Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Free Vent Cal TDAE Product Tank (72-TK-02ABC)

Caricato da

Anonymous p0iwBoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Free Vent Cal TDAE Product Tank (72-TK-02ABC)

Caricato da

Anonymous p0iwBoCopyright:

Formati disponibili

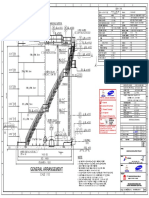

TDAE Product Tank

DOCUMENT NUMBER

VENT CALCULATION

REV

HSD STORAGE TANK

#VALUE!

th

Design Data: API STD 2000, 5 Edition

17.300 mm

17.000 mm

16.660 mm

600 mm

3.728 kL

Tank ID

Height

Design Liquid Level

Low Low Liquid Level

Tank Capacity

Product

Specify Grafity of product

Design Temperature

Operating Temperature

Flash Point

Boiling Point

Design Pressure

Filling rate

Emptying rate

TDAE

0,95

105

70

296

>148.9

0,02

100

400

C

C

C

C

kL/hr

kL/hr

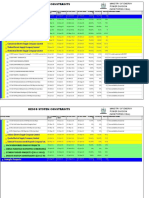

Venting Capacity Calculation

Based on API 2000 5th Edition - Table 1B

Inbreathing due to pumping out

3

= 0.94 times m /hr liquid flow

3

376 Nm /hr air

=

Outbreathing due to pumping in

3

= 1.01 times m /hr liquid flow

3

101 Nm /hr air

=

Based on API 2000 5th Edition - Table 2B

Inbreathing due to thermal effect

3

= 647,00 Nm /hr air (by Interpolation)

Outbreathing due to thermal effect

3

= 472,00 Nm /hr air (by Interpolation)

Total inbreathing capacity

376 +

Total outbreathing capacity

647,00

3

1.023 Nm /hr air

=

=

101 +

3

573 Nm /hr air

472,00

3

573 Nm /hr air

Pressure Condition

Vent capacity

API 2000 - part 4.5.1.1.4 :

The total force caused by internal pressure should not exceed the weight of the roof and attachments, such as platforms

and handrails.

Roof weight

Roof structure weight

Total Roof Weight

=

=

=

28.505 kg

26.754 kg

55.260 kg

Pressure caused by roof weight

MAWP (Restricted by Roof weight)

MAWP (from Design Pressure)

MAWP (Govern)

= (m x g) / Aroof =

0,1474 bar-G

=

3,5000 bar-G

=

=

3,5000 bar-G

+

0,1474 bar-G

API 2000 - part 5.5.1.1.3 :

Under normal conditions, pressure-relieving devices must have sufficient flow capacity to prevent the pressure from

rising more than 10% above the maximum allowable working pressure. During fire emergency conditions, the devices

shall be capable of preventing the pressure from rising more than 20% above the maximum allowable working pressure.

MAWP =

Set pressure =

Inlet pressure =

Outlet pressure =

20% above set pressure

2,8000 bar-G

2,8000 bar-G

1,0133 bar-A

3,8133 bar-A

(pressure from tank)

(atmospheric)

DATE

PAGES

Free Vent Capacity (API STD 2000, par. 4.6.1.2)

Where,

Nm3/hr = theoritical flow rate, Normal cubic meters per hour of test medium

A = minimum flow area of device, cm

P1 = pressure at device inlet, bar-A

3,8133 bar-A

P2 = pressure at device outlet, bar-A

k = ratio of specific heats of test medium

T = absolute temperature at device inlet, K

M = molecular weight of test medium

Z = compressibility factor

573 = 12,503 x 3,8133 x A x

A

=

=

1,0133 bar-A

1,407

422,1 K

28,95

1

sqrt (

2

3,248 cm =

2,033 cm =

0,0003

x(

0,1520

0,1036

))

2

0,503 in

0,801 in

Vaccum Condition

Vent capacity

3

1.023 Nm /hr air

API 650 - part 5.2.4 :

This standard doesn't contain provisions for the design of tanks subject to partial internal vacuum; however, tanks that

meet the minimum requirements of this standard may be subjected to a partial vacuum of 0.25 kPa (1 in. of water) of

water pressure.

MAWV =

Set vacuum =

-0,2500 kPa-G

-0,2000 kPa-G

Inlet pressure =

Outlet pressure =

1,0133 bar-A

1,0113 bar-A

-0,0020 bar-G

1,0113 bar-A

(atmospheric)

(vacuum to tank)

API 2000 - part 4.5.1.1.4 :

Free Vent Capacity (API STD 2000, par. 4.6.1.2)

Where,

Nm3/hr = theoritical flow rate, Normal cubic meters per hour of test medium

2

A = minimum flow area of device, cm

P1 = pressure at device inlet, bar-A

1,0133 bar-A

P2 = pressure at device outlet, bar-A

k = ratio of specific heats of test medium

T = absolute temperature at device inlet, K

M = molecular weight of test medium

Z = compressibility factor

1,0113 bar-A

1,407

333,2 K

28,95

1

1.023 = 12,503 x 1,0133 x A x

A

=

=

sqrt (

2

178,686 cm =

15,083 cm =

Max nozzle pressure venting and vaccum venting is

Use Nozzle venting is

in

0,0004

27,696 in

5,938 in

x(

5,938 in

OK

0,9972

0,9966

))

Potrebbero piacerti anche

- KS-LSN-R.31.02-E.017 - 00A - Detail of Walkway and Handrail For Raw Molasses Storage Tank (R.31.02)Documento6 pagineKS-LSN-R.31.02-E.017 - 00A - Detail of Walkway and Handrail For Raw Molasses Storage Tank (R.31.02)Anonymous p0iwBoNessuna valutazione finora

- Excele Description WTM 201Documento8 pagineExcele Description WTM 201Anonymous p0iwBoNessuna valutazione finora

- KS-LSN-R.31.01-E.017 - 00A - Detail of Walkway and Handrail For Raw Molasses Storage Tank (R.31.01)Documento5 pagineKS-LSN-R.31.01-E.017 - 00A - Detail of Walkway and Handrail For Raw Molasses Storage Tank (R.31.01)Anonymous p0iwBoNessuna valutazione finora

- KS-LSN-R.31.01-E.018 - 00A - Detail of Bridge R.31.01 To R.31.02 For Raw Molasses Storage Tank (R.31.01)Documento1 paginaKS-LSN-R.31.01-E.018 - 00A - Detail of Bridge R.31.01 To R.31.02 For Raw Molasses Storage Tank (R.31.01)Anonymous p0iwBoNessuna valutazione finora

- SHELL PLATE AND TOP ANGLE TANKI MINYAK 20000 Bbls Rev 0 (1 of 2)Documento1 paginaSHELL PLATE AND TOP ANGLE TANKI MINYAK 20000 Bbls Rev 0 (1 of 2)Anonymous p0iwBoNessuna valutazione finora

- GA-C-P-WTM-V-5005-154 Rev 3Documento1 paginaGA-C-P-WTM-V-5005-154 Rev 3Anonymous p0iwBoNessuna valutazione finora

- ROOF DETAIL TANKI MINYAK 20000 Bbls Rev 0 (1 of 2)Documento1 paginaROOF DETAIL TANKI MINYAK 20000 Bbls Rev 0 (1 of 2)Anonymous p0iwBoNessuna valutazione finora

- BOTTOM DETAIL TANKI MINYAK 20000 Bbls Rev 0 PDFDocumento1 paginaBOTTOM DETAIL TANKI MINYAK 20000 Bbls Rev 0 PDFAnonymous p0iwBoNessuna valutazione finora

- Ga - CSS-901 Rev.3Documento1 paginaGa - CSS-901 Rev.3Anonymous p0iwBoNessuna valutazione finora

- Excele Description 901 CSSDocumento8 pagineExcele Description 901 CSSAnonymous p0iwBoNessuna valutazione finora

- Excele Description 901 CSSDocumento8 pagineExcele Description 901 CSSAnonymous p0iwBoNessuna valutazione finora

- CSS-TK-902 Rev.2Documento1 paginaCSS-TK-902 Rev.2Anonymous p0iwBoNessuna valutazione finora

- Orn at Shell Css-tk-901Documento1 paginaOrn at Shell Css-tk-901Anonymous p0iwBoNessuna valutazione finora

- CSS-TK-901 Rev.4Documento1 paginaCSS-TK-901 Rev.4Anonymous p0iwBoNessuna valutazione finora

- Sno M BBB FD 80 171 Rev CDocumento1 paginaSno M BBB FD 80 171 Rev CAnonymous p0iwBoNessuna valutazione finora

- Check, This Drawing Rev.A1 or B: Syofyan Static 2014.05.07 15:08:00 +07'00'Documento2 pagineCheck, This Drawing Rev.A1 or B: Syofyan Static 2014.05.07 15:08:00 +07'00'Anonymous p0iwBoNessuna valutazione finora

- SNO M BBB FD 80 168 - Rev - 0Documento1 paginaSNO M BBB FD 80 168 - Rev - 0Anonymous p0iwBoNessuna valutazione finora

- Main Body - Css-tk-901Documento7 pagineMain Body - Css-tk-901Anonymous p0iwBoNessuna valutazione finora

- SNO M BBB FD 80 166 - Rev - 0Documento1 paginaSNO M BBB FD 80 166 - Rev - 0Anonymous p0iwBoNessuna valutazione finora

- Sno M BBB FD 80 169 Rev CDocumento1 paginaSno M BBB FD 80 169 Rev CAnonymous p0iwBoNessuna valutazione finora

- Sno M BBB FD 80 176 Rev BDocumento1 paginaSno M BBB FD 80 176 Rev BAnonymous p0iwBoNessuna valutazione finora

- SNO M BBB FD 80 173 - Rev - 0 PDFDocumento1 paginaSNO M BBB FD 80 173 - Rev - 0 PDFAnonymous p0iwBoNessuna valutazione finora

- SNO M BBB FD 80 173 - Rev - 0Documento1 paginaSNO M BBB FD 80 173 - Rev - 0Anonymous p0iwBoNessuna valutazione finora

- Sno M BBB FD 80 177 Rev ADocumento2 pagineSno M BBB FD 80 177 Rev AAnonymous p0iwBoNessuna valutazione finora

- Skets COD 2Documento1 paginaSkets COD 2Anonymous p0iwBoNessuna valutazione finora

- SNO M BBB FD 80 175 - Rev - 0Documento1 paginaSNO M BBB FD 80 175 - Rev - 0Anonymous p0iwBoNessuna valutazione finora

- SNO M BBB GA 80 018 - Rev - C1Documento1 paginaSNO M BBB GA 80 018 - Rev - C1Anonymous p0iwBoNessuna valutazione finora

- Sno M BBB Ga 80 017 Rev BDocumento1 paginaSno M BBB Ga 80 017 Rev BAnonymous p0iwBoNessuna valutazione finora

- Data Seismic Tanjung JatiDocumento1 paginaData Seismic Tanjung JatiAnonymous p0iwBoNessuna valutazione finora

- Sno M BBB FD 80 214 Rev C FinalDocumento1 paginaSno M BBB FD 80 214 Rev C FinalAnonymous p0iwBoNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 초고용량 커패시터-2008 PDFDocumento32 pagine초고용량 커패시터-2008 PDFJeimoon YunNessuna valutazione finora

- GATE-2014 Electrical MeasurementsDocumento42 pagineGATE-2014 Electrical MeasurementsRamaDinakaran100% (1)

- Induction MotorDocumento50 pagineInduction MotorMuhammad NurwantaNessuna valutazione finora

- Steam TablesDocumento20 pagineSteam TablesFenny PutriNessuna valutazione finora

- Isro Eectrical QuestionDocumento89 pagineIsro Eectrical QuestionSudip MondalNessuna valutazione finora

- Tugas Termodinamika Kelompok 1Documento8 pagineTugas Termodinamika Kelompok 1Jasmine AprilNessuna valutazione finora

- Tutorial 3 - FiltrationDocumento4 pagineTutorial 3 - FiltrationDinesh Kumar VijeyanNessuna valutazione finora

- L4 Laboratory MathematicsDocumento5 pagineL4 Laboratory MathematicsZeian Jacob BaylaNessuna valutazione finora

- Sairam A - SEMINAR - REPORT - ON - SOLAR - POWER - TOWER - SuDocumento34 pagineSairam A - SEMINAR - REPORT - ON - SOLAR - POWER - TOWER - SuJadhav VishalNessuna valutazione finora

- Short Lab Report SheetDocumento3 pagineShort Lab Report SheetDharmaalManieNessuna valutazione finora

- IEEE Transactions On Energy Conversion, Vol. 3, No. 2, June 1988Documento7 pagineIEEE Transactions On Energy Conversion, Vol. 3, No. 2, June 1988Arif IqbalNessuna valutazione finora

- Automatic Power Factor Controller Using MicrocontrollerDocumento29 pagineAutomatic Power Factor Controller Using Microcontrollervallery1100% (3)

- Friction Sample Question AnswersDocumento7 pagineFriction Sample Question AnswersIbrahim HossainNessuna valutazione finora

- DatasheetDocumento6 pagineDatasheetمحمد مهدی حسنیNessuna valutazione finora

- Product Data Sheet: Circuit Breaker Compact Nsx630N, 50 Ka at 415 Vac, Micrologic 2.3 Trip Unit 630 A, 4 Poles 4DDocumento3 pagineProduct Data Sheet: Circuit Breaker Compact Nsx630N, 50 Ka at 415 Vac, Micrologic 2.3 Trip Unit 630 A, 4 Poles 4DJovan JovanovićNessuna valutazione finora

- 110 To 11 KV SSDocumento7 pagine110 To 11 KV SSUjjal ChakmaNessuna valutazione finora

- HESCODocumento2 pagineHESCOAli Assad MirNessuna valutazione finora

- Voltage During CrankingDocumento5 pagineVoltage During CrankingGomzalez Bin GembozNessuna valutazione finora

- Braking Unit Yaskawa - CDBR - 4045BDocumento54 pagineBraking Unit Yaskawa - CDBR - 4045BAnoop KumarNessuna valutazione finora

- ASTM D2583 Standard Testing Method of Measuring Hardness by Barcol Hardness MethodDocumento8 pagineASTM D2583 Standard Testing Method of Measuring Hardness by Barcol Hardness MethodHASSAN WASEEMNessuna valutazione finora

- Bitumen SpecificationsDocumento2 pagineBitumen SpecificationsAlexander IvanovNessuna valutazione finora

- Micro Processor Based Neutral Earth Resistor Monitoring RelayDocumento3 pagineMicro Processor Based Neutral Earth Resistor Monitoring RelayPrasenjit MaityNessuna valutazione finora

- (Robert P. Benedict, Nicola A. Carlucci (Auth.) ) H (B-Ok - Xyz)Documento198 pagine(Robert P. Benedict, Nicola A. Carlucci (Auth.) ) H (B-Ok - Xyz)oğuz kağanNessuna valutazione finora

- PHY101 Quiz4 2022 Monkey BY ASFAND YARRDocumento16 paginePHY101 Quiz4 2022 Monkey BY ASFAND YARRAlishba khanNessuna valutazione finora

- 9702-P1 WavesDocumento41 pagine9702-P1 WavesZubair AhmadNessuna valutazione finora

- Performance Analysis of An Open Cycle OTEC Power Module On Laboratory ScaleDocumento5 paginePerformance Analysis of An Open Cycle OTEC Power Module On Laboratory ScalearunNessuna valutazione finora

- Work Book Physics Grade 11&12Documento33 pagineWork Book Physics Grade 11&12Yonatan Tolosa100% (2)

- 2d SWBD 6.6 KV 110 VDC System Documentation 47Documento47 pagine2d SWBD 6.6 KV 110 VDC System Documentation 47edtatel73Nessuna valutazione finora

- Troskie HJ Chapter 3Documento58 pagineTroskie HJ Chapter 3ashutosh2009Nessuna valutazione finora

- Free and Forced ConvectionDocumento7 pagineFree and Forced ConvectionRenewable Energy Engi50% (2)