Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tyfo SCH-41 Composite: Using Tyfo S Epoxy

Caricato da

PE EngTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tyfo SCH-41 Composite: Using Tyfo S Epoxy

Caricato da

PE EngCopyright:

Formati disponibili

Tyfo SCH-41 Composite

using Tyfo S Epoxy

DESCRIPTION

TYPICAL DRY FIBER PROPERTIES

The Tyfo SCH-41 Composite is comprised of

Tyfo S Epoxy and Tyfo SCH-41 reinforcing

fabric, which is NSF-Certified. Tyfo SCH-41 is

a custom, uni-directional carbon fabric orientated

in the 0 o direction. The Tyfo S Epoxy is a twocomponent epoxy matrix.

PROPERTY

TYPICAL TEST VALUE

Tensile Strength

580,000 psi (4.0 GPa)

Tensile Modulus

33.4 x 106 psi (230 GPa)

Ultimate Elongation

USE

Tyfo SCH-41 Fabric is combined with Tyfo

Epoxy to add strength to bridges, buildings, and

other structures.

1.7%

Density

0.063 lbs./in. (1.74 g/cm3)

3

Minimum weight per sq. yd.

19 oz. (644 g/m2)

ADVANTAGES

ICC-ES ESR-2103 listed product

Component of UL listed, fire-rated assembly

NSF/ANSI Standard 61 listed product for

drinking water systems

Improved long-term durability

Good high & low temperature properties

Long working time

High tensile modulus and strength

Ambient cure

100% solvent-free

Rolls can be cut to desired widths prior to

shipping

COMPOSITE GROSS LAMINATE PROPERTIES

COVERAGE

Approximately 600 sq. ft. surface area with 3

to 4 units of Tyfo S Epoxy and 1 roll of Tyfo

SCH-41 Fabric when used with the Tyfo

Saturator.

PACKAGING

Order Tyfo S Epoxy in 55-gallon (208L) drums

or pre-measured units in 5-gallon (19L)

containers. Tyfo SCH-41 Fabric typically

shipped in 24 x 300 lineal foot (0.6m x 91.4m)

rolls. Typically ships in 12 x 13 x 27 (305mm

x 330mm x 686mm) boxes.

ASTM

METHOD

TYPICAL

TEST VALUE

DESIGN VALUE*

Ultimate Tensile Strength in

Primary Fiber Direction

D3039

143,000 psi (986 MPa)

(5.7 kip/in. width)

121,000 psi (834 MPa)

(4.8 kip/in. width)

Elongation at Break

D3039

1.0%

0.85%

Tensile Modulus

D3039

13.9 x 10 psi

(95.8 GPa)

11.9 x 106 psi

(82 GPa)

Flexural Strength

D790

17,900 psi (123.4 MPa)

15,200 psi (104.8 MPa)

Flexural Modulus

D790

452,000 psi (3.12 GPa)

384,200 psi (2.65 GPa)

Longitudinal Compressive

Strength

D3410

50,000 psi

(344.8 MPa)

42,500 psi

(293 MPa)

Longitudinal Compressive

Modulus

D3410

11.2 x 106 psi

(77.2 GPa)

9.5 x 106 psi

(65.5 GPa)

Longitudinal Coefficient of

Thermal Expansion

D696

3.6 ppm./oF

Transverse Coefficient of

Thermal Expansion

D696

20.3 ppm./oF

PROPERTY

Nominal Laminate Thickness

0.04 in. (1.0mm)

0.04 in. (1.0mm)

* Gross laminate design properties based on ACI 440 suggested guidelines will vary slightly. Contact Fyfe Co. LLC engineers to

confirm project specification values and design methodology.

EPOXY MIX RATIO

100.0 component A to 42.0 component B

by volume. (100 component A to 34.5 component

B by weight.)

EPOXY MATERIAL PROPERTIES

Curing Schedule 72 hours post cure at 140o F (60o C).

SHELF LIFE

STORAGE CONDITIONS

Store epoxy at 40o to 90o F (4o to 32o C). Avoid

freezing. Store rolls flat, not on ends, at

temperatures below 100 o F (38 o C). Avoid

moisture and water contamination.

CERTIFICATE OF COMPLIANCE

Will be supplied upon request, complete

with state and federal packaging laws

with copy of labels used.

Material safety data sheets will be supplied

upon request.

Possesses 0% V.O.C. level.

5/15 SCH-41

ASTM

METHOD

TYPICAL

TEST VALUE*

Tensile Strength1

D638

Type 1

10,500 psi

(72.4 MPa)

Tensile Modulus

D638

Type 1

461,000 psi

(3.18 GPa)

Elongation Percent

D638

Type 1

5.0%

Flexural Strength

D790

17,900 psi (123.4 MPa)

Flexural Modulus

D790

452,000 psi (3.12 GPa)

Tg

D4065

180o F (82o C)

PROPERTY

Epoxy - two years in original, unopened and

properly stored containers.

Fabric - ten years in proper storage conditions.

Testing temperature: 70o F (21o C)

Crosshead speed: 0.5 in. (13mm)/min. Grips Instron 2716-0055 - 30 kips

* Specification values can be provided upon request.

1

APPLICATION

HOW TO USE

THE TYFO S COMPOSITE SYSTEM

DESIGN

The Tyfo Fibrwrap System shall be designed

to meet specific design criteria. The criteria

for each project is dictated by the engineer of

record and any relevant building codes and/or

guidelines. The design should be based on the

allowable strain for each type of application and

the design modulus of the material. The Fyfe

Co. LLC engineering staff will provide preliminary

design at no obligation.

INSTALLATION

Tyfo System to be installed by Fyfe Co. LLC

trained and certified applicators. Installation

shall be in strict compliance with the Fyfe Co.

LLC Quality Control Manual.

SURFACE PREPARATION

The required surface preparation is largely

dependent on the type of element being

strengthened. In general, the surface must be

clean, dry and free of protrusions or cavities,

which may cause voids behind the Tyfo

composite. Column surfaces that will receive

continuous wraps typically require only a broom

cleaning. Discontinuous wrapping surfaces

(walls, beams, slabs, etc.) typically require a light

sandblast, grinding or other approved methods

to prepare for bonding. Sharp and chamfered

corners will be rounded off by grinding or using

thickened Tyfo S epoxy (Tyfo WS epoxy or

approved repair mortar). At the time of application,

the substrate shall not have any free moisture

on it. If moisture cannot be avoided, the use of

Tyfo WP (Wet-Prime epoxy) is recommended.

Tyfo Fibr Anchors are incorporated in some

designs. The Fyfe Co. LLC engineering staff will

provide the proper specifications and details based

on the project requirements.

Apply one prime coat of Tyfo S Epoxy on the

substrate by using a roller. Saturate the fabric

by feeding it through the Tyfo Saturator.

Apply using the Tyfo wrapping equipment

or approved hand methods (See the Tyfo

Saturator Manual). Prior to the application of

the saturated fabric, fill any uneven surface

with thickened Tyfo S epoxy. Saturate

and apply subsequent layers of the fabric

according to the Specifications and the

Design Requirements. The use of a roller or

hand pressure, ensure proper orientation of

fibers, release or roll out entrapped air and

ensure that each individual layer is firmly

bedded and adhered to the preceding layer

or substrate. Apply a final coat of thickened

Tyfo S Epoxy and detail all fabric edges,

including butt splice, termination points and

jacket edges. Please refer to the NSF Listing

for the NSF-61 Listed Application.

PROTECTIVE COATINGS

In case of plaster final coating, apply sand by

hand for better bonding surface while the final

coat of epoxy is still tacky. In case of paint final

coating, paint between 24 and 72 hours after final

application of epoxy. If more than 72 hours after

application, prepare the surface of the final coat

of epoxy by light sandblast or hand sanding to

slightly etch the surface.

LIMITATIONS

Application temperature of the epoxy is a

minimum 40o F (4o C) and maximum of 100o F

(38o C). DO NOT THIN, solvents will prevent

proper cure.

FIELD QUALITY CONTROL

Record batch numbers for fabric and epoxy used

each day and note locations of installations.

Measure square feet of fabric and volume of

epoxy used each day.

MIXING

For pre-measured units in 5-gallon (19L)

containers, pour the contents of component

B into the pail of component A. For drums,

premix each component: 100.0 parts of

component A to 42.0 parts of component B by

volume (100 parts of component A to 34.5 parts of

component B by weight). Mix thoroughly for five

minutes with a Tyfo low speed mixer at 400-600

RPM until uniformly blended.

CAUTION!

COMPONENT A - Irritant:

Prolonged contact to the skin may cause

irritation. Avoid eye contact.

COMPONENT B - Irritant:

Corrosive. Contact with skin may cause severe

burns. Avoid eye contact. Product is a strong

sensitizer. Use of safety goggles and chemical

resistant gloves recommended. Remove

contaminated clothing. Avoid breathing vapors.

Use adequate ventilation. Use of an organic

vapor respirator recommended.

SAFETY PRECAUTIONS

Avoid breathing vapors. Avoid contact with eyes

and skin. Use of an approved respirator with an

organic absorption cartridge is recommended

for possible vapors. Rubber gloves, rubber

boots, and protective suits are recommended

for handling and application of this material.

Safety glasses or a face shield are recommended

to prevent eye contact.

FIRST AID

In case of skin contact, wash thoroughly with

soap and water. For eye contact, flush

immediately. For respiratory problems, remove

to fresh air. Wash clothing before reuse.

CLEANUP

Collect with absorbent material, flush with

water. Dispose of in accordance with local

disposal regulations. Uncured material can be

removed with approved solvent. Cured materials

can only be removed mechanically.

SHIPPING LABELS CONTAIN

State specification number with modifications,

if applicable

Component designation

Type, if applicable

Manufacturers name

Date of manufacture

Batch name

State lot number, if applicable

Directions for use

Warnings or precautions by law

KEEP CONTAINER TIGHTLY CLOSED.

NOT FOR INTERNAL CONSUMPTION.

CONSULT MATERIAL SAFETY DATA SHEET

(MSDS) FOR MORE INFORMATION.

KEEP OUT OF REACH OF CHILDREN.

FOR INDUSTRIAL USE ONLY.

Fyfe Co. LLC

Tyfo Fibrwrap Systems

3940 Ruffin Road, Suite C, San Diego, CA 92123

Tel: 858.642.0694 Fax: 858.444.2982

E-mail: info@fyfeco.com www.fyfeco.com

Statement of Responsibility: The technical information and application advice in this publication is based on the present state of our best scientific and practical knowledge.

As the nature of the information herein is general, no assumption can be made as to the products suitability for a particular use or application, and no warranty as to its

accuracy, reliability or completeness, either expressed or implied, is given other than those required by State legislation. The owner, his representative or the contractor is

responsible for checking the suitability of products for their intended use. Field service, where provided, does not constitute supervisory responsibility. Suggestions made

by the Fyfe Co., either verbally or in writing, may be followed, modified or rejected by the owner, engineer or contractor since they, and not the Fyfe Co., are responsible

for carrying out procedure appropriate to a specific application.

5/15 SCH-41

Patented in U.S.A., Canada, and other countries. Copyright 2015 Fyfe Co. LLC 18-15

Potrebbero piacerti anche

- Fiber WrapDocumento2 pagineFiber WrapStephen WilberNessuna valutazione finora

- Tyfo SEH 51A CompositeDocumento2 pagineTyfo SEH 51A CompositeThanongsak ImjaiNessuna valutazione finora

- Tyfo SCH AnchorsDocumento2 pagineTyfo SCH AnchorsLindy KhoNessuna valutazione finora

- Tyfo SW-1 EpoxyDocumento2 pagineTyfo SW-1 EpoxyJeje AjrNessuna valutazione finora

- Tyfo SEH-51ADocumento2 pagineTyfo SEH-51AgammankNessuna valutazione finora

- Pricelist Bahan Bangunan NewDocumento1 paginaPricelist Bahan Bangunan NewzainulNessuna valutazione finora

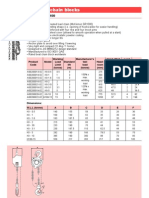

- Fastener BrochureDocumento8 pagineFastener BrochureSugumarNessuna valutazione finora

- Quick guide to choosing the right flooring gratingDocumento32 pagineQuick guide to choosing the right flooring gratingFaris MahmoodNessuna valutazione finora

- Daftar Harga Cat Tembok InteriorDocumento5 pagineDaftar Harga Cat Tembok InteriorAnonymous a2C6YgevfNessuna valutazione finora

- MJC Reverse Jet Cartridge FilterDocumento6 pagineMJC Reverse Jet Cartridge FilterJuan Karlos Alberca AlfaroNessuna valutazione finora

- Elephant Manual Chain BlocksDocumento1 paginaElephant Manual Chain BlocksFeroz HameedNessuna valutazione finora

- Near Zero Leak Kiln Seals Using Graphite Block TechnologyDocumento17 pagineNear Zero Leak Kiln Seals Using Graphite Block TechnologymkpqNessuna valutazione finora

- Conplast CWP: High Performance Integral Crystalline Waterproofing For Concrete Uses DescriptionDocumento3 pagineConplast CWP: High Performance Integral Crystalline Waterproofing For Concrete Uses DescriptionAditya KrisnandaNessuna valutazione finora

- Facade & Fenestration Glass Embedding General GuidelinesDocumento20 pagineFacade & Fenestration Glass Embedding General GuidelinesFrancisco BastidasNessuna valutazione finora

- Inaba-Denko 201103 CatalogDocumento28 pagineInaba-Denko 201103 CatalogAde S100% (1)

- Bridgestone Catalogue PDFDocumento44 pagineBridgestone Catalogue PDFHaviz Albar, S.TNessuna valutazione finora

- Fyfe Corporate BrochureDocumento16 pagineFyfe Corporate BrochuresaikiranNessuna valutazione finora

- Katalog Smart Joint GapuraDocumento5 pagineKatalog Smart Joint GapurarosiNessuna valutazione finora

- Pt. Magdatama - Wabo Stripseal JointDocumento5 paginePt. Magdatama - Wabo Stripseal JointMangisi Haryanto ParapatNessuna valutazione finora

- Brosur Pt. Srirejeki Perdana Steel-1Documento16 pagineBrosur Pt. Srirejeki Perdana Steel-1Agus SofiansyahNessuna valutazione finora

- Foam Chamber Installation GuideDocumento5 pagineFoam Chamber Installation GuideN AfiyahNessuna valutazione finora

- Jotamastic 80: Technical Data SheetDocumento14 pagineJotamastic 80: Technical Data SheetCv RONATAMA GUSLHANNessuna valutazione finora

- Rust-inhibiting yellow primer for steelDocumento2 pagineRust-inhibiting yellow primer for steelPancho JoseNessuna valutazione finora

- Lamella Pre Sed TankDocumento1 paginaLamella Pre Sed TankmilesNessuna valutazione finora

- Produk Range Tms OkDocumento1 paginaProduk Range Tms Oknur wahyu dewi kusrini50% (2)

- Schedule PeralatanDocumento1 paginaSchedule PeralatanHendra FebriantNessuna valutazione finora

- 22-Stainless Steel Aisi 316 (A4)Documento1 pagina22-Stainless Steel Aisi 316 (A4)Paul OnionsNessuna valutazione finora

- Easy Maintenance Air Conditioning System FeaturesDocumento1 paginaEasy Maintenance Air Conditioning System FeaturesKevin Lau100% (1)

- Project Reference Catalogue TOTODocumento36 pagineProject Reference Catalogue TOTOnovalferdyanNessuna valutazione finora

- Fibermesh Sikafiber Guide and ChartDocumento6 pagineFibermesh Sikafiber Guide and ChartajatNessuna valutazione finora

- FRP VesselsDocumento4 pagineFRP VesselsKAMIL SHAIKHNessuna valutazione finora

- List Scaffolding Keluar DR PT. MEI (2020)Documento7 pagineList Scaffolding Keluar DR PT. MEI (2020)Bahar Agus KurniawanNessuna valutazione finora

- Flange Reference ChartDocumento3 pagineFlange Reference ChartJade ClemenoNessuna valutazione finora

- GeoDocumento5 pagineGeoRizal AdyNessuna valutazione finora

- Company Profil PT. Sakura Matriks Utama RevisiDocumento37 pagineCompany Profil PT. Sakura Matriks Utama Revisiyonathan haris tangdililingNessuna valutazione finora

- MTO Generator Box CutDocumento29 pagineMTO Generator Box Cutrony 2222Nessuna valutazione finora

- MODENA Product Brochure (Cooking)Documento21 pagineMODENA Product Brochure (Cooking)Idham SyahNessuna valutazione finora

- Kabel MetalDocumento2 pagineKabel Metalsri haryadiNessuna valutazione finora

- Patchroc RSPDocumento46 paginePatchroc RSPvietpineNessuna valutazione finora

- Annex 7-2 Deviation ListDocumento3 pagineAnnex 7-2 Deviation Listabdullah amanullahNessuna valutazione finora

- PT. INDOPUTRA PERDANA Pawell Chain Block QuotationDocumento1 paginaPT. INDOPUTRA PERDANA Pawell Chain Block QuotationAgung SetiawanNessuna valutazione finora

- Master Glenium SKY 8108: High Range Water Reducing AdmixtureDocumento2 pagineMaster Glenium SKY 8108: High Range Water Reducing Admixturedana setiawanNessuna valutazione finora

- Mesin - Tools FRP Pipe PDFDocumento63 pagineMesin - Tools FRP Pipe PDFpaulNessuna valutazione finora

- Procedure for Fireproof Coating ApplicationDocumento7 pagineProcedure for Fireproof Coating Applicationarrojak maksumNessuna valutazione finora

- T101 Drilling Machine BrochureDocumento4 pagineT101 Drilling Machine BrochureRicardo OrtegaNessuna valutazione finora

- PT Tasblock Industry Indonesia Composite Building MaterialsDocumento81 paginePT Tasblock Industry Indonesia Composite Building MaterialsadjisetiaNessuna valutazione finora

- Brochure Wika CLT - A5 - 280717 PDFDocumento19 pagineBrochure Wika CLT - A5 - 280717 PDFHvbryNessuna valutazione finora

- Mechanical - Anchoring - DynaBolt Plus PDFDocumento6 pagineMechanical - Anchoring - DynaBolt Plus PDFAnonymous dSFbLxc9Nessuna valutazione finora

- Sika Intraplast ZDocumento3 pagineSika Intraplast Zreborn_willyNessuna valutazione finora

- Tabel Berat Besi IIDocumento4 pagineTabel Berat Besi IIHermawan Septian Adittya100% (1)

- Fig. 137: Fig. 137S :: Bolts, Nuts, Pins & U-BoltsDocumento1 paginaFig. 137: Fig. 137S :: Bolts, Nuts, Pins & U-BoltsMarco AntonioNessuna valutazione finora

- C1155Documento8 pagineC1155dinhtung2210Nessuna valutazione finora

- Basf Masterpolyheed 8118 TdsDocumento2 pagineBasf Masterpolyheed 8118 Tdsaji arafat100% (2)

- JIS B 0001: Technical Drawings For Mechanical EngineeringDocumento7 pagineJIS B 0001: Technical Drawings For Mechanical EngineeringAMIT VERMA0% (1)

- Steel Plate For For Boiler Pressure Vessel DIN17135 A ST 41 SteelDocumento1 paginaSteel Plate For For Boiler Pressure Vessel DIN17135 A ST 41 SteelAull Krizz NaGrt0% (1)

- Tyfo SDocumento2 pagineTyfo SAndi AsNessuna valutazione finora

- Nitobond Ep..Documento4 pagineNitobond Ep..budhikurniawanNessuna valutazione finora

- Tyfo WS Epoxy Data Sheet (12-17)Documento2 pagineTyfo WS Epoxy Data Sheet (12-17)Jhonel Loyola MalonzoNessuna valutazione finora

- Nitobond EP : Constructive SolutionsDocumento4 pagineNitobond EP : Constructive SolutionsmilanbrasinaNessuna valutazione finora

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionDa EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNessuna valutazione finora

- Icri 310-2R-2013Documento54 pagineIcri 310-2R-2013Anjali Anju100% (1)

- Tyfo RR Standard Concrete Gray Data SheetDocumento1 paginaTyfo RR Standard Concrete Gray Data SheetPE EngNessuna valutazione finora

- Ufgs 03 01 00 (FRP Spec)Documento10 pagineUfgs 03 01 00 (FRP Spec)PE EngNessuna valutazione finora

- City of LA Research Report #25260L-2014LABC-11-01-2015Documento3 pagineCity of LA Research Report #25260L-2014LABC-11-01-2015PE EngNessuna valutazione finora

- Surveying Exams Part 1Documento26 pagineSurveying Exams Part 1PE Eng80% (5)

- Contractors License - Study GuideDocumento2 pagineContractors License - Study GuidePE EngNessuna valutazione finora

- LawStudyGuide PDFDocumento2 pagineLawStudyGuide PDFPE EngNessuna valutazione finora

- Fyfe Co Brochure 5-5-09Documento20 pagineFyfe Co Brochure 5-5-09PE Eng100% (1)

- Tyfo Fibrwrap Anchor Systems BrochureDocumento8 pagineTyfo Fibrwrap Anchor Systems BrochurePE EngNessuna valutazione finora

- Astm D543Documento7 pagineAstm D543PE EngNessuna valutazione finora

- LawStudyGuide PDFDocumento2 pagineLawStudyGuide PDFPE EngNessuna valutazione finora

- AC125 Requirements and Extended DurabilityDocumento7 pagineAC125 Requirements and Extended DurabilityPE EngNessuna valutazione finora

- Bridge Health Monitoring (BHM) Techniques and Case StudyDocumento12 pagineBridge Health Monitoring (BHM) Techniques and Case StudyPE EngNessuna valutazione finora

- ACI & AASHTO PowerpointDocumento20 pagineACI & AASHTO PowerpointPE EngNessuna valutazione finora

- CA Contractors 2013 PDFDocumento1.067 pagineCA Contractors 2013 PDFJulio SibrianNessuna valutazione finora

- Structure Magazine Article - State of The Industry (Final Draft)Documento4 pagineStructure Magazine Article - State of The Industry (Final Draft)PE EngNessuna valutazione finora

- Asbestos Contractor's Guide and Open Book ExamDocumento52 pagineAsbestos Contractor's Guide and Open Book ExamPE Eng100% (1)

- Bond Behavior of FRP in Structures ASE 9-6Documento120 pagineBond Behavior of FRP in Structures ASE 9-6PE EngNessuna valutazione finora

- Durability of Fibre Reinforced Polymers Used in Concrete StructuresDocumento163 pagineDurability of Fibre Reinforced Polymers Used in Concrete StructuresPE EngNessuna valutazione finora

- Opflow CFRP ArticleDocumento7 pagineOpflow CFRP ArticlePE EngNessuna valutazione finora

- Transitioning From Leak Detection To Leak Prevention Draft PaperDocumento7 pagineTransitioning From Leak Detection To Leak Prevention Draft PaperPE EngNessuna valutazione finora

- 2010 SEAOC Convention ProceedingsDocumento9 pagine2010 SEAOC Convention ProceedingsPE EngNessuna valutazione finora

- Recycling of Denim Fabric Wastes Into High-Performance Composites Using The Needle-Punching Nonwoven Fabrication RouteDocumento15 pagineRecycling of Denim Fabric Wastes Into High-Performance Composites Using The Needle-Punching Nonwoven Fabrication Routeparus bukhariNessuna valutazione finora

- ITW Devcon Material Safety Data Sheet: 5-Minute Epoxy ResinDocumento12 pagineITW Devcon Material Safety Data Sheet: 5-Minute Epoxy ResinBatanNessuna valutazione finora

- SC2031 PDFDocumento4 pagineSC2031 PDFA MahmoodNessuna valutazione finora

- Enviroline 222+ds+eng PDFDocumento4 pagineEnviroline 222+ds+eng PDFMohamed NouzerNessuna valutazione finora

- SP-2888 RG PDSDocumento5 pagineSP-2888 RG PDSreza ashtariNessuna valutazione finora

- Syntho-Steel Datasheet (KR - 09.29.10)Documento1 paginaSyntho-Steel Datasheet (KR - 09.29.10)Masood KhanNessuna valutazione finora

- @ Lectures Chapter 2 Breakdown in Solid and Liquid DielectricsDocumento53 pagine@ Lectures Chapter 2 Breakdown in Solid and Liquid DielectricsSuhail KhokharNessuna valutazione finora

- Jotatemp 250: Technical Data SheetDocumento5 pagineJotatemp 250: Technical Data SheetMedhat Merzek100% (1)

- Mesin - Tools FRP Pipe PDFDocumento63 pagineMesin - Tools FRP Pipe PDFpaulNessuna valutazione finora

- Webinar ChemistryDocumento50 pagineWebinar Chemistryilham ditamaNessuna valutazione finora

- HM-500 Epoxy Injectable Anchor AdhesiveDocumento2 pagineHM-500 Epoxy Injectable Anchor Adhesivezapple ChangNessuna valutazione finora

- BS 7295-2-1990Documento11 pagineBS 7295-2-1990hz135874Nessuna valutazione finora

- Exposed Steel: ArchitecturallyDocumento16 pagineExposed Steel: Architecturallykip099Nessuna valutazione finora

- West Systems Fiberglass Boat Repair & MaintenanceDocumento91 pagineWest Systems Fiberglass Boat Repair & MaintenanceDonát Nagy100% (2)

- Clutch PlateDocumento57 pagineClutch PlatejacabNessuna valutazione finora

- Armorseal 650 SL/RC: Armorseal Heavy Duty Floor CoatingsDocumento4 pagineArmorseal 650 SL/RC: Armorseal Heavy Duty Floor CoatingsOswaldo SantoyoNessuna valutazione finora

- ArmourDocumento5 pagineArmourBiju_PottayilNessuna valutazione finora

- CACRC Comittee InformationDocumento23 pagineCACRC Comittee InformationBebi VatanenNessuna valutazione finora

- Sikafloor®-161 HC: Product Data SheetDocumento5 pagineSikafloor®-161 HC: Product Data SheetsawwahwahNessuna valutazione finora

- Hempadur Mastic 45881: Product CharacteristicsDocumento4 pagineHempadur Mastic 45881: Product CharacteristicsbondsivamaniNessuna valutazione finora

- External/Internal Painting Specification For Carbon Steel VesselsDocumento5 pagineExternal/Internal Painting Specification For Carbon Steel VesselsgaurangNessuna valutazione finora

- RECKLI Cold Cure Resins For Moulding, Modelling and Pattern Making 12-1Documento8 pagineRECKLI Cold Cure Resins For Moulding, Modelling and Pattern Making 12-1rcnexyNessuna valutazione finora

- BQ Rektifikasi Ipoh 2nd FLRDocumento2 pagineBQ Rektifikasi Ipoh 2nd FLRJessica Young100% (1)

- MANUAL - CoatingsDocumento285 pagineMANUAL - Coatingsbacitus100% (6)

- Getting Start of Dispensing-180713Documento33 pagineGetting Start of Dispensing-180713Tuyên VũNessuna valutazione finora

- Q & A BgasDocumento33 pagineQ & A BgasAbdulRahman Mohamed Hanifa86% (7)

- Graphene Oxide Physics and ApllicationsDocumento161 pagineGraphene Oxide Physics and Apllicationsgabriela navarroNessuna valutazione finora

- Penguard FC - English (Uk) - Issued.06.12.2007Documento4 paginePenguard FC - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Evonik-Anquamine 287Documento5 pagineEvonik-Anquamine 287ridho.afifiNessuna valutazione finora