Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TII-HZI-50021179 - 0 0 - TII 15 02 06 Cabinet Systems and Enclosures

Caricato da

Born ToSinTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TII-HZI-50021179 - 0 0 - TII 15 02 06 Cabinet Systems and Enclosures

Caricato da

Born ToSinCopyright:

Formati disponibili

Projectt Name: SER

RC

Title:

AIC:

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

Docum

ment Nr-Rev:

5002

21179 -0.0

Hitachi Zo

osen Inova AG

G

Table of

o conten

nts

1

Introducttion ................................................................................................................................. 4

1.1

1.2

1.3

1.4

1.5

Intention of the doc

cument ..... ................................................ .................................... 4

Definition

ns and abb

breviations ................................................ .................................... 4

Norms an

nd standarrds ............ ................................................ .................................... 5

Supplierss engineeriing ........... ................................................ .................................... 5

Manufactturer ......................... ................................................ .................................... 5

Technicall requiremeents ............................................................................................................. 6

2.1

General ................................. ................................................ .................................... 6

2.1.1

2.1.1.1

2.1.1.2

2.1.2

2.1.3

2.1.3.1

2.2

2.2.1

2.2.2

2.3

2.3.1

2.3.2

2.3.3

2.3.4

2.3.5

2.3.6

2.3.7

2.3.8

2.3.9

2.3.10

2.3.11

2.4

2.4.1

2.4.2

2.4.3

2.4.4

2.4.5

2.4.6

2.4.7

2.4.8

2.4.9

2.4.10

2.4.11

2.4.12

2.4.13

2.4.14

2.4.15

2.4.16

2.4.17

2.4.18

2.4.19

2.4.20

Ambient conditions ................................................................................ ............................................ 6

Conditio

ons for indoo

or installation

n (process arrea) ................................. ............................................ 6

Conditio

ons for outdo

oor installatio

on ....................................................... ............................................ 6

Ex Zone

es (ATEX) .................................................................................. ............................................ 7

Overall size ........................................................................................... ............................................ 7

Dimensions ........................................................................................... ............................................ 7

External characteris

c

stics ......... ................................................ .................................... 7

Degree of protection

n ............................................................................. ............................................ 7

Painting

g ................................................................................................. ............................................ 8

Construcctive Implem

mentation. ................................................ .................................... 8

General requiremen

nts ........................................................................... ............................................ 8

Base ....................................................................................................... ............................................ 8

Lifting gear

g

............................................................................................ ............................................ 9

Doors...................................................................................................... ............................................ 9

Lock........................................................................................................ ............................................ 9

Screws, bolts, and nuts

n ......................................................................... ............................................ 9

Partition

ns ............................................................................................... ............................................ 9

Spare space

s

.......................................................................................... ............................................ 9

Cooling .................................................................................................. .......................................... 10

Docume

ent pocket .................................................................................. .......................................... 10

Wiring colours

c

....................................................................................... .......................................... 10

Electrical Implemen

ntation ...... ................................................ .................................. 10

General requiremen

nts ........................................................................... .......................................... 10

Voltage levels ........................................................................................ .......................................... 11

Short circuit withstand ........................................................................... .......................................... 11

Insulatio

on ............................................................................................... .......................................... 11

Individu

ual circuit con

nfiguration ............................................................... .......................................... 11

Mains supply

s

isolatio

on ........................................................................... .......................................... 11

Control supply ....................................................................................... .......................................... 12

Miniaturre Circuit Bre

eakers MCB............................................................ .......................................... 12

Air circu

uit breakers ................................................................................ .......................................... 12

Fuses ..................................................................................................... .......................................... 12

Isolator switches ................................................................................... .......................................... 13

Motor sttarters ........................................................................................ .......................................... 13

Relays and timers ................................................................................. .......................................... 13

E-stops .................................................................................................. .......................................... 13

LEDs ...................................................................................................... .......................................... 13

Auxiliaryy switches .................................................................................. .......................................... 14

Wiring ..................................................................................................... .......................................... 14

Termina

als .............................................................................................. .......................................... 15

Cable entry

e

............................................................................................ .......................................... 16

Cable seal ............................................................................................. .......................................... 16

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 2 of

o 20

Projectt Name: SER

RC

Title:

AIC:

2.4.21

2.4.22

2.4.23

2.4.24

2.4.25

2.4.26

2.5

2.6

2.6.1

2.6.2

2.6.3

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

Docum

ment Nr-Rev:

5002

21179 -0.0

Hitachi Zo

osen Inova AG

G

Cable fixing ........................................................................................... .......................................... 16

Cable shielding...................................................................................... .......................................... 16

Earthing

g ................................................................................................. .......................................... 16

Internal lighting ...................................................................................... .......................................... 16

Socket outlet ......................................................................................... .......................................... 17

Anti-con

ndensation heater

h

...................................................................... .......................................... 17

Labelling and marking ........... ................................................ .................................. 17

Protective

e measure

es ............. ................................................ .................................. 18

Equipottential bondin

ng ........................................................................... .......................................... 18

Insulatio

on ............................................................................................... .......................................... 18

Earthing

g ................................................................................................. .......................................... 18

Quality in

nspections and commiissioning ................................................................................ 19

Documen

ntation .......................................................................................................................... 20

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 3 of

o 20

Projectt Name: SER

RC

Title:

AIC:

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

5002

21179 -0.0

Docum

ment Nr-Rev:

Introdu

uction

1.1

Intentio

on of the docume

ent

Hitachi Zo

osen Inova AG

G

This Tech

hnical Implementation IInstruction (TII)

(

specifies the requuirements fo

or electrical and

control en

nclosures and cabinetss of standalone system

ms, installedd outside of

o electrical and

control roo

oms; but th

hese specififications ma

ay also be applied

a

to ooverall plan

nt systems, and

systems in

nside electrrical and con

ntrol rooms

s for the projject Severnnside.

1.2

Definitions and abbrevia

ations

Table 1: Abbreviatio

ons

Short term

Lo

ong term

HZI

Co

ompany Hita

achi Zosen Inova AG, purchaser

Supplier

HZ

ZI's contracttor

Sub-conttractor

Su

upplier of w

works and pllant section

ns who is noot a contrac

ctor/supplie

er of

HZ

ZI

TII

HZ

ZI Technica

al Implemen

ntation Instru

uction: geneeral technic

cal information,

such as corro

osion protec

ction, steel structures

s

eetc.

TSD

Te

echnical Sp

pecification Documentt: specific technical information for

ea

ach lot

PED

Project Execu

ution Docum

ment

EIC

Ele

ectrical and

d Control

BS

British standa

ard

DIN

De

eutsches Insstitut fr No

ormung (German Standdardisation Institute)

EN

Eu

uropean No rm

IEC

Intternational E

Electrotechnical Comm

mission

MCB

Miniature Circcuit Breakerrs

MCCB

Mo

oulded Cas e Circuit Brreakers

Ex

Ex

xplosion

RAL

Co

olour match ing system

AC3

Th

he category of the contactor for sq

quirrel cage motors

KKS

Po

ower plant cclassification

n system

BIL

Ba

asic insulatio

on level

PCS

Process contrrol system

HRC

Hig

gh rapturing

g capacity

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 4 of

o 20

Projectt Name: SER

RC

Title:

AIC:

1.3

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

Docum

ment Nr-Rev:

5002

21179 -0.0

Hitachi Zo

osen Inova AG

G

Norms and stan

ndards

The equip

pment, systtems, and work supp

plied shall comply

c

withh the requiirements off the

documentts PED EIC Stand

dards and

d regulatio

ons with the docu

ument num

mber

50021204

4 and TII 16

6.02 Regula

ations and standards

s

with

w the doccument num

mber 50021202.

1.4

Supplie

ers engin

neering

The engin

neering is to be done

e in accord

dance with the requirrements off the docum

ment

PED EIC Suppliers engineering

e

g with the document

d

number 500221205.

plier is to design,

d

sup

pply and in

nstall all ca

abinet systeems and enclosures.

e

The

The supp

equipment shall be complete in all respects

s and shall include all iitems which

h are necesssary

nd proper operation an

nd maintena

ance.

for safe an

1.5

Manufa

acturer

The list off approved suppliers

s

ca

an be found

d in the doc

cument PE D EIC List of productss and

suppliers with the do

ocument nu mber 50021203.

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 5 of

o 20

Projectt Name: SER

RC

Title:

AIC:

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

5002

21179 -0.0

Docum

ment Nr-Rev:

Technical req

quirements

2.1

General

2.1.1

Ambientt condition

ns

Hitachi Zo

osen Inova AG

G

The electtrical cabin

nets and e

enclosures must withs

stand all fooreseeable environme

ental

conditionss inside the

e plant. Add

ditional info

ormation reg

garding thee site can be

b found in

n the

documentt TII 16.01 General Infformation with

w the doc

cument num

mber 500212

201.

For outdoo

or installatio

on, direct exxposure to sunlight and exposuree to firedamp environm

ments

must be avoided.

a

Ap

ppropriate p

protective co

ontainers or enclosurees must be installed where

w

necessaryy.

2.1.1.1 Condition

ns for indoor installattion (proce

ess area)

Ambient te

emperature

e:

+5 C tto +50 C

Ambient te

emperature

e (short-time

e maximum)

+55 C

C

Ambient te

emperature

e (24 h averrage as per EN 60204)

C

+40 C

The temp

perature dis

stribution i n the boile

er house is extremelly uneven and is larrgely

determine

ed by the the

ermal condiitions in the

e open boile

er house struucture.

Parts of th

he plant whiich come in

nto direct or indirect con

ntact with thhe combusttion processs are

exposed to considera

able heat ra

adiation in some circum

mstances.

e case at tthe loading hopper, be

elow and addjacent to the combusstion

This is esspecially the

grate, at th

he slag hop

pper and at the apron conveyor

c

for slag remooval.

Parts of th

he plant wh

hich are in contact witth the wate

er/steam cirrcuit also ge

enerate a lo

ot of

heat. Thiss applies in particular to

o the boiler drum.

Po

osition:

Am

mbient humiidity:

Vib

bration/oscillation:

Atm

mosphere:

Exx classification:

Exxposure to water:

w

wa ll-mounted or free-stan

nding

ma

ax. 98 % relative humid

dity

n/a

a

dussty and agg

gressive

Ex zone definition

drip

pping waterr, water spra

ay

Exposure to water att floor level due to maintenance and

a cleaninng work mus

st be taken

n into

consideration at all elevations. D

Dripping watter and water spray aree likewise possible.

p

ns for outdoor installa

ation

2.1.1.2 Condition

Am

mbient temp

perature (24

4 h average

e as per EN 60204)

+35 C

Am

mbient temp

perature:

-25 C to +35 C

Dirrect exposu

ure to sunlig

ght in particu

ular must be

e avoided w

with outdoorr installation

n.

Po

osition:

wa ll-mounted or free-stan

nding

Am

mbient humiidity:

ma

ax. 95 % relative humid

dity

Vib

bration/oscillation: n/a

a

Atm

mosphere:

dussty and agg

gressive

Exx classification:

as per Ex zone definition

Exxposure to water:

w

gro

oundwater, dripping wa

ater, water sspray, rainw

water

d enclosuress installed outdoors

o

must be chossen in acco

ordance with

h the

Cabinet syystems and

Ex zone plan for th

he corresp onding zon

ne and the

e Ex apprroval proce

edure mustt be

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 6 of

o 20

Projectt Name: SER

RC

Title:

AIC:

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

Docum

ment Nr-Rev:

5002

21179 -0.0

Hitachi Zo

osen Inova AG

G

implemented accordiingly. There

e must be a clear sep

paration beetween the Ex and non Ex

zone.

Applicable

e Ex regulattions and gu

uidelines must

m

be obse

erved.

2.1.2

Ex Zones

s (ATEX)

The local control and

d junction bo

oxes shall be

b selected and implem

mented in accordance

a

with

the Ex zon

ne plan.

The cabinets/boxes must be constructe

ed according to the valid Ex standards and

regulations which inc

clude the se

eparation of Ex zones, and

a non Exx zones.

afe circuitryy is routed from

f

a haza

ardous areaa to a safe area

a

instrum

ment

Where intrinsically sa

panel, it shall

s

be connected thrrough Zene

er Barriers located in the safe area (instrum

ment

panel) of suitable ratting and mo

ounted on an

a insulated

d earthing bbusbar hav

ving facilities for

connection of a separate dedica

ated outgoin

ng cable to a "clean earrth" system.

2.1.3

Overall size

s

2.1.3.1 Dimensio

ons

Approval is

i required from the em

mployer for any other dimensionss and generral arrangem

ment

than those

e shown below:

eight x Width

h x Depth (iin mm)

He

2000 x 1000 x 800

2000 x 800 x 800

2000 x 600 x 600

port: Maximu

um width allowable for transport 11000 mm

Separation for transp

2.2

Externa

al charac

cteristics

s

2.2.1

Degree of

o protectiion

The IPratings should comply witth the follow

wing ratings when the ddoors are closed, electtrical

equipment mounted, and cabless glanded offf:

osed, dust ffree electric

cal room or container

In totally enclo

In plant area

utdoors and

d indoors su

ubject to water spray orr heavy conndensation:

Ou

If subjected

s

to

o occasiona

al submersio

on:

IP31

IP54

IP55W

IP68

The enclo

osure classification of m

main and auxiliary cab

ble boxes w

with the cable(s) termin

nated

shall not be

b less than

n that of the

e associated

d equipmen

nt, subject tto a minimu

um classifica

ation

of IP54.

d to the attmosphere they must be

Note: In instances where encclosures arre exposed

blown sand..

protected against ingress of dusst and windb

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 7 of

o 20

Projectt Name: SER

RC

Title:

AIC:

2.2.2

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

Docum

ment Nr-Rev:

5002

21179 -0.0

Hitachi Zo

osen Inova AG

G

Painting

The corrossion protecttion shall be

e according

g to the document TII 16.04 Corro

osion protecction

with the do

ocument nu

umber 5002

21972.

Refer alsso to the document

d

oncept witth the doc

cument num

mber

TII 16.10 Colour co

50021981. Unless otherwise spe

ecified the colour

c

shall be RAL 70035.

Approval shall

s

be obttained for th

he colours to be used.

2.3

Constru

uctive Im

mplementtation

2.3.1

General requireme

ents

Cabinets and

a enclosu

ures shall b

be constructted from she

eet steel, m

minimum thic

ckness 1.6 mm,

folded and

d braced as

s necessaryy to ensure rigidity.

r

Dependen

nt on the ov

verall dimen

nsions, cabin

nets and en

nclosures m

may be eithe

er wall moun

nting

type, complete with fiixing lugs o r free stand

ding.

ompartments shall be accessible from the fro

ont or rear aas applicab

ble using hin

nged

Cabinet co

doors. Do

oors shall be provided with sealin

ng gaskets and shall bbe secured by square key,

operated catches.

c

Low voltag

ge switchbo

oards, for b

both AC and

d DC system

ms, shall bee of the air insulated metal

m

clad type to Form 4B

B Type 7 fo

or incomers

s and Form 4B Type 5 for tiers housing

h

fee

eders

with more

e than one feeder perr level (cable terminals

s shall be pprotected by

b suitable rigid

covers pre

eventing ina

advertent acccess to live

e terminals, rubber booots will not be

b accepted

d).

Where vents need to

o be provide

ed for cooling, or relea

ase of gassses, they shall be covvered

with a messh robust and dense e

enough to:

pre

event the in

ngress of inssects

access to live componen

nts

ury to the operator

inju

Furthermo

ore, the ven

nts should direct gase

es away fro

om an operrator and should not allow

a

dripping water

w

to ente

er the cabin

nets and enclosures.

All outdoo

or kiosks, pa

anels, cabin

nets and enclosures mu

ust have suun/rain shad

des.

2.3.2

Base

Where the

e control eq

quipment ccomprises two or more

e cabinets or enclosures a moun

nting

frame sha

all be provided beneath

h the cabine

et or enclosu

ures

If a base is required then

t

it shou

uld comply with

w the follo

owing speciifications:

ase height

Ba

Ma

aximum ove

erall cabinett height

200 mm

2200 mm

Note: All locally insta

alled cabine

ets and encllosures plac

ced on conccrete area have

h

a 100 mm

concrete base.

b

When configurin

ng the conttrols, the co

ombined heeights of th

he cabinet base

b

and the co

oncrete bas

se provided by the clien

nt shall be taken into a ccount.

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 8 of

o 20

Projectt Name: SER

RC

Title:

AIC:

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

Docum

ment Nr-Rev:

5002

21179 -0.0

Hitachi Zo

osen Inova AG

G

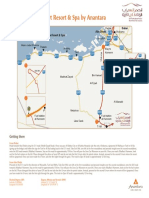

Airr extraction

2000

Controls

Air intake

Approx.

1300

Cable entrry at the side in

n

cabinet base

200

100

Con

ncrete base

2.3.3

Lifting ge

ear

Cabinets and

a enclosu

ures over 12

200 mm in height must be fitted w

with removable eyebolts.

2.3.4

Doors

Cabinets and

a enclosu

ures over 8

800 mm in width

w

must be fitted witth double doors

d

which

h can

be opened

d by 180.

2.3.5

Lock

Ergoform--S with doub

ble-bit key, 3 mm

2.3.6

Screws, bolts, and

d nuts

Unless ottherwise ag

greed, all sscrews, bo

olts and nu

uts shall bee hexagonal, ISO me

etric,

commercial standards and shall be rust pro

oof.

or surface of

o control pa

anels shall bbe domed and

a chrome

ed or

Nuts protrruding from the exterio

cadmium plated.

ng screws shall

s

not be utilised for any purpos

se.

Self-tappin

Removablle covers sh

hall be equiipped with captive

c

scre

ews.

2.3.7

Partition

ns

Cabinets and

a enclosu

ures must h

have partitio

ons between

n individual cabinets an

nd enclosurres

2.3.8

Spare sp

pace

Minimum 20 %

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 9 of

o 20

Projectt Name: SER

RC

Title:

AIC:

2.3.9

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

Docum

ment Nr-Rev:

5002

21179 -0.0

Hitachi Zo

osen Inova AG

G

Cooling

Cabinets and

a enclosu

ures not in air conditio

oned rooms must have anti-conde

ensation hea

ating

devices with

w a circula

ating fan; a

and a forced

d air, or airr-conditioneer, cooling system

s

whicch is

dust and vermin pro

oof. The inte

erior cabine

et temperature must bbe maintain

ned at betw

ween

+5 C and

d +35 C.

In genera

al all contro

ol panels m

must be de

esigned with

h a naturall air circula

ation ventila

ation

system.

s are install ed in dusty

y area or in an area of high ambie

ent temperature,

If local control panels

ent types off cooling me

ethods are allowed, if required; annd depend on the abiliity of

two differe

the heat trransfer capabilities of tthe cabinet, the heat generation

g

oof the equip

pment inside

e the

cabinets, and

a the surrrounding am

mbient cond

ditions.

IP6

65 cabinet with

w heat si nks inside and

a outside

e and circulaating fan

IP6

65 cabinet with

w split airr conditione

er

2.3.10 Document pocket

Mounted on

o inside off door of cab

binet (or enclosure)

2.3.11 Wiring colours

The wiring

g colours should

s

com

mply with the requirements of thee documentt TII 15.0

02.02

Cable trayys and cabliing with the

e documentt number 50

0021175.

2.4

Electric

cal Imple

ementatio

on

2.4.1

General requireme

ents

All electriccal compon

nents shall be adequa

ately rated for their m

most onerou

us duty and

d the

specified ambient tem

mperature. When equipment is mounted

m

in panels, cabinets etc., due

en of any he

eat generate

ed by the eq

quipment thherein and the

t compon

nents

account shall be take

shall be appropriatel

a

y selected,, rated or de-rated

d

as necessaryy to suit the

e most one

erous

operating temperaturres within th

he enclosure

e.

ng part of the equipm

ment shall be

b capablee of carrying its site rated

r

Every currrent carryin

current co

ontinuously under the ssite ambien

nt conditions as speciffied and shall not be rated

r

on the ba

asis of air conditione d rooms even

e

when these are specified. The maxim

mum

continuous operating temperaturre of the eq

quipment ma

ay not be exxceeded.

hboards shall be eithe r single-pole and neutrral, or triplee pole and neutral

n

type

e and

The switch

shall be eq

quipped witth means to

o provide ov

ver-current protection

p

too each circuit.

Switchbbo

oards for us

se on directt current sy

ystems shall be doublee pole types

s equipped with

adequately rated fuse

es.

cted on the incoming sside of a dis

stribution board

Switch fusse units or disconnect ors connec

shall be mechanically attached

d to the board

b

with solid coppper electric

cal connecttions

between the units.

oing circuits of the ca

abinet and enclosure shall be m

mounted on withdraw

wable

The outgo

carriages unless othe

erwise agre

eed with the purchase

er. The withhdrawable units

u

must have

h

the followiing characte

eristics:

Th

he withdraw

wable unit syystem comp

prises the components

c

s permanen

ntly mounted on

the

e frame, the

e withdrawa

able units themselves and

a the conttacting elem

ments.

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 10 of

o 20

Projectt Name: SER

RC

Title:

AIC:

170000

2.4.2

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

Docum

ment Nr-Rev:

5002

21179 -0.0

Hitachi Zo

osen Inova AG

G

A multifunctio

onal wall sshall be in

nstalled between the bus bar and equipm

ment

compartments

s. This sha

all house the

e metal enc

closed multti-terminal bus

b bars, which

w

are

e sealed offf from the e

equipment compartme

c

nt with mullti-terminal bus bar covvers,

ensuring touc

ch protection

n.

Th

he contact openings in the multi-terminal bus bar ccovers hav

ve to meett the

req

quirements for protecti on IP20 and

d must be safe

s

to toucch.

Th

he withdrawable units sshall be con

nnected on the incominng and outg

going side using

u

plu

ug connecto

ors (primaryy and auxilia

ary electric circuits).

Voltage levels

l

The voltag

ge levels are specified

d in the doc

cument TIII 16.01 Genneral Inform

mation with

h the

documentt number 50

0021201. Th

he system frequency

f

is

s 50 Hz.

The contro

ol voltage in

n the panelss must be 24

2 VDC or 230

2 VAC L/ N/PE from UPS. It sha

all be

approved by HZI.

All electriccal equipme

ent shall, exxcept wherre otherwise

e specified, be capable of continu

uous

operation at a voltage

e with a freq

quency in th

he range of 47 to 51 Hzz.

n the switch

hgear mustt be designe

ed for a voltage level of 0.85 and

d 1.1 x Un; and

In addition

must have

e the capability to ride tthrough a 1.5 sec 70 % voltage diip.

The switcchboard over voltage withstand capability must be teested in accordance with

EN 61439

9 and must be designe

ed to withsttand the short time oveervoltages required byy the

applicable

e regulations

s and stand

dards.

2.4.3

Short cirrcuit withs

stand

Cabinets and enclos

sures must be capable

e of withsta

anding withhout injury the mechanical

and electrrical stresse

es set up byy the maxim

mum prospe

ective fault ccurrent for twice

t

the pe

eriod

required to

o disconnec

ct such faultt on any cirrcuit.

2.4.4

Insulatio

on

The equip

pment rating

gs, and cle

earances, shall be rate

ed, designeed and teste

ed to withsstand

the expeccted BIL and

d SWIL exp

pected. The

e required test

t

voltagees, ratings, and clearan

nces

are speciffied in EN 60439.

2.4.5

Individua

al circuit configurat

c

tion

The switcchgear insid

de the cab

binet and enclosures shall be ccomprised of type te

ested

assemblie

es (TTA); be

b of a w

well proven design; and designeed for S1 (IEC 6003

34-1)

continuous operation

n, and in g

general AC

C3 (IEC 60

0947-4-1) ssquirrel cag

ge starting and

stopping.

ations and componen

nts for speecific types

s and size

es of

The particular circuit configura

nsumers are

e specified in the doc

cument with

h the namee TII 15.02

2.01 LV Driives

drives/con

with the document nu

umber 5002

21189, and also the do

ocument witth the name

e TII 16.25 EUUV-EM Fu

unction Typicals with tthe docume

ent number 50021198. The require

ements in th

hese

documentts must be complied

c

wiith.

2.4.6

Mains su

upply isola

ation

The mainss supply sh

hall be conn

nected to th

he control equipment

e

vvia an isola

ating switch and

shall be mechanicall

m

y interlocke

ed with the equipment door to prrevent open

ning of the door

osition.

until the sw

witch is in the "OFF po

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 11 of

o 20

Projectt Name: SER

RC

Title:

AIC:

2.4.7

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

Docum

ment Nr-Rev:

5002

21179 -0.0

Hitachi Zo

osen Inova AG

G

Control supply

s

The contrrol voltage used for th

he switchge

ear shall be

e 230 VAC

C UPS. All PCS Input and

output sig

gnals, interlo

ocks and s afety circuits, and insttrumentatio n, and any

y control circuits

leaving the

e cabinet must

m

be 24 V

VDC.

The contro

ol supply fo

or each set o

of equipment shall be provided byy one single

e phase, do

ouble

wound, co

opper, naturral air coole

ed transform

mer, with one leg solidlyy earthed (n

neutral).

The transsformer inpu

ut and outp

put circuits,, shall be protected

p

bby suitable rated minia

ature

circuit breakers (MCB

Bs).

2.4.8

Miniature

e Circuit Breakers

B

M

MCB

MCBs sha

all be confin

ned to auxil iary circuits

s such as co

ontrol and inndication.

All miniature circuit breakerss (MCBs) shall be of the hhigh speed

d fault lim

miting

thermal/m

magnetic type from 0 to 63 A.

All moulde

ed case circ

cuit breakerrs (MCCBs) shall be of

o the manu ally operate

ed trip-free type

with therm

mal or magn

netic overlo ad protectio

on and with

h instantaneeous-magne

etic short ciircuit

trips in ea

ach pole frrom 63 to 2500 A. MCBs and MCCBs

M

maay be used subject to

o the

protection grading sa

atisfactorily w

with other circuit

c

break

kers and fusses.

nd MCCBs shall be equipped with quick

k make annd quick break

b

trip free

MCBs an

mechanisms that prevent the bre

eaker being

g held in aga

ainst overlooads or faults.

a

ts shall be ssuch as to ensure

e

simu

ultaneous oopening of all

a phases.

Tripping arrangemen

The actua

ator shall ha

ave two po

ositions on, off for MCBs,

M

threee positions,, "on", "off" and

"tripped" for

f MCCBs. To reset ffrom the "trripped" pos

sition the acctuator shall first pass into

the "off" position.

p

MC

CBs on the main switch

hboard shall have facillities for loc

cking in the "off"

position. This

T

particular point wil l be fixed during the de

etailed engiineering perriod.

The ruptu

uring capac

city of the MCB and

d MCCBs shall not bbe less than that off the

switchboa

ard itself, or if this is nott the case back

b

up fuse

es must be included.

2.4.9

Air circu

uit breakerrs

Air circuit breakers must

m

be used

d for income

ers and feeders abovee 630 A.

2.4.10 Fuses

MCBs and

d MCCBs shall

s

be use

ed in preferrence to fus

ses. The em

mployers prior

p

approvval is

required, stating

s

the justification

j

for the use

e of fuses.

Where fusses are used they mustt comply with the follow

wing:

Co

omposite fuse and sw itch equipm

ment may comprise

c

eitther fuse-sw

witch units with

integral fuses, or switch-ffuse units in which the

e air break sswitch and the

t connecttions

fro

fuse shall be

om it to the associated

a

b so designed as to m

minimise the

e possibilityy of a

fau

ult. The equ

uipment sha

all comply with

w the req

quirements of EN 6094

47-2, 3, or 4 as

applicable.

he fuse swittch operatin

ng mechanism shall be

e of the sprring-loaded type, such that

Th

the

e speed of operation

o

ca

annot be co

ontrolled by the operatoor.

Fu

ull closing orr opening o

of the switch

h shall not depend

d

upoon the opera

ator pushing

g the

operating han

ndle fully ho

ome. In the

e event of a spring fai lure it shalll be possible to

open the switc

ch without e

endangering

g the opera

ator.

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 12 of

o 20

Projectt Name: SER

RC

Title:

AIC:

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

Docum

ment Nr-Rev:

5002

21179 -0.0

Hitachi Zo

osen Inova AG

G

Wh

here fuse switches

s

are

e mounted above busbar chambeers, close fitting

f

shield

ds of

inssulating ma

aterial shalll be provid

ded to prevent objectts falling in

nto the bu

usbar

chambers.

Pa

arts that re

emain alive

e when co

overs are opened shhall be shrrouded aga

ainst

accidental con

ntact with to

ools. Units shall

s

be scrreened to ppermit work in safety on

n the

loa

ad side of any circuit w

with adjacent circuits "liv

ve".

Fu

use switche

es for cubiccle mountin

ng shall ha

ave provisioon for ope

erating auxiliary

sw

witches for control and

d interlock purposes. Provision foor locking switches in

n the

open position shall be prrovided

use and link

k carriers an

nd bases sh

hall be of an approvedd manufactu

ure and of such

s

Fu

forrm and matterial so as to protect persons

p

from shock annd burns in normal serrvice

and maintena

ance. Furthe

ermore, fuse links, fuse

e contacts aand fixed co

ontacts sha

all be

shielded to prevent

p

ina dvertent co

ontact with live metall whilst the

e fuse is being

b

insserted or withdrawn.

Fu

uses shall be

e of the non

n-deterioratting HRC ca

artridge typee. Fuse hold

ders shall be

b so

designed as to

t permit de

etection of fuse

f

rupturin

ng without rremoving th

he bridge. "Z

Zed"

n type fuse s shall nott be permittted exceptt with the approval

a

off the

and screw in

Em

mployer.

Te

est links in current

c

transsformer circ

cuits shall be of the bollted or plug in type.

Th

he labelling of fuses, ca

arriers and bases shalll comply witth the applicable stand

dard.

d to panels, boards and desks for fuses and links shall

Ide

entification labels fixed

ge and ratin

describe theirr duty, voltag

ng.

use and link carriers an

nd bases shall be colou

ur coded as required by

y the Emplo

oyer

Fu

Fu

use holders shall be o

of an appro

oved non hy

ygroscopic insulation suitable forr the

recceipt of HRC

C fuses

2.4.11 Isolator switches

s

All isolatin

ng switches shall be off the fault make/load

m

break

b

type w

with mechanical ON-O

OFF

indication and manua

al actuating mechanism

ms and early

y break auxxiliary conta

act.

2.4.12 Motor starters

All motor starters shall be airr break contactor typ

pe for frequuent duty to specifica

ation

IEC 6094

satisfying Class I, Category AC

47-1, with contactors

c

C-3 rating of specifica

ation

IEC 60947

7-4.

Circuit bre

eakers and contactors should be selected

s

to comply

c

withh full type 2 coordinatio

on.

a

timers

s

2.4.13 Relays and

Plug-in typ

pes are preferred, com

mplete with screw

s

type terminals

t

onn the base.

2.4.14 E-stops

3-pole, fail safe, switc

ches shall b

be used for E-stops

2.4.15 LEDs

Visual ind

dication mu

ust be don e with multi-chip light emitting diode (LED

D). The usse of

conventional filamentt or neon la mps is not permitted.

nce of 100000 hours and

a

be ablle to

The light emitting diiodes mustt have a liffe expectan

ervoltage.

withstand a 20 % ove

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 13 of

o 20

Projectt Name: SER

RC

Title:

AIC:

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

5002

21179 -0.0

Docum

ment Nr-Rev:

Hitachi Zo

osen Inova AG

G

The LED covers sha

all be in the

e standard colours,

c

red

d, green, bllue, white and

a amber. The

colour sha

all be in the glass and n

not an applied coating. Transpareent synthetic

c materials may

be used in

nstead of glass subjectt to the approval of HZI.

Where illu

uminated pu

ushbuttons are used fo

or control purposes,

p

thhe illuminated pushbutttons

shall be engraved with a clear in

nstruction such

s

as 'pus

sh to open' or 'push to

o close', and

d the

lamp shalll illuminate

e in accorda

ance with the

t

above colour codee after the instruction has

been carrried out and

d the devicce has ope

erated. In case

c

of usee of LEDs, the associiated

colours must be linke

ed with the sstatus of the

e non-illuminated pushhbutton.

herwise agrreed with th

he purchase

er all LED colours

c

shaall conform to the follow

wing

Unless oth

practice:

sed or operrative positio

on

Grreen energis

Re

ed de energ

gised or inop

perative pos

sition

Am

mber fault or abnormal condition

Wh

hite healthy

y or normal condition

Blu

ue other purposes, to b

be used with descriptiv

ve label

LED test facilities

f

are

e not require

ed.

Indication circuits sha

all be fused or protecte

ed.

2.4.16 Auxiliary

y switches

s

Auxiliary switches

s

sh

hall be of ap

pproved sta

andard and contacts shhall have a positive wiiping

action whe

en closing.

2.4.17 Wiring

Where busbars are used

u

in the constructio

on of the pa

anels, thesee shall be hard

h

drawn high

conductiviity (HDHC) copper. Th e maximum

m current de

ensity shall bbe 1.66 A/ mm.

m

Busbars shall

s

be of HDHC

H

copp

per supporte

ed on non-tracking insuulators and be designe

ed to

withstand the dynam

mic forces occurring under

u

the specified

s

s hort circuit conditionss. All

busbars bolts

b

shall be high tenssile steel. Other

O

power conductorss shall be stranded

s

copper

conductorr, PVC insullated of 600

0 V/1000 V grade.

Control an

nd instrumentation wirin

e carried out in 600 V ggrade insula

ated cable.

ng, shall be

The wiring

g insulation

n shall be sselected to ensure com

mpliance w

with requirem

ments for fllame

retardation

n, reduced propagation

moke and ha

alogen/acidd emission for

f the cablle as

n or low sm

a whole, as

a specified.

Conductorrs shall be multi-strand

m

ded, copperr; the minimum size shaall be 1 mm

m.

Wiring colours for diffferent voltag

ge levels an

nd applications and cirrcuits must be differentt and

the colourrs need to be

b approved

d by the employer.

Wiring sha

all be supp

ported on tra

ated accordding to voltage levels, and

ays and to be segrega

also according to AC

C and DC vvoltage. If approval

a

is obtained frrom the em

mployer trun

nking

may be used

u

howev

ver the vo ltage levels

s shall be segregatedd and the bunched cross

c

sectional area of wiring shall no

ot exceed 45

4 % of the

e cross secttional area of the trunkking.

Where thiss is not pos

ssible due to

o the applic

cation then wiring may be run in neat

n

and ord

derly

loomed patterns,

p

su

uitably stra

apped with

h approved proprietarry strappin

ng materials, if

approved by the emp

ployer.

oming and outgoing ca

able cores shall

s

be lab

belled as sppares, and terminated,

t

with

Spare inco

enough le

ength to be moved

m

anyw

where in the

e enclosure

e.

All panel wiring

w

shall be terminatted, using suitably

s

size

ed compresssion crimp lugs or pinss.

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 14 of

o 20

Projectt Name: SER

RC

Title:

AIC:

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

Docum

ment Nr-Rev:

5002

21179 -0.0

Hitachi Zo

osen Inova AG

G

Where wirre wrap and terminal point conne

ections hav

ve been term

minated witth the aid of

o an

accepted semi-autom

matic or au

utomatic, po

ower tool such tools sshall be pro

ovided with

h the

enclosure.

s

within

n desks and

d panels sha

all be set att an angle tto afford ea

asy identifica

ation

Terminal strips

and accesss.

All interna

al wiring to

o terminal blocks for the connection of ouutgoing or interconneccting

nals from one side only

circuits sh

hall approac

ch the termin

y.

Electrical equipment mounted iin or on sw

witchgear, panels

p

and desks, sha

all have readily

accessible

e connectio

ons and sha

all be wired

d to termina

al blocks foor the recep

ption of exte

ernal

cabling.

g shall comply with the

e appropriatte standard and shall bbe capable of withstan

nding

The wiring

without de

eterioration the conditio

ons at Site, due allowance being m

made for su

uch tempera

ature

conditionss as may arise within

n any encllosure. The

e insulatingg material shall be fllame

retardant.

All wiring shall be of

o adequatte cross se

ectional are

ea to carryy prospectiv

ve short ciircuit

currents without

w

risk of

o damage to conducto

ors, insulatio

on or joints

All cables shall be te

erminated b

by crimp-on ferrules an

nd connecteed to screw

w terminals. The

section off the termin

e equal or higher than

nals shall be

n one and a half time

e the conne

ected

wire sectio

ons.

Connectio

ons to app

paratus mo

ounted on doors or between ppoints subjject to rela

ative

movement shall be arranged so that they are subjected

d to torsion rather than

n bending.

All auxiliary switches

s, whether i n service or

o not in the

e first instannce, shall be

b wired up to a

terminal board

b

and sh

hall be arra nged in the

e same sequ

uence on si milar equipment.

Panel secctions accom

mmodating equipment at voltages

s higher thaan 125 V (no

ominal) sha

all be

partitioned

d off and the

e voltage cllearly labelled. Adjacen

nt terminalss to which wires

w

of diffe

erent

voltage, polarity

p

or phase are connected shall be separated

s

bby a protru

uding insula

ating

barrier. Th

his requirem

ment also a

applies to te

erminals ca

arrying wirees of the sa

ame voltage

e but

originating

g from differrent sourcess.

Where an overall screen is used

d, this shall be a metallic screen oor low resisttance tape, with

w

as above. When two lengths of screen

ned cable aare to be connected at a

a drain wire

terminal block

b

(e.g. junction boxx) a separa

ate terminal shall be prrovided to maintain

m

sccreen

continuity..

Please allso refer to

o the docu

ument TII 15.02.02 Cable traays and ca

abling with the

documentt number 50

0021175.

2.4.18 Terminalls

Low voltag

ge switchbo

oards, for b

both AC and

d DC system

ms, shall bee of the air insulated metal

m

clad type to Form 4B Type 7 ffor incomerrs and bus sections, F

Form 4 B Type

T

6 for tiers

housing fe

eeders where there is o

only one fee

eder per lev

vel (plastic covers shall be installe

ed to

prevent in

nadvertent access

a

to livve terminals

s) and Form

m 4B Type 5 for tiers housing

h

fee

eders

with more

e than one feeder perr level (cable terminals

s shall be pprotected by

b suitable rigid

covers pre

eventing ina

advertent acccess to live

e terminals, rubber booots will not be

b accepted

d).

Sufficient terminals shall be p

provided to

o permit all cores onn multi-core

e cables to

o be

terminated

d. Terminals

s for spare cores shall be numberred and be located at such

s

positio

on as

will provid

de the max

ximum leng

gth of spare

e core. At least 10 % spare terminals shall be

provided in all cases.

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 15 of

o 20

Projectt Name: SER

RC

Title:

AIC:

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

Docum

ment Nr-Rev:

5002

21179 -0.0

Hitachi Zo

osen Inova AG

G

Terminal boards

b

shall be mountted vertically, not less than 150 m

mm above th

he gland pla

ates,

and space

ed not less

s than 100m

mm apart, on the side

e of the ennclosure an

nd set obliq

quely

towards th

he rear doors.

The cabin

nets and enclosures

e

e separate terminals for interna

al and exte

ernal

must have

connections, and nott more than

n one wire shall

s

be con

nnected to each terminal. Wires shall

be groupe

ed on the terminal acco

ording to the

eir functions

s.

Access to terminals shall

s

not be obstructed by equipment.

al blocks sh

hall provide a degree of

o protection

n of not lesss than IP2X

X when correctly

All termina

installed, either

e

inherently or by provision off insulating covers.

Conductorr up to 35 mm

m

Terminal strips shall be of the rail mountted box typ

pe with a ppressure pa

ad between

n the

conductorr and the cla

amping scre

ews.

Conductorr sizes exce

eeding 35 m

mm

Terminalss shall be off the stud tyype to acce

ept crimped cable lugs.. Complete with separa

ating

barriers an

nd protectiv

ve covers.

2.4.19 Cable en

ntry

Enclosure

es and cabin

nets mounte

ed above th

he floor mus

st have botttom cable entry.

Floor mou

unted cabine

ets may havve cable en

ntry from below and/or sside of base.

Removablle, undrilled

d cable glan

nd plates, with

w a minimum gauge oof 4 mm, sh

hall be provvided

and be so located that ample

e internal space is allowed for tthe satisfac

ctory entry and

terminating of cables

2.4.20 Cable se

eal

According

g to BS. Ple

ease also re

efer to the document

d

TII 15.02.0 2 Cable tra

ays and cab

bling

with the do

ocument nu

umber 5002

21175.

2.4.21 Cable fix

Cable gua

ard rail for strain relief

2.4.22 Cable sh

hielding

Shielding bus with cla

amping bra cket > 180. A shieldin

ng bus with screw term

minals will no

ot be

accepted.

2.4.23 Earthing

g

Each cabiinet shall be

e complete with an earth bar secu

urely bondeed to the ca

abinet steelw

work

for accep

pting an ea

arth conducctor. Earth busbars, shall

s

be HD

DHC copper and havve a

minimum cross secttional area of 150 mm

m2. Each ca

abinet doorr shall be earthed to this

cabinet ea

arth bar.

Each cabiinet must be connecte

ed to the ea

arthing syste

em via the equipotential bonding rails

or to the earthing

e

cab

ble or the m

main cable conduit. Minimum crosss-section sh

hall be 35 mm.

m

2.4.24 Internal lighting

l

The cabinet must hav

ve a door op

ernal light according too BS.

perated inte

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 16 of

o 20

Projectt Name: SER

RC

Title:

AIC:

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

Docum

ment Nr-Rev:

5002

21179 -0.0

Hitachi Zo

osen Inova AG

G

2.4.25 Socket outlet

o

The cabin

net must ha

ave a switcched socke

et outlet prrotected byy a residual current ciircuit

breaker acccording to BS.

2.4.26 Anti-con

ndensation

n heater

Anti-conde

ensation he

eaters shall be supplied

d for local control paneels to preven

nt condensa

ation.

The appa

aratus so protected

p

sh

hall be des

signed so that the m

maximum pe

ermitted risse in

temperatu

ure is not ex

xceeded if th

he heaters are energis

sed while th e apparatus

s is in opera

ation.

The switcchboard antti condensa

ation heate

ers shall be

e fed from an LV sin

ngle phase and

neutral supply, manually switche

ed by a two

o pole switch

h with red laamp, mounted on the back

b

of the boa

ard, panel or cubicle an

nd bus wired through th

he board. LLabels shall be provide

ed on

the switch

h stating "He

eater Suppl y". Heater terminals

t

sh

hall be shroouded and la

abelled "He

eater

2.5

Labellin

ng and marking

m

The labellling must co

omply with the docum

ment TII 15.02.08 Idenntification an

nd marking EIC

componen

nts with the

e documentt number 50

0021275.

All labels shall

s

be in English.

E

Marking shall

s

be ap

pproved by the HZI and

a

indicate

ed on the mechanical and electtrical

drawing. Dual

D

design

nations are fforbidden.

When a wire

w

numbe

ering system

m is used, it should be in accoordance with a recogn

nised

marking system or wiith a functio

onal marking

g system orr as specifieed elsewherre

pment shall have pote

ential risk off electrical shock warrning plates

s as require

ed by

The equip

the regula

ations, and as

a necessa

ary, includin

ng on the co

ontrol cabinnet. Remova

able coverss and

rear doorss giving acc

cess to live e

equipment shall be pro

ovided with a notice ins

scribed "Danger

- Live Equ

uipment".

Each cubicle and ite

em of equip

pment and componentt, must havve a durablle label of noncorrodible

e material e.g. stainlesss steel or tra

afollite (or similar), indeelibly stamp

ped or engra

aved,

and legibly marked with

w the equ

uipment ite

em number and descri ption, corre

espond with

h the

drawings and documentation. Th

he labels sh

hall have bllack characcters at leas

st 6 mm high on

a white background.

b

. These lab

bels shall be

b trafollite and not bbe of the plastic strip type

Labels sh

hall be affixed by mea

ans of mach

hine screws

s, and prom

minently dis

splayed. La

abels

shall be fixed to all equipme nt, prior to

o despatch

h. The labeels shall not

n be fixed to

componen

nts but sha

all be posittioned adjacent to the

e componennt such tha

at they are

e not

nt. In all cas

obscured by any othe

er equipmen

ses the labe

el should bee positioned

d so as to le

eave

no doubt as

a the item to which it rrefers.

All the pan

nels must be

b labelled a

at the front,, and rear, of

o the fixed part, using the KKS ciircuit

designatio

on as speciffied on the project sing

gle line diag

gram or loopp diagram. The

T informa

ation

conveyed shall includ

de a descrip

ption, conne

ected equip

pment numbber, and the

e function of

o the

equipment.

All wiring and cores in control a

and instrument cables shall be ideentified in accordance

a

with

the associated schem

matic and/o r wiring diagrams eithe

er by meanss of discrette wire num

mbers

or wire colours, except when an automatic or proprieta

ary system oof wiring is used, e.g. point

p

to point wiring

w

on a mother

m

boa

ard. Each end of every

y core shall be identifie

ed using plastic

interlockin

ng cable ferrules, ferrul es to match

h the type of

o terminal, iindelibly ma

arked with black

b

characterss. Each core shall be id

dentified by

y colour and

d terminal bblock identiffication toge

ether

with an id

dentification

n tracer perr bundle. Heat

H

shrink marking ssleeves may be used,, but

adhesive markers arre not acce

eptable. Split or clip-on

n ferrules sshall not be

e utilised. Spare

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 17 of

o 20

Projectt Name: SER

RC

Title:

AIC:

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

Docum

ment Nr-Rev:

5002

21179 -0.0

Hitachi Zo

osen Inova AG

G

incoming and outgo

oing cable cores shall be labelle

ed as spa res, and te

erminated, with

enough le

ength to be moved anyywhere in th

he enclosurre. Where i nstruments

s are termin

nated

in a plug and

a socket type conne

ection both the plug an

nd the sockket shall have permane

ently

attached identifying la

abels. Wirin

ng which is permanentlly connecteed to plugs or

o sockets need

n

not be ide

entified.

2.6

Protecttive meas

sures

The insta

allation and

d equipmen

nt supplied

d must comply with the requirrements of the

documentt TII 15.02.03 Earthin

ng, lightning

g protection

n and equippotential bo

onding with

h the

documentt number 50

0021130.

2.6.1

Equipote

ential bonding

All expose

ed conductiive parts off equipmentt shall be bonded to thhe local earrth bar, and

d the

power sup

pply protective earth co

onductor.

2.6.2

Insulatio

on

Physical protective measure sshall be ap

pplied to prevent inaddvertent co

ontact with live

componen

nts e.g. The contacts of all conttrol and sellector switcches shall be

b shroude

ed to

minimise the

t ingress of dust and

d accidentall contact.

2.6.3

Earthing

g

The local control stattion must h ave separa

ate earth ba

ars for the ssignal cable

e earths and

d the

protective earth (pow

wer supply).

e armouring

g may be u

used as the

e protective

e earth; hoowever, if th

he local co

ontrol

The cable

box/station contains switchgear , or is used

d for distribu

uting powerr, it must be earthed via

v a

dedicated earth wire connected to the elec

ctrical earthing system. The spare core inside

e the

cable can be used for this purpo

ose.

All doors with electriical compo nents mustt have be connected

c

w

o the

with an earth strap to

protective earth bar.

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 18 of

o 20

Projectt Name: SER

RC

Title:

AIC:

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

Docum

ment Nr-Rev:

5002

21179 -0.0

Hitachi Zo

osen Inova AG

G

Quality

y inspec

ctions a

and com

mmissio

oning

The quality inspectio

ons and co

ommissioning must comply withh the requirements off the

documentt PED EIC Suppliers e

engineering with the do

ocument nuumber 5002

21205.

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 19 of

o 20

Projectt Name: SER

RC

Title:

AIC:

170000

TII 15.02.0

06 Cabinet systems and

a

enclosure

es

Docum

ment Nr-Rev:

5002

21179 -0.0

Hitachi Zo

osen Inova AG

G

Docum

mentatio

on

The docu

umentation must com

mply with the requirements of tthe docum

ment PED EIC

Suppliers engineering

g with the d

document number

n

500

021205.

Print date 25.09.13 07:20

La

ast saved 24.09.13

Page 20 of

o 20

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- TII-HZI-50021973 - 0.0 - TII 16.05 Thermal and Sound InsulationDocumento19 pagineTII-HZI-50021973 - 0.0 - TII 16.05 Thermal and Sound InsulationBorn ToSinNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- TII-HZI-50021252 - 1.0 - TII 16.20 Requirements For Contractors Technical DocumentsDocumento14 pagineTII-HZI-50021252 - 1.0 - TII 16.20 Requirements For Contractors Technical DocumentsBorn ToSin0% (1)

- TII-HZI-50021298 - 0.0 - TII 15.05.02 Instrumentation Master CatalogueDocumento202 pagineTII-HZI-50021298 - 0.0 - TII 15.05.02 Instrumentation Master CatalogueBorn ToSinNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- TII-HZI-50021280 - 2.2 - TII 16.03 Steel Structures, Platforms, Stairs, RailingsDocumento24 pagineTII-HZI-50021280 - 2.2 - TII 16.03 Steel Structures, Platforms, Stairs, RailingsBorn ToSinNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- TII-HZI-50021972 - 1.0 - TII 16.04 Corrosion ProtectionDocumento40 pagineTII-HZI-50021972 - 1.0 - TII 16.04 Corrosion ProtectionBorn ToSinNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- TII-HZI-50021275 - 0.0 - TII 15.02.08 Identification and Marking EIC ComponentsDocumento11 pagineTII-HZI-50021275 - 0.0 - TII 15.02.08 Identification and Marking EIC ComponentsBorn ToSinNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Welding Consumables Handbook 0609Documento647 pagineWelding Consumables Handbook 0609Born ToSin100% (1)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- TII-HZI-50022349 - 0.0 - TII 16.08 DuctsDocumento13 pagineTII-HZI-50022349 - 0.0 - TII 16.08 DuctsBorn ToSinNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- TII-HZI-50021981 - 1.0 - TII 16.10 Colour ConceptDocumento18 pagineTII-HZI-50021981 - 1.0 - TII 16.10 Colour ConceptBorn ToSinNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- JTE - HZI - 50021543 - 0.0 - Work Instruction OM For System SuppliersDocumento23 pagineJTE - HZI - 50021543 - 0.0 - Work Instruction OM For System SuppliersBorn ToSinNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- TGE-HZI-50021204 0.0 EIC Standards and RegulationsDocumento15 pagineTGE-HZI-50021204 0.0 EIC Standards and RegulationsBorn ToSinNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- RT AsmeDocumento2 pagineRT AsmeBorn ToSinNessuna valutazione finora

- TII-HZI-50022348 - 0.0 - TII 16.09 Welding, Steel Structure, Metal ConstructionDocumento11 pagineTII-HZI-50022348 - 0.0 - TII 16.09 Welding, Steel Structure, Metal ConstructionBorn ToSinNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- JTE - HZI - 50021543 - 0.0 - Work Instruction OM For System SuppliersDocumento23 pagineJTE - HZI - 50021543 - 0.0 - Work Instruction OM For System SuppliersBorn ToSinNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Follow Up Log Sheet That Done by Chimec Rep. For (CH1038 & CH1052 & CH1030) at Wells On 2010Documento16 pagineFollow Up Log Sheet That Done by Chimec Rep. For (CH1038 & CH1052 & CH1030) at Wells On 2010Born ToSinNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Rotator TNA 40 (40 TM) : EuropeDocumento1 paginaRotator TNA 40 (40 TM) : EuropeBorn ToSinNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Rotator TNA 40 (40 TM) : EuropeDocumento1 paginaRotator TNA 40 (40 TM) : EuropeBorn ToSinNessuna valutazione finora

- Cobalt Alloy 188 Data Sheet - Sept - PDFDocumento1 paginaCobalt Alloy 188 Data Sheet - Sept - PDFBorn ToSinNessuna valutazione finora

- Iso 14 1982 PDFDocumento14 pagineIso 14 1982 PDFBorn ToSin67% (3)

- Zavar Precaik Dodataog Materijala Struja Napon - Brzina Dodavanja Zice Unos TopioteDocumento1 paginaZavar Precaik Dodataog Materijala Struja Napon - Brzina Dodavanja Zice Unos TopioteBorn ToSinNessuna valutazione finora

- Pipeline Maintenance Procedure C 70 C G 007 00 A1Documento138 paginePipeline Maintenance Procedure C 70 C G 007 00 A1Born ToSin100% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- ASME Stamp 2Documento1 paginaASME Stamp 2Born ToSinNessuna valutazione finora

- Cobalt Alloy 188 Data Sheet - SeptDocumento1 paginaCobalt Alloy 188 Data Sheet - SeptBorn ToSinNessuna valutazione finora

- Welding Handbook ESABDocumento529 pagineWelding Handbook ESABErdinc_Bal_1026100% (8)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Uporedna Tabela ESAB To BOEHLERDocumento5 pagineUporedna Tabela ESAB To BOEHLERBorn ToSin100% (1)

- Pressure Proced TestDocumento6 paginePressure Proced Testjamaljamal20Nessuna valutazione finora

- PP 2006 03Documento4 paginePP 2006 03Born ToSinNessuna valutazione finora

- BS en 1044-1999 - Brazing Filler MetalsDocumento26 pagineBS en 1044-1999 - Brazing Filler MetalsBorn ToSinNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- p91 WeldingDocumento5 paginep91 Weldingsaji_t1984100% (1)

- Qasr Al Sarab Desert Resort Location Map June2012Documento1 paginaQasr Al Sarab Desert Resort Location Map June2012Anant GârgNessuna valutazione finora

- Recruitment and Selection in Canada 7Th by Catano Wiesner Full ChapterDocumento22 pagineRecruitment and Selection in Canada 7Th by Catano Wiesner Full Chaptermary.jauregui841100% (51)

- Surface Finish Measurement NotesDocumento32 pagineSurface Finish Measurement NotesAneez ShresthaNessuna valutazione finora

- MSDS DowthermDocumento4 pagineMSDS DowthermfebriantabbyNessuna valutazione finora

- Ecall Vs NG EcallDocumento6 pagineEcall Vs NG EcallTrần Văn DũngNessuna valutazione finora