Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

L6590 Flyback

Caricato da

Catalina Alexandra BranTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

L6590 Flyback

Caricato da

Catalina Alexandra BranCopyright:

Formati disponibili

AN1523

APPLICATION NOTE

11W FLYBACK CONVERTER FOR AUXILIARY POWER

SUPPLY APPLICATION USING THE L6590

by Claudio Spini

This document describes an 11W Switch Mode Power Supply reference design, dedicated to Consumer

Applications, e.g. TV chassis auxiliary power supply, low cost Set-top box or digital equipment. The

board accepts full range input voltage (90 to 265Vrms) and delivers 2 output voltages. It is based on the

monolithic controller L6590, integrating the controller and a POWERMOS and working at fixed frequency, PWM mode and including a stand-by function to minimize the power consumption during light load

operation. It incorporates also all the protections, offering a complete and very compact solution for low

power SMPS.

c

u

d

)

s

t(

Introduction

Low power SMPS are today very popular in consumer applications for example like low-cost cable, terrestrial

decoders or high end TV chassis and the manufacturers need to design circuits with good performance, small

size with high cost effectiveness. An integrated monolithic solution controlling the SMPS like the L6590 makes

it a very suitable device, able to satisfy all the requirements of a compact and flexible solution, integrating all the

necessary functions to obtain a robust design just adding few external components. In this proposed reference

design, the board is thru-hole technology, without any heat sink. A specific application circuit fully tested is proposed and the test results, including thermal and EMI, are enclosed in this document. The transformer data are

included too, making it a good way to achieve a very short time to market solution.

e

t

le

SMPS Main characteristics

INPUT AND OUTPUT VOLTAGES:

)

s

(

ct

INPUT VOLTAGE:

u

d

o

Vin:

90 264 Vrms

f:

r

P

e

45 66 Hz

t

e

l

o

o

r

P

o

s

b

O

-

OUTPUT VOLTAGES AT FULL LOAD:

Vout

Iout

Pout

STABILITY

[V]

[A]

[W]

1.4

7.5

2%

12

0.3

3.6

5%

POUT (W) = 11.1

STAND BY:

During the stand-by operation the power consumption from the mains has to be 1W, when the circuit

delivers 50mA from the 5V output and the 12V is unloaded.

PROTECTIONS:

Overload ad short circuit on both outputs, with auto-restart at short removal. An OVP circuit for openloop protection.

SAFETY:

In acc. with EN60065, creepage and clearance minimum distance is 4.8mm

EMI:

In acc. with EN50022 Class B

s

b

O

March 2002

1/24

AN1523 APPLICATION NOTE

Electrical diagram

D5

BYW100-200

T1

2362.0019 rev. C

12V @0.3A

R12

NTC_10R

L1

2*27MH B82731

JP1

D6

DF04G

1

3

C11

470uF-25V YXF

3

D1

BZW06-188

C1

22uF-400V

4

C5

100N-250Vac X2

R8

2K7

2

F1

FUSE1

D2

STTA106

DRAIN

VIN: 88-265 Vrms

VFB

R13

4K7

COMP

4

GND

GND

GND

8

IC1

L6590_MINIDIP

D3

1N4148

Q1

BC548

D4

BYW98-200

R1

12R

VCC

5V @1.4A

R9

1K0

C2

22uF-25V

R10

33K

L2

4u7

C7

1000uF-25V YXF

C8

220uF-10V-ZL

R7

560R

GND

Q2

BC548

R11

10K

C4

2N2-2KV (Y1)

C6

2u2-50V

c

u

d

R2

6K8

R3

560R

o

r

P

R4

2K4-1%

OPT1

PC817

3

C3

2N2

C10

330PF

e

t

le

R5

1K0

so

b

O

-

C9

100NF

)

s

t(

R6

2K4-1%

IC2

TL431ACZ

The SMPS topology is the standard Fly-back, working in continuous mode at low input voltage. Core of this

SMPS is the L6590, a monolithic device integrating the controller and a 700V MOSFET, available in Minidip or

SO-16 popular packages. In this design, the Minidip has been used. The switching frequency is fixed by an

internal oscillator at 65KHz during normal operation. When a light load is detected, the oscillator switches automatically to 22KHz, thus increasing the stand-by performance of the circuit. At start-up, the L6590 is activated

by an internal current source that draws current from the DC bus and charges the capacitor C2. Thanks to this

circuit, the wake-up time is shorter than the conventional resistor solution and independent from the input mains

voltage. The current source is internally disconnected after that the Vcc voltage has reached the VccON value,

to prevent power dissipation during light load operation. During normal operation, the device is powered by the

transformer, via the diode D3. The network Q1, Q2, C6, R9, R10, R11 improves the circuit performance during

faults. The components C3 and R2 belong to the feedback loop. The power dissipation of the L6590 is ensured

by a copper area on the bottom side of the printed circuit board.

The transformer is a layer type, using Triple Insulation Wire for the secondary windings, manufactured by ELDOR in accordance with the EN60065. The transformer reflected voltage is ~105V and the ferrite core size is

a small, standard E20. The Transil D1 and the diode D2 clamp the peak of the leakage inductance voltage spike

at a safe level for the operation of the L6590, providing enough room for the leakage inductance voltage spike

with still margin for reliability.

The output rectifiers have been chosen in accordance with the maximum reverse voltage and their power dissipation. Standard, low-cost, axial, fast recovery rectifiers have been selected in order to avoid transformer fractional number of turns and to obtain the output voltage values as close as possible to the nominal ones. Of

course, using High-voltage Schottky rectifier the efficiency at full load would be higher but the cost and the output voltage precision would be adversely affected. A small LC filter has been added on the +5V in order to filter

the high frequency ripple without increasing the output capacitors size.

)

s

(

ct

u

d

o

r

P

e

t

e

l

o

s

b

O

2/24

AN1523 APPLICATION NOTE

The output voltage regulation is performed by the secondary feedback on the 5V output. The feedback network

is the typical using a TL431 driving an optocoupler, in this case a PC817, and insuring the insulation required

by the safety regulation between primary and secondary. The opto-transistor drives directly the COMP pin of

the L6590 modulating the PWM internal block of the L6590. The stability of the 12V is guaranteed by the transformer coupling.

The input EMI filter is a classical LC-filter, 1-cell for differential and common mode noise. A NTC has been inserted in series with the bulk capacitor to prevent very high peak current at plug insertion, while a standard 5*20

fuse protects in case of catastrophic failures. The PCB type is single layer, FR-4, 2 oz (70m) thickness. The

L6590 power dissipation is ensured by a copper area of 4 cm2 connected to primary return.

Here following some waveforms during the normal operation at full load are depicted:

Figure 1. Vds & Id @FULL LOAD

Figure 2. Vds & Id @FULL LOAD

Vin = 115 Vrms - 50 Hz

Vin = 220 Vrms - 50 Hz

c

u

d

e

t

le

CH1:

VPIN1 DRAIN VOLTAGE

CH4:

DRAIN CURRENT

(s)

)

s

t(

o

r

P

o

s

b

O

CH1:

VPIN1 DRAIN VOLTAGE

CH4:

DRAIN CURRENT

t

c

u

The pictures of figure 1 and 2 show the drain voltage and current at the peak of the nominal input mains voltage

during normal operation at full load. The circuit works in continuous mode for the effect of the voltage ripple

across the input bulk capacitor at 115V while it goes in a depth discontinuous mode at 220V. Here are captured

the trace at the peak of the input voltage sine wave.

Figure 3 gives the measurement of the drain peak voltage at full load and maximum input mains voltage. The

voltage peak, which is 604V, guarantees a reliable operation of the L6590 thanks to a good margin against the

maximum BVDSS of the device, which is 700V. Hence, a derating of 86% is achieved in the worst mains line

condition. The maximum PIV of the diodes (on figure 4) has been measured during the worst operating condition at 265Vac and it is indicated on the right of each picture. The margin, with respect to the maximum voltage

sustained by the diodes, assures a safe operating condition for the devices, contributing to obtain a high MTBF

of the circuit, using the MIL-HDBK217 calculation method.

In figure 5 and 6 the most salient controller IC signals are represented. In both pictures, it is possible to distinguish clean waveforms free of hard spikes or noise that could affect the controller correct operation

d

o

r

P

e

t

e

l

o

s

b

O

3/24

AN1523 APPLICATION NOTE

Figure 3. Vds @FULL LOAD&VinMAX

Figure 4. PIV @FULL LOAD&VinMAX

Vin = 265 Vrms - 50 Hz

Vin = 265 Vrms - 50 Hz

CH1:

VPIN1 DRAIN VOLTAGE

Figure 5. L6590 signals @FULL LOAD

Vin = 115 Vrms - 50 Hz

c

u

d

CH3:

+5V DIODE: ANODE VOLTAGE

CH4:

+12V DIODE: ANODE VOLTAGE

e

t

le

o

r

P

Figure 6. L6590 signals @FULL LOAD

o

s

b

O

-

Vin = 220 Vrms - 50 Hz

)

s

(

ct

u

d

o

r

P

e

t

e

l

o

s

b

O

CH1:

VPIN1 DRAIN VOLTAGE

CH1:

VPIN1 DRAIN VOLTAGE

CH2:

VPIN4 COMP

CH2:

VPIN4 COMP

CH3:

VPIN3 Vcc

CH3:

VPIN3 Vcc

4/24

)

s

t(

AN1523 APPLICATION NOTE

Output voltage measurement and efficiency calculation @normal operation

In the following table the output voltage cross regulation is measured and the overall efficiency of the converter

is calculated at both the nominal input voltages. The output voltages have been measured after the load connector.

5V

12V

115Vac

PoutTOT

Vout

@Iout

Vout

@Iout

[V]

[A]

[V]

[A]

[W]

[W]

full load

4.99

1.400

12.11

0.304

10.67

15.12

70.6%

half load

5.01

0.650

11.97

0.15

5.05

7.00

72.2%

5V

Pin

12V

)

s

t(

220Vac

c

u

d

PoutTOT

Vout

@Iout

Vout

@Iout

[V]

[A]

[V]

[A]

[W]

full load

4.99

1.400

12.11

0.304

10.67

half load

5.01

0.650

11.99

o

r

P

Pin

e

t

le

o

s

b

O

-

5.05

0.15

[W]

14.90

71.6%

6.90

73.3%

The output voltages are within the tolerances in all conditions, at both full and half load. The efficiency calculated

is good for this kind of converters, then the power dissipation is low and even this affect positively the long-term

reliability of the circuit.

)

s

(

ct

u

d

o

Output voltage measurement and efficiency calculation @stand-by operation

Like in the previous section, the output voltage and the efficiency have been checked and the input power has

been measured. It is clearly visible that with the required stand-by load (5V@50mA and 12V@0mA) the input

power consumption is well below 1W at both the input voltage range. Besides, the circuit has been characterised

at both the nominal input voltage values for different output load, giving very interesting results:

t

e

l

o

r

P

e

5V

s

b

O

12V

115Vac

PoutTOT

Pin

Vout

@Iout

Vout

@Iout

[V]

[mA]

[V]

[mA]

[W]

[W]

5.02

10

11.92

0.050

0.288

17.4%

5.02

30

12.35

0.151

0.430

35.0%

5.02

50

12.65

0.251

0.579

43.3%

5.02

80

13.06

0.402

0.795

50.5%

5.02

100

13.27

0.502

0.941

53.4%

5/24

AN1523 APPLICATION NOTE

5V

12V

220Vac

PoutTOT

Vout

@Iout

Vout

@Iout

Pin

[V]

[mA]

[V]

[mA]

[W]

[W]

5.02

10

11.95

0.050

0.330

15.2%

5.02

30

12.34

0.151

0.474

31.8%

5.02

50

12.66

0.251

0.627

40.0%

5.02

80

13.06

0.402

0.842

47.7%

5.02

100

13.28

0.502

0.986

50.9%

the circuit efficiency is always high and the input power is lower than 1W with twice the specified standby load. In figure 7 the input power as a function of the 5V current, without load on the 12V is represented. The

only shortcoming is the 12V variation: the 12V increases above its limit when the +5V current exceeds 50mA,

due to coupling between the transformer windings. A bit heavier bleeder on the 12V solves this problem very

easily. Decreasing the R8 to 1.2k or providing for the same residual load, brings the mains power consumption to 1.06W @220Vac delivering 5V@100mA, or to 0.69W@220Vac delivering 5V@50mA. At the opposite, accepting an higher voltage variation of the 12V, it decreases the input power significantly: increasing R8

to 10K when delivering 5V@100mA, decrease the consumption to 0.935W@220Vac. Hence, a compromise between the bleeder resistors and the residual loads can be easily found giving the best results in standby. In fact, if a stable load is present on the 5V and we remove the 5V bleeder (R8), delivering 5V@100mA the

consumption becomes 0.886W@220Vac.

c

u

d

e

t

le

Figure 7. Input power @stand-by

o

r

P

Figure 8. L6590 signals @ I+5V=50m A-I+12V=0

I+5V=50mA - I+12V=0

o

s

b

O

-

Vin = 220 Vrms - 50 Hz

)

s

(

ct

INPUT POWER @LOW LOAD

1.100

1.000

u

d

o

0.900

0.800

r

P

e

0.700

Pin [W]

)

s

t(

0.600

t

e

l

o

0.500

0.400

0.300

bs

Pin @220Vac [W]

0.200

Pin @115Vac [W]

0.100

0.000

10

30

50

Iout +5V

80

100

CH1:

VPIN1 DRAIN VOLTAGE

CH2:

VPIN4 - COMP

CH3:

VPIN3 - Vcc

In figure 8 there are the waveforms relevant to the L6590 during standby operation: it is easy to recognize that

the switching frequency has decreased from the initial value to about 22KHz. This feature is very important to

6/24

AN1523 APPLICATION NOTE

decrease the switching losses during light load operation, thus improving the stand-by efficiency. For reference,

also the Vcomp and the Vcc are captured. In detail, the Vcc shows that there is still margin when working at

light load respect to the Vccoff value (which is 6.5V typ. and 7Vmax.). This guarantees that even with a different

transformer batch, delivering may be a bit lower Vcc, the converter will still work correctly, without showing any

irregular behaviour at start-up or inopportune missing start-up due to a Vcc too low, unable to power correctly

the primary controller.

Output voltage ripple @full load

In Figure 9 the output voltage ripple at switching frequency have been measured. As per the previous measures,

the probes have been connected on test points after the output connector. The ripple and the spikes are very

low making this design suitable to power sensitive loads. In Figure 10, the residual ripple on the output voltages

at mains frequency is measured. The low frequency residual ripple compared with the 100Hz undulation across

C1 (input Elcap), demonstrates an excellent rejection of the circuit (~66dB) at 115V. Obviously the low frequency rejection becomes even higher when the circuit is working at 220Vac (figure 10). At that voltage, the rejection

becomes 76dB and this means a residual line ripple on the 5V output of 3mV only.

Figure 9. HF RIPPLE

Figure 10. LINE RIPPLE REJECTION

Vin = 115 Vrms - 50 Hz @FULL LOAD

Vin = 115 Vrms - 50 Hz @FULL LOAD

c

u

d

e

t

le

)

s

(

ct

r

P

e

u

d

o

REF1:

VRIPPLE +5V

CH3:

VRIPPLE +12V

t

e

l

o

)

s

t(

o

r

P

o

s

b

O

CH1:

VC1+

CH2:

+12VOUT

CH3:

+5VOUT

s

b

O

7/24

AN1523 APPLICATION NOTE

Dynamic Load Tests

Load condition:

+12V:

FULL LOAD

+5V:

LO A D 50% 100% , 12Hz

Figure 11. DYNAMIC LOAD TEST

Figure 12. DYNAMIC LOAD TEST

Vin = 115 Vrms - 50 Hz @FULL LOAD

Vin = 220 Vrms - 50 Hz @FULL LOAD

c

u

d

CH1:

VC1+

CH3:

+5VOUT

CH4:

+5IOUT

)

s

(

ct

e

t

le

)

s

t(

o

r

P

o

s

b

O

CH1:

VC1+

CH3:

+5VOUT

CH4:

+5IOUT

The pictures 11 and 12 show the output voltage regulation against a dynamic load variation of +5V output, at

the nominal mains voltage values. As shown in the pictures, the voltage variation is always better than 1% and

the response is fast, within 2 ms. This allows to power P or any logic circuitry without the risk of inopportune

reset or logic malfunctioning. Even the 12V variation is good, remaining within its tolerance with still margin.

u

d

o

r

P

e

t

e

l

o

Start-Up Behaviours @full load

In figure 13 and 14 there are the rising slopes at full load of the output voltages at nominal input mains voltages.

As shown in the pictures, the rising time at 220Vac is a bit faster than at 115Vac, however they are similar. The

rising slopes are always monotonic overall the input mains range. This characteristic is quite important powering a P and its peripherals as in this case, thus avoiding problem at start-up for the equipment.

In figure 15, there are the same waveforms captured during the start-up in stand-by. Even in this case, the behaviour of the circuit is always correct overall the input mains range.

A slight overshoot is present in all conditions but it is negligible because the voltage remains always under control and the variation is within the tolerances.

s

b

O

8/24

AN1523 APPLICATION NOTE

Figure 13. START-UP BEHAVIOUR

Figure 14. START-UP BEHAVIOUR

Vin = 115 Vrms - 50 Hz @FULL LOAD

Vin = 220 Vrms - 50 Hz @FULL LOAD

CH3:

+5VOUT

CH3:

+5VOUT

CH4:

+12VOUT

CH4:

+12VOUT

Figure 15. START-UP BEHAVIOUR

Vin = 115 Vrms - 50 Hz @STAND-BY

)

s

(

ct

u

d

o

r

P

e

t

e

l

o

s

b

O

CH3:

+5VOUT

CH4:

+12VOUT

e

t

le

c

u

d

)

s

t(

o

r

P

Wake-up time

In the following picture (Figure 16), there are the

waveforms with the wake-up time measured at 115V

input mains. Thanks to the L6590 internal current

source, the capacitor C2 is charged with a constant

current, independent from the input mains value. This

means that the power supply wake-up time is perfectly constant. Thus, the annoying problem of a very

long start-up time, especially at low mains, is solved

without adding any additional extra component. Besides, it is a key feature during stand-by operation because it is disconnected from the mains helping a lot

the power consumption decreasing.

The measured time in Figure 16 at 115Vac is less

than 150ms but it doesn't show variations from 88 to

265 Vac.

The traces shown in Figure 16 are the drain voltage,

the Vcc and the +5V output: on the picture is clearly

visible that no overshoots, undershoots, dips or any

lost of control happens during the power supply startup phase and the circuit starts correctly overall the input mains range

o

s

b

O

-

9/24

AN1523 APPLICATION NOTE

Figure 16. WAKE UP TIME

Vin = 115 Vrms - 50 Hz @FULL LOAD

CH1:

VPIN1 - DRAIN VOLTAGE

CH2:

VPIN3 - Vcc

CH3:

+5VOUT

Turn-Off

Even at turn off the transition is clean, without any abnormal behaviour like overshoots or glitches both on

the output voltages. Checking the full load condition,

a restart attempt is present on the Vcc voltage: it is

due to the circuit Q1, Q2,R9, R10, R11, C6 connected to the COMP pin. During the switching off phase

the energy in the bulk capacitor is no more refreshed,

then the voltage on it starts to decrease. This provides for an increasing of the COMP pin voltage due

to the loop intervention which is regulating the output

voltage while the input voltage is decreasing. At a

certain value the COMP voltage is able to switch on

Q1 and then Q2, thus disconnecting the transformer

from Vcc, so that the L6590 stops the operation. Because the circuit is switched off externally, the bulk

capacitor has still some energy stored and when the

Vcc has dropped below the Vccoff the IC detects that

residual input voltage higher than its Drain start voltage (Vdsmin). Hence the L6590 reactivates the internal current source like in a normal start-up, and the

voltage on the Vcc pin tends to increase again. But

checking the Fig. 17 it is important to note that the

Vcc value is far from the Start Threshold voltage (Vccon), then no any perturbation appears on the output,

avoiding any problem..

c

u

d

e

t

le

Figure 17. TURN-OFF

o

r

P

Figure 18. TURN-OFF

Vin = 115 Vrms - 50 Hz @FULL LOAD

)

s

(

ct

o

s

b

O

-

Vin = 115 Vrms - 50 Hz @STAND-BY

u

d

o

r

P

e

t

e

l

o

s

b

O

CH1:

VPIN1 DRAIN VOLTAGE

CH1:

VPIN1 DRAIN VOLTAGE

CH2:

VPIN3 - Vcc

CH2:

VPIN3 - Vcc

CH3:

+5VOUT

CH3:

+5VOUT

10/24

)

s

t(

AN1523 APPLICATION NOTE

Short-Circuit Tests @ Full Load

The short circuit tests have been done in two phases, making the test shorting by a power switch the output

electrolytic capacitor or making the short by the active load option. This gives an idea about the circuit behaviour

with a hard short (at very low impedance) or with a "soft" short that could happen on the STB main board, having

slightly higher impedance. All the tests have been done at maximum, nominal and minimum input voltage. For

all conditions the drain voltage is always below the BVDSS, while the mean value of the output current has a

value close to the nominal one, thus preventing component melting for excessive dissipation in case of long term

shorts. The auto-restart is correct at short removal in all conditions.

Figure 19. SHORT ON +5V

Figure 20. SHORT ON +5V

Vin = 88 Vrms - 50 Hz @FULL LOAD

Vin = 265 Vrms - 50 Hz @FULL LOAD

c

u

d

e

t

le

)

s

t(

o

r

P

CH1:

VPIN1 DRAIN VOLTAGE

CH1:

VPIN1 DRAIN VOLTAGE

CH2:

VPIN3 - Vcc

CH2:

VPIN3 - Vcc

CH4:

ISHORT CIRCUIT

CH4:

ISHORT CIRCUIT

so

(s)

Figure 21. SHORT ON +12V

ct

Vin = 88 Vrms - 50 Hz @FULL LOAD

u

d

o

b

O

-

Figure 22. SHORT ON +12V

Vin = 265 Vrms - 50 Hz @FULL LOAD

r

P

e

t

e

l

o

s

b

O

CH1:

VPIN1 DRAIN VOLTAGE

CH1:

VPIN1 DRAIN VOLTAGE

CH2:

VPIN3 - Vcc

CH2:

VPIN3 - Vcc

CH4:

ISHORT CIRCUIT

CH4:

ISHORT CIRCUIT

11/24

AN1523 APPLICATION NOTE

As clearly indicated by the waveforms, the circuit starts to work in hiccup mode, keeping the current mean value

of the shorted output at levels within component rating. Because the working time and the dead time are imposed by the charging and discharging time of the auxiliary capacitor C2, it is almost constant varying the input

mains voltage thanks to the internal start-up current source already mentioned.

Short-Circuit Tests @ Stand-by

A short circuit when the SMPS works at light-load is always a critical fault condition for any power supply circuit.

In this condition, the energy deliverable to the short is the maximum one, and then it is the most stressing situation for the output rectifiers and besides, sometimes the primary hiccup mode is not triggered. This may happen because the short circuit reflected impedance on the auxiliary winding it is not low enough for decreasing

the Vcc voltage below the under-voltage lockout threshold or spikes are present at turn off on the auxiliary winding which are capable of powering the IC. The proposed circuit, even in this load condition, provides the same

results as the previous tests, both at 115Vac and at 220 Vac, making it reliable in all the working situations

independently from the transformer coupling.

Figure 23. SHORT ON +5V

Figure 24. SHORT ON +5V

Vin = 88 Vrms - 50 Hz @STAND-BY

Vin = 265 Vrms - 50 Hz @STAND-BY

c

u

d

e

t

le

CH1:

VPIN1 DRAIN VOLTAGE

CH2:

VPIN3 - Vcc

CH4:

ISHORT CIRCUIT

t

e

l

o

o

r

P

e

s

b

O

12/24

du

)

s

(

ct

o

r

P

o

s

b

O

CH1:

VPIN1 DRAIN VOLTAGE

CH2:

VPIN3 - Vcc

CH4:

ISHORT CIRCUIT

)

s

t(

AN1523 APPLICATION NOTE

Short circuit of the output rectifiers

Another frequent problem in a power supply is relevant to the protection of the SMPS itself: thus sometimes it is easy to find circuits with a good protection

capability against shorts of the load but which are not

able to survive in case of a very hard short like an output electrolytic capacitor or a diode. Besides, in case

of a rectifier shorted, the equivalent circuit of the basic converter changes: in fact, due to the missing

(shorted) rectifier the energy stored is delivered even

during the on time, like in forward mode with reverse

polarity of the trafo. To insure reliable operation of

the circuit, even this fault condition has been simulated (figure 25) shorting each rectifier, then has been

proven that the circuit can withstand this failure without any performance degradation. The circuit in fact

works in hic-cup mode and then it restarts correctly to

deliver the output voltages if the short is removed.

This exceeds the requirements of the VDE and IEC

safety rules, and ensures a considerable time saving

during the qualification phase of the SMPS, avoiding

failures during the qualification tests, retrofit and new

testing, sometimes with a short time available to

solve the issue.

Figure 25. SHORT ON +5V RECTIFIER

Vin = 220 Vrms - 50 Hz @FULL LOAD

c

u

d

CH1:

VPIN1 - DRAIN VOLTAGE

CH2:

VPIN3 - Vcc

e

t

le

)

s

t(

o

r

P

Switch On and Turn Off In Short Circuit Condition

The following pictures show the SMPS behaviour during the start-up phase with an output voltage shorted. As

clearly visible the circuit starts correctly then it works in hiccup mode protecting itself. The start-up phase is

clean in all conditions, without showing any dangerous transition for the SMPS circuitry.

Figure 26. SWITCH ON WITH +5V SHORTED

Vin = 88 Vrms - 50 Hz @FULL LOAD

o

r

P

e

c

u

d

(t s)

o

s

b

O

-

Figure 27. SWITCH ON WITH +5V SHORTED

Vin = 265 Vrms - 50 Hz @STAND-BY

t

e

l

o

s

b

O

VPIN1 DRAIN VOLTAGE

CH1:

CH2:

VPIN3 - Vcc

CH2:

VPIN3 - Vcc

CH3:

+5Vout

CH3:

+5Vout

CH1:

VPIN1 DRAIN VOLTAGE

13/24

AN1523 APPLICATION NOTE

Figure 28. TURN-OFF WITH +5V SHORTED

Figure 29. TURN-OFF WITH +5V SHORTED

Vin = 88 Vrms - 50 Hz @FULL LOAD

Vin = 265 Vrms - 50 Hz @STAND-BY

VPIN1 DRAIN VOLTAGE

VPIN3 - Vcc

+5Vout

CH1:

CH2:

CH3:

CH1:

CH2:

CH3:

VPIN1 DRAIN VOLTAGE

VPIN3 - Vcc

+5Vout

c

u

d

)

s

t(

o

r

P

Even at turn off in short circuit the SMPS functioning is good, protecting properly the circuit. No any abnormal

transition or level has been observed during the tests, confirming the design robustness proven so far.

e

t

le

Over Voltage Protection

A dangerous fault that could happen is the failure of the feedback circuitry. If this occurs, the SMPS output voltages can get to very high values, depending on the load on each output and on the transformer coupling between the windings. Consequently, the rectifiers and the output capacitors are overstressed or damaged. A

possible solution could be to oversize the components but this should be expensive and uneconomic. Hence,

to avoid this SMPS failure a suitable protection circuit has been added inside the L6590 and it doesn't require

any external component for the threshold setting. Hence, this fail has been simulated opening the feedback

loop and the circuit has been tested, giving the results shown in figures 30 and 31:

Figure 30. OPEN LOOP

Figure 31. OPEN LOOP

)

s

(

ct

du

Vin = 88 Vrms - 50 Hz @FULL LOAD

o

r

P

e

o

s

b

O

-

Vin = 265 Vrms - 50 Hz @FULL LOAD

t

e

l

o

s

b

O

CH1:

CH2:

CH3:

14/24

VPIN1 DRAIN VOLTAGE

VPIN3 - Vcc

+5Vout

CH1:

CH2:

CH3:

VPIN1 DRAIN VOLTAGE

VPIN3 - Vcc

+5Vout

AN1523 APPLICATION NOTE

The figure 32 has been acquired testing the open

loop protection when working in stand-by: as visible,

even in this condition the circuit stops the switching

cycles when the Vcc reaches 16.5V and the value of

the output voltages never overstress the output electrolytic capacitors.

In case a lower OVP threshold is required, it is possible to connect the inverting input of the E/A (VFB-pin

5) to ground via a resistor (e.g. 1K) and a zener between the pin 5 and Vcc. A small ceramic capacitor in

parallel to the resistor could be required. In this case

the OVP threshold will be VZENER + 2.5V.

Figure 32. OPEN LOOP

Vin = 220 Vrms - 50 Hz @STAND-BY

CH1:

VPIN1 - DRAIN VOLTAGE

CH2:

VPIN3 - Vcc

CH3:

+5VOUT

CH4:

+12VOUT

c

u

d

e

t

le

)

s

t(

o

r

P

Conducted Noise Measurements (Pre-Compliance Test)

The following pictures are shown the quasi-peak conducted noise measurements at full load and standby with

both nominal input mains voltages. The limits shown on the diagrams are referred to the EN55022 CLASS B,

which is the most widely used for domestic equipment like a TV or a STB. As visible on the diagrams, there is

a good margin of the measures with respect to the limits in overall conditions.

(s)

Figure 33. QUASI-PEAK MEASURE

ct

Vin = 115 Vrms - 50 Hz @FULL LOAD

Limits: EN55022 CLASS B

u

d

o

o

s

b

O

-

Figure 34. QUASI-PEAK MEASURE

Vin = 220 Vrms - 50 Hz @ FULL LOAD

Limits: EN55022 CLASS B

r

P

e

t

e

l

o

s

b

O

15/24

AN1523 APPLICATION NOTE

Figure 35. QUASI-PEAK MEASURE

Figure 36. QUASI-PEAK MEASURE

Vin = 115 Vrms - 50 Hz @STAND-BY

Limits: EN55022 CLASS B

Vin = 220 Vrms - 50 Hz @STAND-BY

Limits: EN55022 CLASS B

c

u

d

)

s

t(

Thermal measures

In order to check the reliability of the design, a thermal mapping by means of an IR Camera has been done.

Here below the thermal measures on the board at both nominal input mains voltage at ambient temperature

(25C) are shown. The pointers AD have been placed across some key components affecting the reliability of

the circuit. The points correspond to the following components:

e

t

le

so

TESTED POINT

A

IC1 - L6590

D1 - BZW06188

T1 - TRAFO

D4 BYW98-200

b

O

-

o

r

P

NOTES

Copper dissipating area: 4 cm2

c

u

d

(t s)

Lead length: 13mm each side Diode mounted 7mm from the

top of PCB surface

Checked the hottest point

Lead length: 8 mm each side Diode body placed on PCB

surface

As shown on the maps, all the other points of the board are within the temperature limits ensuring a reliable

performance of the devices. TAMB = 25C for all measures

o

r

P

e

Figure 37. TEMPERATURE IR MEASURE

Figure 38. TEMPERATURE IR MEASURE

Vin = 115 Vrms - 50 Hz @FULL LOAD

Vin = 220 Vrms - 50 Hz @FULL LOAD

t

e

l

o

s

b

O

16/24

AN1523 APPLICATION NOTE

Conclusions

A SMPS for Consumer application has been completely designed and tested, checking the performance thoroughly. The test results has been positive and the initial requirements of high reliability, low cost and low complexity have been met successfully.

References

[1] AN1261 - Getting familiar with the L6590 family high-voltage fully integrated power supply

[2] AN1262 - Offline fly-back converters design methodology with the L6590 family

ANNEX1: Part List

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Designator

C1

C10

C11

C2

C3

C4

C5

C6

C7

C8

C9

D1

D2

D3

D4

D5

D6

F1

IC1

IC2

L1

L2

OPT1

Q1

Q2

R1

R10

R11

R12

R13

R2

R3

R4

R5

R6

R7

R8

R9

T1

Description

Supplier

ELCAP

ELNA

CERCAP

AVX

ELCAP

RUBYCON

ELCAP

ELNA

CERCAP

AVX

CERCAP-SAFETY

CERA-MITE

X CAP-MKT

EPCOS

ELCAP

RUBYCON

ELCAP

RUBYCON

ELCAP

RUBYCON

CERCAP

AVX

STMicroelectronics

AXIAL TRANSIL DIODE

STMicroelectronics

ULTRA FAST REC. RECTIFIER

GEN. PURPOSE DIODE

WISHAY

STMicroelectronics

FAST REC. RECTIFIER

STMicroelectronics

FAST REC. RECTIFIER

BRIDGE RECTIFIER

GEN. SEMICOND.

T2A - 250V

STMicroelectronics

INTEGRATED CONTROLLER

STMicroelectronics

SHUNT REGULATOR

2*27mH FILTER COIL

EPCOS

INDUCTOR

PANASONIC

OPTOCOUPLER

SHARP

SMALL SIGNAL BJT

ZETEX

SMALL SIGNAL BJT

ZETEX

SFR25

BEYSCHLAG

SFR25

BEYSCHLAG

SFR25

BEYSCHLAG

NTC THERMISTOR

EPCOS

SFR25

BEYSCHLAG

SFR25

BEYSCHLAG

SFR25

BEYSCHLAG

MBA0204

BEYSCHLAG

SFR25

BEYSCHLAG

MBA0204

BEYSCHLAG

SFR25

BEYSCHLAG

SFR25

BEYSCHLAG

SFR25

BEYSCHLAG

POWER TRANSFORMER

ELDOR CORPORATION

PCB - SINGLE SIDE - 70um - 100x50 mm

)

s

(

ct

u

d

o

r

P

e

t

e

l

o

s

b

O

Part Type

22uF-400V

330PF

470uF-25V YXF

22uF-25V

2N2

2N2-2KV (Y1)

100N-250Vac - B81133

2u2-50V - YK

1000uF-25V YXF

220uF-10V-ZL

100NF

BZW06-188

STTA106

1N4148

BYW98-200

BYW100-200

DF04G

FUSE1

L6590_MINIDIP

TL431ACZ

B82731-R2501-A30

4.7uH ELC08D

PC817

BC548

BC548

12R - 1/4W - 5%

33K - 1/4W - 5%

10K - 1/4W - 5%

NTC_10R S236

4K7 - 1/4W - 5%

6K8 - 1/4W - 5%

560R - 1/4W - 5%

2K4 - 1/4W - 1%

1K0 - 1/4W - 5%

2K4 - 1/4W - 1%

560R - 1/4W - 5%

2K7 - 1/4W - 5%

1K0 - 1/4W - 5%

2362.0019 rev. C

c

u

d

e

t

le

)

s

t(

o

r

P

o

s

b

O

-

17/24

AN1523 APPLICATION NOTE

ANNEX 2 - Switch Mode Transformer Specification

COPIA ASSEGNATA A:

Copy assigned to:

ELDOR CORPORATION S.p.A.

Via Plinio, 10

22030 ORSENIGO - Como - Italy

Tel. +39 031 636111 - Telefax +39 031 636263

SWITCH MODE TRANSFORMER SPECIFICATION

CODE

2362.0019 C

FIRST ISSUE DATE

12/02/2002

c

u

d

Table of contents:

e

t

le

1.0 GENERAL INFORMATION

o

s

b

O

-

2.0 ELECTRICAL CHARACTERISTICS

3.0 SAFETY

4.0 MATERIAL LIST

)

s

(

ct

o

r

P

5.0 MECHANICAL CHARACTERISTICS

u

d

o

r

P

e

EVOLUZIONE DELLE REVISIONI / revision evolution:

t

e

l

o

REV

rev

s

b

O

18/24

DATA

EMESSO DA:

VERIFICATO DA:

APPROVATO DA:

date

issued by:

checked by:

approved by:

12/02/02

GL. Verga

DOCUMENTO N / document Nbr:

PAGINE

MODIFICATE:

changed

pages:

DESCRIZIONE MODIFICA:

change description:

)

s

t(

AN1523 APPLICATION NOTE

ANNEX 2 - Switch Mode Transformer Specification (continued)

1.0

GENERAL INFORMATION

1.1

Description

The magnetic circuit comprises two soft ferrite E-cores glued together and gapped on the central leg.

The windings are placed concentrically on single plastic bobbin made in self extinguish material.

The transformer comply with the standard (Refer to pharagraf 3.0 SAFETY) for the component connected to the

mains because:

the use of triple insulation wire (three different layers) for the secondary winding.

the thickness of insulation that exceed 0.40 mm.

the shape of coilformer that maintain the safety creeping distance from the core , that is consired

belong the primary side, and the secondary output pins and the circuit components.

Winding outputs are made through 8 pins placed in two parallel rows (Refer to page 6).

1.2

Application

The transformer is designed for use in a switch mode flyback power supply.

1.2.1 Operating conditions

Operating ambient temperature:

0C to +60C

Operating humidity range non condensing

10% to 85%RH

Ambient temperature is the medium value measured at 30 mm. of distance from the surface of the transformer.

When the transformer is placed inside a metallic shield the above temperature value will be referred to the inside of

the shield even if it is closer then 30 mm to the SMT.

1.3

c

u

d

Storage conditions

Storage temperature

-20C to +50C

After storage to allow a minimum of 24 hours recovery time before testing.

1.4

Marking

The component is marked with:

Eldor part number and customer part number (if required).

Production date.

1.5

Packaging

TDB

1.6

Weight

The transformer weight is approx 15g.

)

s

(

ct

e

t

le

)

s

t(

o

r

P

o

s

b

O

-

u

d

o

r

P

e

t

e

l

o

s

b

O

SWITCH MODE TRANSFORMER SPECIFICATION

CUSTOMER CODE

This document and its content are property of ELDOR CORPORATION S.p.A. No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of ELDOR CORPORATION S.p.A.

2362.0019 C

ISSUE A

DOC.N.

PAG. 2 / 6

19/24

AN1523 APPLICATION NOTE

ANNEX 2 - Switch Mode Transformer Specification (continued)

2.0

ELECTRICAL CHARACTERISTICS

For pins identification refer to mechanical drawing

2.1

Static characteristics

2.1.1 Inductance and DC resistance:

Measurement of inductance is made using a LCR bridge at frequency of 10KHz at output voltage of 1 V r.m.s.

Measurement of resistance is made using a four wire ohmmeter.

Temperature should be 23 2C.

Between pin

2.1.2

L(mH)

2.0

2 and pin 1

tol(%)

10

tol(%)

15

R()

2.31

Leakage Inductance:

LL=

%Lp

(pin

pin

Measurement is made with the secondary windings short circuited.

Measurement if inductance is made using a LCR bridge at frequency of 10 kHz and at output voltage of 1 V R.M.S.

)

s

t(

2.1.3 Withstanding voltage

The transformer shall withstand a voltage of 3.75kV RMS for 60 seconds between primary winding and secondary

windings.

The frequency of the test voltage shall be 50 or 60Hz.

2.2

c

u

d

Test circuit diagram and application conditions

+V

Drain

u

d

o

)

s

(

ct

r

P

e

t

e

l

o

supply IC

e

t

le

o

s

b

O

8

o

r

P

+12V/0.3A

+5V/1.4A

bs

SWITCH MODE TRANSFORMER SPECIFICATION

CUSTOMER CODE

This document and its content are property of ELDOR CORPORATION S.p.A. No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of ELDOR CORPORATION S.p.A.

20/24

2362.0019 C

ISSUE A

DOC.N.

PAG. 3 / 6

AN1523 APPLICATION NOTE

ANNEX 2 - Switch Mode Transformer Specification (continued)

2.3

Temperatures

2.3.1 Temperature raise of the primary coil

The raising in primary winding shall be made in the following condition: Vin nom. and all loads at maximum current,

except that for the Audio output that must be adjusted at 50% Imax.

Raise of temperature after 4 hours must be lower than 55C

2.3.2 Maximum allowable temperatures

In the application, TV set with cabinet closed, at the maximum allowable ambient temperature (See IEC68-1 clause

4.6.2) and at the maximum working conditions (see 2.3.1) after 4 hours the temperature of the transformer must

be = 115C.

To satisfy the above conditions it is raccomanded to provide the SMT with sufficient cool air flow around it.

2.4

Core saturation

Test must be performed in the following way:

a) The SMT must be placed in oven at ambient temperature of 100C for 2 hours.

b) Using the circuit as per figure, connect the primary winding to LCR meter operating at frequency of 1

kHz and output voltage of 1 V.

c) Superimpose through the power supply a dc current and read on the LCR meter the correspondent

value of the inductance. Do this up to a current value of I peak max input current.

d) The value of the inductance must not shows saturation (0.7Lp).

c

u

d

C (40000 F or more)

+

A

CHOKE

(1H or more)

e

t

le

)

s

(

ct

o

r

P

LCR

METER

SPECIMEN

)

s

t(

o

s

b

O

-

Saturation current @100C

1,10

u

d

o

1,00

t

e

l

o

bs

Lx/Lp

r

P

e

0,90

0,80

0,70

0,60

0,50

0,15

0,3

0,45

0,6

0,75

0,9

I (A)

SWITCH MODE TRANSFORMER SPECIFICATION

CUSTOMER CODE

This document and its content are property of ELDOR CORPORATION S.p.A. No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of ELDOR CORPORATION S.p.A.

2362.0019 C

ISSUE A

DOC.N.

PAG. 4 / 6

21/24

AN1523 APPLICATION NOTE

ANNEX 2 - Switch Mode Transformer Specification (continued)

3.0

SAFETY

According to international standard EN60065- EN60950 for the Class II at the following conditions of

primary voltage: VRMS <300V; Vp<600V

All the transformers are tested at the end of the manufacturing lines for the withstanding voltage in between

primary and secondary in the following conditions:

Test voltage

=

4.2 kV RMS

Duration of test =

1 seconds

File records of the test are mantained in Eldor Quality Assurance Dept.

4.0

MATERIAL LIST

NR.

SMT PART NAME

KIND OF MATERIAL

MANUFACTURER

TRADE MARK/TYPE

BOBBIN

Polyamide 4/6 (PA4/6) DSM

Stanyl TE250F6

INSULATING TAPE

Polyester film

1350

TERMINAL PINS

Tinned steel

FERRITE CORE

N67 or equivalent

Epcos AG, AVX,

Samwha, Ferroxcube,

E20/10/6

ISU, DMEG,Tridelta or

equivalent

PRIMARY WINDINGS

Enamelled wire

Grade 2 - Class F

Elektrisola Atesina srl,

Nexans

Pirelli cavi e sistemi

or equivalent

SECONDARY

WINDINGS

Triple insulated wire

The Furukawa Electric TEX-E

ADHESIVE

LOCTITE

Loctite 480

ELASTIC ADHESIVE

3M

Scotch Grip EC -1022

MARKING OR LABEL Marking

3M

)

s

(

ct

u

d

o

r

P

e

t

e

l

o

UL FILE

NUMBER

94V-0

E119177

UL 130C

E17385

c

u

d

e

t

le

o

r

P

)

s

t(

E206440

o

s

b

O

2

8

7

s

b

O

SWITCH MODE TRANSFORMER SPECIFICATION

CUSTOMER CODE

This document and its content are property of ELDOR CORPORATION S.p.A. No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of ELDOR CORPORATION S.p.A.

22/24

UL

RATING

2362.0019 C

ISSUE A

DOC.N.

PAG. 5 / 6

AN1523 APPLICATION NOTE

ANNEX 2 - Switch Mode Transformer Specification (continued)

5.0

MECHANICAL DRAWINGS

0.1

22.4

14.1 +0.8

0

ALL DIMENSIONS IN mm

GENERAL TOLERANCE 0.2

25.5

0.1

c

u

d

REFERENCE MARK FOR PINS IDENTIFICATION

20 +0.8

-0.6

=

5.9

10.1

)

s

(

ct

6.8

o

s

b

O

9.45

o

r

P

4.5 0.5

7.5 0.1 5 0.1

= =

17.5

=

=

e

t

le

19 0.1

0

-0.5

)

s

t(

7.5 0.1 5 0.1

= =

17.5

=

=

16.25 0.1

r

P

e

HOLES PATTERN

Component Side

8

7.5 0.1 5 0.1

= =

u

d

o

t

e

l

o

s

b

O

16.25 0.1

N 8 holes

+0.1

1.3 0

SWITCH MODE TRANSFORMER SPECIFICATION

CUSTOMER CODE

This document and its content are property of ELDOR CORPORATION S.p.A. No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of ELDOR CORPORATION S.p.A.

2362.0019 C

ISSUE A

DOC.N.

PAG. 6 / 6

23/24

AN1523 APPLICATION NOTE

c

u

d

e

t

le

)

s

(

ct

)

s

t(

o

r

P

o

s

b

O

-

u

d

o

r

P

e

t

e

l

o

s

b

O

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2002 STMicroelectronics - All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -Malaysia - Malta - Morocco Singapore - Spain - Sweden - Switzerland - United Kingdom - United States.

http://www.st.com

24/24

Potrebbero piacerti anche

- 60W Wide-Range Power Supply For LCD Monitor or TV, Using The L5991Documento17 pagine60W Wide-Range Power Supply For LCD Monitor or TV, Using The L5991Grzegorz WegnerNessuna valutazione finora

- DC/DC Converter Operation GuideDocumento6 pagineDC/DC Converter Operation GuidesaeidraminaNessuna valutazione finora

- AND8099/D 5.0 V, 2.0 A Flyback Converter: Application NoteDocumento8 pagineAND8099/D 5.0 V, 2.0 A Flyback Converter: Application NoteIgor MairinckNessuna valutazione finora

- Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)Documento15 pagineObsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)teomondoNessuna valutazione finora

- Ca3130, Ca3130aDocumento17 pagineCa3130, Ca3130aproctepNessuna valutazione finora

- AND9065/D 5 Key Steps To Design A Compact, High Efficiency PFC Stage Using The NCP1612Documento14 pagineAND9065/D 5 Key Steps To Design A Compact, High Efficiency PFC Stage Using The NCP1612Jonatan LunaNessuna valutazione finora

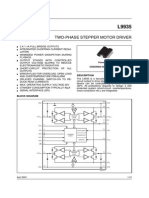

- Two-Phase Stepper Motor Driver: DescriptionDocumento19 pagineTwo-Phase Stepper Motor Driver: DescriptionDan EsentherNessuna valutazione finora

- 100 VOLT 30 AMP H-Bridge PWM Motor Driver/Amplifier: M.S.Kennedy CorpDocumento7 pagine100 VOLT 30 AMP H-Bridge PWM Motor Driver/Amplifier: M.S.Kennedy CorpDaniel SanchezNessuna valutazione finora

- LD7552 DS 00Documento10 pagineLD7552 DS 00BRIGHT_SPARKNessuna valutazione finora

- Principles Applications ICL7660Documento10 paginePrinciples Applications ICL7660Juan F. RamosNessuna valutazione finora

- Simple PWM Boost Controller: Power Management Features DescriptionDocumento11 pagineSimple PWM Boost Controller: Power Management Features DescriptionJoe MiguelNessuna valutazione finora

- Programmable, Isolated Voltage-to-Current Converter: LoadDocumento4 pagineProgrammable, Isolated Voltage-to-Current Converter: Loadhermon_agustioNessuna valutazione finora

- High Efficiency 2A Step Down ConverterDocumento9 pagineHigh Efficiency 2A Step Down Converterbob75Nessuna valutazione finora

- Iraudamp1 PDFDocumento22 pagineIraudamp1 PDFamijoski6051Nessuna valutazione finora

- Viper 100 ADocumento31 pagineViper 100 AvasilesicoeNessuna valutazione finora

- Ncl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsDocumento10 pagineNcl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsKhúc Hành QuânNessuna valutazione finora

- Mini Project DocumentationDocumento34 pagineMini Project DocumentationSri Krishna RakeshNessuna valutazione finora

- High Power Class D Audio Amplifier DesignDocumento24 pagineHigh Power Class D Audio Amplifier DesignChuYurNessuna valutazione finora

- UC2842 Philips AN1272 PDFDocumento7 pagineUC2842 Philips AN1272 PDFupali01Nessuna valutazione finora

- 15 To 60 Watt Audio Amplifiers Using Complementary Darlington Output Transistors - An-483BDocumento8 pagine15 To 60 Watt Audio Amplifiers Using Complementary Darlington Output Transistors - An-483BAnonymous kdqf49qb100% (1)

- 100W Inverter Circuit Using CD4047 ICDocumento7 pagine100W Inverter Circuit Using CD4047 ICSruthi ReddyNessuna valutazione finora

- High Power Class D Audio Power Amplifier Using IR2011SDocumento22 pagineHigh Power Class D Audio Power Amplifier Using IR2011SAbubakar SidikNessuna valutazione finora

- 2.5A Power Switching Regulator: DescriptionDocumento16 pagine2.5A Power Switching Regulator: Descriptionbikram9830Nessuna valutazione finora

- A5800 and A5801: Discontinued ProductDocumento13 pagineA5800 and A5801: Discontinued Productitamar_123Nessuna valutazione finora

- LM324 OpampDocumento9 pagineLM324 OpampYuvarajaNessuna valutazione finora

- Iraudamp 1Documento22 pagineIraudamp 1luizcpimentaNessuna valutazione finora

- MillMinder Audio Signal MonitorDocumento15 pagineMillMinder Audio Signal Monitorescorpion311Nessuna valutazione finora

- DiDocumento5 pagineDiTao Quang BinhNessuna valutazione finora

- 5-10542 Viper 100 DatasheetDocumento9 pagine5-10542 Viper 100 DatasheetMahmoud NaguibNessuna valutazione finora

- Wi-Fi Home AutomationDocumento23 pagineWi-Fi Home Automationchandru_8Nessuna valutazione finora

- Precision Phase-Locked Loop: ... The Analog Plus CompanyDocumento21 paginePrecision Phase-Locked Loop: ... The Analog Plus Companykao08Nessuna valutazione finora

- UC3842 current mode controller application noteDocumento7 pagineUC3842 current mode controller application noteCui BapNessuna valutazione finora

- 3A PWM Step-Down Converter AX3102Documento8 pagine3A PWM Step-Down Converter AX3102Agung DuemilanoveNessuna valutazione finora

- Topswitch Desgin NoteDocumento2 pagineTopswitch Desgin NotegubiliNessuna valutazione finora

- Block Diagram For Simple Traffic Light SystemDocumento17 pagineBlock Diagram For Simple Traffic Light SystemVishwaraj Bhagwat88% (16)

- lx1692 PDFDocumento15 paginelx1692 PDFvideosonNessuna valutazione finora

- Ta8264ahq PDFDocumento14 pagineTa8264ahq PDFArguetaManuelNessuna valutazione finora

- 10884Documento13 pagine10884karthikeidNessuna valutazione finora

- Amplifier TA8276HDocumento15 pagineAmplifier TA8276HjoeyjbNessuna valutazione finora

- Isolated Flyback Switching Regulator W - 9V OutputDocumento16 pagineIsolated Flyback Switching Regulator W - 9V OutputCasey DialNessuna valutazione finora

- MW Inverter IC RM6203Documento7 pagineMW Inverter IC RM6203KybernetikumNessuna valutazione finora

- Quad Power Amplifier For Car Radio: Protections: DescriptionDocumento18 pagineQuad Power Amplifier For Car Radio: Protections: DescriptionMiloud ChouguiNessuna valutazione finora

- An1344 Application Note: Vipower: 108W Power Supply Using Viper100ADocumento11 pagineAn1344 Application Note: Vipower: 108W Power Supply Using Viper100AKush DewanganNessuna valutazione finora

- Ica Withoutreadingsmanual PDFDocumento90 pagineIca Withoutreadingsmanual PDFKimharly VersozaNessuna valutazione finora

- R1114x SERIES: Low Noise 150ma Ldo RegulatorDocumento31 pagineR1114x SERIES: Low Noise 150ma Ldo Regulatoraranjessyzat4134Nessuna valutazione finora

- 114-115 DIY AC-DC Signal Mixer July 15Documento2 pagine114-115 DIY AC-DC Signal Mixer July 15Daniel CafuNessuna valutazione finora

- LM3916 LED VU Meter Circuit GuideDocumento27 pagineLM3916 LED VU Meter Circuit GuidekrishnayahooNessuna valutazione finora

- Electronics Lab ManualDocumento92 pagineElectronics Lab ManualVolodya SmolyakNessuna valutazione finora

- 300 Watt Power AmplifierDocumento10 pagine300 Watt Power AmplifiersasamajaNessuna valutazione finora

- AND9218/D 5 Key Steps To Designing A Compact, High Efficiency PFC Stage Using The NCP1602Documento19 pagineAND9218/D 5 Key Steps To Designing A Compact, High Efficiency PFC Stage Using The NCP1602Jonatan LunaNessuna valutazione finora

- TNY176PNDocumento22 pagineTNY176PNDíaz Rivero Cesar EnriqueNessuna valutazione finora

- Lica ManualDocumento99 pagineLica Manualspeak2dasNessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsDa EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsNessuna valutazione finora

- 110 Integrated Circuit Projects for the Home ConstructorDa Everand110 Integrated Circuit Projects for the Home ConstructorValutazione: 4.5 su 5 stelle4.5/5 (2)

- Identification of Distributed Parameter Systems BaDocumento18 pagineIdentification of Distributed Parameter Systems BaCatalina Alexandra BranNessuna valutazione finora

- Schema KSDocumento5 pagineSchema KSCatalina Alexandra BranNessuna valutazione finora

- TN Lab 9 1Documento6 pagineTN Lab 9 1Catalina Alexandra BranNessuna valutazione finora

- New Doc 2017-10-26Documento13 pagineNew Doc 2017-10-26Catalina Alexandra BranNessuna valutazione finora

- New Doc 2017-04-20Documento9 pagineNew Doc 2017-04-20Catalina Alexandra BranNessuna valutazione finora

- New Doc 2017-10-26 PDFDocumento13 pagineNew Doc 2017-10-26 PDFCatalina Alexandra BranNessuna valutazione finora

- New Doc 2017-10-12Documento18 pagineNew Doc 2017-10-12Catalina Alexandra BranNessuna valutazione finora

- Lab 5 DivideDocumento4 pagineLab 5 DivideCatalina Alexandra BranNessuna valutazione finora

- New Doc 2017-04-20Documento14 pagineNew Doc 2017-04-20Catalina Alexandra BranNessuna valutazione finora

- Intelligent Urban TransportationDocumento15 pagineIntelligent Urban TransportationCatalina Alexandra BranNessuna valutazione finora

- STEVAL-ILL010V1: High Intensity LED Dimming Driver Evaluation Board Based On The L6902Documento4 pagineSTEVAL-ILL010V1: High Intensity LED Dimming Driver Evaluation Board Based On The L6902Catalina Alexandra BranNessuna valutazione finora

- Topologies For Switched Mode Power SuppliesDocumento18 pagineTopologies For Switched Mode Power Suppliesgreenman33a2815100% (5)

- Arhivare PDFDocumento7 pagineArhivare PDFElena FlorinaNessuna valutazione finora

- Semafoare, FinalDocumento2 pagineSemafoare, FinalCatalina Alexandra BranNessuna valutazione finora

- Topologies For Switched Mode Power SuppliesDocumento18 pagineTopologies For Switched Mode Power Suppliesgreenman33a2815100% (5)

- An 1382 - 6 Low Voltage Differential Signaling LVDS by AgilentDocumento20 pagineAn 1382 - 6 Low Voltage Differential Signaling LVDS by AgilentJose Gonzalez100% (1)

- Unit - 4 Iot Technology Fundamentals: Architecture Reference ModelDocumento5 pagineUnit - 4 Iot Technology Fundamentals: Architecture Reference ModelMANTHAN GHOSHNessuna valutazione finora

- 1 General Description: Automotive LCD Driver For Low Multiplex Rates Including A 6 Channel PWM GeneratorDocumento76 pagine1 General Description: Automotive LCD Driver For Low Multiplex Rates Including A 6 Channel PWM GeneratorcarlosgnNessuna valutazione finora

- GSM Based Power Grid Monitoring SystemDocumento41 pagineGSM Based Power Grid Monitoring SystemPreetham SurepallyNessuna valutazione finora

- William Stallings Computer Organization and Architecture 10 EditionDocumento57 pagineWilliam Stallings Computer Organization and Architecture 10 EditionAbood AbujamousNessuna valutazione finora

- User Manual-XRN-410S, 810S-ENGLISH - Web-0224 PDFDocumento96 pagineUser Manual-XRN-410S, 810S-ENGLISH - Web-0224 PDFcreateopNessuna valutazione finora

- Theremin SchematicsDocumento1 paginaTheremin SchematicsKkillurNessuna valutazione finora

- MicroprocessorDocumento15 pagineMicroprocessorRatnaprabha BirwadkarNessuna valutazione finora

- Kyambogo University: Group: Next LevelDocumento27 pagineKyambogo University: Group: Next LevelAthiyo MartinNessuna valutazione finora

- Philips drivers from 5-10 inchesDocumento5 paginePhilips drivers from 5-10 inchesMarco Dei Bi AivNessuna valutazione finora

- EE 271 Digital Circuits and Systems: Course Specification (Syllabus)Documento41 pagineEE 271 Digital Circuits and Systems: Course Specification (Syllabus)R.R.S. SavichevaNessuna valutazione finora

- Interview QuestionDocumento15 pagineInterview QuestionNadeem AhmedNessuna valutazione finora

- Agp, Pci, Pci-X, Pci-E Transfer Rates - BusDocumento15 pagineAgp, Pci, Pci-X, Pci-E Transfer Rates - Busnw3Nessuna valutazione finora

- Power Monitor (R3) - Data - Sheet - V1Documento2 paginePower Monitor (R3) - Data - Sheet - V1prekNessuna valutazione finora

- Cadence MixerDocumento118 pagineCadence MixerVăn Công100% (1)

- Release 6 3gpp UmtsDocumento102 pagineRelease 6 3gpp Umtsoussama khelladiNessuna valutazione finora

- 39408, CP25QXVT80 Wengler Level SensorDocumento19 pagine39408, CP25QXVT80 Wengler Level SensorVigneshkumar JagannathanNessuna valutazione finora

- Installation, Service, and User Guide: IBM System Storage SAN80B-4Documento87 pagineInstallation, Service, and User Guide: IBM System Storage SAN80B-4Fouad BaroutNessuna valutazione finora

- Mixers 2Documento20 pagineMixers 2Nelson BernardoNessuna valutazione finora

- Standby & Restricted Earth FaultDocumento7 pagineStandby & Restricted Earth FaultanjnaNessuna valutazione finora

- Data Communication and NetworkingDocumento1 paginaData Communication and NetworkingSyedkareem_hkgNessuna valutazione finora

- Re - 1973-03Documento100 pagineRe - 1973-03Anonymous kdqf49qb100% (1)

- Windcrest Autodialler Full Remote Programming InstructionDocumento5 pagineWindcrest Autodialler Full Remote Programming InstructionChris MillsNessuna valutazione finora

- LCD TV: Service ManualDocumento41 pagineLCD TV: Service ManualbjesodragNessuna valutazione finora

- SMD L132Documento8 pagineSMD L132Aliou SouaneNessuna valutazione finora

- NCE3065QDocumento7 pagineNCE3065QMar GaoNessuna valutazione finora

- 12-24VDC Powered Ignition System: N N N N N N NDocumento2 pagine12-24VDC Powered Ignition System: N N N N N N NLeinner RamirezNessuna valutazione finora

- PPL NavigationDocumento5 paginePPL NavigationChina LalaukhadkaNessuna valutazione finora

- PSP Assignment1 MzeeshanDocumento11 paginePSP Assignment1 MzeeshanMuhammad ZeeshanNessuna valutazione finora

- LZS RT4A4L24 Datasheet enDocumento5 pagineLZS RT4A4L24 Datasheet enRichard ReyesNessuna valutazione finora