Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Strengthened Joint Design-Update

Caricato da

Phan Trọng NghĩaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Strengthened Joint Design-Update

Caricato da

Phan Trọng NghĩaCopyright:

Formati disponibili

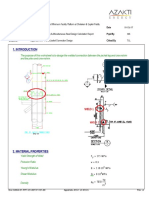

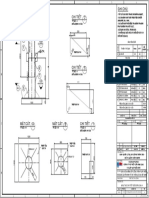

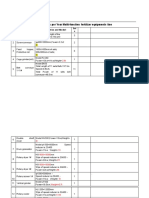

Joint:

567 & 568

Detail:

JOINT TYPE

Chord Member

567-412

Brace Member

567-558

Chord Diameter

Chord nominal Thickness

D

Tn

=

=

1067 mm

25 mm

Chord Can Thickness

Chord Length

Chord Ultimate Strength

Tc

Lc

=

=

=

38 mm

1362 mm

345 Mpa

345 Mpa

=

=

345 Mpa

Loadout

Chord Yield Strength

Chord Effective Strength

Analysis

Critical Load case

Joint Safety Factor

Fult

Fy

Fyc

=

=

FS

Allowable Stress Modifier

L722

1.6

Brace Diameter

Brace Thickness

d

t

=

=

762 mm

25 mm

Brace Angle

Ratios

=

=

90 deg

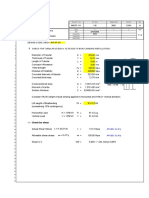

Ultimate Strength factor (Axial Compression) Qu

Ultimate Strength factor (Inplane Bending)

Qu

Ultimate Strength factor (Outplane Bending)

Chord Load Factor

(Minimum of 0.8Fult and Fy)

D/d

t/Tc

D/2Tc

0.71

0.66

=

=

14.04

0.51

1.03

2.8 + (20 + 0.8)1.6 but <= 2.8+361.6

12.74

(5+0.7)1.2

9.83

Qu

2.5+(4.55+0.2)2.6

5.50

Qf

0.960

0.16

=

=

42380.68 kN

13884.2 kNm

3807.4 kN

2749.3 kN

=

=

if(>0.9,(4-3)Lc/1.5D,Lc/(2.5D))

Geometric factor

API RP 2A Table 4.3-2

If ( >0.6, Q =

[

C1

0.3

The parameter A is defined as follows

The yield axial capacity of chord

The plastic moment capacity of the chord

Chord forces & moment ( from SACS)

kN/kNm

Py

Mp

=

=

2 0. 5

[( ) ( ) ]

Area of chord x Fy

Plastic section mudule .Fy

Mopb

Mc

Mipb

-1322.5

C3

0.8

FSP c 2 FSM c

+

Py

Mp

Pc

FS . M ipd

FS .Pc

C 2

C 3 A2

Py

Mp

( ) (

C2

0

-1312.85

Amod

1+C 1

0.3

, 1.0)

(10.833 )

Ref. API- RP- 2A

12.97

1322.57

1.000

2

F yc T c

FS sin

Allowable capacity for brace axial load

(Pa)c

Allowable Axial Force Unstiffened

Pa

Allowable Capacity for brace bending Moment

Maipb

Qu . Qf

F yc T c d

FS sin

Allowable Capacity for brace bending Moment

Maopb

Qu . Qf

F yc T c d

FS sin

341734203.xls Joint 567-X

Qu . Qf

[ r +( 1r )(T n /T c )2 ] ( P a )c

2

Amod

2239.2 kNm

Amod

1252.6 kNm

Printed 01/05/2017 04:19:37

With stiffened Ring, Pa Total

Pa of Chord ( Unstiffened)

Number of Rings,N

Pa of Internal Ring

Therefore Pa total

=

=

2 ;Thickness of Ring =

Brace Force

Ring Stiffened joint unity check

341734203.xls Joint 567-X

Pa of Chord (Unstiffened) + Pa of Internal Ring

Allowable axial force unstiffened

38 mm

; Width of Ring =

483

= Shear Area section of Ring x 0.4.Fy

(Pa of Chord (Unstiffened) + N.Pa of Internal Ring) x Amod

P

My

-385.71 kNm

Mz

-1271.65 kNm

IR

P

M

| |+

Pa Ma

=

mm

2749.29

kN

Section area of ring

=

2532.85

=

kN

7815.0

Check again

18354 mm2

API 2A-C4.6.c

kN

-8346.18 kN ;

( )

ipb

+|

M

|1.0

Ma

Axial

In-plane Bending

Out-plane Bending

IR

1.07

0.03

1.02

2.113

Printed 01/05/2017 04:19:37

Joint:

567 & 568

Detail:

JOINT TYPE

Chord Member

:

:

T

567-412

Brace Member

567-558

Chord Diameter

Chord nominal Thickness

D

Tn

=

=

1067 mm

25 mm

Chord Length

Chord Ultimate Strength

Lc

Fult

Fy

=

=

1362 mm

345 Mpa

=

=

345 Mpa

345 Mpa

Chord Yield Strength

Chord Effective Strength

Fyc

Analysis

Critical Load case

=

=

Loadout

L722

(Minimum of 0.8Fult and Fy)

Joint Safety Factor

Allowable Stress Modifier

FS

=

=

1.6

1.00

Brace Diameter

Brace Thickness

Brace Angle

d

t

=

=

=

762 mm

25 mm

90 deg

Ratios

=

=

D/d

t/Tc

=

=

0.71

0.66

=

=

D/2Tc

if(>0.9,(4-3)Lc/1.5D,Lc/(2.5D))

=

=

14.04

0.51

1.03

Ultimate Strength factor (Axial Compression) Qu

2.8 + (20 + 0.8)1.6 but <= 2.8+361.6

20.86

Ultimate Strength factor (Inplane Bending)

Qu

(5+0.7)1.2

9.83

Ultimate Strength factor (Outplane Bending)

Qu

2.5+(4.55+0.2)2.6

5.50

Chord Load Factor

Qf

0.980

0.16

42380.68 kN

Geometric factor

API RP 2A Table 4.3-2

The yield axial capacity of chord

Py

Mp

The plastic moment capacity of the chord

Chord forces & moment ( from SACS)

kN/kNm

0. 3

,1.0)

(10.833 )

FS . M ipd

FS . Pc

C 2

C 3 A2

Py

Mp

( ) (

C2

0

Mc

-1312.85

-1322.5

12.97

1322.57

Allowable Axial Force Unstiffened

Pa

Allowable Capacity for brace bending Moment

Maipb

Allowable Capacity for brace bending Moment

Maopb

With stiffened Ring, Pa Total

Pa of Chord ( Unstiffened)

=

=

2 0. 5

Area of chord x Fy

Plastic section mudule .Fy

Mopb

(Pa)c

Ring Stiffened joint unity check

Qu . Q f

F yc T 2c

FS sin

[ r +(1r )(T n /T c )2 ] (P a )c

F yc T 2c d

FS sin

F yc T 2c d

Qu . Q f

FS sin

Qu . Q f

13884.2 kNm

6365.1 kN

4596.2 kN

Amod

2285.8 kNm

Amod

1278.7 kNm

Pa of Chord (Unstiffened) + Pa of Internal Ring

Allowable axial force unstiffened

38 mm

; Width of Ring =

585

= Shear Area section of Ring x 0.4.Fy

(Pa of Chord (Unstiffened) + N.Pa of Internal Ring) x Amod

P

Mipb

=

=

-8346.18 kN ;

-385.71 kNm

Mopb

-1271.65 kNm

IR

P

M

| |+

Pa M a

Axial

1.000

3 ;Thickness of Ring =

Brace Force (from joint can output)

[( ) ( ) ]

FSP c 2 FSM c

+

Py

Mp

Mipb

Allowable capacity for brace axial load

C3

0.5

Pc

1+C 1

Amod

341734203.xls Joint 567

[

C1

0.2

The parameter A is defined as follows

Number of Rings,N

Pa of Internal Ring

Therefore Pa total

If ( >0.6,Q =

Ref. API- RP- 2A

( )

In-plane Bending

ipb

+|

=

mm

4596.15

kN

Section area of ring

=

3067.74

=

13799.4

=

kN

kN

22230 mm2

API 2A-C4.6.c

M

|1. 0

Ma

Out-plane Bending

IR

Printed 01/05/2017 04:19:37

0.60

341734203.xls Joint 567

0.03

0.99

1.628

Check again

Printed 01/05/2017 04:19:37

Potrebbero piacerti anche

- Star Plate Check Connection Number: Node Number: G H O P NDocumento7 pagineStar Plate Check Connection Number: Node Number: G H O P Nyogs_184Nessuna valutazione finora

- Plan Elevation: D D B P M T T ADocumento18 paginePlan Elevation: D D B P M T T ASai SushankNessuna valutazione finora

- D-1. Sacs Output - 2011Documento40 pagineD-1. Sacs Output - 2011Wistie AnnelyaNessuna valutazione finora

- GoM Offshore Structures Design CriteriaDocumento32 pagineGoM Offshore Structures Design CriteriaDonald.KNessuna valutazione finora

- Calculation Sheet: Tubular Brace ParametersDocumento52 pagineCalculation Sheet: Tubular Brace ParametersRamesh SelvarajNessuna valutazione finora

- Wing Plate BucklingDocumento2 pagineWing Plate BucklingSai SushankNessuna valutazione finora

- Spectral Fatigue Analysis of Jacket Stuctures in Mumbai High Field PDFDocumento13 pagineSpectral Fatigue Analysis of Jacket Stuctures in Mumbai High Field PDFA_saravanavelNessuna valutazione finora

- Cylindrical Member DesignDocumento5 pagineCylindrical Member DesignolomuNessuna valutazione finora

- Appendix e (Sacs Output)Documento6 pagineAppendix e (Sacs Output)Tran Van DaiNessuna valutazione finora

- Sum FHT MD-SLDDocumento5 pagineSum FHT MD-SLDNebula RockbandNessuna valutazione finora

- App 10 Longitudial Shear 2 UC 283Documento3 pagineApp 10 Longitudial Shear 2 UC 283yuNessuna valutazione finora

- Esteem Foundation 1Documento1 paginaEsteem Foundation 1Afif AzharNessuna valutazione finora

- Seainp - ZULF EDP-1 OBSDocumento37 pagineSeainp - ZULF EDP-1 OBSRamesh SelvarajNessuna valutazione finora

- Input Parameters: 1.1. Input Surface Areas 1.1.1. Above Mudline Without Corrosion Protection CoatingDocumento6 pagineInput Parameters: 1.1. Input Surface Areas 1.1.1. Above Mudline Without Corrosion Protection CoatingThomas StephenNessuna valutazione finora

- Appendix A1Documento22 pagineAppendix A1Thomas StephenNessuna valutazione finora

- Bearing CapacityDocumento20 pagineBearing CapacityJhoan ParedesNessuna valutazione finora

- Fatigue of Steel StructuresDocumento12 pagineFatigue of Steel Structuresshimic32000Nessuna valutazione finora

- User's Manual: USFOS Release 8-5 GUI Version 2.5Documento66 pagineUser's Manual: USFOS Release 8-5 GUI Version 2.5Binod DhakalNessuna valutazione finora

- Inplace Analysis: Check Print For Submission To Client As RequiredDocumento4 pagineInplace Analysis: Check Print For Submission To Client As RequiredRamesh SelvarajNessuna valutazione finora

- Subsee Suction Pile Installation AnalysisDocumento11 pagineSubsee Suction Pile Installation AnalysisKen KennyNessuna valutazione finora

- Acceleration Value (Motion)Documento5 pagineAcceleration Value (Motion)bong2rmNessuna valutazione finora

- BOX Sec-Beam-Column-AiscDocumento6 pagineBOX Sec-Beam-Column-AiscWintun73Nessuna valutazione finora

- Appendix D 2Documento7 pagineAppendix D 2Wistie AnnelyaNessuna valutazione finora

- Fatigue AnalysisDocumento2 pagineFatigue AnalysisZulham MochtarNessuna valutazione finora

- Aisc Asd Gusset Plate Aisc341 16Documento12 pagineAisc Asd Gusset Plate Aisc341 16Zarna Modi100% (1)

- Padeye Design CheekDocumento1 paginaPadeye Design CheekPawan ShettyNessuna valutazione finora

- Haunch End PlateDocumento5 pagineHaunch End PlateArbiNessuna valutazione finora

- Dent Depth CalculationDocumento1 paginaDent Depth CalculationSai SushankNessuna valutazione finora

- E2336 - DESIGN INPUT REQUIRED - COMBINED NAVAL and STRUCTURALDocumento6 pagineE2336 - DESIGN INPUT REQUIRED - COMBINED NAVAL and STRUCTURALRamesh SelvarajNessuna valutazione finora

- The Purpose of This Worksheet Is To Design The Welded Connection Between The Jacket Leg and Crownshim and The Piles and CrownshimDocumento5 pagineThe Purpose of This Worksheet Is To Design The Welded Connection Between The Jacket Leg and Crownshim and The Piles and CrownshimThomas StephenNessuna valutazione finora

- Load Out FixDocumento47 pagineLoad Out FixAnonymous SC5fatrFM3Nessuna valutazione finora

- STD TOPSIDE LIFT DESIGNDocumento91 pagineSTD TOPSIDE LIFT DESIGNSarva BharNessuna valutazione finora

- J336-ST-DOC-RPT-001 - Analysis of CSC Tank Frame - Rev 0Documento21 pagineJ336-ST-DOC-RPT-001 - Analysis of CSC Tank Frame - Rev 0Thomas StephenNessuna valutazione finora

- Calculation Note Stabbing Guide Design Design Code Check:Api RP 2A Check For Tubular Ø 323.9 X 12.70 Due To Boatlanding InstallationDocumento8 pagineCalculation Note Stabbing Guide Design Design Code Check:Api RP 2A Check For Tubular Ø 323.9 X 12.70 Due To Boatlanding InstallationSai SushankNessuna valutazione finora

- Pile DriveabilityDocumento11 paginePile DriveabilityEmmanuel Fosteris100% (1)

- The Equivalent Axial Tension Capacity of Soil For 42" Pile Is Calculated As Follows. T OD / Od TDocumento4 pagineThe Equivalent Axial Tension Capacity of Soil For 42" Pile Is Calculated As Follows. T OD / Od TRamesh SelvarajNessuna valutazione finora

- Structure Calculation of Loading DockDocumento19 pagineStructure Calculation of Loading Dockmhajaraswadi2023Nessuna valutazione finora

- Module 1 - Lecture 2 (Introduction)Documento12 pagineModule 1 - Lecture 2 (Introduction)SuryaNessuna valutazione finora

- Staad ExampleDocumento45 pagineStaad ExamplehgorNessuna valutazione finora

- THAIOIL - VER BRACING-L SECTION - BOLTED - 003 - Rev ADocumento15 pagineTHAIOIL - VER BRACING-L SECTION - BOLTED - 003 - Rev ACivil StructureNessuna valutazione finora

- Fatigue Design FaDocumento6 pagineFatigue Design FaSani Adipura WinataNessuna valutazione finora

- E-2. Fatigue Lives Plot - 2019Documento8 pagineE-2. Fatigue Lives Plot - 2019Wistie AnnelyaNessuna valutazione finora

- M1 195 C195 AO34-4-07-X00-MC-0-DD-S164: (MM) (MM) (MM) (MM) (MM) (MM)Documento2 pagineM1 195 C195 AO34-4-07-X00-MC-0-DD-S164: (MM) (MM) (MM) (MM) (MM) (MM)innovativekarthiNessuna valutazione finora

- Soroosh and Nowrooz Integrated Development Project: SO EST AN Spp1 55000 D0Documento54 pagineSoroosh and Nowrooz Integrated Development Project: SO EST AN Spp1 55000 D0AnjuNessuna valutazione finora

- PADEYE Design AnalysisDocumento9 paginePADEYE Design AnalysisRamesh SelvarajNessuna valutazione finora

- Beam DesignDocumento11 pagineBeam DesignImranSohailNessuna valutazione finora

- Design Head: ABS MODU 2014, Part 3-2-3/15.3 Page No. 82Documento2 pagineDesign Head: ABS MODU 2014, Part 3-2-3/15.3 Page No. 82YusufNessuna valutazione finora

- Seismic Co-Efficient Calculation As Per NBCC - Equivalent Static Force Procedure For Structures Satisfying The Conditions of ArticleDocumento8 pagineSeismic Co-Efficient Calculation As Per NBCC - Equivalent Static Force Procedure For Structures Satisfying The Conditions of ArticleVEERAM AJITHNessuna valutazione finora

- Mathcad - Laydown Area Deck PlateDocumento3 pagineMathcad - Laydown Area Deck PlatePradeep ChitluriNessuna valutazione finora

- Spliced ColumnsDocumento5 pagineSpliced ColumnsALPHYL BALASABASNessuna valutazione finora

- Any Materials Permitted (602.5) 1 1 1 1 1: Windows (T-715.5) Door&Shutter (T-715.3)Documento19 pagineAny Materials Permitted (602.5) 1 1 1 1 1: Windows (T-715.5) Door&Shutter (T-715.3)Manju BirjeNessuna valutazione finora

- ABS Seminar On Baltic Ice ClassDocumento69 pagineABS Seminar On Baltic Ice ClassJonathanNessuna valutazione finora

- CD CM Overrides For Report Conductor Shielding FactorDocumento2 pagineCD CM Overrides For Report Conductor Shielding FactorRamesh SelvarajNessuna valutazione finora

- Change The Pile Diameter Pile Dia. (MM) Pile Spacing (M) E (KN/MM) A (MM) I (MM)Documento2 pagineChange The Pile Diameter Pile Dia. (MM) Pile Spacing (M) E (KN/MM) A (MM) I (MM)jmpkumaraNessuna valutazione finora

- Stair CaseDocumento15 pagineStair CasePremasiri KarunarathnaNessuna valutazione finora

- Beam CheckDocumento4 pagineBeam CheckSai SushankNessuna valutazione finora

- 2b Genie ModellingDocumento78 pagine2b Genie Modellingvenkiee100% (1)

- Collapse AnalysisDocumento27 pagineCollapse AnalysisLaxmi StrulNessuna valutazione finora

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsDa EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNessuna valutazione finora

- 6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3Documento8 pagine6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3abdulNessuna valutazione finora

- W2V7 Exploration Regional Evaluation V2016 HandoutDocumento9 pagineW2V7 Exploration Regional Evaluation V2016 HandoutJessica KingNessuna valutazione finora

- Multi Lift Point CalcsDocumento3 pagineMulti Lift Point CalcsPhan Trọng NghĩaNessuna valutazione finora

- Goi Don L4Documento1 paginaGoi Don L4Phan Trọng NghĩaNessuna valutazione finora

- Bolt Type Anchor Shackles 1019695Documento1 paginaBolt Type Anchor Shackles 1019695Phan Trọng NghĩaNessuna valutazione finora

- W2V11 - Production Mechanisms - Handout PDFDocumento12 pagineW2V11 - Production Mechanisms - Handout PDFannisamuliahati100% (1)

- MB-01. MBQH Ben - Pa1Documento1 paginaMB-01. MBQH Ben - Pa1Phan Trọng NghĩaNessuna valutazione finora

- W1V6 - Origin of Hydrocarbon Resources2 - HandoutDocumento13 pagineW1V6 - Origin of Hydrocarbon Resources2 - HandoutDanilson Paulo MelicioNessuna valutazione finora

- W1V2 - Energy Commodity Markets - HandoutDocumento7 pagineW1V2 - Energy Commodity Markets - HandoutGiovanny LizarazoNessuna valutazione finora

- PDMS CommandsDocumento24 paginePDMS CommandsShahrouz Raeisi85% (13)

- 12 Versia - M03 - Vvedenie V AVEVA PDMSDocumento65 pagine12 Versia - M03 - Vvedenie V AVEVA PDMSPhan Trọng NghĩaNessuna valutazione finora

- Main Equipment ListDocumento6 pagineMain Equipment ListPhan Trọng NghĩaNessuna valutazione finora

- Manual of Purlin and Girt DesignDocumento64 pagineManual of Purlin and Girt DesigntitlesaengNessuna valutazione finora

- Stratco Steel Framing Purlins Girts DesignDocumento54 pagineStratco Steel Framing Purlins Girts DesignPhan Trọng NghĩaNessuna valutazione finora

- Basicloadoutmethodologiesintroduction 130326020122 Phpapp01Documento117 pagineBasicloadoutmethodologiesintroduction 130326020122 Phpapp01salem01mustafaNessuna valutazione finora

- AVEVA PDMS 12 SP6.25 Crack PDFDocumento6 pagineAVEVA PDMS 12 SP6.25 Crack PDFIsaías de la Cruz0% (1)

- ViplamDocumento52 pagineViplamPhan Trọng NghĩaNessuna valutazione finora

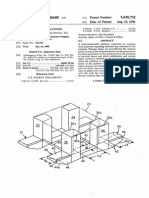

- Umted States Patent (191 (11) Patent Number: 5 038 702: Bowes (45) Date of Patent: Aug. 13, 1991Documento15 pagineUmted States Patent (191 (11) Patent Number: 5 038 702: Bowes (45) Date of Patent: Aug. 13, 1991Phan Trọng NghĩaNessuna valutazione finora

- IntonationDocumento1 paginaIntonationPhan Trọng NghĩaNessuna valutazione finora

- SD BK - TNG 001 Ts ST DW 102-01-0 - Ts Main Deck Primary Framing - Mad 1Documento1 paginaSD BK - TNG 001 Ts ST DW 102-01-0 - Ts Main Deck Primary Framing - Mad 1Phan Trọng NghĩaNessuna valutazione finora

- Concepts of Modern Physics Beiser 6th EditionDocumento246 pagineConcepts of Modern Physics Beiser 6th EditionAlex Martínez100% (2)

- Couette Flow of Micropolar Fluids: Theory GoverningDocumento6 pagineCouette Flow of Micropolar Fluids: Theory GoverningSrinivas JangiliNessuna valutazione finora

- Persamaan DiferensialDocumento9 paginePersamaan DiferensialUla RidhaNessuna valutazione finora

- How Acoustic Levitation WorksDocumento8 pagineHow Acoustic Levitation WorksclarinvalNessuna valutazione finora

- Nuclear Engineering Question BankDocumento5 pagineNuclear Engineering Question Bankaerochandru.87Nessuna valutazione finora

- 5-1 13 3/8" Surface Casing DesignDocumento10 pagine5-1 13 3/8" Surface Casing Designeng20072007Nessuna valutazione finora

- Skills Sheet F12 - MatricesDocumento2 pagineSkills Sheet F12 - MatricesAlice YipNessuna valutazione finora

- 400/415 V Network Voltage: Capacitors and Banks 50 HZDocumento2 pagine400/415 V Network Voltage: Capacitors and Banks 50 HZnicesreekanthNessuna valutazione finora

- Influence of Size Ion On The Stability of Chloroplumbates PDFDocumento7 pagineInfluence of Size Ion On The Stability of Chloroplumbates PDFUriel VázquezNessuna valutazione finora

- Chemical Bonding (F Only)Documento28 pagineChemical Bonding (F Only)Raju SinghNessuna valutazione finora

- ATOMIC ABSORPTION SPECTROSCOPY PPT SampleDocumento10 pagineATOMIC ABSORPTION SPECTROSCOPY PPT SamplegungankerkettaNessuna valutazione finora

- Cswip 3.1 Difficul - Multichoice QuesDocumento11 pagineCswip 3.1 Difficul - Multichoice QuesLuan Nguyen0% (1)

- Principles of Finned Tube Heat Exchanger Design For Enhanced Heat TransferDocumento20 paginePrinciples of Finned Tube Heat Exchanger Design For Enhanced Heat Transferunknown8787Nessuna valutazione finora

- The Preparation of Magnetic Nanoparticles For Applications in BiomedicineDocumento17 pagineThe Preparation of Magnetic Nanoparticles For Applications in BiomedicineMadavat Prem Pai LópezNessuna valutazione finora

- Projectile MotionDocumento15 pagineProjectile MotionAndi Rafika Dwi Rachma100% (1)

- Lewis Structures: Molecular Structure and BondingDocumento83 pagineLewis Structures: Molecular Structure and Bondingحني اسفيانيNessuna valutazione finora

- The Mechanics of The Atom - by Max BornDocumento346 pagineThe Mechanics of The Atom - by Max Bornahsbon100% (2)

- Thermodynamics FundamentalsDocumento84 pagineThermodynamics FundamentalsKC Paguinto100% (1)

- Fundamentals of Statistical Mechanics: EnsemblesDocumento10 pagineFundamentals of Statistical Mechanics: EnsemblesRUIVTOMNessuna valutazione finora

- ESO Annual Report 2016Documento126 pagineESO Annual Report 2016European Southern ObservatoryNessuna valutazione finora

- Volumes by Shell MethodDocumento16 pagineVolumes by Shell Methodayesha noorNessuna valutazione finora

- Introduction to connections on principal fibre bundlesDocumento12 pagineIntroduction to connections on principal fibre bundlesMike AlexNessuna valutazione finora

- 1.1 Vector Algebra: 1.1.1 ScalarsDocumento7 pagine1.1 Vector Algebra: 1.1.1 ScalarsreachsudhirNessuna valutazione finora

- Report #2 EASDocumento5 pagineReport #2 EASVanessa NguyenNessuna valutazione finora

- MECH 344/M Machine Element DesignDocumento75 pagineMECH 344/M Machine Element DesignlitonNessuna valutazione finora

- Esc201: Introducton To Electronics: FiltersDocumento31 pagineEsc201: Introducton To Electronics: Filtersash jayNessuna valutazione finora

- Viscous ForceDocumento20 pagineViscous ForceMostafaNessuna valutazione finora

- BMS481 3.0Documento45 pagineBMS481 3.0syuhadahNessuna valutazione finora

- AAS PTC Thermistors TrainingDocumento41 pagineAAS PTC Thermistors TraininglegasuNessuna valutazione finora

- Split Up Syllabus Class Xii Physics 22-23Documento1 paginaSplit Up Syllabus Class Xii Physics 22-23ROHIT SIHRANessuna valutazione finora