Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Steel Scrap - 1373692311

Caricato da

swapnilnagare0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

23 visualizzazioni1 paginaSteel Scrap_1373692311

Titolo originale

Steel Scrap_1373692311

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoSteel Scrap_1373692311

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

23 visualizzazioni1 paginaSteel Scrap - 1373692311

Caricato da

swapnilnagareSteel Scrap_1373692311

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

May 2013

Indian scrap industry

Ferrous Scrap is an essential input in Mini steel industry.

Steel is most recyclable material. The US is the largest

exporter in the world, and ships over 90 countries including

China, South Korea, Turkey, Taiwan and India. Turkey is the

largest importer of scrap.

Cast iron scraps of different categories are available in

India. Scraps, generated by sectors such as

Automobiles, Railways, and Engineering are pressed

into bundles. Ship breaking is the major source of

scrap generation with largest concentration in the

West Coast of India. Major production sites are

Gujarat, Mumbai, and Kolkata. Alang and Sosiya yards

of Bhavnagar accounts for 90% of scrap breaking

industry concentration. In the public sector, MSTC

(Metal Scrap Trade Corporation Ltd.) and FSNL (Ferro

Scrap Nigam Ltd.) are involved in scrap trading and

recovery activities respectively.

Apart from the US, India imports also from the UK and

Netherland. Secondary steelmakers are the largest

importers of steel scrap. The total ferrous scrap import in

India is 6.03 MT (2011-12). Indian steel mills import mostly

shredded or Heavy Melting Steel (HMS) grades. This

constitutes around 65% of total import.

The world produces about a total of 10 MTPA of stainless

steel scrap. India imports about 1 MT of these scrap. Many

units use 50-60% imported scrap as raw material for

production of stainless steel. Jindal Stainless is the largest

producer of stainless steel in India.

Steel scrap is most recyclable material. With the use of

scrap in steel making, there is 74% saving on electricity

over virgin steel produced from iron ore. This also

reduces emissions. This CO2 emission is 58% less

compared to virgin steel produced from iron ore. It

helps in energy conservation.

It also reduces load on land fill disposal units and

prevents abandoned steel products in environment.

@ copyright Eastern Resources 2013

Potrebbero piacerti anche

- Sterlite Industries Limited: The Federation of UniversitiesDocumento21 pagineSterlite Industries Limited: The Federation of Universitieskohinoor_roy5447Nessuna valutazione finora

- Environmental IssuesDocumento8 pagineEnvironmental IssueskaumaaramNessuna valutazione finora

- Cover PagedssadfsafasDocumento2 pagineCover PagedssadfsafasVipul JindalNessuna valutazione finora

- Sterlite Industries (India) LimitedDocumento9 pagineSterlite Industries (India) Limitedbhanu_sbiNessuna valutazione finora

- ISRI Fact Iron Steel 041213Documento1 paginaISRI Fact Iron Steel 041213Rohit RanjanNessuna valutazione finora

- Tata Steel and SailDocumento25 pagineTata Steel and SailVikas VimalNessuna valutazione finora

- Study of Red Mud As An Alternative Building Material For Interlocking Block Manufacturing in Construction IndustryDocumento7 pagineStudy of Red Mud As An Alternative Building Material For Interlocking Block Manufacturing in Construction Industryneerj2996Nessuna valutazione finora

- Steel IndustryDocumento21 pagineSteel IndustryBhupen YadavNessuna valutazione finora

- MIning IndustryDocumento37 pagineMIning Industrypkjain009Nessuna valutazione finora

- Cluster IronDocumento31 pagineCluster IronPraneeth Kumar V RNessuna valutazione finora

- Iron and Steel IndustryDocumento17 pagineIron and Steel IndustryEMJAY100% (1)

- Zinc MarketDocumento10 pagineZinc Marketchandoo.upadhyayNessuna valutazione finora

- Metals 210708Documento24 pagineMetals 210708aaNessuna valutazione finora

- Strengths-: Swot Analysis of Steel SectorDocumento5 pagineStrengths-: Swot Analysis of Steel SectorPrakhar BhatnagarNessuna valutazione finora

- Iron and Steel Industry in IndiaDocumento16 pagineIron and Steel Industry in IndiaAnonymous gQyrTUHX38100% (1)

- IntroductionDocumento114 pagineIntroductionBahish VadakkanNessuna valutazione finora

- SteelDocumento1 paginaSteelAnees Abdul LatheefNessuna valutazione finora

- Assignment of MarketingDocumento9 pagineAssignment of MarketingHemant DubeyNessuna valutazione finora

- Iron Ore PPT Ann ThomasDocumento5 pagineIron Ore PPT Ann Thomasannthomas1428Nessuna valutazione finora

- CCI Iron and Steel Industry in IndiaDocumento16 pagineCCI Iron and Steel Industry in IndiaShubham KhattriNessuna valutazione finora

- Iron and Steel 2009 - Industry AnalyticsDocumento75 pagineIron and Steel 2009 - Industry AnalyticsGaurav Kumar100% (5)

- Commodity Profile - Copper: Properties & UsesDocumento11 pagineCommodity Profile - Copper: Properties & UsesAnup Kumar O KNessuna valutazione finora

- A Study of Electronic Data Storage Steel Factory in Mumbai11 150218034403 Conversion Gate02Documento51 pagineA Study of Electronic Data Storage Steel Factory in Mumbai11 150218034403 Conversion Gate02NIKHIL CHAUHANNessuna valutazione finora

- Importance of Mineral Based IndustriesDocumento2 pagineImportance of Mineral Based Industriesshadow146Nessuna valutazione finora

- Uttara Satish Lokita Prashan T Rahul Rinaldo Shekhar: Group Name: Show SteelersDocumento57 pagineUttara Satish Lokita Prashan T Rahul Rinaldo Shekhar: Group Name: Show SteelersSantanu SamantaNessuna valutazione finora

- Capital BudgetingDocumento105 pagineCapital BudgetingAjay Kumar Mahto100% (1)

- Study of Red Mud As An Alternative Building Material For Interlocking Block Manufacturing in Construction IndustryDocumento6 pagineStudy of Red Mud As An Alternative Building Material For Interlocking Block Manufacturing in Construction IndustrySalahuddin QuadriNessuna valutazione finora

- A Report On Merger and Acquisition OF Tata-CorusDocumento70 pagineA Report On Merger and Acquisition OF Tata-CorusKshitiz PandyaNessuna valutazione finora

- Business Marketing AssingmentDocumento8 pagineBusiness Marketing AssingmentAyush SharmaNessuna valutazione finora

- The Way Forward - Vision 2020Documento9 pagineThe Way Forward - Vision 2020Animesh SharmaNessuna valutazione finora

- Vtu HR Project On Employee Job Satisfaction.Documento70 pagineVtu HR Project On Employee Job Satisfaction.Naveen Babu DNessuna valutazione finora

- Analysis Effectiveness Training and Development Programme in SailDocumento11 pagineAnalysis Effectiveness Training and Development Programme in Sailpratiksha singhNessuna valutazione finora

- Perspective 1010Documento7 paginePerspective 1010Narendra MuppasaniNessuna valutazione finora

- Critical Analysis of Essar SteelDocumento7 pagineCritical Analysis of Essar SteelNikita KashyapNessuna valutazione finora

- Logistics of Indian Steel IndustryDocumento28 pagineLogistics of Indian Steel Industryvishalchandu86% (7)

- Mineral and Energy ResourcesDocumento9 pagineMineral and Energy ResourcesgamersahabdeepNessuna valutazione finora

- Fact Sheet Steel and Raw MaterialsDocumento2 pagineFact Sheet Steel and Raw MaterialsSravanNessuna valutazione finora

- Marketing Strategies and 4 P's of Bokaro SteelDocumento73 pagineMarketing Strategies and 4 P's of Bokaro SteelAmit Kumar100% (7)

- MSPLDocumento16 pagineMSPLYashaswini SNessuna valutazione finora

- Scope and Potential of Indian Aluminium Industry: An Indepth AnalysisDocumento11 pagineScope and Potential of Indian Aluminium Industry: An Indepth Analysisvivekjain007Nessuna valutazione finora

- Essar Steel Finance ReportDocumento53 pagineEssar Steel Finance ReportJigar PatelNessuna valutazione finora

- Chapter1: Industry Profile: 1.1) ZINCDocumento46 pagineChapter1: Industry Profile: 1.1) ZINCsyed bismillahNessuna valutazione finora

- Why Steel Consumption in India Should Rise?Documento4 pagineWhy Steel Consumption in India Should Rise?fahrgeruste3961Nessuna valutazione finora

- Steel: A Cornerstone of The World's EconomyDocumento6 pagineSteel: A Cornerstone of The World's EconomyWaleed BaigNessuna valutazione finora

- MA Presentation FinalDocumento16 pagineMA Presentation FinalTapas PalNessuna valutazione finora

- Project Report On Comparative Analysis of Public and Private Sector Steel Companies in IndiaDocumento57 pagineProject Report On Comparative Analysis of Public and Private Sector Steel Companies in IndiaDharminder KumarNessuna valutazione finora

- Aluminium Industry in IndiaDocumento3 pagineAluminium Industry in IndiakabifcNessuna valutazione finora

- Original Kalyani ReportDocumento70 pagineOriginal Kalyani ReportRahul Yargattikar100% (1)

- Project Report On Comparative Analysis of Public and Private Sector Steel Companies in IndiaDocumento48 pagineProject Report On Comparative Analysis of Public and Private Sector Steel Companies in IndiaHillary RobinsonNessuna valutazione finora

- Bhushan Power & Steel LimitedDocumento64 pagineBhushan Power & Steel LimitedSyaape100% (1)

- Processing of Indium A ReviewDocumento8 pagineProcessing of Indium A Reviewpmanquera89Nessuna valutazione finora

- AntimonyDocumento4 pagineAntimonyabhay_pratap_2Nessuna valutazione finora

- Production and ConsumptionDocumento3 pagineProduction and ConsumptionPulak SarkarNessuna valutazione finora

- Iron and Steel Industries in IndiaDocumento9 pagineIron and Steel Industries in IndiaSushil HongekarNessuna valutazione finora

- Steel Industries Problem by Amitab - MudgalDocumento22 pagineSteel Industries Problem by Amitab - MudgalRavinder Singh PadamNessuna valutazione finora

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkDa EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNessuna valutazione finora

- METALLURGY AND WHEELS - The Story of Men, Metals and MotorsDa EverandMETALLURGY AND WHEELS - The Story of Men, Metals and MotorsNessuna valutazione finora

- Heat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingDa EverandHeat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingValutazione: 1 su 5 stelle1/5 (1)

- Extractive Metallurgy 2: Metallurgical Reaction ProcessesDa EverandExtractive Metallurgy 2: Metallurgical Reaction ProcessesValutazione: 5 su 5 stelle5/5 (1)

- Forging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingDa EverandForging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingValutazione: 5 su 5 stelle5/5 (1)

- Us Ma Mergers and Acquisitions Trends 2016 Year End Report PDFDocumento15 pagineUs Ma Mergers and Acquisitions Trends 2016 Year End Report PDFswapnilnagareNessuna valutazione finora

- NEW SEC System in IndiaDocumento38 pagineNEW SEC System in IndiaAjay GupteNessuna valutazione finora

- 2014 Danaher Analyst Event PresentationDocumento110 pagine2014 Danaher Analyst Event PresentationswapnilnagareNessuna valutazione finora

- Netmagic Mumbai Data Center BrochureDocumento3 pagineNetmagic Mumbai Data Center BrochureswapnilnagareNessuna valutazione finora

- Knowledge Builder CapsuleDocumento38 pagineKnowledge Builder Capsuleaggarwalmegha100% (1)

- Soft Drinks PMDocumento8 pagineSoft Drinks PMswapnilnagareNessuna valutazione finora

- Product Placement in BollywoodDocumento6 pagineProduct Placement in BollywoodswapnilnagareNessuna valutazione finora

- SL1000 - PpaDocumento16 pagineSL1000 - PpaswapnilnagareNessuna valutazione finora

- In TMT e Commerce in India Noexp PDFDocumento27 pagineIn TMT e Commerce in India Noexp PDFSagar GuptaNessuna valutazione finora

- 2014 Danaher Analyst Event PresentationDocumento110 pagine2014 Danaher Analyst Event PresentationswapnilnagareNessuna valutazione finora

- Solar Park GuidelinesDocumento51 pagineSolar Park Guidelinesswapnilnagare100% (1)

- Deq WB Wws CBRTAProductGuideDocumento296 pagineDeq WB Wws CBRTAProductGuideswapnilnagareNessuna valutazione finora

- Data File E Tailing Market in IndiaDocumento17 pagineData File E Tailing Market in IndiaswapnilnagareNessuna valutazione finora

- Knowledge Builder CapsuleDocumento38 pagineKnowledge Builder Capsuleaggarwalmegha100% (1)

- Guide On Creating A Basic Drupal Website: Open Your Website and Login With Your Drupal Website Username and PasswordDocumento13 pagineGuide On Creating A Basic Drupal Website: Open Your Website and Login With Your Drupal Website Username and PasswordswapnilnagareNessuna valutazione finora

- Brita E14Documento2 pagineBrita E14swapnilnagareNessuna valutazione finora

- Kotler Summary PDFDocumento238 pagineKotler Summary PDFOmar Hasan100% (3)

- Mckinsey ReviewDocumento3 pagineMckinsey ReviewSubha RudraNessuna valutazione finora

- 2011 FM End TermDocumento9 pagine2011 FM End TermswapnilnagareNessuna valutazione finora

- Consumer Behaviour For Fruit Juices Mark PDFDocumento6 pagineConsumer Behaviour For Fruit Juices Mark PDFswapnilnagareNessuna valutazione finora

- Date CP Price/Unit Units CP BrokerageDocumento8 pagineDate CP Price/Unit Units CP BrokerageswapnilnagareNessuna valutazione finora

- MC Course Book SoftDocumento260 pagineMC Course Book Softswapnilnagare100% (3)

- Docoding of Part CodesDocumento1 paginaDocoding of Part CodesswapnilnagareNessuna valutazione finora

- WAC DhaniramDocumento8 pagineWAC DhaniramswapnilnagareNessuna valutazione finora

- WAC PapfishDocumento11 pagineWAC PapfishswapnilnagareNessuna valutazione finora

- New Doc 2Documento20 pagineNew Doc 2swapnilnagareNessuna valutazione finora

- A New Way To Measure Word-Of Mouth MarketingDocumento9 pagineA New Way To Measure Word-Of Mouth MarketingsoortyNessuna valutazione finora

- Case1 1,1 2,2 1,2 2,2 3,3 1,3 2,4 1,4 2,5 1 pb2 6,3 9Documento20 pagineCase1 1,1 2,2 1,2 2,2 3,3 1,3 2,4 1,4 2,5 1 pb2 6,3 9amyth_dude_9090100% (2)

- Transporter BrochureDocumento8 pagineTransporter BrochuresandrofriasNessuna valutazione finora

- Child Labour PolicyDocumento4 pagineChild Labour Policysvyasjaydip1990Nessuna valutazione finora

- Artigo Sobre Laminados de BlisterDocumento4 pagineArtigo Sobre Laminados de BlisterSeidler Rodrigo Santos ZiserNessuna valutazione finora

- D 70 Product Data 10 15Documento2 pagineD 70 Product Data 10 15marcos crisostoNessuna valutazione finora

- 1210.0 Gas Piping InstallationDocumento8 pagine1210.0 Gas Piping InstallationHu Hin AngNessuna valutazione finora

- Spiral Groove BearingDocumento2 pagineSpiral Groove BearingrichartinNessuna valutazione finora

- Iws Journal Oct 18 Weld 17 Bead 3Documento24 pagineIws Journal Oct 18 Weld 17 Bead 3Vijay KumarNessuna valutazione finora

- iBend-Catalog (WEB - ENG) 201904Documento21 pagineiBend-Catalog (WEB - ENG) 201904MOISESNessuna valutazione finora

- Power Distribution System (PDS) Alba Line 6 ExpansionDocumento1 paginaPower Distribution System (PDS) Alba Line 6 ExpansionSatish KumarNessuna valutazione finora

- Bauxite & AluminaDocumento18 pagineBauxite & AluminaPehtemNessuna valutazione finora

- MECH1210 LEC04 Material Removal Processes TurningDocumento60 pagineMECH1210 LEC04 Material Removal Processes Turningmaryam.saleh.alyamani2204971Nessuna valutazione finora

- A Fabrication Report On AMMCDocumento58 pagineA Fabrication Report On AMMCSai RamNessuna valutazione finora

- AHSS Joining - An Investigation of Resistance Welding Performance of AHSSDocumento115 pagineAHSS Joining - An Investigation of Resistance Welding Performance of AHSSAlief PambudhiNessuna valutazione finora

- Innopur Sport Pu Binder-100Documento2 pagineInnopur Sport Pu Binder-100Govardhan Ravi100% (1)

- Essay 9 Corrosion Removal and ReprotectionDocumento2 pagineEssay 9 Corrosion Removal and ReprotectionDenver Jude BrittoNessuna valutazione finora

- Course Objective... : Chapter 1 - 1Documento15 pagineCourse Objective... : Chapter 1 - 1carlos pucciniNessuna valutazione finora

- Welding - Recommendations For Welding of Metallic MaterialsDocumento32 pagineWelding - Recommendations For Welding of Metallic MaterialsBouzaida MaherNessuna valutazione finora

- WR-PR-015 Pressure VesselDocumento20 pagineWR-PR-015 Pressure Vesselarsil5840Nessuna valutazione finora

- OME553 Industrial Safety Engineering: (Open Elective)Documento47 pagineOME553 Industrial Safety Engineering: (Open Elective)Jana garan.s100% (1)

- Cu1 - Design Arc Welding WSQDocumento2 pagineCu1 - Design Arc Welding WSQAfthabNessuna valutazione finora

- Product CatalogDocumento107 pagineProduct CatalogRizwan FaridNessuna valutazione finora

- Baumer NV4 DS 1208Documento2 pagineBaumer NV4 DS 1208BillwallaNessuna valutazione finora

- C617 Capping Cylindrical Concrete Specimens-3Documento1 paginaC617 Capping Cylindrical Concrete Specimens-3Fitria RindangNessuna valutazione finora

- TSB1503G: Toyota Engineering StandardDocumento18 pagineTSB1503G: Toyota Engineering StandardKrzysztof KołodziejczykNessuna valutazione finora

- 000-ENP-REQ Rev 4Documento6 pagine000-ENP-REQ Rev 4Emma TaroniNessuna valutazione finora

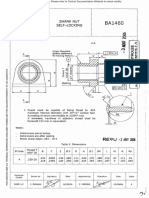

- Shank Nut Self-Locking: REPU-2AOUT2006Documento3 pagineShank Nut Self-Locking: REPU-2AOUT2006Renato WatanabeNessuna valutazione finora

- 05315Documento4 pagine05315Adnan ColoNessuna valutazione finora

- Kenmore 385.19110 Sewing Machine Instruction ManualDocumento83 pagineKenmore 385.19110 Sewing Machine Instruction ManualiliiexpugnansNessuna valutazione finora

- 09 Samss 030Documento8 pagine09 Samss 030Kalanithi KasirajanNessuna valutazione finora

- 07 - Redox ReactionsDocumento55 pagine07 - Redox ReactionsenderothNessuna valutazione finora