Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

What You're Not Measuring Could Be Affecting Your Productivity

Caricato da

Quelmis De La Cruz Vilca AmesquitaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

What You're Not Measuring Could Be Affecting Your Productivity

Caricato da

Quelmis De La Cruz Vilca AmesquitaCopyright:

Formati disponibili

What youre not measuring could be

affecting your productivity

If youre not measuring the effectiveness

of your haul truck operator training,

youre missing a valuable opportunity.

Mines often use instructor-led training

with PowerPoint slides to convey critical

safety procedures, introduce the trucks

controls and train operators to perform

key tasks productively. But this

approach isnt very effective with adult

learners, because trainees may not

retain a significant amount of the

material presented using this method. In addition, many mines dont have a systematic

way to measure how much knowledge their trainees have retained before putting them

behind the wheel of a haul truck.

The productivity imperative

Mining operations have a singular focus on maintaining a high level of productivity and

profitability. Haul truck operators who do not understand the interdependencies between

their own work cycles and those of the shovel and dozer operators with whom they work

can easily undermine the mines productivity.

Haul truck operators who dump loads outside target areas, fail to position accurately at

the shovel or inadvertently damage expensive truck tires can have a significant negative

impact on the mines productivity and profitability. Perhaps the training they received

was inadequate or the method used to train them did not encourage retention of the

information.

Big opportunities exist to increase the effectiveness and productivity of new and existing

haul truck operators. Areas of concern include:

Overspeeding, improper braking, dry steering and other undesirable

operating practices, which can cause a high level of reactive maintenance

and ultimately tend to shorten truck life.

New truck operators dont understand how their performance affects the

productivity of the rest of the mines operations. The fact is that they are

part of an interdependent production system. How they manage their haul

2010-12 VISTA Training Inc.

-2-

cycles has a direct impact on the ability of other haul truck, shovel and

dozer operators to do their jobs. Ultimately, the productivity of a mine is only

as good as its weakest link.

Trainees may take too long to reach their production targets. The faster

they can operate safely, productively and independently, without the need

for truck mentors production operators who double as field trainers the

more the mine profits.

Classroom training is hard to schedule without idling trucks and negatively

affecting the mines productivity. Learning should take place when it creates

the least impact on the mines productivity, but too often the ability to do this

is dictated by the availability of trainers and training facilities.

Trainees arent retaining enough of what theyre learning in the classroom,

resulting in a greater need for field training. Like most classroom education,

instructor-led operator training may succeed in stuffing the learners shortterm memory, but often this knowledge is not retained in the field. This

results in a greater amount of remedial training in the mines production

loop, which can cause a serious drain on its overall productivity.

Lack of consistency between shifts and operators can cause significant

variance in productivity. Often, no benchmarks are established for operator

performance, because little or no data about trainee performance

including strengths and weaknesses has been captured during the

learning process.

Haul truck safety remains a big issue; from 1995 to 2007 there were 108

fatal haul truck accidents in the U.S, according to an analysis of data from

the Mine Safety & Health Administration (MSHA).

The bottom line is that improving the efficiency of haul truck operator training can

generate a big payoff for mines in terms of improved productivity, reduced operating

costs and increased safety.

One potential solution: Blended learning

A blended learning curriculum can help mines address these challenges. It utilizes

multiple media to deliver learning that is best suited to the needs of adults. It often

includes these components:

Computer-based learning

Check your knowledge quizzes and tests

Simulation

Job aids and other performance support tools

Assessment data and feedback loops

Structured on-the-job coaching and mentoring

2010-12 VISTA Training Inc.

-3-

Well-designed blended learning solutions can provide real advantages in the mining

environment:

Content delivered via computer-based training technologies is very

consistent all new operators receive the same critical messages.

It accommodates differing learning styles of individual trainees.

It encourages self-directed learning, which means that more training can be

delivered with fewer trainers. The extensive investment of time required to

conduct classroom training limits the trainers ability to provide

individualized on-the-job coaching and mentoring.

Simulations and structured coaching allow for immediate feedback and

hands-on application of learning.

Coaches are armed with assessment data, enabling them to target their

coaching to address individual trainee needs.

In short, minimum effort and resources are employed to gain maximum results.

A practical blended learning framework for the mining industry

A blended learning curriculum is the ideal fit for the needs of the mining industry. Heres

why:

1. Blended learning is focused on the way that adults learn

Effective computer-based training programs adhere to adult learning principles.

Adults need to know why they are learning something.

Adults learn by doing.

Adults are problem-solvers.

Adults learn best when the content is of immediate use.

At the beginning of a multi-lesson program and at the start of each new lesson, learners

benefit from seeing the whole concept or complete idea.

If, for example, the lesson is about how to position the truck for loading, the complete

skills sequence approach into the shovel pit, correct waiting position, clockwise or

counterclockwise turn, location of self-spotting aids, back-in techniques and final loading

position are introduced at the start of the lesson.

Next, the specific tasks involved in positioning for loading are presented in a logical

sequence, allowing the learner to build upon a growing base of knowledge and skill.

The content presented should always address the underlying whys. Consequences to

the operators personal safety, the safety of others, or to equipment or the environment

must be clearly communicated.

When operators understand why they are required to follow a procedure or perform a

task in particular sequence, they are far less likely to engage in risky behavior.

2010-12 VISTA Training Inc.

-4-

2. Engaging content helps trainees retain knowledge better

Mine workers, like many skilled blue-collar workers, are not traditional learners. They

have not always been successful in classroom-type settings, preferring to learn on the

job in a hands-on environment. To engage and hold their interest, content needs to:

Limit the amount of text on screens.

Offer audio narration using people who talk like haul truck operators, not like

radio announcers.

Use the right media for the right purpose.

o High-quality images, illustrations and graphics.

o Video and animation segments that are designed to demonstrate the

steps involved in performing various tasks.

o Performance support tools job aids, diagrams and checklists that can

be utilized on the job.

Include frequent interactive questions to check for understanding and

scenarios that require higher-level problem-solving.

3. Simulations provide trainees with hands-on experience of common tasks

Simulation helps trainees gain experience in the core skills of operating a mining truck

productively, in a safe environment. By learning key tasks and by gaining confidence in

their skills, new operators tend to come up to speed faster once they graduate to the

actual haul trucks.

A low cost, PC-based simulator provides new hires with consistent training, because

everyone works through the same exercises, and they do so in a logical, skill-building

order. This enables mines to establish performance benchmarks and elevate the overall

proficiency of their truck operators. Mines can also use a simulator to pre-screen new

hires and identify those with the greatest natural aptitude for operating equipment.

Simulators will never replace seat-time in real equipment, but they can dramatically

reduce the demands of training on production machines.

4. Computer-based training modules provide greater flexibility

Computer-based training modules can now be delivered via a web browser, to any

computer with a high-speed internet connection. That means that trainees can access

this information at times and locations that are most advantageous to the mine when

they cause the least disturbance to its productivity.

In addition, these learning materials can be designed so that trainees can view them on

a self-paced basis, freeing up trainers to focus on higher-level coaching tasks. Learning

modules can also incorporate quizzes, to help mines assess what trainees have actually

retained, and where they need additional coaching.

2010-12 VISTA Training Inc.

-5-

5. On-the-job training materials tie it all together

As trainees learn truck operation skills in the training modules and truck simulations, a

series of structured on-the-job ride-along activities conducted in the field reinforce what

they have learned and provide a critical hands-on component to the learning process.

Ideally, all field trainers should receive coaching guides, to help them structure these onthe-job activities and bring a stronger level of consistency to the field training process.

These materials should include space for recording operator assessments, notes and

checklists, which provide documentation that the trainee has successfully completed

each on-the-job exercise.

Who offers such an integrated curriculum?

VISTA Training recently launched its innovative new TruckLogic haul truck training

curriculum, which is designed to help mines train new operators faster and at a lower

cost than traditional instructor-led training, while also improving safety in the mine. This

new program is the first of its kind in the mining industry.

TruckLogic combines web-based training, low-cost simulation and on-the-job tools into a

comprehensive curriculum that is designed with adult learners in mind. Based on a

blended learning model, it helps operators retain what theyve learned better than

traditional classroom-style training.

For more information, please contact VISTA Training at 800-942-2886 or send an e-mail

to trucklogic@vista-training.com.

More information can also be found on the TruckLogic website.

2010-12 VISTA Training Inc.

Potrebbero piacerti anche

- Vista Trucklogic BrochureDocumento4 pagineVista Trucklogic BrochureQuelmis De La Cruz Vilca AmesquitaNessuna valutazione finora

- Need For Training: 1. Higher ProductivityDocumento13 pagineNeed For Training: 1. Higher ProductivitykomalgunjiteNessuna valutazione finora

- Pertinent Documents: Republic of The Philippines ACCESS EJC - Montilla, 9800 City of TacurongDocumento7 paginePertinent Documents: Republic of The Philippines ACCESS EJC - Montilla, 9800 City of TacurongcherylpuebloNessuna valutazione finora

- New Technology Based TrainingDocumento7 pagineNew Technology Based TrainingMukesh Kumar SinghNessuna valutazione finora

- List of Training Methods: 1. Technology-Based LearningDocumento10 pagineList of Training Methods: 1. Technology-Based Learningfarjana mitaNessuna valutazione finora

- MotorolaDocumento5 pagineMotorolaSayali Diwate100% (1)

- Training MethodsDocumento9 pagineTraining Methodsaswathi1Nessuna valutazione finora

- Modern Methods of Vocational and Industrial TrainingDa EverandModern Methods of Vocational and Industrial TrainingNessuna valutazione finora

- Industrial Training2Documento26 pagineIndustrial Training2AKSHIT 12Nessuna valutazione finora

- MotorolaDocumento6 pagineMotorolaAsif AshrafNessuna valutazione finora

- Simulator Training Course STW 43-3-4 - Model Course - Train The Simulator Trainer and Assessor (Secretariat)Documento125 pagineSimulator Training Course STW 43-3-4 - Model Course - Train The Simulator Trainer and Assessor (Secretariat)geims1180% (5)

- EdD103 - CR - ALAGON, AMANAH, ANDALOCDocumento17 pagineEdD103 - CR - ALAGON, AMANAH, ANDALOCJACKIE-LOU CALOPEZ ANDALOCNessuna valutazione finora

- Module 5: Management of Training and Employer-Employee RelationsDocumento7 pagineModule 5: Management of Training and Employer-Employee RelationsJithesh VNessuna valutazione finora

- WK 4 Human Resource Training and Development - 1 - 1Documento15 pagineWK 4 Human Resource Training and Development - 1 - 1kenlay makanaNessuna valutazione finora

- Is There A Role For Virtual Reality in Maintenance Training?Documento10 pagineIs There A Role For Virtual Reality in Maintenance Training?Tim_NutmanNessuna valutazione finora

- Training Methods: Why Is Choosing A Training Method Important?Documento14 pagineTraining Methods: Why Is Choosing A Training Method Important?ShareenNessuna valutazione finora

- Trainig Center - Technical Rescue Training Hurdles and Solutions How To Fund and Run Handson Training CenterDocumento9 pagineTrainig Center - Technical Rescue Training Hurdles and Solutions How To Fund and Run Handson Training CenterGaudencio BoniceliNessuna valutazione finora

- BUS 375 Technological Based Employee TraniningDocumento11 pagineBUS 375 Technological Based Employee TraniningMoazzam ShahNessuna valutazione finora

- Sesiขn #6 (PM) - Tratamiento, Intervenciขn, Prevenciขn y Supervisiขn (Psicologกa Industrial) - Anejo #1Documento2 pagineSesiขn #6 (PM) - Tratamiento, Intervenciขn, Prevenciขn y Supervisiขn (Psicologกa Industrial) - Anejo #1Luz N. FernándezNessuna valutazione finora

- Seri CultureDocumento87 pagineSeri CultureThanh ThuanNessuna valutazione finora

- Elgi FinalDocumento85 pagineElgi FinalPavoNessuna valutazione finora

- CallaghanDocumento4 pagineCallaghanFixNessuna valutazione finora

- E-Learning in The Industrial Refrigeration: IndustryDocumento11 pagineE-Learning in The Industrial Refrigeration: IndustryRASHEED YUSUFNessuna valutazione finora

- Work at Height Course For WorkersDocumento5 pagineWork at Height Course For Workersvepybakek1t3100% (2)

- Activity (Employee Training)Documento2 pagineActivity (Employee Training)Maxin PineNessuna valutazione finora

- Marine Engg - Sector NCVT MesDocumento30 pagineMarine Engg - Sector NCVT MesRENGANATHAN PNessuna valutazione finora

- SUMMARY REPORT InternDocumento3 pagineSUMMARY REPORT Internnur amanina ayuniNessuna valutazione finora

- B19WQTTDocumento43 pagineB19WQTTKnow HowNessuna valutazione finora

- TQM Activity: College of Business and AccountancyDocumento3 pagineTQM Activity: College of Business and AccountancyLess BalesoroNessuna valutazione finora

- Training Institutes: Modi Institute of Management and Techonology KotaDocumento25 pagineTraining Institutes: Modi Institute of Management and Techonology Kotadivyathomas0240% (5)

- Difference Between Apprenticeship and InternshipDocumento5 pagineDifference Between Apprenticeship and Internshipchicken pork adoboNessuna valutazione finora

- Ref Final MarchDocumento26 pagineRef Final Marchajaysharma19686191Nessuna valutazione finora

- Allencomm Microlearning Powerful Training Tool For OnboardingDocumento14 pagineAllencomm Microlearning Powerful Training Tool For OnboardingJStone100% (1)

- Dgms Cir WRT mvtr1Documento20 pagineDgms Cir WRT mvtr1ramkumarNessuna valutazione finora

- Activity (Employee Training) - GUNDAYAO, REJOICE R.Documento2 pagineActivity (Employee Training) - GUNDAYAO, REJOICE R.Rejoice GundayaoNessuna valutazione finora

- BUILDING THE SKILLS: LEARNING EXPERIENCE AT A CHARTERED ACCOUNTANT FIRMDa EverandBUILDING THE SKILLS: LEARNING EXPERIENCE AT A CHARTERED ACCOUNTANT FIRMNessuna valutazione finora

- Session 14 - HRM - Training & DevelopmentDocumento24 pagineSession 14 - HRM - Training & DevelopmentPedro CruzNessuna valutazione finora

- Developing Human ResourcesDocumento89 pagineDeveloping Human ResourcesSäñtosh ÄdhïkärïNessuna valutazione finora

- Technical ReportDocumento9 pagineTechnical Reportbenjamin danladiNessuna valutazione finora

- NIIT - IMPERIA - World Education Award 2011Documento5 pagineNIIT - IMPERIA - World Education Award 2011NIIT_IMPERIANessuna valutazione finora

- Portfolio Project: EDUC 765: Trends and Issues in Instructional DesignDocumento21 paginePortfolio Project: EDUC 765: Trends and Issues in Instructional Designapi-361466236Nessuna valutazione finora

- Concept MapDocumento4 pagineConcept MapRegine Joy PeraltaNessuna valutazione finora

- Assignment Mam Aqsa 0124Documento4 pagineAssignment Mam Aqsa 0124ali burhan tahirNessuna valutazione finora

- ASCI Chapter One and Two Homework 2Documento5 pagineASCI Chapter One and Two Homework 2Levi BrownNessuna valutazione finora

- Vestibule Training Plan-Safety in WorkshopDocumento8 pagineVestibule Training Plan-Safety in WorkshopEdy Halen L. TauthoNessuna valutazione finora

- Motor WindingDocumento40 pagineMotor WindingALI AKBARNessuna valutazione finora

- Managing Performance Through Training and Development 6th Edition Saks Solutions ManualDocumento11 pagineManaging Performance Through Training and Development 6th Edition Saks Solutions Manualchristopherbrownfpoqagcisz100% (36)

- Andaloc Term Paper Peace EducationDocumento11 pagineAndaloc Term Paper Peace EducationJACKIE-LOU CALOPEZ ANDALOCNessuna valutazione finora

- Off The Job Training Methods.Documento8 pagineOff The Job Training Methods.Jakaria Khan100% (1)

- Week 9Documento17 pagineWeek 9kielaustin1968Nessuna valutazione finora

- Training and Development Module 5 - 2023Documento7 pagineTraining and Development Module 5 - 2023Revenlie GalapinNessuna valutazione finora

- Unit 3 Employee Training and DevelopmentDocumento23 pagineUnit 3 Employee Training and Developmentkumar sahityaNessuna valutazione finora

- Division of Work: Topic 1 Elearning ImportanceDocumento9 pagineDivision of Work: Topic 1 Elearning ImportanceTAREK536281Nessuna valutazione finora

- Portfolio Project: EDUC 765: Trends and Issues in Instructional DesignDocumento15 paginePortfolio Project: EDUC 765: Trends and Issues in Instructional Designapi-283326236Nessuna valutazione finora

- Training Effectiveness Measurement for Large Scale Programs: Demystified!Da EverandTraining Effectiveness Measurement for Large Scale Programs: Demystified!Nessuna valutazione finora

- Advanced CADCAMDocumento34 pagineAdvanced CADCAMNusrat IqbalNessuna valutazione finora

- Work at Height Assessor Course CentreDocumento7 pagineWork at Height Assessor Course Centrekqgcnxejd100% (1)

- Industrial Training ReportDocumento22 pagineIndustrial Training ReportAce100% (2)

- Training Module FinaleDocumento21 pagineTraining Module FinaleAurora Dayao PastoleroNessuna valutazione finora

- Zhjqag 232 PDFDocumento1 paginaZhjqag 232 PDFQuelmis De La Cruz Vilca AmesquitaNessuna valutazione finora

- Technology and ServicesDocumento4 pagineTechnology and ServicesQuelmis De La Cruz Vilca AmesquitaNessuna valutazione finora

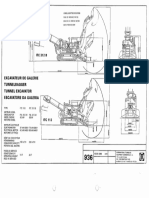

- Schaeff ITC 312Documento1 paginaSchaeff ITC 312Quelmis De La Cruz Vilca AmesquitaNessuna valutazione finora

- Troidon 66 PDFDocumento4 pagineTroidon 66 PDFQuelmis De La Cruz Vilca AmesquitaNessuna valutazione finora

- Alldrive 9 Tonne Power Swivel: SpecificationsDocumento2 pagineAlldrive 9 Tonne Power Swivel: SpecificationsQuelmis De La Cruz Vilca AmesquitaNessuna valutazione finora

- 2090 9tonne Front Tip UK PDFDocumento2 pagine2090 9tonne Front Tip UK PDFQuelmis De La Cruz Vilca AmesquitaNessuna valutazione finora

- 9tonne Front Tip UK PDFDocumento2 pagine9tonne Front Tip UK PDFQuelmis De La Cruz Vilca AmesquitaNessuna valutazione finora

- 9tonne Front Tip UK PDFDocumento2 pagine9tonne Front Tip UK PDFQuelmis De La Cruz Vilca AmesquitaNessuna valutazione finora

- 10tonne Front Tip UK PDFDocumento2 pagine10tonne Front Tip UK PDFQuelmis De La Cruz Vilca AmesquitaNessuna valutazione finora

- HF6 Assessment Progress Test 2ADocumento3 pagineHF6 Assessment Progress Test 2ACarla Couto100% (3)

- TheWisestCalendar 2024 by PavanBhattadDocumento22 pagineTheWisestCalendar 2024 by PavanBhattadSachin SharmaNessuna valutazione finora

- SupervisorDocumento2 pagineSupervisorapi-78116377Nessuna valutazione finora

- Level 1: True True Fals e True Fals e Fals eDocumento3 pagineLevel 1: True True Fals e True Fals e Fals eEgor Rybkin0% (1)

- 'White Room Torture' A Sensory Denial Method Which Obliterates All Sense of RealismDocumento7 pagine'White Room Torture' A Sensory Denial Method Which Obliterates All Sense of RealismFilip ShulevskiNessuna valutazione finora

- 450px Huffman2Documento23 pagine450px Huffman2Nam PhanNessuna valutazione finora

- Chapter 14 Managing TeamsDocumento24 pagineChapter 14 Managing TeamsmevasNessuna valutazione finora

- Las Pequeñas Cosas Que Hacen Que Los Empleados Se Sientan ApreciadosDocumento7 pagineLas Pequeñas Cosas Que Hacen Que Los Empleados Se Sientan ApreciadosFidel Porras TapiaNessuna valutazione finora

- 77-Article Text-218-1-10-20220630Documento16 pagine77-Article Text-218-1-10-20220630EDIT VLOGNessuna valutazione finora

- Rose CompanyDocumento8 pagineRose Companyravina10008100% (1)

- Aprendizaje Significativo de Ausubel y Segregación EducativaDocumento20 pagineAprendizaje Significativo de Ausubel y Segregación EducativaLizet SantacruzNessuna valutazione finora

- Self TalkDocumento14 pagineSelf TalkAzizan AbasNessuna valutazione finora

- Lesson PlanDocumento22 pagineLesson PlanHarim Qudsi100% (1)

- 25 Test Bank QuestionsDocumento6 pagine25 Test Bank QuestionsS. Jacobs100% (1)

- Problem 1: A Study of 11,160 Alcohol Drinkers On University Campuses RevealedDocumento3 pagineProblem 1: A Study of 11,160 Alcohol Drinkers On University Campuses RevealedHaroldNessuna valutazione finora

- Department of Education: Republic of The PhilippinesDocumento1 paginaDepartment of Education: Republic of The PhilippinesRonalaine IrlandezNessuna valutazione finora

- Nursing ResearchDocumento5 pagineNursing Researchprokuno89% (9)

- The Alter Ego EffectDocumento1 paginaThe Alter Ego EffecthemsrNessuna valutazione finora

- Cardcaptor Sakura Fortune TranslationDocumento8 pagineCardcaptor Sakura Fortune TranslationMaria Zamantha Gatchalian100% (1)

- Special Meeting 8.14.15 Agenda and Materials Website1 - 8Documento452 pagineSpecial Meeting 8.14.15 Agenda and Materials Website1 - 8KOLD News 13Nessuna valutazione finora

- J Gray Theorists and TheoriesDocumento7 pagineJ Gray Theorists and Theoriesapi-528983071Nessuna valutazione finora

- Social Media Documentary ScriptDocumento2 pagineSocial Media Documentary Scriptapi-477398424Nessuna valutazione finora

- The Perception of Grade 11 Humss Students of Felix Amante Senior High School To Gender Inequaluity of The Young Generation School Year 2022Documento15 pagineThe Perception of Grade 11 Humss Students of Felix Amante Senior High School To Gender Inequaluity of The Young Generation School Year 2022Jerymy Dareen Alamares SantosNessuna valutazione finora

- FallaciesDocumento12 pagineFallaciesNahyanNessuna valutazione finora

- Week 25 New Kinder DLL From New TG 2018Documento10 pagineWeek 25 New Kinder DLL From New TG 2018Ecyoj Bantaculo Casilac100% (1)

- An Introduction To The Competing Values FrameworkDocumento4 pagineAn Introduction To The Competing Values FrameworknmandavaNessuna valutazione finora

- Ccss Lesson Plan On Supplementary Complementary AnglesDocumento9 pagineCcss Lesson Plan On Supplementary Complementary Anglesapi-314719374100% (2)

- Gcic NCP Seizure PICUOSMUNDocumento2 pagineGcic NCP Seizure PICUOSMUNhanyaklein100% (3)

- L2-Analyze Humor - Two Legs or OneDocumento10 pagineL2-Analyze Humor - Two Legs or Oneashu karen100% (2)

- Alternative Indicators of Well-Being For VanuatuDocumento115 pagineAlternative Indicators of Well-Being For VanuatuonibabaNessuna valutazione finora