDocumento6 pagineOtn, Otr, Otf TransformersDott PalmitoNessuna valutazione finora

- Low Voltage Air-Breaker 600V BelowDocumento19 pagineLow Voltage Air-Breaker 600V BelowonyekaNessuna valutazione finora

- Industrial Rectifier BrochureDocumento12 pagineIndustrial Rectifier Brochure666667Nessuna valutazione finora

- ABB Applying High Impedance Differential Protection With IED 670Documento9 pagineABB Applying High Impedance Differential Protection With IED 670Neelakandan MasilamaniNessuna valutazione finora

- Neutral Grounding ResistorDocumento4 pagineNeutral Grounding ResistorViswanathan VNessuna valutazione finora

- Shunt&Series Reactors and Their FactoryDocumento64 pagineShunt&Series Reactors and Their FactoryAnonymous 2l8XJIV100% (1)

- Daewoo Dtq-20u9sc 21u9ss CsDocumento10 pagineDaewoo Dtq-20u9sc 21u9ss CsgongussNessuna valutazione finora

- CAG14Documento8 pagineCAG14aja295Nessuna valutazione finora

- ALSTOM Instntneous Voltage Relay VAGM HighResDocumento4 pagineALSTOM Instntneous Voltage Relay VAGM HighResMorgan Brooks0% (1)

- Nitronex An9Documento9 pagineNitronex An9sanghomitraNessuna valutazione finora

- Selection of Switchyard EquipmentDocumento64 pagineSelection of Switchyard EquipmentKunzes Dolkar100% (2)

- RM st60Documento2 pagineRM st60Hồ ThànhNessuna valutazione finora

- LineTrapsAir Core, Dry TypeDocumento8 pagineLineTrapsAir Core, Dry TypeSINU0607IITEEENessuna valutazione finora

- Reliable Protection For Systems, Generators and Motors Up To 1600 ADocumento32 pagineReliable Protection For Systems, Generators and Motors Up To 1600 Ataufiq4923Nessuna valutazione finora

- Commutation ChokesDocumento10 pagineCommutation Chokestudor_x27Nessuna valutazione finora

- Auxiliary Units For 7SR23 Catalogue Sheet PDFDocumento12 pagineAuxiliary Units For 7SR23 Catalogue Sheet PDFSteven RodriquezNessuna valutazione finora

- 1VGA671067 - ZVC Reactor StarterDocumento2 pagine1VGA671067 - ZVC Reactor StarterKhajonsak SratonghoonNessuna valutazione finora

- HiZ Auxiliary Units Catalogue SheetDocumento12 pagineHiZ Auxiliary Units Catalogue SheetSteven RodriquezNessuna valutazione finora

- PirDocumento31 paginePirdilipelineNessuna valutazione finora

- 2010 11 IAS PresentationDocumento32 pagine2010 11 IAS PresentationNorozKhanNessuna valutazione finora

- Guidelines For Selecting Trigger Circuits For Thyristors: Basic RequirementsDocumento4 pagineGuidelines For Selecting Trigger Circuits For Thyristors: Basic RequirementsEngr Armghan ZafarNessuna valutazione finora

- Finder CatalogueDocumento18 pagineFinder CatalogueGeorge GeorgeNessuna valutazione finora

- Service Manual: ModelDocumento60 pagineService Manual: ModeldonobeeNessuna valutazione finora

- Sharp 27ks100 SMDocumento62 pagineSharp 27ks100 SMperseo232Nessuna valutazione finora

- Difference Between Vacuum Circuit Breaker & Vacuum ContactorDocumento2 pagineDifference Between Vacuum Circuit Breaker & Vacuum ContactorMohan K67% (3)

- Frako ProductsDocumento56 pagineFrako Productserkamlakar2234Nessuna valutazione finora

- Neutral Earthing ResistorsDocumento4 pagineNeutral Earthing ResistorsjaytamijNessuna valutazione finora

- 14T1LDocumento53 pagine14T1Lsuranovi6858100% (2)

- Grounding TransformersDocumento4 pagineGrounding Transformersmuaz_aminu1422Nessuna valutazione finora

- GE Surge ArresterDocumento22 pagineGE Surge ArresterMohamed SamyNessuna valutazione finora

- Reg No#23 (Talha Saleem)Documento11 pagineReg No#23 (Talha Saleem)Talha ChaudryNessuna valutazione finora

- LUCY SwitchgearDocumento8 pagineLUCY SwitchgearHillary McgowanNessuna valutazione finora

- Digital Testing of HV Circuit BreakerDocumento21 pagineDigital Testing of HV Circuit Breakervamshi4all100% (10)

- 3ee, Ef Seimens Surge ArrestersDocumento32 pagine3ee, Ef Seimens Surge ArrestersKenneth ParkerNessuna valutazione finora

- CURRENT TRANSFORMERS - GoodDocumento4 pagineCURRENT TRANSFORMERS - GoodNguyễn QuyềnNessuna valutazione finora

- Switchyard FinalDocumento6 pagineSwitchyard FinalPritam SamantaNessuna valutazione finora

- Measurement of High Voltages and CurrentsDocumento35 pagineMeasurement of High Voltages and Currentssyed1188Nessuna valutazione finora

- Instrument Transformer CVT TransformerDocumento6 pagineInstrument Transformer CVT Transformerkajrare_1947Nessuna valutazione finora

- Submitted To, Name-Mr. Ankush Tandon Sir (Assistant Professor)Documento15 pagineSubmitted To, Name-Mr. Ankush Tandon Sir (Assistant Professor)Himanshu Soni100% (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesDa EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNessuna valutazione finora

- 110 Waveform Generator Projects for the Home ConstructorDa Everand110 Waveform Generator Projects for the Home ConstructorValutazione: 4 su 5 stelle4/5 (1)

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionNessuna valutazione finora

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- Cable Sizing and Schedule-R - 02 - (As BUILT)Documento6 pagineCable Sizing and Schedule-R - 02 - (As BUILT)Ade Y SaputraNessuna valutazione finora

- SEMA AH Hook Block Assly. Sheet 2 3Documento1 paginaSEMA AH Hook Block Assly. Sheet 2 3Ade Y SaputraNessuna valutazione finora

- SEMA MH Hook Block Assly. Sheet 1 3Documento1 paginaSEMA MH Hook Block Assly. Sheet 1 3Ade Y SaputraNessuna valutazione finora

- Paper Title (Use Style - Paper Title)Documento6 paginePaper Title (Use Style - Paper Title)Ade Y SaputraNessuna valutazione finora

- Fuse Modular Terminal Block - DT 6/2,5-DREHSILED 24 (5X20) - 3034251Documento18 pagineFuse Modular Terminal Block - DT 6/2,5-DREHSILED 24 (5X20) - 3034251Ade Y SaputraNessuna valutazione finora

- 2MLD09-0100-01664365 B: ClientDocumento1 pagina2MLD09-0100-01664365 B: ClientAde Y SaputraNessuna valutazione finora

- Section:A-A': Typical Power JointDocumento1 paginaSection:A-A': Typical Power JointAde Y SaputraNessuna valutazione finora

- Acsr SPLN 41-7 PDFDocumento2 pagineAcsr SPLN 41-7 PDFAde Y Saputra100% (1)

- 3147 Hoist r3Documento1 pagina3147 Hoist r3Ade Y SaputraNessuna valutazione finora

- 50 AMP WELDER ReceptacleDocumento2 pagine50 AMP WELDER ReceptacleAde Y SaputraNessuna valutazione finora

- Acsr Din en 50182Documento1 paginaAcsr Din en 50182Ade Y SaputraNessuna valutazione finora

- Star - DeltaDocumento4 pagineStar - DeltaAde Y SaputraNessuna valutazione finora

- Jual Besi Pipa Galvanis Medium - Harga Distributor - TokoBesiBajaDocumento5 pagineJual Besi Pipa Galvanis Medium - Harga Distributor - TokoBesiBajaAde Y SaputraNessuna valutazione finora

- Variable Frequency DriveDocumento40 pagineVariable Frequency DriveAde Y Saputra100% (1)

- Gantt Chart From Buckman To Install Equipment PPM# 7Documento3 pagineGantt Chart From Buckman To Install Equipment PPM# 7Ade Y SaputraNessuna valutazione finora

- PPM #7 High Pressureshower Piping ChecklistDocumento1 paginaPPM #7 High Pressureshower Piping ChecklistAde Y SaputraNessuna valutazione finora

- Engineering Note: PT - Indah Kiat Pulp & Paper TBKDocumento8 pagineEngineering Note: PT - Indah Kiat Pulp & Paper TBKAde Y SaputraNessuna valutazione finora

- NGR GarutRev1Documento1 paginaNGR GarutRev1Ade Y SaputraNessuna valutazione finora

- 2X30Mw Coal Fired Power Plant Project Tawang Moinit - North Sulawesi Design Review Pltu Amurang-MinahasaDocumento1 pagina2X30Mw Coal Fired Power Plant Project Tawang Moinit - North Sulawesi Design Review Pltu Amurang-MinahasaAde Y SaputraNessuna valutazione finora

- Buckman Installation Equipment Biocide N FCDocumento1 paginaBuckman Installation Equipment Biocide N FCAde Y SaputraNessuna valutazione finora

- Form A WeekDocumento2 pagineForm A WeekAde Y SaputraNessuna valutazione finora

- Specification of Nalco Equipment NO Equipment Name Spesification/Unit QTY Dimension Tag NumberDocumento2 pagineSpecification of Nalco Equipment NO Equipment Name Spesification/Unit QTY Dimension Tag NumberAde Y SaputraNessuna valutazione finora

- Untitled - Bus LoadingDocumento32 pagineUntitled - Bus LoadingAde Y SaputraNessuna valutazione finora

- Pt. Indah Kiat Pulp & Paper Corp. TBK: Prepared By: Zulhendra / Stepanus M Approv By: RizwanDocumento2 paginePt. Indah Kiat Pulp & Paper Corp. TBK: Prepared By: Zulhendra / Stepanus M Approv By: RizwanAde Y SaputraNessuna valutazione finora

- JVC Lt-26c31bje (ET)Documento38 pagineJVC Lt-26c31bje (ET)sabre504Nessuna valutazione finora

- Password Based Door Lock System Using 8051 MicrocontrollerDocumento18 paginePassword Based Door Lock System Using 8051 MicrocontrollerAdharsh SurendhiranNessuna valutazione finora

- 19 LED Animated Christmas StarDocumento38 pagine19 LED Animated Christmas StarJane-Josanin ElizanNessuna valutazione finora

- Electrical Circuits, PowerDocumento8 pagineElectrical Circuits, PowerYash KshirsagarNessuna valutazione finora

- Cro Bar CalculationDocumento2 pagineCro Bar CalculationRamakrishnan AlagarsamyNessuna valutazione finora

- Codigos Error Crown SC 5245-40Documento56 pagineCodigos Error Crown SC 5245-40MIGUEL PEÑA78% (9)

- Spesifikasi JuknisDocumento96 pagineSpesifikasi JuknisbisriNessuna valutazione finora

- K7QO - QRP - Laboratory PDFDocumento136 pagineK7QO - QRP - Laboratory PDFdetroit_me2553100% (1)

- IPC-MC-790 en Guidelines For Multichip Module Technology UtilizationDocumento15 pagineIPC-MC-790 en Guidelines For Multichip Module Technology UtilizationcdmingNessuna valutazione finora

- Dtc113 Zm/Ze/Zua/Zca/Zsa NPN Small Signal Transistor: Package Packing Marking Part NoDocumento3 pagineDtc113 Zm/Ze/Zua/Zca/Zsa NPN Small Signal Transistor: Package Packing Marking Part Nodjahid abdullohNessuna valutazione finora

- Electricity Exercises 1Documento31 pagineElectricity Exercises 1topcat100% (1)

- Accuspin 1 120V 230VDocumento60 pagineAccuspin 1 120V 230VAndrew HolmesNessuna valutazione finora

- Electives 2 Part 3Documento155 pagineElectives 2 Part 3Johnfer AquinoNessuna valutazione finora

- Fire Safety and Alerting System in RailwaysDocumento6 pagineFire Safety and Alerting System in RailwaysMo DiggaNessuna valutazione finora

- Electricity: NameDocumento2 pagineElectricity: NameWilfredo Nellas BalbonaNessuna valutazione finora

- Experiment 3: To Verify Kirchhoff's Voltage and Current Laws ExperimentallyDocumento3 pagineExperiment 3: To Verify Kirchhoff's Voltage and Current Laws ExperimentallyWaseem HaiderNessuna valutazione finora

- Melody Technical Manual - Chapter04Documento10 pagineMelody Technical Manual - Chapter04Nassima BELILNessuna valutazione finora

- Daewoo Cm900 Chassis Dtc25g1vm TV SMDocumento41 pagineDaewoo Cm900 Chassis Dtc25g1vm TV SMtipudelacablutvNessuna valutazione finora

- Vansco VMM Diagnostics Rev 6 - CUBEXDocumento27 pagineVansco VMM Diagnostics Rev 6 - CUBEXHector Sepulveda Orellana100% (3)

- Lbyec2e Assignment1Documento1 paginaLbyec2e Assignment1Danica Allyana NgNessuna valutazione finora

- UFS Application Note - Nt358E00Documento14 pagineUFS Application Note - Nt358E00Ankur TomarNessuna valutazione finora

- VF PS1 BrochureDocumento23 pagineVF PS1 Brochurethienvuong90Nessuna valutazione finora

- STRAIN GAUGES-ppt1Documento31 pagineSTRAIN GAUGES-ppt1Stuti ParmarNessuna valutazione finora

- NovaSensor NPH 081114 Low Pressure To 8Documento4 pagineNovaSensor NPH 081114 Low Pressure To 8pfalencarNessuna valutazione finora

- Hr598d-p (Hr500) Bfrallk Lgefs Afn35914271 EvDocumento97 pagineHr598d-p (Hr500) Bfrallk Lgefs Afn35914271 EvfanchheizNessuna valutazione finora

- Service Manual: Wi-Fi & 3D Ready / DVB-T / T2 / C / S / S2 PAL / Secam System Colour TelevisionDocumento148 pagineService Manual: Wi-Fi & 3D Ready / DVB-T / T2 / C / S / S2 PAL / Secam System Colour TelevisionOnet Dorel100% (1)

- M2252D PS PDFDocumento36 pagineM2252D PS PDFCarmen da SilvaNessuna valutazione finora

- Fan 6961Documento13 pagineFan 6961Ariel NavarreteNessuna valutazione finora

- A Peak Hold Energy Readout Circuit For Use With Pyroelectric Laser Energy MonitorsDocumento3 pagineA Peak Hold Energy Readout Circuit For Use With Pyroelectric Laser Energy Monitorspasargad135106Nessuna valutazione finora

- Ee - Module 3 - April 2012Documento3 pagineEe - Module 3 - April 2012Znevba Quintano100% (2)