Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Simulation of Dstatcom Under Different Fault Conditions

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Simulation of Dstatcom Under Different Fault Conditions

Copyright:

Formati disponibili

IPASJ International Journal of Electrical Engineering (IIJEE)

Web Site: http://www.ipasj.org/IIJEE/IIJEE.htm

Email: editoriijee@ipasj.org

ISSN 2321-600X

A Publisher for Research Motivation........

Volume 4, Issue 12, December 2016

Optimal PID Control of a BLDC Motor Using

TLBO Algorithm

A. Sri Priyanka1, A .V. Naresh Babu2 , A. Bala Naga Lingaiah3

1

PG Student [P.E], Dept. of EEE, DVR & Dr. HS MIC College of Technology, Andhra Pradesh, India

2

Professor, Dept. of EEE, DVR & Dr. HS MIC College of Technology, Andhra Pradesh, India

Assistant Professor, Dept. of EEE, DVR & Dr. HS MIC College of Technology, Andhra Pradesh, India

ABSTRACT

Due to the increasing gain in importance of the BLDC motor in industrial and home appliances made its effective

control much important to meet the requirements of efficient performance. The PID controller finds its applicability

in industries and control of different plants for which its parameters are to be tuned effectively. This paper presents

TLBO for determining the optimal parameters of a PID controller for controlling and improving performance of a

BLDC motor. TLBO algorithm is used to tune the PID Controller and obtain optimal parameters. TLBO is a

population based algorithm. It is inspired by the influence of the teaching by the teacher on the students in a class.

Due to its attractive characteristics and high efficiency TLBO has been successfully applied to many real world

optimization problems. The results obtained from TLBO based controller show significant improvement in

performance of BLDC than the existing methods.

Keywords: BLDC Motor, PID controller, Teaching Learning Based Optimization

1. INTRODUCTION

Brushless Direct Current motors attain an extremely significant place as electric drives are finding applications in wide

range of areas such as in automotives, industrial automation, medical, aerospace, computers, consumer and

instrumentation. Due to its high efficiency, reliability, low maintenance, compact size, high starting torque, noiseless

operation and long operating life BLDC motor is rapidly gaining popularity in recent years [1-3]. It has permanent

magnet as rotor, there is no excitation loss, simple construction is realized and operation is very reliable. BLDC motor

is having more advantages when compared to that of the conventional DC motor. The differences are absence of

brushes and commutator. The BLDC motor uses an electronic commutator due to this wear and tear problem which was

a drawback in conventional DC motor is avoided. The BLDC motor is inherently electronically controlled.PID

controller is the most commonly used for improving stability and improving overall performance of system. The

conventional PID control method uses trial and error method which is a difficult task [4-8].Now, the optimization

techniques are widely used in motor control system due to its simplicity. The term optimization is defined as either

maximizing or minimizing the tasks in order to obtain the best solution. Teaching Learning Based Optimization

technique is inspired by the nature of influence of a teacher on learners [9-10]. In comparison with other algorithms,

TLBO is a simple and robust technique involving only few computations. It is a population based algorithm consists of

two phases: teaching phase and learning phase.

2. PERMANENT MAGNET BRUSHLESS DC MOTOR MODELING

The BLDC motor is usually a 3-phase, 4-pole permanent magnet motor. The control parameters are designed from the

transfer function of the system [1].The equivalent circuit of the BLDC motor is similar to that of a conventional DC

motor and is shown in Fig 1.

Volume 4, Issue 12, December 2016

Page 22

IPASJ International Journal of Electrical Engineering (IIJEE)

A Publisher for Research Motivation........

Volume 4, Issue 12, December 2016

Web Site: http://www.ipasj.org/IIJEE/IIJEE.htm

Email: editoriijee@ipasj.org

ISSN 2321-600X

Fig 1: Equivalent Circuit of BLDC Motor

The general transfer function of BLDC motor is given by

Kt

G(s)

2

LJs (LB RJ)s K t K b

(1)

Where,

= motor torque constant, J = moment of inertia, B = viscous friction constant,

R = resistance, L= inductance

= back emf constant,

The MATLAB (The Math Works, Natick, Massachusetts, USA) system identification toolbox is used to find the

transfer function of the motor and its drive circuit [4]. Fig 2 shows the structure of closed loop system with PID tuning

algorithms.

312.3S 1.7774e4

G c (S)

(2)

2

S 10.2S 54.32

Fig 2 : Structure of closed loop system with PID tuning algorithms

3. PID CONTROLLER

PID control is a control strategy that has been successfully used over many years. The PID controller has been widely

adopted as the control strategy in the production process. Basically, a proportional-plus-integral-plus-derivative (PID)

controller will improve the speed of the response, steady-state error and system stability. However, the setting of PID

parameters is related to the characters of system process. Thus, optimum PID parameters are needed to approach the

desired performance .Some of the reasons that have made PID control so popular in the academic and industry sectors

are its wide range of applicability, simplicity, robustness and near-optimal performance. The transfer function of PID

controller is given by

Volume 4, Issue 12, December 2016

Page 23

IPASJ International Journal of Electrical Engineering (IIJEE)

Web Site: http://www.ipasj.org/IIJEE/IIJEE.htm

Email: editoriijee@ipasj.org

ISSN 2321-600X

A Publisher for Research Motivation........

Volume 4, Issue 12, December 2016

G(s) K P

Ki

KdS

(3)

S

Where K P = proportional gain, K = integral gain, K d = derivative gain

i

The optimum search of the controller parameters for speed control of BLDC motor is made according to the criteria of

performance index [8]. These criteria include WGAM2 (weighted goal attainment method 2), this has better

performance and less disadvantages than other indices. It is given by .

WGAM2

(1 e

is the weighting factor,

steady state error

).(M P e ss ) (e

is the rise time,

(4)

).(t s t r )

is the maximum overshoot,

is the settling time,

is the desired

4. TEACHING LEARNING BASED OPTIMIZATION ALGORITHM

TLBO is a population based algorithm gives global solution. TLBO population is a group of learners or a class of

learners. In TLBO algorithm, the population consists of different design variables [9]. Different design variables will be

analogous to different subjects offered to learners. Learners result is analogous to the fitness. The teacher is

considered as the best solution obtained. TLBO involves only two phases. They are Teaching phase and Learning

phase.

TEACHING PHASE

In this phase, a teacher tries to ameliorate the mean result of class in the subject taught by him/her based on level of

knowledge and skill he/she had in that particular subject.

Let M i be the mean, T be teacher at iteration i

i

T will try to move mean M i towards its own level, so new mean will be T designated as M new

i

i

The solution is obtained according to the difference between the existing and the new.

Difference Mean i ri (M new TF M i )

(5)

is random number in range of [0, 1], TF is a teaching factor that decides the value of mean to be changed.

The value of TF can be either 1 or 2, which is again a heuristic step and decided randomly with equal probability as

Where

TF round[1 rand(0,1){2 1}]

This difference modifies the existing solution according to the following expression

X new,i X old,i Differencemean i

(6)

(7)

X new,i New position of learner i, X old,i = Old position of learner i

LEARNING PHASE

In the course of time, a learner gains knowledge not only from the teacher but also may attain knowledge by interacting

randomly with other learners with the help of communication and discussions. If a leaner interacts with other learner

who has more knowledge than him or her, he/she tries to learn new things and tries to increase his/her knowledge. For

a class of n learners the learning phenomenon of this phase is expressed as follows.

For i=1:

Randomly select two learners X i andX j , where i

If f(X i ) f(X j )

X new,i X old,i ri (X i X j )

Else

Volume 4, Issue 12, December 2016

(8)

Page 24

IPASJ International Journal of Electrical Engineering (IIJEE)

Web Site: http://www.ipasj.org/IIJEE/IIJEE.htm

Email: editoriijee@ipasj.org

ISSN 2321-600X

A Publisher for Research Motivation........

Volume 4, Issue 12, December 2016

X new,i X old,i ri (X j X i )

End

End

(9)

ALGORITHM

The step-wise procedure for the implementation of TLBO is given in this section.

Step 1: Define the optimization problem and initialize the optimization parameters.

Step 2: Initialize the population

Generate a random population according to the population size and number of design variables.

For TLBO, the population size indicates the number of learners and the design variables indicate the

subjects (i.e. courses) offered.

Step 3: Teacher phase

Calculate the mean of the population and determine the best solution.

Step 4: Learner phase

Learners increase their knowledge with the help of their mutual interaction.

The mathematical expression is explained in learning phase.

Step 5: Termination criterion

Stop if the maximum generation number is achieved; otherwise repeat from Step 3.

5. SIMULATION RESULTS AND DISCUSSIONS

BLDC motor parameters are provided in the Table1. Parameters of the teaching learning based optimization algorithm

are given in the Table 2.The range of values for different parameters are also considered. Parameters like no. of

iterations, population size, no. of variables etc are considered and performance of the BLDC motor with TLBO

controller and results for conventional controller are given in Table 3.

Table 1: BLDC Motor Parameters

Parameters

Values

Speed

2000 rpm

Power

370 W

V

220 V

R

2.8750

L

8.5 mH

J

0.0008 kg.

B

0.0003 N.m.sec/rad

Kb

0.175 V.sec

Table 2: Algorithm Parameters

Parameters

No of iterations

Population size

No of variables

Values

200

5

3

Either 1 or 2

Range of [0,1]

Kp limits

0 to 2

Ki limits

0 to 4

limits

0 to 1

Table 3: Performance of the PID Controller

Rise time(sec)

Settling time(sec)

Conventional

Controller

0.0037

0.0237

7.7347e-04

0.2026

0.8768

TLBO

based

Controller

1.3519

3.9676

0.1016

0.0366

0.0638

Maximum overshoot%

Peak

Peak Time(sec)

Error

7.6117

1.0761

0.3800

4.1672

0

1

0.09

0.0125

Parameters

Kp

Ki

Volume 4, Issue 12, December 2016

Page 25

IPASJ International Journal of Electrical Engineering (IIJEE)

A Publisher for Research Motivation........

Volume 4, Issue 12, December 2016

Web Site: http://www.ipasj.org/IIJEE/IIJEE.htm

Email: editoriijee@ipasj.org

ISSN 2321-600X

The optimum PID parameters are searched for the transfer function of the identified model obtained by equation (2)

w.r.t the criteria of performance indices WGAM2. The step response of motor for conventional controller is shown in

the Fig 3, the step responses of TLBO based controller is shown in Fig 4and the convergence graph of the TLBO

method is shown in the Fig 5.

Fig 3 Step response of conventional PID controller

Fig 4 Step response of TLBO based PID controller

Volume 4, Issue 12, December 2016

Page 26

IPASJ International Journal of Electrical Engineering (IIJEE)

A Publisher for Research Motivation........

Volume 4, Issue 12, December 2016

Web Site: http://www.ipasj.org/IIJEE/IIJEE.htm

Email: editoriijee@ipasj.org

ISSN 2321-600X

Fig 5 Convergence Characteristics

From the Fig 3 and Fig 4, it can be observed that the settling time is reduced when PID controller is controlled by the

TLBO algorithm. The best convergence characteristics with TLBO algorithm plotted between iterations and error are

shown in Fig 4. The value of error is found to be reduced with the increase in no. of iterations; this shows the

performance of the TLBO algorithm. The values of rise time and peak time have proven that the usage of TLBO

algorithm provides best results. The optimum PID parameters are obtained using the TLBO algorithm.

6. CONCLUSION

In this paper, optimal PID controller is tuned and parameters were derived through TLBO algorithms. Simulation

results shows that the characteristics of PID controller according to the performance criteria index WGAM2 obtained

by using TLBO are more efficient than the results obtained without TLBO. In this method, the system provides reduced

settling time, overshoot, rise time and error. The convergence characteristic of TLBO shows a reduction in the error

value. The proposed technique can have an efficient search for the optimal PID controller parameters and this method

provided good speed control of BLDC motor.

REFERENCES

[1]. A. Kiruthika and A. Albert Rajan, Mathematical modelling and speed control of a sensored brushless DC motor

using intelligent controller, IEEE International Conference on Emerging trends in Computing, Communication

and Nanotechnology (ICECCN), pp.211-216,2013.

[2]. Tony Mathew and Caroline Ann Sam, Modelling and closed loop control of BLDC motor using a single current

sensor, IJAREEIE, vol.2, no.6, pp.2525-2531, June 2013.

[3]. R.Akhila and S.Nikhil, A comparative study of sensor and sensor less control of four-switch inverter fed

permanent magnet brushless DC motor, IEEE International conference on power, signals, controls and

computations, Jan 2012.

[4]. Lennart Ljung, System identification toolbox 7.3: Users Guide, Math Works Inc., 2009.

[5]. Chen and Shih-Feng, Particle swarm optimization for PID controllers with robust testing, International

conference on machine learning and cybernetics, pp.956 961, Aug 2007.

[6]. Kh .Ang , G.Chong and Yun Li , PID control system analysis, design and technology ,IEEE Trans. control

system technology,pp.559-576,July 2005.

[7]. P.Cominos and N. Munro, Linear programming for optimum PID controller tuning, IEE Proceedings- Control

Theory and Applications, pp.46-53, 2002.

[8]. Sangram Keshari Mallick and Mehetab Alam Khan, Study of the design and tuning methods of PID controller

based on Fuzzy logic and genetic algorithm, May 2011.

[9]. R.V. Rao, V.J. Savsani and D.P. Vakharia, Teaching-learning-based optimization: A novel optimization method

for continuous non-linear large scale problems, Information Sciences, pp.115, 2012.

[10]. Pooja Sharma and Rajeev Gupta, Tuning of PID controller for a linear BLDC motor using TLBO technique,

IEEE International Conference on Computational Intelligence and Communication Networks, 2014.

Volume 4, Issue 12, December 2016

Page 27

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocumento6 pagineDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocumento12 pagineStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocumento6 pagineAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocumento7 pagineTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Soil Stabilization of Road by Using Spent WashDocumento7 pagineSoil Stabilization of Road by Using Spent WashInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- The Mexican Innovation System: A System's Dynamics PerspectiveDocumento12 pagineThe Mexican Innovation System: A System's Dynamics PerspectiveInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocumento9 pagineAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Performance of Short Transmission Line Using Mathematical MethodDocumento8 paginePerformance of Short Transmission Line Using Mathematical MethodInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Staycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityDocumento10 pagineStaycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- A Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)Documento10 pagineA Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)International Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Ijaiem 2021 01 28 6Documento9 pagineIjaiem 2021 01 28 6International Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Design and Detection of Fruits and Vegetable Spoiled Detetction SystemDocumento8 pagineDesign and Detection of Fruits and Vegetable Spoiled Detetction SystemInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Synthetic Datasets For Myocardial Infarction Based On Actual DatasetsDocumento9 pagineSynthetic Datasets For Myocardial Infarction Based On Actual DatasetsInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Impact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryDocumento8 pagineImpact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- A Deep Learning Based Assistant For The Visually ImpairedDocumento11 pagineA Deep Learning Based Assistant For The Visually ImpairedInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Swot Analysis of Backwater Tourism With Special Reference To Alappuzha DistrictDocumento5 pagineSwot Analysis of Backwater Tourism With Special Reference To Alappuzha DistrictInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Design and Manufacturing of 6V 120ah Battery Container Mould For Train Lighting ApplicationDocumento13 pagineDesign and Manufacturing of 6V 120ah Battery Container Mould For Train Lighting ApplicationInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Anchoring of Inflation Expectations and Monetary Policy Transparency in IndiaDocumento9 pagineAnchoring of Inflation Expectations and Monetary Policy Transparency in IndiaInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- The Effect of Work Involvement and Work Stress On Employee Performance: A Case Study of Forged Wheel Plant, IndiaDocumento5 pagineThe Effect of Work Involvement and Work Stress On Employee Performance: A Case Study of Forged Wheel Plant, IndiaInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Guidelines For Choosing A Property Method For Aspen PlusDocumento4 pagineGuidelines For Choosing A Property Method For Aspen Plusashraf-84100% (1)

- R16 - Optimization Techniques - PTM PDFDocumento2 pagineR16 - Optimization Techniques - PTM PDFpadmajasivaNessuna valutazione finora

- Tutorial Sol CH 9Documento11 pagineTutorial Sol CH 9Sameer BitthariaNessuna valutazione finora

- Math 3101: Probability & Statistics - 3 Credits Prerequisite: Math 1100Documento13 pagineMath 3101: Probability & Statistics - 3 Credits Prerequisite: Math 1100AliceLazarNessuna valutazione finora

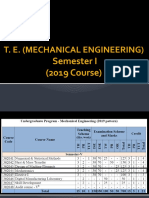

- IntroductionDocumento11 pagineIntroductionHOD MechanicalNessuna valutazione finora

- Three Term ControlDocumento12 pagineThree Term Controlpop3alyNessuna valutazione finora

- UntitledDocumento248 pagineUntitledAliah Gie ZabalaNessuna valutazione finora

- EEC 4043 LECT011 Compensator Design I - Lead and LagDocumento39 pagineEEC 4043 LECT011 Compensator Design I - Lead and Lagjaltiti0% (1)

- 6025 - Computer Sales and Service SystemDocumento34 pagine6025 - Computer Sales and Service SystemVISHESHNessuna valutazione finora

- 2020 - Sept25 - ME 004ADocumento15 pagine2020 - Sept25 - ME 004ADaniel ManivoughNessuna valutazione finora

- Engr. Ehtisham Ul Haq: Professional SummaryDocumento2 pagineEngr. Ehtisham Ul Haq: Professional SummaryEhitishamNessuna valutazione finora

- Kassaye WassieDocumento100 pagineKassaye WassieJeji HirboraNessuna valutazione finora

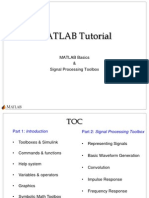

- MATLAB Tutorial: MATLAB Basics & Signal Processing ToolboxDocumento47 pagineMATLAB Tutorial: MATLAB Basics & Signal Processing ToolboxSaeed Mahmood Gul KhanNessuna valutazione finora

- Session01 MET437-Introduction To Servo Systems (Motion Control)Documento14 pagineSession01 MET437-Introduction To Servo Systems (Motion Control)Ahmad A. Al-AteeqiNessuna valutazione finora

- RMF KS EIE PIT FRCS Control System Glossary 07-07-2015Documento7 pagineRMF KS EIE PIT FRCS Control System Glossary 07-07-2015Kleberson MeirelesNessuna valutazione finora

- Navigation of Multiple Mobile Robots in A Highly Clutter Terrains Using Adaptive Neuro Fuzzy Inference System 2015 Robotics and Autonomous SystemsDocumento11 pagineNavigation of Multiple Mobile Robots in A Highly Clutter Terrains Using Adaptive Neuro Fuzzy Inference System 2015 Robotics and Autonomous SystemsMuthukumaranNessuna valutazione finora

- Gupta Et Al-2016-Quality and Reliability Engineering InternationalDocumento10 pagineGupta Et Al-2016-Quality and Reliability Engineering InternationalEli PaleNessuna valutazione finora

- 28 - 7-PDF - Thermodynamics (Red Book) 2Documento1 pagina28 - 7-PDF - Thermodynamics (Red Book) 2PranayNessuna valutazione finora

- Calculating Specific Heat WorksheetDocumento3 pagineCalculating Specific Heat WorksheetAmanda ClayNessuna valutazione finora

- Scrum TestDocumento3 pagineScrum TestMeduzagyzaNessuna valutazione finora

- Lab2 PDFDocumento5 pagineLab2 PDFtrial errorNessuna valutazione finora

- SS Notes PDFDocumento113 pagineSS Notes PDFKhurram RehmanNessuna valutazione finora

- Lesson Plan Che463Documento3 pagineLesson Plan Che463Rafiqah RahimNessuna valutazione finora

- Thermodynamics, Heat & EnthalpyDocumento16 pagineThermodynamics, Heat & EnthalpyTorontoAliNessuna valutazione finora

- CPM (Network Analysis)Documento15 pagineCPM (Network Analysis)ThuTaNaingNessuna valutazione finora

- 04-2019-Peserta MCU-BIO MEDIKA-JKTDocumento20 pagine04-2019-Peserta MCU-BIO MEDIKA-JKTBeny FirmansyahNessuna valutazione finora

- 'AI & Machine Vision Coursework Implementation of Deep Learning For Classification of Natural ImagesDocumento13 pagine'AI & Machine Vision Coursework Implementation of Deep Learning For Classification of Natural ImagesResearchpro GlobalNessuna valutazione finora

- CSE3001 - Software EngineeringDocumento76 pagineCSE3001 - Software EngineeringHarsha VardhanNessuna valutazione finora

- INVERTED PENDULUM On A Cart WITH Linear ACTUATORDocumento14 pagineINVERTED PENDULUM On A Cart WITH Linear ACTUATORRitesh YadavNessuna valutazione finora

- UNIT-7 Dynamic ProgrammingDocumento191 pagineUNIT-7 Dynamic ProgrammingKashish shahNessuna valutazione finora