Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

0620000008

Caricato da

mahsaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

0620000008

Caricato da

mahsaCopyright:

Formati disponibili

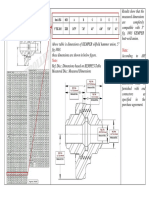

Tech Unit No: 0620000008

Revision: C

Approved By: Quality Engineer

Date: 2015-1-7

MWB Top-Set Bridge Plug

DESCRIPTION:

The Map Oil Tools Model MWB Top-Set Wireline Bridge Plug is

a compact and economical unit engineered for fast running

downhole on electric wireline.

FEATURES:

Positively-secured packing element and one piece slips

combine to resist premature setting due to well debris or

rough handling and assures protection from the hazards of

high-speed running in the well.

The flat metal backup rings prevent extrusion of the

rubber at high pressure and temperature. Because of their

design, the metal-to-metal contact developed by these

backup rings is made more secure by pressure increases.

An internal ratchet lock ring retains the dynamic force

induced in the retainers during the setting operation. This

simple mechanism assures continued compression of the

packing elements regardless of pressure differentials.

Case-hardened, one piece slips, designed to bite casing

hardness up to P110, are located at each end of plug - final

assurance of plug pack-off security. When the need arises,

these slips are easily drilled out.

Casing

Setting Range

Tool OD

Min ID Max ID (in.)

(in.)

(in.)

Shear

Stud

Value

(lbs)

Bridge Plug

Setting

Tool

OD

(in.)

Wt

(lbs/ft)

2 3/8

4.0-5.8

1.780

2.074

1.75

2 7/8

6.4-6.5

2.340

2.525

2.22

3 1/2

12.8-15.8

2.548

2.764

2.43

13,000

3 1/2

5.7-10.3

2.867

3.258

2.75

5.6-14.0

3.340

3.732

3.14

4 1/2

9.5-15.1

3.826

4.090

3.59

11.5-20.8

4.156

4.560

3.93

11.5-20.8

4.156

4.560

3.93

5 1/2

13.0-23.0

4.580

5.044

4.31

5 1/2

13.0-23.0

4.580

5.044

4.31

0620431008

5 3/4

14.0-26.0

4.890

5.290

4.70

6 5/8

17.0-32.0

5.595

6.135

17.0-35.0

6.004

7 5/8

20.0-39.0

8 5/8

Part Number

Approx.

Weight

KG LBS

Wireline

Adapter Kit

0620175008

0610175050

0620222088

0610222050

0620243008

11

0610243050

9,000

0620275008

13

20,000

0620314008

10

23

0620314100

0620359008

14

31

0620359100

16

35

19

42

0620470008

27

60

0620470100

5.37

0620537008

38

84

0620537100

6.538

5.68

0620568008

41

91

0620568110

6.625

7.125

6.31

0620631008

47

104

0620631100

24.0-49.0

7.511

8.097

7.12

0620712008

58

128

0620712100

9 5/8

29.3-58.4

8.435

9.063

8.12

0620812008

74

163

0620812100

10 3/4

32.75-60.7

9.660

10.192

9.43

0620943008

128

281

0620943100

60.0-83.0

10.192

10.772

9.94

0620994008

135

297

0620994100

38.0-60.0

10.772

11.150

10.43

0621043008

150

330

0621043100

13 3/8

48.0-80.7

12.175

12.715

11.88

0621188008

219

482

0621188100

16

65.0-118.0

14.576

15.25

14.12

0621412008

280

616

0621412100

20

94.0-133.0

18.730

19.124

18.37

0621837008

370

814

0621837100

11 3/4

9,000

1 11/16

GO

#10

0620393007

33,000

#20

0620393008

#10

0620431007

#20

50,000

Diff.

Pressure

(275 F)

0620275050

0620275100

0620393110

10,000

0620393100

0620431110

0620431100

8,000

3,000

1,500

Note: The following configurations are available upon request:

(1) High temperature packing elements;

(2) Carbide inserted slips for premium casing;

WIRELINE SET BRIDGE PLUG:

The Map Oil Tools MWB Top-Set Bridge Plug can be

set using a Baker style Pressure Setting Assembly

(Wireline Setting Tool or Hydraulic Setting Tool). If

other manufacturers equipment is to be used for

setting, please contact your Map Oil Tools

representative for the appropriate change-over kit. A

Wireline Adapter Kit is required to adapt the

appropriate Pressure Setting Assembly to the Bridge

Plug. Please check the Tool Compatibility Guide on

Page 2 for the proper setting equipment.

OPERATION:

The Map Oil Tools MWB Top-Set Bridge Plug is

attached to the Wireline Pressure Setting Assembly

with the appropriate Wireline Adapter Kit and run to

the setting depth. When the Pressure Setting

Assembly is actuated, the Adjuster Sub moves upward

with respect to the setting sleeve of the adapter kit

and squeezes the plug, thus setting the slips and

packing-off the element.

The Pressure Setting Assembly develops force in

excess of that required to set the plug. This excess

force is used to release the running mechanism from

the bridge plug by breaking the tension stud between

the two.

ASSEMBLY OF WIRELINE SET BRIDGE PLUG AND

ADAPTER KIT TO THE #10 WIRELINE PRESSURE

SETTING ASSEMBLY :

1. Screw Setting Sleeve onto the Wireline Pressure

Setting Assembly.

2. Install the Lock Spring on the Tension Stud.

3. Make Tension Stud up to Wireline Pressure

Setting Assembly until Setting Sleeve contacts the

Bridge Plug.

ASSEMBLY OF WIRELINE SET BRIDGE PLUG AND

ADAPTER KIT TO THE #20 WIRELINE PRESSURE

SETTING ASSEMBLY :

1. Make up Adjuster Sub onto the Wireline Pressure

Setting Assembly and install Set Screw.

2. Screw Setting Sleeve onto the Wireline Pressure

Setting Assembly and install Set Screw.

3. Be sure the Tension Stud is installed in the Bridge

Plug and install the Lock Spring on the Tension

Stud. Stud should make up approximately 15/16

for the 4-1/2 thru 5-1/2 sizes & 1-1/8 for all

larger tools.

4. Make up Tension Stud to the Adjuster Sub until

Setting Sleeve contacts the Bridge Plug.

ASSEMBLY OF WIRELINE SET BRIDGE PLUG AND

ADAPTER KIT TO THE 1 11/16 GO WIRELINE

PRESSURE SETTING ASSEMBLY :

1. Screw Setting Sleeve onto to the Wireline

Pressure Setting Assembly

2. Ensure the Tension Stud is installed in Bride Plug.

3. Make up Tension Stud to Wireline Pressure

Setting Assembly.

CAUTION: DO NOT WRENCH! All above operations

should be performed by hand.

NOTE: (6-5/8 & larger) This step is easier if performed

while the Pressure Setting Assembly is hanging in the

derrick.

Once the plug has been made up to the setting

equipment, proceed by running to setting depth and

set the tool per wireline operating procedures. When

the Pressure Setting Assembly is removed from the

well, remove the wireline adapter kit for reuse.

Baker Style Adapter

Setting Sleeve

GO Style Adapter

Tension Stud

SIZE: 2 7/8" 4 1/2"

SIZE: 5" 20"

Wireline Adapter Kit Dimensional Data

Dim

(in) 2 3/8" 2 7/8"

A

B

C

D

E

1.750

1.406

-

2.250

Size

3 1/2"

3 1/2"

12.8-15.8# 5.7-10.3#

2.438

7.313

1.500

1.875

-

2.750

1.875

-

4"

4 1/2"

5"

5 1/2" 5 3/4" 6 5/8"

3.140 3.500 3.938 4.313 4.700

12.875

16.000

12.500

2.125

3.000

3.063 3.750

-

7"

5.375 5.688

10.500

4.500

7 5/8" 8 5/8" 9 5/8" 10 3/4"

6.313

9.563

5.000

7.125 8.125 9.438

9.125

9.500

6.000 7.000 8.000

8.750

2.938

11 3/4" 11 3/4"

13 3/8"

60-83# 38-60#

16"

20"

9.938 10.438 11.875 14.125 18.375

9.906

11.875

8.500 9.406 10.000 12.500 17.000

Wireline Adapter Kit Parts List

2 3/8" 3 1/2"

Size and Part Number

3 1/2"

12.8-15.8#

Qty

2 3/8"

2 7/8"

Setting Sleeve

0610175050

0610222050

Wireline Pressure Setting Tool

Item #

Description

3 1/2"

5.7-10.3#

Setting Sleeve Only

1

0620243050

0610275050

1 11/16" GO

Wireline Adapter Kit Parts List

4" 7"

Size and Part Number

Item #

Description

Qty

4"

4 1/2"

5"

5 1/2"

5"

5 1/2"

5 3/4"

6 5/8"

7"

0620314100

0620359100

0620393110

0620431110

0620393100

0620431100

0620470100

0620537100

0620568100

0610314050

0610356050

0610393150

Not Used

0610431150

0610393050

0610431050

0610475050

0660020035

0610537050

0610568050

1

2

Setting Sleeve

Adjuster Sub

1

1

Lock Spring

0525307201

0525307202

Socket Set Screw

Not Used

0545620092

Wireline Pressure

Setting Tool

Baker #10

Baker #20

Wireline Adapter Kit Parts List

7 5/8" - 20"

Size and Part Number

Item #

Description

Qty

7 5/8"

8 5/8"

9 5/8"

10 3/4"

11 3/4"

60-83#

11 3/4"

38-60#

13 3/8"

16"

20"

0620631100

0620712100

0620812100

0620943100

0620994100

0621043100

0621188100

0621412100

0621837100

0610631050

0610712050

0610812050

0610950050

0610994050

0611043050

0611200050

0621412050

0621837050

Setting Sleeve

Adjuster Sub

0660020035

Lock Spring

0525307202

Socket Set Screw

0545620092

Wireline Pressure

Setting Tool

Baker #20

RECOMMENDED REMOVAL TECHNIQUES FOR

CEMENT RETAINERS & BRIDGE PLUGS:

Drilling is the preferred method for removing

drillable cement retainers and bridge plugs since it

usually can be accomplished in less than 10 percent

of the time required to mill-out the same device.

This can best be explained by the fact that milling

causes small cuttings that tend to block mill

penetration while the drilling causes a chiseling

effect which breaks pieces away and floats them to

the surface. Drilling with a short tooth medium hard

formation rock bit is usually the best combination

for retainer and plug removal.

SUGGESTED DRILLING TECHNIQUE:

Though the best drilling technique will vary with

equipment availability, a typical combination would

consist of a short or medium tooth hard formation

bit (IADC codes 2-1, 2-2, 2-3, 2-4, and 3-1), 75 to

120 RPM rotary speed and drill collars as necessary

for weight and bit stabilization.

To drill the retainer or plug:

1. Apply 5,000 7,000 lbs. until the top end of the

mandrel is drilled (4 5 in.)

2. Increase weight to 2,000 3,000 lbs. per inch of

bit diameter to drill out the remainder of the

retainer.

EXAMPLE: use 9,500 14,250 lbs. for a 4-3/4

diameter bit.

When normal circulation is to be used, place a junk

basket above the bit. If reverse circulation is

planned, a casing scraper or other equipment in the

tubing string above the bit should have an inside

fluid passage as large as the passage through the bit

so cuttings will not bridge off the I.D.

Penetration may be stopped by bit tracking which

is usually caused by insufficient weight on the bit.

Bit tracking occurs when bit teeth travel in the same

indentation of track made by the previous tooth.

Successive tooth impact to the same location will

sometimes deepen the track until the indentations

equal the tooth length, reducing the impact of the

teeth to the point they will no longer penetrate.

Drilling penetration may be reestablished by raising

the bit off of the retainer, and then lowering the bit

back onto the retainer while maintaining rotation.

NOTE: Drilling times are directly related to tool size,

bit stability, drilling weight, pump rate, bit RPM,

type of bit, drilling fluid, etc. The combination of

high mud viscosity and high pump rates may lift the

bit off of the retainer during drilling. The same

consideration should be used when drilling cement

retainers and bridge plugs as would be used when

drilling medium hard rock formations.

SUGGESTED MILLING TECHNIQUE:

If equipment availability or other considerations

dictate that the milling technique must be used, the

recommended combination is a concave face junk

mill, rotated at 60 150 RPM with 5,000 8,000

lbs. on the mill.

Use mud viscosity of 60 cps and a minimum annular

velocity of 120 ft. /min. to assure cutting removal.

When ready to begin milling operations, start the

mill above the target and lower it slowly onto the

target. Do not apply weight in excess of the

recommended amount; high weight can tear out

chunks of cast iron and make a bailer trip necessary

to remove them and reestablish drilling

penetration. Maintain a constant milling rate by

adding weight as the retainer is milled away.

Variations in bit speed and weight should be made

to help break up metal parts to re-establish bit

penetration should it cease while drilling.

Potrebbero piacerti anche

- Packer 7in Crest-II Sapex SpecDocumento3 paginePacker 7in Crest-II Sapex SpecbayuNessuna valutazione finora

- Cementing Plugs AND Ancillary EquipmentDocumento16 pagineCementing Plugs AND Ancillary EquipmentTeguh Akbar HarahapNessuna valutazione finora

- Annexure-1 - Sub Surface Testing of Liner Hanger, Tie Back Packer & SISO Anchor Seal Assembly PDFDocumento7 pagineAnnexure-1 - Sub Surface Testing of Liner Hanger, Tie Back Packer & SISO Anchor Seal Assembly PDFMehdi NorouziNessuna valutazione finora

- MH Hyd Tac Tm-353!01!3Documento6 pagineMH Hyd Tac Tm-353!01!3David MannNessuna valutazione finora

- Control Unit Model: WC-CUDocumento3 pagineControl Unit Model: WC-CUmahsaNessuna valutazione finora

- Elder Tools International: DescriptionDocumento7 pagineElder Tools International: Descriptionnurwinanto01Nessuna valutazione finora

- Ttt2b Drillable TlsDocumento26 pagineTtt2b Drillable TlsMahmoud Ahmed Ali AbdelrazikNessuna valutazione finora

- Lock-Set, J-LokDocumento3 pagineLock-Set, J-LokYaqoob IbrahimNessuna valutazione finora

- Botil Model BTCN Mechanical Set PackerDocumento2 pagineBotil Model BTCN Mechanical Set PackerReivaj JavierNessuna valutazione finora

- D&L Double Grip Pkr-Asi-Xpacker1c PDFDocumento2 pagineD&L Double Grip Pkr-Asi-Xpacker1c PDFMoh Syamsul BahriNessuna valutazione finora

- BakerDocumento4 pagineBakerWilliam EvansNessuna valutazione finora

- 7.000 X 2.875 DLH Packer With J-Release (17-26) 938-7000-028 Rev ADocumento5 pagine7.000 X 2.875 DLH Packer With J-Release (17-26) 938-7000-028 Rev ANorbey Ashley Gasca AlzateNessuna valutazione finora

- 2024 - 13.375 TST-2 Service PackerDocumento15 pagine2024 - 13.375 TST-2 Service PackerDhenny FarialNessuna valutazione finora

- Wellhead Equipment CatalogDocumento29 pagineWellhead Equipment CatalogDewy PambayunNessuna valutazione finora

- Wire Line SettingDocumento19 pagineWire Line SettingNagarjunSHNessuna valutazione finora

- 1PackerSystem PackerAccessories&tools PDFDocumento21 pagine1PackerSystem PackerAccessories&tools PDFAnand aashishNessuna valutazione finora

- Arrow-Pak 7.0 X 4Documento9 pagineArrow-Pak 7.0 X 4Tech AlfaNessuna valutazione finora

- A Type PerforatorDocumento0 pagineA Type PerforatorLazaro DhNessuna valutazione finora

- Liner PackersDocumento1 paginaLiner PackersMohamed ElabbasyNessuna valutazione finora

- Packer Systems Technical Unit Model "M" Expansion Joint, Sizes 2-3/8, 2-7/8, 3-1/2, and 4-1/2Documento4 paginePacker Systems Technical Unit Model "M" Expansion Joint, Sizes 2-3/8, 2-7/8, 3-1/2, and 4-1/2eberthson hernandezNessuna valutazione finora

- TU-045 - AS-RBP - 9-5.8 inDocumento4 pagineTU-045 - AS-RBP - 9-5.8 inAtom InsideNessuna valutazione finora

- ELDER IX 5 5 X 2 375Documento8 pagineELDER IX 5 5 X 2 375crni rokoNessuna valutazione finora

- Section 04 - GmaDocumento6 pagineSection 04 - GmaHunterNessuna valutazione finora

- Top-Co - AutoFill - BV & HF ValvesDocumento4 pagineTop-Co - AutoFill - BV & HF ValvesJuan LacorteNessuna valutazione finora

- B. P. Tapon MolibleDocumento16 pagineB. P. Tapon Molibleolger nino100% (1)

- Packer CupDocumento2 paginePacker Cupmiguel mendozaNessuna valutazione finora

- Sect 06 Full-Opening EquipmentDocumento44 pagineSect 06 Full-Opening EquipmentpaimanNessuna valutazione finora

- NCS Liner HangersDocumento5 pagineNCS Liner Hangerssmithyry2014Nessuna valutazione finora

- Trackmaster TT PsDocumento2 pagineTrackmaster TT PsPaola SamoNessuna valutazione finora

- M "EA" R C P P N - 25.214: Odel Etrievamatic Ementer Acker Roduct ODocumento2 pagineM "EA" R C P P N - 25.214: Odel Etrievamatic Ementer Acker Roduct ORodolfo Rider100% (1)

- C2™ Liner Setting Sleeve With Tieback ExtensionDocumento5 pagineC2™ Liner Setting Sleeve With Tieback Extensionjosephbenetton100% (1)

- Pump Out Plug Operating InstructionsDocumento6 paginePump Out Plug Operating InstructionsEvolution Oil ToolsNessuna valutazione finora

- Sliding SleveDocumento4 pagineSliding SleveMarceloNessuna valutazione finora

- Seal Bore Packer System - RetrievableDocumento8 pagineSeal Bore Packer System - RetrievableFabio ParceroNessuna valutazione finora

- 2023 10.75 TST-2 Service PackerDocumento15 pagine2023 10.75 TST-2 Service PackerDhenny FarialNessuna valutazione finora

- E-Hydro Trip Sub Technical DatasheetDocumento4 pagineE-Hydro Trip Sub Technical DatasheetEvolution Oil ToolsNessuna valutazione finora

- PCK para Limpiar PunzadosDocumento19 paginePCK para Limpiar PunzadosRodolfo RiderNessuna valutazione finora

- Junk Catcher AssembliesDocumento10 pagineJunk Catcher AssembliesMicNessuna valutazione finora

- Plug Setting Tool and Junk Basket: Purpose of The ServiceDocumento15 paginePlug Setting Tool and Junk Basket: Purpose of The Servicerobin2806Nessuna valutazione finora

- D601005184 Man 001Documento17 pagineD601005184 Man 001Riski Kurniawan100% (1)

- Bico Handbk 11-11Documento88 pagineBico Handbk 11-11faishal hafizhNessuna valutazione finora

- Magnum Composite Plug Catalog 06-30-10Documento21 pagineMagnum Composite Plug Catalog 06-30-10Emad JamshidiNessuna valutazione finora

- Completion Schematic #1: Stimulate and Test ZonesDocumento1 paginaCompletion Schematic #1: Stimulate and Test Zonesasset_kulmagambetovNessuna valutazione finora

- Ps 0412 0600obh WDocumento1 paginaPs 0412 0600obh WHunterNessuna valutazione finora

- Sur-Set™ Selective Seating Nipples: Flow Control Systems Technical UnitDocumento3 pagineSur-Set™ Selective Seating Nipples: Flow Control Systems Technical UnitTamer Hesham AhmedNessuna valutazione finora

- Parveen PRHP Packer: Downhole Completion EquipmentDocumento5 pagineParveen PRHP Packer: Downhole Completion EquipmentsambhajiNessuna valutazione finora

- Slickplug BrochureDocumento7 pagineSlickplug BrochuretonyNessuna valutazione finora

- 2RH™ Liner Setting ToolDocumento14 pagine2RH™ Liner Setting TooljosephbenettonNessuna valutazione finora

- DLH Packer SGDocumento14 pagineDLH Packer SGsong LiNessuna valutazione finora

- New BDMI L 4.5 HE0Documento6 pagineNew BDMI L 4.5 HE0Natanael SaputraNessuna valutazione finora

- LipeDocumento76 pagineLipemahmod alrousanNessuna valutazione finora

- Pds Products HRP ESP PackersDocumento2 paginePds Products HRP ESP PackersfredyNessuna valutazione finora

- FB2 - RB2Documento15 pagineFB2 - RB2Sajida QadeerNessuna valutazione finora

- Packer HP 6 Technical LiteratureDocumento7 paginePacker HP 6 Technical LiteratureRaul Diaz100% (1)

- Half Mule Shoe Guide 88050307Documento2 pagineHalf Mule Shoe Guide 88050307satyendraNessuna valutazione finora

- TIC CatalogDocumento424 pagineTIC Catalogmglsite1Nessuna valutazione finora

- 3 PC MB DogboneDocumento18 pagine3 PC MB DogboneLeilani JohnsonNessuna valutazione finora

- Model MS ManualsDocumento15 pagineModel MS ManualsbarrettshawnNessuna valutazione finora

- Assembly and Tensioning of High Strength Bolts andDocumento14 pagineAssembly and Tensioning of High Strength Bolts andKirtichandraKomarrajuNessuna valutazione finora

- Operating: Maintenance ManualDocumento18 pagineOperating: Maintenance ManualAnonymous reYe6iCCNessuna valutazione finora

- CFW 50 W 144Documento2 pagineCFW 50 W 144mahsaNessuna valutazione finora

- DYNAenergetics 2.875 PA Auto-Vent Firing Head Field Assembly ProcedureDocumento7 pagineDYNAenergetics 2.875 PA Auto-Vent Firing Head Field Assembly ProceduremahsaNessuna valutazione finora

- DYNAenergetics Absolute Pressure Activated Firing Head Running ProcedureDocumento3 pagineDYNAenergetics Absolute Pressure Activated Firing Head Running ProceduremahsaNessuna valutazione finora

- Drill Pipe SpecificationDocumento2 pagineDrill Pipe SpecificationmahsaNessuna valutazione finora

- DYNAenergetics Absolute Pressure Activated Firing Head Field Assembly ProcedureDocumento9 pagineDYNAenergetics Absolute Pressure Activated Firing Head Field Assembly ProceduremahsaNessuna valutazione finora

- 1412 Det Pi NB HNS 1 4S 111213Documento1 pagina1412 Det Pi NB HNS 1 4S 111213mahsaNessuna valutazione finora

- DYNAenergetics 1.90 Short Mechanical Firing Head Re-Dress ProcedureDocumento8 pagineDYNAenergetics 1.90 Short Mechanical Firing Head Re-Dress ProceduremahsaNessuna valutazione finora

- Sintering Effect On The Performance of Tungsten-Copper Powder LinerDocumento2 pagineSintering Effect On The Performance of Tungsten-Copper Powder LinermahsaNessuna valutazione finora

- DYNAenergetics 1.90 Short Mechanical Firing Head Running ProcedureDocumento4 pagineDYNAenergetics 1.90 Short Mechanical Firing Head Running ProceduremahsaNessuna valutazione finora

- 2211 TCP Mechanical Firing Head 130618Documento1 pagina2211 TCP Mechanical Firing Head 130618mahsaNessuna valutazione finora

- Coiled Tubing Safety Impact Firing Head (HP) - by DynaDocumento16 pagineCoiled Tubing Safety Impact Firing Head (HP) - by DynamahsaNessuna valutazione finora

- 2222 TCP Firing Head Auto Vent Pressure Activated 120531Documento2 pagine2222 TCP Firing Head Auto Vent Pressure Activated 120531mahsaNessuna valutazione finora

- 2212 TCP Firing Head Pressure Activated 130120 1Documento2 pagine2212 TCP Firing Head Pressure Activated 130120 1mahsaNessuna valutazione finora

- Analysis of Stress Square Thread Power Screws Using AnsysDocumento6 pagineAnalysis of Stress Square Thread Power Screws Using AnsysmahsaNessuna valutazione finora

- Ds BurnDocumento63 pagineDs BurnmahsaNessuna valutazione finora

- 3 18 Quick Change SIE TypeDocumento1 pagina3 18 Quick Change SIE TypemahsaNessuna valutazione finora

- Percussion Inititator Non Breaching 2317025Documento1 paginaPercussion Inititator Non Breaching 2317025mahsaNessuna valutazione finora

- 1.5625 in Kit Super Cutter, HMX, 38.8 G: Packing InformationDocumento1 pagina1.5625 in Kit Super Cutter, HMX, 38.8 G: Packing InformationmahsaNessuna valutazione finora

- O Dtic:, CST AvailableDocumento32 pagineO Dtic:, CST AvailablemahsaNessuna valutazione finora

- Dynamic Underbalanced Perforating: YAN Etro QuipmentDocumento4 pagineDynamic Underbalanced Perforating: YAN Etro QuipmentmahsaNessuna valutazione finora

- CPST Pressure Setting Tool PDFDocumento1 paginaCPST Pressure Setting Tool PDFmahsaNessuna valutazione finora

- Hammer UnionDocumento1 paginaHammer Unionmahsa100% (1)

- TorpedoDocumento6 pagineTorpedomahsaNessuna valutazione finora

- 1.812 In. Kit Tubing Cutter, HMX, Supercutter: Packing InformationDocumento1 pagina1.812 In. Kit Tubing Cutter, HMX, Supercutter: Packing InformationmahsaNessuna valutazione finora

- Question Tags ExerciseDocumento2 pagineQuestion Tags Exercisesamanik swiftNessuna valutazione finora

- All That Jazz - 3 Horns + Rhythm - Evans - Sammy Davis, Jr.Documento27 pagineAll That Jazz - 3 Horns + Rhythm - Evans - Sammy Davis, Jr.David CsizmadiaNessuna valutazione finora

- Ebc Fitting InstructionsDocumento1 paginaEbc Fitting InstructionsNdao86Nessuna valutazione finora

- Indian Diet Plan For BodybuildingDocumento3 pagineIndian Diet Plan For BodybuildingPintu MaharanaNessuna valutazione finora

- April Free Chapter - Fifty Shades Freed by E. L. JamesDocumento29 pagineApril Free Chapter - Fifty Shades Freed by E. L. JamesRandomHouseAU89% (27)

- Chapter VIl Framework For Web MarketingDocumento38 pagineChapter VIl Framework For Web MarketingJared L. ClaveriaNessuna valutazione finora

- 2024 Paper 1 Specimen PaperDocumento10 pagine2024 Paper 1 Specimen PaperstanfordmarindaNessuna valutazione finora

- Diagnostics Apps Check 240416Documento153 pagineDiagnostics Apps Check 240416Muhammad NaumanNessuna valutazione finora

- Presentation Michael Jackson InglesDocumento2 paginePresentation Michael Jackson InglesClara Luz Cantillo EscorciaNessuna valutazione finora

- APE4517 R0 V 06Documento2 pagineAPE4517 R0 V 06Víctor Romeu67% (3)

- Schoenberg On Tonal FunctionDocumento17 pagineSchoenberg On Tonal FunctionfsarkNessuna valutazione finora

- 2009-10 Vancouver Canucks Media GuideDocumento262 pagine2009-10 Vancouver Canucks Media GuideYosooNessuna valutazione finora

- How To Find A Licoreria Cerca de MiDocumento7 pagineHow To Find A Licoreria Cerca de MiHammad ChaudhryNessuna valutazione finora

- In Vehicle Infotainment (IVI) Platform 0213 3Documento2 pagineIn Vehicle Infotainment (IVI) Platform 0213 3Cimpean GabrielNessuna valutazione finora

- Viewsonic vg1921wm-2Documento63 pagineViewsonic vg1921wm-2Ricardo BlackmooreNessuna valutazione finora

- LeisureDocumento4 pagineLeisurePorshothman ElenggovenNessuna valutazione finora

- 9nygu9 PDFDocumento2 pagine9nygu9 PDFo_zuwaNessuna valutazione finora

- 11 Types of FolktalesDocumento4 pagine11 Types of Folktales2022ctecarlonscNessuna valutazione finora

- Onkyo TX Nr525Documento50 pagineOnkyo TX Nr525unindikaNessuna valutazione finora

- Bradley MemoriesDocumento36 pagineBradley MemoriesAnnette Edwards100% (5)

- VIV PR Vivendi Q1 2022 RevenuesDocumento9 pagineVIV PR Vivendi Q1 2022 RevenuesRafa BorgesNessuna valutazione finora

- ConnecTIng People EZ430 Chronos WorkshopDocumento33 pagineConnecTIng People EZ430 Chronos WorkshopHannes FouldsNessuna valutazione finora

- GAP Diagnostic EASC V1.0: Installation Manual Document Version: 1.0.5.1Documento11 pagineGAP Diagnostic EASC V1.0: Installation Manual Document Version: 1.0.5.1Denis PitnjakovicNessuna valutazione finora

- Invoice: To Pay Your Invoice Online, Please VisitDocumento1 paginaInvoice: To Pay Your Invoice Online, Please VisitubyisismayilNessuna valutazione finora

- Konig DVB-S2 Rec20Documento93 pagineKonig DVB-S2 Rec20ornotNessuna valutazione finora

- Common Sense Media 2021Documento64 pagineCommon Sense Media 2021Alcione Ferreira SáNessuna valutazione finora

- Ang TR B2, Perfect TensesDocumento11 pagineAng TR B2, Perfect TensesDanuta KochanowiczNessuna valutazione finora

- Manual Telecomanda Universala WellDocumento17 pagineManual Telecomanda Universala WellLucian Bălan83% (6)

- Buns Rolls Using Pande Sal RecipeDocumento3 pagineBuns Rolls Using Pande Sal Recipejerimiah_manzonNessuna valutazione finora

- Listening Section TranskripDocumento5 pagineListening Section Transkripkhasan basyirNessuna valutazione finora