Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Assignment 2 (Storage Tanks)

Caricato da

Maria Cecille Sarmiento GarciaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Assignment 2 (Storage Tanks)

Caricato da

Maria Cecille Sarmiento GarciaCopyright:

Formati disponibili

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Department of Chemical Engineering

Assignment No. 2

Double Dehydration of Oil Palm Empty

Fruit Bunch for the Production of

Isosorbide

(Design of Storage Tanks)

Equipment Design, Lecture

Submitted By:

Abad, Goldie Mae C.

Barros, Diego Sylvano J.

Garcia, Maria Cecille S.

Mercurio, Maria Fatima DS.

Submitted To:

Engr. April Anne Tigue

Double Dehydration of Oil Palm (Elaeis guineensis) Empty Fruit Bunch

9

for the Production of Isosorbide

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Department of Chemical Engineering

July 29, 2015

Water Storage Tank

A. Design Description

Water Storage Tank is specifically designed to hold and transport water

to the dilution tanks to prepare the concentration of the chemicals to

be used in the production of isosorbide.

B. Design Selection

The storage tank with ellipsoidal dishes was selected since the water to

be stored can be maintained at room temperature thus is considered to

be a low pressure vessel. It is also more economical to use as

compared with hemispherical cylinders and spheres.

C. Principle of Operation

The tank is composed of two nozzles: (1) feed inlet, and (2) water

outlet. The water will be fed into the feed inlet located a few points

from the level of the tank. When the water is needed, a valve is used to

regulate the flow into the outlet nozzle located at the bottom of the

tank.

D. Materials of Construction

The equipment will be constructed using a stainless steel Type 301

which is the most common material for low-cost general purpose which

is used when corrosion is not severe. In this case, water is not corrosive

and reactive. The material can also withstand a temperature range of

0-100C which is suitable to the operation since it will be stored at

room temperature. The maximum allowable tensile stress for steel is

11,000 psi up to 650F (p. 62, Process Equipment Design, Hesse et. al).

E. Data and Assumption

1. The capacity of tank is good for a three day operation.

2. The volume of water needed is 40000 L per day. (Based from

material balance).

Double Dehydration of Oil Palm (Elaeis guineensis) Empty Fruit Bunch

9

for the Production of Isosorbide

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Department of Chemical Engineering

3. The density of water at 25C is 997.042 kg/m3 (Perrys Chemical

Engineering Handbook 8th edition, sec 2-91).

F. Design Consideration

1. Minimum corrosion allowance is employed with 1/16 in. taken

from Process Equipment Design by Hesse, p. 73.

2. The tank has a storage capacity of 80% of the total capacity of

the tank from the average of 80-90% range from existing

performances of commercially available storage tanks.

3. Overall uncertainties often do fall in the range of 10-20%. Thus,

to cancel this out the same amount of safety factor should be

used. A 20% safety factor will be used (p. 7, Chemical Process

Equipment, Selection and Design, Couper et. al).

4. The efficiency of lap-welded joints is 80% (Plant Design and

Economics

for

Chemical

Engineers,

5th

ed.,

Peters

and

Timmerhaus, pg. 555. Table 12-10).

5. The height to diameter ratio of the tank is 2 (Perrys Chemical

Engineering Handbook 7th edition by Perry and Green, pg 10139).

G. Design Requirements

1. Tank Capacity

2. Tank Dimensions

a. Diameter

b. Height

c. Shell Thickness

d. Head and bottom thickness

H. Design Equations and Calculation

1. Tank Capacity

V eachtank =120,000 L=120 m3

Considering the 80% filling capacity of a standard storage tank,

and a safety factor of 20%,

Double Dehydration of Oil Palm (Elaeis guineensis) Empty Fruit Bunch

9

for the Production of Isosorbide

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Department of Chemical Engineering

120 m3

V t =1.2

0.80

V t =180 m3

2. Tank Diameter

V =V cylinder +V ellipsoidalhead bottom

2

V=

2

4 D

D H+

h

4

3

2

( )

Where:

D = Tank Diameter

H = Tank Height

h = Head Elliptical Depth

Since H = 2D and h=1/4 of the inner diameter of the head (or D)

in standard ellipsoidal tanks, based from Process Equipment

Design by Hesse, page 86,

4 D 2

V = D2 H +

h

4

3

2

( )

V=

2(

4 D

D 2 D)+

4

3

2

( ) ( D4 )

3 D3

V= D +

2

12

V=

7 3

D

12

180 m3 =

7 3

D

12

D=4.6139 m

Use D = 5 m

3. Tank Height

H= 2D

Since depth for Ellipsoidal head and bottom is D/4,

D

H h+b =2 =0.5 D

4

H total=2 D+0.5 D=2.5 D

Double Dehydration of Oil Palm (Elaeis guineensis) Empty Fruit Bunch

9

for the Production of Isosorbide

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Department of Chemical Engineering

H total=2.5 ( 4.6139 m )=11.5348 m

Use H = 12 m

4. Shell Thickness

Using equation 4-3, Process Equipment Design by Hesse page

85:

t S=

pD

+C

2 Se p

Where:

tS= thickness of the plate

p = Internal Pressure

D = Internal Diameter

S= Allowable Working Stress

e = Efficiency

C = Corrosion Allowance

To solve for the value of S, use equation 41, Process Equipment

Design by Hesse:

S = (SU)(Fm)(Fa)(Fs)

Where:

SU = 11000 psi (Table 3.1, Process Equipment Design by

Hesse)

Fm = 1.00 for high tensile strength carbon steels

Fa = Fr =1.00 since radiographing and stress relieving is

not required

Fs = 0.25 (Table 4.2, Process Equipment Design by Hesse)

Therefore:

S = 11000 x 1.00 x 1.00 x 1.00 x 0.25 = 2750 Psi

Solving the internal pressure, p:

kg

lb

=997.042

=62.2433

m3

ft 3

p=

Hg

=

gc

( 11.5348 m ) x

1 ft

lb

x 62.2433 3

0.3048 m

ft

144 2

1 ft 2

=16.3578 psi

Double Dehydration of Oil Palm (Elaeis guineensis) Empty Fruit Bunch

9

for the Production of Isosorbide

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Department of Chemical Engineering

Assume C = 1/16,

0.3048 m

1

16.3578 Psi ( 4.6139 m )

+

2 ( 2750 ) ( 0.80 )16.3578 Psi 16

t S =

12

t S=0.7403 18.80 mm

Use tS = 19 mm

5. Head and Bottom Thickness

Use equation 45 of Process Equipment Design by Hesse for

standard ellipsoidal head and bottom:

pD

t H=

2 Se

Where:

tS= thickness of the plate

p = Internal Pressure

D = Internal Diameter

S= Allowable Working Stress

e = Efficiency and adding 1/16 in. as Corrosion Allowance.

12

0.3048 m 1

16.3578 psi x ( 4.6139m ) x

+

2 ( 2750 ) ( 0.80 ) 16

t H =

t H =0.7378 18.74 mm

Use tH = 19 mm

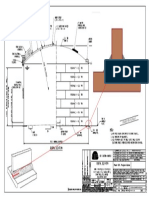

DESIGN SPECIFICATION: WATER STORAGE TAN

Design Function

Double Dehydration of Oil Palm (Elaeis guineensis) Empty Fruit Bunch

9

for the Production of Isosorbide

De

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Department of Chemical Engineering

Water Storage Tank is

specifically designed to hold

and transport water to the

dilution tanks to prepare the

concentration of the

chemicals to be used in the

production of isosorbide.

Th

ell

selec

m

te

con

pres

more

hemis

Content

Gauge

Fill Pipe

Shell Plates

Vessel

Base

Outlet

Stream

It is suitable for hydrostatic depth

measurement

It provides the pathway for the

feedstock in entering the vessel

These are metallic plates that are

joint together to create the outer

covering of the storage tank

It is the primary structure that

provides containment of water

It serves as the support system for

the vessel

It provides the exit for the water

effluent

Cut Away View

Design Parts and Utility

Double Dehydration of Oil Palm (Elaeis guineensis) Empty Fruit Bunch

9

for the Production of Isosorbide

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Department of Chemical Engineering

2.56 m3

2.56 m3

Design Dimensions

Tank Capacity

180 m3

Orientation

Other De

Vertical

Mat

Material of Co

Tank Height

12 m

Shell Thickness

19 mm

Tank Diameter

5m

Head Thickness

19 mm

Residence Time

3 days

Support

Bracket

Support

Double Dehydration of Oil Palm (Elaeis guineensis) Empty Fruit Bunch

9

for the Production of Isosorbide

Accessories:

Potrebbero piacerti anche

- Concrete Pipe Installation Guide-CPMDocumento17 pagineConcrete Pipe Installation Guide-CPMSankar CdmNessuna valutazione finora

- Storage Tank DesignDocumento42 pagineStorage Tank Designronavanessa70% (10)

- BOQ Air Liquide Project (Diesel Tank)Documento19 pagineBOQ Air Liquide Project (Diesel Tank)Remmo S Ardiansyah100% (1)

- Inspection and Refurbishment of Floating, Fixed Roof and Sphere Storage TanksDocumento97 pagineInspection and Refurbishment of Floating, Fixed Roof and Sphere Storage TanksOsama HadiNessuna valutazione finora

- Geodesic Aluminum Dome & Cover Roof Specification API 650 Appendix GDocumento6 pagineGeodesic Aluminum Dome & Cover Roof Specification API 650 Appendix GpassionNessuna valutazione finora

- Chevron Specification TAM-MN-2Documento9 pagineChevron Specification TAM-MN-2Burak GülenNessuna valutazione finora

- GS 158-1 Internal Floating Decks For Storage Tanks: March 1998Documento38 pagineGS 158-1 Internal Floating Decks For Storage Tanks: March 1998Mohd KhairulNessuna valutazione finora

- Proposed Rule: Domestic Mail Manual: Domestic Mailing Services New StandardsDocumento45 pagineProposed Rule: Domestic Mail Manual: Domestic Mailing Services New StandardsJustia.comNessuna valutazione finora

- VaconoDome Technical CommentaryDocumento29 pagineVaconoDome Technical CommentaryOmar GRNessuna valutazione finora

- Tank Fabrication SpecsDocumento21 pagineTank Fabrication Specsjlcheefei9258100% (1)

- Shop Fabrication Inspection: 1 Material Receiving Inspection ReportDocumento7 pagineShop Fabrication Inspection: 1 Material Receiving Inspection ReportManoj PrabakaranNessuna valutazione finora

- BTE Dome Brochure Jun 10Documento2 pagineBTE Dome Brochure Jun 10م.ذكى فضل ذكىNessuna valutazione finora

- Annular Plate RemovalDocumento2 pagineAnnular Plate RemovalVishvjeet Prakash TiwariNessuna valutazione finora

- Bunded Steel Fuel Tanks - SmallDocumento1 paginaBunded Steel Fuel Tanks - SmallNAHASALI11Nessuna valutazione finora

- OSHA Standard For Fixed Ladders SummaryDocumento12 pagineOSHA Standard For Fixed Ladders SummarysesabcdNessuna valutazione finora

- Molasses Tank 18092020Documento31 pagineMolasses Tank 18092020Keshav GopaulNessuna valutazione finora

- Tanks PresentationDocumento29 pagineTanks Presentationkrish585100% (1)

- Introduction To Storage Tanks & Api650Documento12 pagineIntroduction To Storage Tanks & Api650Dhakshina KNessuna valutazione finora

- Chapter One General Introduction: 1.1 Background StudyDocumento32 pagineChapter One General Introduction: 1.1 Background StudyBassey ItaNessuna valutazione finora

- Storage Tank DesignDocumento6 pagineStorage Tank DesignlinevisionlimitedNessuna valutazione finora

- Presser Vessel DesignDocumento30 paginePresser Vessel DesignAsila Ahmed100% (1)

- BlowersDocumento58 pagineBlowersmahmad61100% (1)

- Tank GADocumento1 paginaTank GASubramanianNessuna valutazione finora

- 114-F - OASE Solution Storage Tank - R0 PDFDocumento33 pagine114-F - OASE Solution Storage Tank - R0 PDFManish542Nessuna valutazione finora

- Work Procedure Pipe SupportDocumento10 pagineWork Procedure Pipe Supportmc chesterNessuna valutazione finora

- Cat 120H, 12H, 140H, 143H, 160H, 163H TransmisiónDocumento8 pagineCat 120H, 12H, 140H, 143H, 160H, 163H TransmisiónJefferson Maldonado.Nessuna valutazione finora

- Name Designation JOB Job Description Crew NoDocumento52 pagineName Designation JOB Job Description Crew NoattaullaNessuna valutazione finora

- Pressure Vessel Design: Chapter 13: Mechanical Design of Process Equipment by Towler & SinnotDocumento40 paginePressure Vessel Design: Chapter 13: Mechanical Design of Process Equipment by Towler & SinnotEzekielNessuna valutazione finora

- Scissor Shoe Installation Guide Jan 2005 PDFDocumento32 pagineScissor Shoe Installation Guide Jan 2005 PDFMohsen Halweni50% (2)

- JMS For Erection of Stiffener Angle With Existing Curb Channel With Erection of Deflector Plate Arrangement For Tank006Documento9 pagineJMS For Erection of Stiffener Angle With Existing Curb Channel With Erection of Deflector Plate Arrangement For Tank006AshutoshNessuna valutazione finora

- Engineering Design Guide For Storage TanksDocumento107 pagineEngineering Design Guide For Storage Tankssonng.engNessuna valutazione finora

- 500 Shell Design PDFDocumento28 pagine500 Shell Design PDFaliNessuna valutazione finora

- 2.2.3 Floating Roof Tanks: Figure 1.4 Single Deck Pontoon Type Floating Roof (Bob. L & Bob. G, N.D, p.155)Documento3 pagine2.2.3 Floating Roof Tanks: Figure 1.4 Single Deck Pontoon Type Floating Roof (Bob. L & Bob. G, N.D, p.155)evrim77100% (1)

- Case StudyDocumento11 pagineCase StudyJesusa Nambio Sapungan100% (1)

- Tanks - BasicDocumento15 pagineTanks - BasicDedy WindiyantoNessuna valutazione finora

- Storage Tank Design and TypesDocumento28 pagineStorage Tank Design and TypesHariq HannNessuna valutazione finora

- 47 Sorbitol Storage Tank Oct20Documento6 pagine47 Sorbitol Storage Tank Oct20Karl RaymundoNessuna valutazione finora

- Tankfarm Area DesignDocumento10 pagineTankfarm Area DesignPrasanna kumar subudhi100% (1)

- Hot Bolting FPSO BrazilDocumento1 paginaHot Bolting FPSO BrazilKhan Arshi100% (1)

- IELTS Speaking Part 1 Dos and Don'tsDocumento4 pagineIELTS Speaking Part 1 Dos and Don'tsMaria Cecille Sarmiento GarciaNessuna valutazione finora

- 2015 References Terminals EDocumento59 pagine2015 References Terminals EAllyson JohnsonNessuna valutazione finora

- Tks 324 Mechanical Design of Process Equipment-01Documento62 pagineTks 324 Mechanical Design of Process Equipment-01Rahani Hyuga100% (1)

- Vertical Steel Tank Storage Tank DrawingDocumento2 pagineVertical Steel Tank Storage Tank DrawingbharathpeNessuna valutazione finora

- Storage Tanks & Vessels DesignDocumento27 pagineStorage Tanks & Vessels DesignBassem Balghouthi100% (1)

- Tender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Documento7 pagineTender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Shilpa SinghNessuna valutazione finora

- External Floating Roof Tank Design & ComponentsDocumento2 pagineExternal Floating Roof Tank Design & Componentsarif99pakNessuna valutazione finora

- Jsa For Roof Air LiftDocumento2 pagineJsa For Roof Air LiftKoshy ThankachenNessuna valutazione finora

- 6-12-0001 Rev 6 General Spec For Pressure VesselsDocumento15 pagine6-12-0001 Rev 6 General Spec For Pressure Vesselsravi2007Nessuna valutazione finora

- Datasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDocumento4 pagineDatasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDylan RamasamyNessuna valutazione finora

- Ladder and Self Closing Gate For Storage TankDocumento15 pagineLadder and Self Closing Gate For Storage TankAkshat JainNessuna valutazione finora

- Karmatech Brochure 2Documento8 pagineKarmatech Brochure 2Anonymous 3akQhQFJSLNessuna valutazione finora

- 2015 Orooji Pardis Lessons Learned From Decommissioning of A Liqud Ammonia Storage TankDocumento19 pagine2015 Orooji Pardis Lessons Learned From Decommissioning of A Liqud Ammonia Storage TankAdnan AliNessuna valutazione finora

- TSM Tank JackingDocumento2 pagineTSM Tank JackingLuis LugoNessuna valutazione finora

- Drawing Autocad 2dDocumento5 pagineDrawing Autocad 2dMuhammad Muzamil MazriNessuna valutazione finora

- Vacono Erection ManualDocumento60 pagineVacono Erection Manualjfilipovic67% (3)

- Multiple Storage Tank Fabrication Procedure (US Patent 4142284)Documento5 pagineMultiple Storage Tank Fabrication Procedure (US Patent 4142284)PriorSmart100% (1)

- Engineering Thermodynamics ProblemsDocumento3 pagineEngineering Thermodynamics Problemsdhruv0010% (1)

- AWS A5.12: Material Safety Data Sheet (MSDS)Documento3 pagineAWS A5.12: Material Safety Data Sheet (MSDS)Mani VannanNessuna valutazione finora

- Abschn 14Documento3 pagineAbschn 14Vikas NaikNessuna valutazione finora

- Foundation Option For LNG TanksDocumento2 pagineFoundation Option For LNG TankssekarsanthanamNessuna valutazione finora

- ITP F TK-4101 & TK-4201 A/B: Persian Gulf Star Gas Condensate Refinery-Kal Station Booster PumpDocumento20 pagineITP F TK-4101 & TK-4201 A/B: Persian Gulf Star Gas Condensate Refinery-Kal Station Booster PumpHamid MansouriNessuna valutazione finora

- Types of BoilerDocumento8 pagineTypes of Boilerjay0% (1)

- Annex C External Floating RoofDocumento1 paginaAnnex C External Floating Roofamshiv0% (1)

- MQ SP M 4003 PDFDocumento18 pagineMQ SP M 4003 PDFjaseelNessuna valutazione finora

- GLACIER LAr Tank Design (Deliverable 2.2)Documento76 pagineGLACIER LAr Tank Design (Deliverable 2.2)atiqulaNessuna valutazione finora

- Ateco Internal Floating Roof Datasheets Form PDF FormatDocumento2 pagineAteco Internal Floating Roof Datasheets Form PDF FormatatecotanksNessuna valutazione finora

- Water Storage Tank Design DescriptionDocumento5 pagineWater Storage Tank Design Descriptiondanena88Nessuna valutazione finora

- Perencanaan Make Up Water Tank Kapasitas 500 KL PLTGU Blok I, II, & Iii PT PJB Up GresikDocumento9 paginePerencanaan Make Up Water Tank Kapasitas 500 KL PLTGU Blok I, II, & Iii PT PJB Up GresikMaman GocekNessuna valutazione finora

- Kuya 48Documento5 pagineKuya 48Maria Cecille Sarmiento GarciaNessuna valutazione finora

- IELTS General Reading Test 2. Section 3Documento3 pagineIELTS General Reading Test 2. Section 3Maria Cecille Sarmiento GarciaNessuna valutazione finora

- IELTS General Reading Test 2. Section 1Documento4 pagineIELTS General Reading Test 2. Section 1Maria Cecille Sarmiento GarciaNessuna valutazione finora

- A Review On Process Fault Detection and DiagnosisDocumento3 pagineA Review On Process Fault Detection and DiagnosisMaria Cecille Sarmiento GarciaNessuna valutazione finora

- Packaging DevelopmentDocumento46 paginePackaging DevelopmentMaria Cecille Sarmiento GarciaNessuna valutazione finora

- Fluid MechDocumento7 pagineFluid MechMaria Cecille Sarmiento GarciaNessuna valutazione finora

- Heat TransferDocumento6 pagineHeat TransferMaria Cecille Sarmiento GarciaNessuna valutazione finora

- Case Studies For AppraisalDocumento9 pagineCase Studies For AppraisalMaria Cecille Sarmiento GarciaNessuna valutazione finora

- Science and Technology Writing Task 2 Questions For IeltsDocumento1 paginaScience and Technology Writing Task 2 Questions For IeltsMaria Cecille Sarmiento GarciaNessuna valutazione finora

- Instrumentation and Process Control LayoutDocumento2 pagineInstrumentation and Process Control LayoutMaria Cecille Sarmiento GarciaNessuna valutazione finora

- With Page No.1Documento5 pagineWith Page No.1Maria Cecille Sarmiento GarciaNessuna valutazione finora

- Re AttendanceDocumento3 pagineRe AttendanceMaria Cecille Sarmiento GarciaNessuna valutazione finora

- Gambide Chemicals: Innovating Isosorbide Production from Agricultural WasteDocumento2 pagineGambide Chemicals: Innovating Isosorbide Production from Agricultural WasteMaria Cecille Sarmiento GarciaNessuna valutazione finora

- Chemical Characteristics and Its ApplicationsDocumento1 paginaChemical Characteristics and Its ApplicationsMaria Cecille Sarmiento GarciaNessuna valutazione finora

- LabDocumento4 pagineLabMaria Cecille Sarmiento GarciaNessuna valutazione finora

- PLANNING TECHNICAL ACTIVITIESDocumento29 paginePLANNING TECHNICAL ACTIVITIESMaria Cecille Sarmiento GarciaNessuna valutazione finora

- CHE 412 CHE Thermodynamics IIDocumento4 pagineCHE 412 CHE Thermodynamics IIMaria Cecille Sarmiento GarciaNessuna valutazione finora

- CHE 424 Process and Dynamics ControlDocumento6 pagineCHE 424 Process and Dynamics ControlMaria Cecille Sarmiento GarciaNessuna valutazione finora

- CHE 427 Field Trips and SeminarsDocumento4 pagineCHE 427 Field Trips and SeminarsMaria Cecille Sarmiento GarciaNessuna valutazione finora

- Chemical Conversion of Biomass To Green ChemicalsDocumento32 pagineChemical Conversion of Biomass To Green ChemicalsMaria Cecille Sarmiento GarciaNessuna valutazione finora

- WasDocumento1 paginaWasMaria Cecille Sarmiento GarciaNessuna valutazione finora

- Che 431Documento4 pagineChe 431Maria Cecille Sarmiento GarciaNessuna valutazione finora

- CHE 413 Momentum TransferDocumento4 pagineCHE 413 Momentum TransferMaria Cecille Sarmiento GarciaNessuna valutazione finora

- Chemical Characteristics and Its ApplicationsDocumento1 paginaChemical Characteristics and Its ApplicationsMaria Cecille Sarmiento GarciaNessuna valutazione finora

- Chemical Characteristics and Its ApplicationDocumento9 pagineChemical Characteristics and Its ApplicationMaria Cecille Sarmiento GarciaNessuna valutazione finora

- Conceptual, Theoretical Framework and Methodology: Pamantasan NG Lungsod NG MaynilaDocumento84 pagineConceptual, Theoretical Framework and Methodology: Pamantasan NG Lungsod NG MaynilaMaria Cecille Sarmiento GarciaNessuna valutazione finora

- INDUSTRIAL SECURITY KEY FACTORSDocumento5 pagineINDUSTRIAL SECURITY KEY FACTORSMaria Cecille Sarmiento GarciaNessuna valutazione finora

- CRCM Manual 2 9 16Documento33 pagineCRCM Manual 2 9 16Kamagara Roland AndrewNessuna valutazione finora

- The Properties of WaterDocumento6 pagineThe Properties of WaterannisyaNessuna valutazione finora

- Wind Load CompututationsDocumento31 pagineWind Load Compututationskim suarezNessuna valutazione finora

- ATS1801 - Interface PC - ImpDocumento8 pagineATS1801 - Interface PC - ImpluismantonioNessuna valutazione finora

- Ricoh 301 PARTS CATALOGDocumento68 pagineRicoh 301 PARTS CATALOGbefremdenNessuna valutazione finora

- Baja Parts Catalog PX250S Motorcycle VIN Prefix LUAHDocumento20 pagineBaja Parts Catalog PX250S Motorcycle VIN Prefix LUAHholycostNessuna valutazione finora

- Fall Protection Marking GuidelinesDocumento2 pagineFall Protection Marking GuidelinescuervohijoguachoNessuna valutazione finora

- Time Table Spring 2017 18Documento10 pagineTime Table Spring 2017 18SuvamNessuna valutazione finora

- Argelith Lieferprogramm GBDocumento24 pagineArgelith Lieferprogramm GBmutyokaNessuna valutazione finora

- Ee09 704 - Electrical Machine Design Model QPDocumento2 pagineEe09 704 - Electrical Machine Design Model QPGīřïşh McNessuna valutazione finora

- 70005144e 1314001 PDFDocumento501 pagine70005144e 1314001 PDFLuis FernandoNessuna valutazione finora

- Evaporative Pre CoolerDocumento46 pagineEvaporative Pre CoolerLizbeth Ramirez AlanyaNessuna valutazione finora

- Canusa GTS - 3LPEDocumento2 pagineCanusa GTS - 3LPEarifin rizalNessuna valutazione finora

- DESIGN II - ChemTran General Reference GuideDocumento332 pagineDESIGN II - ChemTran General Reference GuideDebabrata MitraNessuna valutazione finora

- DiGas 4000 Light E 08.02Documento2 pagineDiGas 4000 Light E 08.02manit1963Nessuna valutazione finora

- Electrostatic and Electromagnetic Forces: Electronic Address: Tim - Henley@mail - Utoronto.caDocumento9 pagineElectrostatic and Electromagnetic Forces: Electronic Address: Tim - Henley@mail - Utoronto.caTimothy Murray HenleyNessuna valutazione finora

- Dokumen - Tips Carte Ford C Max 2007Documento278 pagineDokumen - Tips Carte Ford C Max 2007Rostás MiklósNessuna valutazione finora

- Deterministic Inventory Control FormulasDocumento6 pagineDeterministic Inventory Control FormulasvivekNessuna valutazione finora

- Signals and Systems - MjrobertsDocumento3 pagineSignals and Systems - Mjrobertspriyakanthr5883100% (1)

- Transmission ErrorDocumento7 pagineTransmission ErrorTapas JenaNessuna valutazione finora

- FTS ScaleoEUserManualEN 10 1082177Documento2.044 pagineFTS ScaleoEUserManualEN 10 1082177JNessuna valutazione finora

- Company Profile 2021Documento18 pagineCompany Profile 2021Hamza FaheemNessuna valutazione finora

- GameBoy Programming ManualDocumento298 pagineGameBoy Programming Manualdiceman2037100% (4)

- Sauer-Danfoss Loop Flushing ValveDocumento8 pagineSauer-Danfoss Loop Flushing Valvedmt wayNessuna valutazione finora