Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Informe Lab 2 Estructuras

Caricato da

Andrés ToalaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Informe Lab 2 Estructuras

Caricato da

Andrés ToalaCopyright:

Formati disponibili

I.

EXECUTIVE SUMMARY

In this laboratory session, we determine the mechanical properties of materials

common to marine structures. For this we have done two experiments one of

traction and another of flexion to samples of materials like aluminium, steel and

bronze. In the first experiment tensions were applied to aluminium and steel

specimens until the rupture occurred. In this test, we obtained data of applied

load in intervals of time, with these we could obtain the graph of stress vs

deformation. To determine the stresses of maximum stress and rupture, in

addition to the yield stress and reduction in the cross-sectional area of the

specimen. While for the second part, the experiment of four point bending test

was carried out, in which the unitary deformations in both directions were

measured through extensometers, which correlates the Poisson coefficient. It

was also possible to obtain the Young's Module through an empirical equation

that relates the longitudinal deformation of the test rod with the applied load and

the relative positions of the supports and the loads. The results and graphs

obtained coincide with the standard values of the properties already known of

the materials used for the experiments.

II.

INTRODUCTION

If a material is stressed, the length of the material increases and eventually, if

the force applied is large, the material may rupture. In this report, will study the

connection between the effects of forces (stresses) and the deformations that

they produce in a sample of material.

The stress test is used to evaluate various mechanical properties of the

materials that are important in the design, within which the resistance of metals

and alloys is emphasized.

The mechanical properties that are important engineering and can be deduced

from the stress-strain test are:

1.

2.

3.

4.

5.

Young modulus

Elastic limit at 0.2%

Maximum tensile strength

Percentage of fracture elongation

Percentage reduction in fracture area

When a rod is flexed, it undergoes an elongation by its convex portion and a

contraction by the concave. The elastic characteristics of the rod are

determined by the Young's modulus of the material of which it is made and its

Poisson's coefficient, . Thus, the value of said modulus can be determined by

bending experiments.

III.

SUMMARY OF EXPERIMENT DESIGN

a. PROBLEM STATEMENT

General Objective: To determine experimentally basic mechanical

properties of common marine structural materials.

o Specific objective:

Experiment 1: To determine Young modulus and Poisson

ratio of some structural materials.

Experiment 2: To determine yield strength, yield point

elongation, tensile strength, elongation, and reduction of

area.

Problem:

o Experiment 1: Aluminum and steel specimens under stress

o Experiment 2: Aluminum, steel and bronze rods under flexion

Hypothesis:

o Experiment 1: Strictly the Hookes Law is worth up to the

proportionality limit

o Experiment 2: The elastic characteristics of a material are defined

by its Young's modulus and its Poisson coefficient.

b. VARIABLES

Direct variables:

o Experiment 1: Length, Breadth, Thickness, Load

o Experiment 2: Load, Length between loads, Length between

supports, Breadth, Thickness.

Indirect variables:

o Experiment 1: Stress, Strain.

o Experiment 2: Young modulus, Poisson ratio, Strain.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- PDFDocumento44 paginePDFRebecca Hartman75% (4)

- Characteristics of DC Motor: 1. Torque-Armature Current CharacteristicsDocumento8 pagineCharacteristics of DC Motor: 1. Torque-Armature Current CharacteristicsBilbo BagginsNessuna valutazione finora

- ROHR2fesu FeaturelistDocumento20 pagineROHR2fesu FeaturelistJohan ConradieNessuna valutazione finora

- CE 249 MidtemDocumento6 pagineCE 249 MidtemJepoy EliseoNessuna valutazione finora

- Enerpac E325e GB PDFDocumento224 pagineEnerpac E325e GB PDFrudiNessuna valutazione finora

- Assignment - 1 Solution PDFDocumento7 pagineAssignment - 1 Solution PDFDavid StuartNessuna valutazione finora

- Dokumen - Tips Stenter-DryerDocumento18 pagineDokumen - Tips Stenter-DryerchuyNessuna valutazione finora

- 10 Technologies/Methods For Controlling Nox & Sox Emissions From ShipsDocumento2 pagine10 Technologies/Methods For Controlling Nox & Sox Emissions From ShipsRaji MNNessuna valutazione finora

- Product 1301454674 PDFDocumento4 pagineProduct 1301454674 PDFGabriela E MateiNessuna valutazione finora

- L3548 4 07Documento2 pagineL3548 4 07Héctor Hugo Sánchez GómezNessuna valutazione finora

- Tech Spec For Centrifugal PumpDocumento5 pagineTech Spec For Centrifugal PumpRoby Mirza100% (1)

- Electrical Systems Console (S - N 512911001 - 512911999) - 331Documento3 pagineElectrical Systems Console (S - N 512911001 - 512911999) - 331Ronaldo Javier Vergara AnayaNessuna valutazione finora

- 2 Trident Dryer Package (0421)Documento29 pagine2 Trident Dryer Package (0421)Jorge RicaurteNessuna valutazione finora

- Spare Parts For Powerplant-And Marine Diesel EnginesDocumento3 pagineSpare Parts For Powerplant-And Marine Diesel EnginesJavedNessuna valutazione finora

- Poster On Quantifying Atomic Vibration at Solid Liquid InterfaceDocumento1 paginaPoster On Quantifying Atomic Vibration at Solid Liquid InterfaceDeep PatelNessuna valutazione finora

- 02 The Wind Turbine-0001Documento16 pagine02 The Wind Turbine-0001vodasanket100% (1)

- Integral Relation For A Control Volume (Part 1)Documento15 pagineIntegral Relation For A Control Volume (Part 1)Muhammad Amni FitriNessuna valutazione finora

- GF SlabDocumento8 pagineGF Slabcheligp1981Nessuna valutazione finora

- Steam and Oil Flushing Procedure of LDO & HFODocumento10 pagineSteam and Oil Flushing Procedure of LDO & HFOislamfarag2Nessuna valutazione finora

- Thakur Institute of Aviation Technology: Module 17.4: Propeller SynchronisingDocumento4 pagineThakur Institute of Aviation Technology: Module 17.4: Propeller SynchronisingAshwini ChaurasiaNessuna valutazione finora

- Building Utilities Reviewer ComprehensiveDocumento3 pagineBuilding Utilities Reviewer ComprehensiveReynald HarrisNessuna valutazione finora

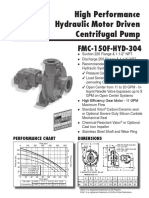

- FMC-150F-HYD-304 - 04-13 Bomba AceDocumento2 pagineFMC-150F-HYD-304 - 04-13 Bomba AceEmerson GomesNessuna valutazione finora

- Ne6 3911gb-MidlumDocumento234 pagineNe6 3911gb-MidlumDinu GabrielNessuna valutazione finora

- Kohn-Sham Equations For DFTDocumento15 pagineKohn-Sham Equations For DFTRikardo Pino RiosNessuna valutazione finora

- CH1Documento34 pagineCH1none5402Nessuna valutazione finora

- Steam Turbine Description HP Turbine Casing Supports and GuidesDocumento2 pagineSteam Turbine Description HP Turbine Casing Supports and GuidesAmit MukherjeeNessuna valutazione finora

- ASME Boiler and Pressure Vessel Code, Section III NF, EditioDocumento101 pagineASME Boiler and Pressure Vessel Code, Section III NF, EditiorazvannuNessuna valutazione finora

- Strida Folding Bike - Personal Tips and Facts From The CreatorDocumento8 pagineStrida Folding Bike - Personal Tips and Facts From The CreatorGeorg100% (2)

- Filtro Carbon ActivoDocumento1 paginaFiltro Carbon ActivoZzmangostazZNessuna valutazione finora

- ZL-7901A en V2.6b PDFDocumento8 pagineZL-7901A en V2.6b PDFElio Jose Burgos Brieva100% (1)