Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

A Mathematical Model For Dispersion in The Direction of Flow in Porous Media

Caricato da

Bahman MatouriTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

A Mathematical Model For Dispersion in The Direction of Flow in Porous Media

Caricato da

Bahman MatouriCopyright:

Formati disponibili

.

5p4iw93

A Mathematical Model for Dispersion in the Direction

Of Flow in Porous Media

H. A. DEANS

ABSTRACT

A three-pararneter

mathematical

model for onedimensional

flow in porous media is developed,

The objective

of the mode[ is to predict accurately

the longitudinal

dispersion

associated

wit h the

flow of either gases or liquids over a wide range of

Reynolds

number.

A qualitative

analysis

of the model parameters

Published

experimental

pulse-response

is given,

curves are compared w itb results Predicted by the

model. Several general types of problems are given

for which the model can be used.

INTRODUCTION

The problem of multicomponent single-phase flow

through porous media is encountered in the study

of petroleum reservoirs,

gae chromatographic

and

ion-exchange

columns, industrial

fixed-bed contacters and elsewhere. These particular exampIes

span the wide range of flow conditions possible;

Reynolds numbers of less than 10+ are not unusual

in oil-production problems, while values in excese

of 103 are common in large fixed-bed operations.

The study of flow-dependent

transport phenomena

i,s complic~ted both by the changes in the character

of the flow over rhis. range, and by the irregularity y

of the flow boundaries inherent to porous media.

Dispersion

is one of the important phenomena

known to depend fundamentally on flow conditions

as weH as on fluid and, medium properties. As, used

in this paper, the term dispersion

refers to the

observed mixing of fIuid, elements of different composition which occurs in flow systems. The actual

mechanism may be one or more of a number listed

below. Only dispersion in the direction of the mean

flow (referred to as axial or longi~udinal dispersion

(or mixing) is considered

here, although lateral

dispersion ar)ses as part of certain coupled mechi

anisms.

1

.

M~CHANISljS FOR LONGITUDINAL

DiSperSiOn

A number of distinct

rnechaniams sre.knowns,s~

7t8

Originaf manuscript received in Soaiet y of Petroleum En@neers

office

%pt. 5, 1962. Revised

manuscript received

Jam 28,

1963. Pqer

presented

at Joint SPR.AtChE

Sytrponhn

held

Aug, 26.29, .1962, in Denver, COIO.

heferencee

given at end of pspert

.

RICE U.

HOUSTON,

TEX.

to contribute to the phenomenon of longitudinal

dispersion.

The more important of these are as

follows.

1. Molecular diffusion in the flow direction,

2, Turbulent (eel 1) mixing.

3. Lateral

transport

processes

coupled

with

velocity

and/or

residence

time distributions,

including: (a) t Taylor diffusion caused by the

interaction of velocity profiles in individual voids

with lateral molecular diffusion; (b) separation and

remixing or interdiffusion of streams, having different

velocities around particles; and (c) the coupling of

gross velocity profiles, caused by viscous instability

..

or inhomogeneous porosity, with Iateral dispersion.

4. Finite mass-transfer

rate between a porous

matrix and the flowing phase, and finite diffusion

rate inside eIements of the porous matrix.

It is a well documented fact that these mechanisms,

whether acting individually

or in combinations,

produce essentially

similar integral effects. The

observed dispersion can be described approximately

by solutions of the diffusion equation with a propetly

chosen dispersion coefficient.

Necessary conditions for equivalence between dispersion and diffusion are discussed by Klinkenberg

and Sjenitzer. 7 AppiarentIy thr$se conditions are not

satisfied exactly in many real systems. %est fit

,

solutions of the diffusion equatibn often depart

appreciably from measured breakthrough curves for

the usual pulse- or step-forced experimental systems.

In particular, pulse response curves usuaHy show

some degree of asymmetry and [tailing

which

cannot be reproduced b y the one-parameter diffusion

model.

The

three-parameter

model proposed

herein

attempts to produce these effects in a realistic

manner. Asymmetry and ~ailing are predicted for

certsiru sets of parameter values, while for other

sets the new model agrees with the diffusion model.

VELOCITY Di?iPENDENCE OF DISPERSION

Molecular diffusion apparently controls at sufficiently low Reyuolds number in both gas and liquid

sYstems.2t3 At Re > 201 turbulent cell mixing is

dominant for gases flowing at Iow pressure; the

data of McHenry and Wilhelm8 show that the mixing

ceH is approximately

1 particle diameter long in

random sphere packs, On the other hand, the data

.

.. .

.

.

...-

tailing and asymmetry for pulsed systems. However,

cettqin basic advantages of the cell model should

be noted.

1. Serial solution of ordinary differential equations

is required, rather than solution of a boundary-value

partial differential equation.

2. Complications

such as additional

transport

phenomena, chemical reactions,

or flow ptofiles

can be added to the cell model without changing

its mathematical form or markedly increasing the

difficulty of obtaining solutions to the equations

for a single cell.

The addition of parameters to account for asymmerry, etc., can make use of these advantages

only if the basic form of the cell model is retained.

The procedure used here to add parameters is

based on the concept of capacitance 3 in a porous

medium, which implies the presence of a nonflowing

volume in the medium. If it is to have an effect on

the flowing stream, this stagnant volume must be

tonne cted to the flowing voIume by some sort of

resistance

to material transport. Hence, at least

two new parameters

are introduce~

a stagnant

voIume fraction, and a mass-transfer

factor, For

this simpIest modification of the celI model, the

equations for cell t Me

of other investigators 3*5 indicate that this limiting

situation is reached in liquids only at Re > 103 if

at all.

Fig, 1 is a replot of dispersion data from several

sources, reduced via the diffusion model, Of particular interest is the aImost linear dependence

of

~ . Re on velocity for liquids in the range 10-3 <

Re < K?. 315$10Effotw.2*4 to explain this behavior

in terms of the capillary diffusion effect of Taylorg

are otd y qua] itative, since # . Re is predicted to

vary with the square of velocity.

ALTERNATE

MATHEMATICAL MODELS

Several authors l-86 have pointed out the equivalence between the diffusion model and the series

of perfectly mixed cells in limiting cases. In the

latter model, the ith cell in the series is governed

by the simple material balance

-c, =

Cf-1

+ . . . . . . . . . . (1)

i = 1, 2, . . . . fi

where Ci is the concentration of a trace component

in the flowing stream and ~is dimensionless

time

based on the mean residence time in the mixing

ceJ1. If a mathematical pulse ~ (O+)& introduced

into the first cell at F = O+. the Nth cell will

produce a concentration

vs. time curve which is

closely approximated. by

-

:(2)

if ~ is chosen properly, and ~ is not too small.

E q. 2 is the anaIytical solution_of_the

d~fusion

eq~tion

for pulse forcing, with N, r and x being

the dittiensionless total Iength, of medium, time and

dispersion

modulus, respectively

(based on the

cell length). This equation is commonly. used to

obtain dispersion

coefficients

from experimental

pulse - response

curves.

The simple cell model also centsins one parameter,

which is the lengtlf of the mixing cell. Like the

diffusion model, it does not predict the observed

. -?WS

7/,-4

Ioa

/,

i.

LAO, C*,-U2,

+- RW.2 , H.-A,

If Z becomes very large, or / approaches zero,

Eqs, 3 and 4 will reduce to Eq. 1, whose limiting

behavior

is known. Gases at low pressure

are

probabIy characterized

by large ~ as will be discussed Iater.

The limit of large N for fixed path length L is

also interesting. This corresponds to a small value

of 1, the length of the mixing cell; in this case

Eqs. 3 and 4 may be approximated b y

SAND

-==(w)~+/~

ax

5A!I0

REF. 6, OASES, SPHtRtS

--

ETC.

REF.S, LIQUIDS,SPKRW$,

R*

FIG.

19 $

I

lot

ac*

f =a

dr

I

,.3

(C- C*),

OSXAN

.

.. .

r = 1, 2, .. . N

LIMITING BEHAVIOR OF THE

THREE-PARAMETER MODEL

------W.S,UQIJW,

iwrntt

---- REF.10, Uaulos. Wm

,/

/

sOCIETY

......

. (5)

. . . . . . . . ..(6).

.

OF

.-

.,

(4)

. . . . ..#

~..

,,6 p-

18

. . (3)

where f is the fraction of cell volume which is

nonflowing, Cf* is the tracer concentration in this

fraction, ~is a dimensiortlesa atass-transfer modulus

and F is again dimensionless

time based on the

mean residence time in the entire cell .volunie.

./

*.Re,

dCj *

-#&+/T

dCi *

f.~

= E(Cj-C~)

fry/

,/

+.=,:;

102

-cf=(I

(fi-z12

c(K3=&eq

la

c~1

PETROI.

. . .

EIJ.M ENGINEERS

JOIiRNAL

.-

----

. ...!.--

._

,,

..

..

where the longitudinal variable x, the total

a and r are now dimensionless

based

characteristic

length d.

The solution of Eqs. 5 and 6 for the pulse

ment conditions C(X,O) = C*(z, O) = (), O <

C(O, r) = 8(0+) is

N,

C(N, r) = e-d

a(r-N(l

. . . . . . . .

-/))

......

11(22)

=

z

includes

experix < N;

The velocity and mass transport in. an average

void in a porous medium are complicated functions

of position as well as Re and fluid properties. The

division of celI volume into flowing and stagnant

segments separated by a resistance is obviously an

extreme limit which can be justified only on the

grounds of simplicity. If the model is accepted, the

following assumptions

can be justified by dimensional cons ideations.

1. The velocity distribution,

hence R and ~/,

should depend on Re m-tly.

2. The resistance

factor, in which the mass

transport

is lumped, may depend on Re and the

Schmidc number. Z should decrease as Sc increases,

so that the capacitance effect will be more significant

for systems with large values of SC,

For gases (Sc on the order of unity), the capacitance

effect is apparently

insignificant,

The

limiting behavior at high Re c= be realized in the

cell model (Eq. 1) by letting N equal the ratio of

flow-path length to mixing-cell length. The latter

has been obkerveds to be approximately 1 partic~e

diameter in random sphere packs (i.e., Z = d, N = N,

(7)

unit impuhe function

= ]1 (iz) is the firstfirst kind of imaginary

z,

e2z

7=(8)

Under conditions such that I T-N I <<~N and ctN >> I,

tk square roots in Eq. 7 can be expsnded in the

form

.,

.,...

. . . . . . . ...

the latter

authors fit using Eq. 2.

ANALYSIS OF MODEL PARAMETERS

where ~(r - N( 1 -f) ) ia the

located at r = Af(l -/). Ii(z)

order Bessel function of the

argument. For large argument

length

on the

,,

(9)

etc. ),

Although the diffusion model is physically the

correct one at low R e, the cell model can be used

if ~ is allowed to vary with fluid properties. Agreement is obtain~d between the two models for long

flow paths if N = ~ PeL.

For liquids (Schmidr number on the order of 103),

The use of Eqs. 8 and g in E.q. 7 leads to

JL4!ll

C(N)

e 4(2)

0 (0)

This is the solution predicted by the diffusion

model for # = ~2/a, so that the three-parameter

model reduces to a one-parameter

limit in this

I

case,

Eq. 10 also predicts that the dispersing pulse

will move through the model with a dimensionless

ve]ocity of unity, rather than 1/(1-/), which is in

with experimental

observation.

agreement

This

paradoxical

behavior of the nonflowing volume is

encountered in a number of simiIar situations. ~

NUMERICAL

SOLUTION FOR SMALL

..

,

i

!

,

1

I

Eqs, 3 and 4 have been integrated numerically

on the Rice U. computer for a number of combinations

of the parameters ~ tt and h? Figs. 2 and 3 indicate

the variety of b~eakthrough-curve shapes avail abIe.

The curve for N = cu in Fig; 2 was computed from

Eq. 7.

Figs. 4 and 5 give best fits of experimen~al

curves publ i shed by Canberry and Brecton. 3 Fig. 4

.

MARCH,

..

.

196S

...

.;

1 -----

~~,=

r

FIG. 2

-.

RWERCNCE

3

RUN 13, .aml.

._

R,_

6La cm.

91.8 cm.

---+

lHIS WORti ,

f.,

. -. . . ..

-\

I

\

t

,,

.

-- . ~..

<i

-

k

R..oel

tc,,

N-294

R-106!

..

100

LL-

----CL,

Cfi

snhsr,,

-.

1)$-(

-~

- -4--

1.

/

t.

FIG,

FIG.

capacitance

is apparently the dominarit effect over

a wide range of I/e, The effective dispersion coefficient increases linearly with Re, beginning at

the lower limit of the molekular diffusivity at Re

on the order of 10-3, Z% seen in Fig. 1, # for liquids

remains significantly higher than the limiting value

for gases even at Re = 5 x 102.

Fig. 4 shows the extent to which experimental

cwves may depart from the cliffus ion model, ,In

this case, the best fit using the three-parameter

cell model gives (~2fla) = 4,3, which is more than

twice the value of @quoted by the authors? Attempts

to fit the curves in Fig. 5 with Eq. 2 leads to

different values of ~ for the two fIow-path lengths.

DETERMINATION OF PARAMETERS

USE OF THE MODEL

AND

T&e necessary data for ,a general determination

of N, ~ and E are not presently

available. Data on

gas systems can give little information, since the

capacit ante effect is small. Much of the liquid

data was taken under conditions such that the onedimensional

flow assumptions

are invalid;

the,

information obtained is characteristic

of the individual systems rather than porous media in general,

For a specific system, the model may be useful

even if the fIow is not one-dimensional.

The experimental curve in Fig. 4 is for a system with tube-toparticle diameter ratio of about 10. Lateral mixing,

coupled with gross velocity profile, probably contributed significantly

to the measured dispersion,

In many flow problems, dispersion may be safely

Some instances

where it must be

disregarded.

included

in reasonably

accurate manner are in:

calculations;

(z) certain

(I) miscible-displacement

chemical-reactor

design problems; end (3) chromatographic techniques

for measuring other trenspok

phenomena.

Most of the specific probIems in these categories

must be attacked by numerical methods in any case.

The three-parameter cell model can be used in place

of the basic. continuity equations in these calculations,

The

since it is quite amenabIe

model parameters

to generalization.

must be predetermined

for

the system of interest if dispersion

for accurately.

is to be accounted

NOMENCLATURE

Re = Reynolds

number, i7d/v where U = mean

interstitial velocity, d = a length parameter

character sti c of the porous matrix, and

v = kinematic viscosity of the fIowing fluid

Sc = Schmidt number, v/Din where Dm = a cheracteriatic molecuhr diffusivity

Peclet number, ZL/Dm where L =total length

of flow path

where

dispersion moduli, DE/Cd, or DE/ii,

DE = effective

long itudin al dispersion

coefficient, and 2 = length of a mixing cell

in the cell model

dimensionless

time, ti7d or tZ[

dimensionless

flow path Iength, L/c! or L/l

dimensionless mass-t&nsfer parameter, based

ondorl

.

fraction

of cell volume which ii nonflowing

f

REFERENCES

L

Aris, R.

and Amundsonz

N. R.: AfChE Jorm. (1957)

Vol. 3, 280,

R. J.; Rayne, J. R, end Terry, W, M., Jr.:

2. Blackwell,

~~Factor~ ~fluenc~g

the Efficiency

of Miscible

Displacement),

L

Trans.,

AIME (1959) Vol. 216,

3. Carberry,

J. J. and Bretton,

R, H.: AICbE Jour.

(195S) Vol. 4, 367.

4.

Coltina,

R. E;

Flow of Fluids Though

Porous

Materials, Reinhold Publishing

Cozp., N. Y. (1961).

R. A. tid White, R., R.: A1CM3 jour. (1958)

vol. 4, 16L

H. A. end Lapidus,

L.: AICbE Jorw, (1960),

6, Deana,

VOL 6, 663.

5. Ebach,

7. Klinkenberg,

A. and Sjenitzer,

(1956) vol.

5, 25S.

8, McHmry,

K. W. and Wilhelm,

(1957) vol. 3, 33.

F.:

R. H.: AIChE

Taylor, G, L: Proc., Roy. Sec.

151A, 42 L

D. U.: AICZIE

10. von Rosenberg,

55.

9.

Eng, Sci.

Cbem,

London

~osr.

Jour.

(1953)

(1956)

VOL

VOL

2,

***

2,

. .

sOCti

,,

TY

OF

..

P8TROLEUM

,,

,,

..

..-.

ENGINEERS

.

.* .-.

JO UR-NA:I.

.$

.-

Potrebbero piacerti anche

- J. Wijmans - R. Baker - The Solution Diffusion Model - A ReviewDocumento21 pagineJ. Wijmans - R. Baker - The Solution Diffusion Model - A ReviewNicolasNessuna valutazione finora

- Analysis of Mass Transfer During Ultrafiltration of PEG-6000 in A Continuous Stirred Cell: Effect of Back TransportDocumento8 pagineAnalysis of Mass Transfer During Ultrafiltration of PEG-6000 in A Continuous Stirred Cell: Effect of Back TransportcharruNessuna valutazione finora

- A Discrete Model For The Apparent Viscosity of Polydisperse Suspensions Including Maximum Packing FractionDocumento14 pagineA Discrete Model For The Apparent Viscosity of Polydisperse Suspensions Including Maximum Packing FractionLuke ParryNessuna valutazione finora

- Bourdet 1985Documento12 pagineBourdet 1985husseinhshNessuna valutazione finora

- Multi Scale Mixed Finite Element Modeling of Coupled Wellbore Near-Well FlowDocumento9 pagineMulti Scale Mixed Finite Element Modeling of Coupled Wellbore Near-Well Flowpetar_damyanovNessuna valutazione finora

- France (1974)Documento18 pagineFrance (1974)julianaNessuna valutazione finora

- Simulation Study of Mass Transfer Coefficient in Slurry Bubble Column Reactor Using Neural NetworkDocumento11 pagineSimulation Study of Mass Transfer Coefficient in Slurry Bubble Column Reactor Using Neural NetworkEmad ElsaidNessuna valutazione finora

- Suspension of Solid ParticalesDocumento16 pagineSuspension of Solid ParticalesAnSasoriNessuna valutazione finora

- A Case of Negative Apparent Activation Energy Due To Pore Diffusion EffectsDocumento3 pagineA Case of Negative Apparent Activation Energy Due To Pore Diffusion EffectsBamrung SungnoenNessuna valutazione finora

- Multi-Physics Analysis of Microfluidic Devices With Hydrodynamic Focusing and DielectrophoresisDocumento15 pagineMulti-Physics Analysis of Microfluidic Devices With Hydrodynamic Focusing and DielectrophoresisBogdan1988Nessuna valutazione finora

- SPE 145808 Three-Phase Unsteady-State Relative Permeability Measurements in Consolidated Cores Using Three Immisicible LiquidsDocumento12 pagineSPE 145808 Three-Phase Unsteady-State Relative Permeability Measurements in Consolidated Cores Using Three Immisicible LiquidsCristian TorresNessuna valutazione finora

- DePietro 2015Documento8 pagineDePietro 2015pedroNessuna valutazione finora

- L3 Competency EquationsDocumento12 pagineL3 Competency Equationskrymxen100% (1)

- Membrane Gas Separation - Davis and RandalDocumento7 pagineMembrane Gas Separation - Davis and RandalMuzzy VoraNessuna valutazione finora

- Chapter 00 - OverviewDocumento7 pagineChapter 00 - OverviewLeonardo Octavio Olarte SánchezNessuna valutazione finora

- Using Percolation Theory To Predict Oil !eldperformanceDocumento6 pagineUsing Percolation Theory To Predict Oil !eldperformanceXuan BinhNessuna valutazione finora

- Effect of Channel Dimensions On Micro PEM Fuel Cell Performance Using 3D ModelingDocumento6 pagineEffect of Channel Dimensions On Micro PEM Fuel Cell Performance Using 3D ModelingSergi C. CortadaNessuna valutazione finora

- International Journal of C 2009 Institute For Scientific Numerical Analysis and Modeling Computing and InformationDocumento14 pagineInternational Journal of C 2009 Institute For Scientific Numerical Analysis and Modeling Computing and Informationa_minisoft2005Nessuna valutazione finora

- 0022 460x (77) 90521 1 PDFDocumento33 pagine0022 460x (77) 90521 1 PDFJabbar AljanabyNessuna valutazione finora

- 1991 SPE21893 Hu Whitson Yuanchang EORDocumento35 pagine1991 SPE21893 Hu Whitson Yuanchang EORPorfirio AguileraNessuna valutazione finora

- Jce-1983-393 - Modernization of The Van Deemter EquationDocumento6 pagineJce-1983-393 - Modernization of The Van Deemter EquationSolomon EricksonNessuna valutazione finora

- Lattice Boltzmann MethodDocumento11 pagineLattice Boltzmann MethodNishant KumarNessuna valutazione finora

- Fundamental Principles of Ultrafiltration PDFDocumento15 pagineFundamental Principles of Ultrafiltration PDFalmutaz9879Nessuna valutazione finora

- Theory of Microemulsions: Comparison With Experimental Behavior+Documento5 pagineTheory of Microemulsions: Comparison With Experimental Behavior+jagruthimsNessuna valutazione finora

- PhysRevE 54 406Documento5 paginePhysRevE 54 406ASHES BANERJEENessuna valutazione finora

- C8 CusslerDocumento33 pagineC8 Cusslerraj_zzz80Nessuna valutazione finora

- A Review of Diffusion and Dispersion in Porous MediaDocumento15 pagineA Review of Diffusion and Dispersion in Porous MediaBahman MatouriNessuna valutazione finora

- Daly Of: University California, Los Alamos Scientific Laboratory, Los Alamos, New MexicoDocumento32 pagineDaly Of: University California, Los Alamos Scientific Laboratory, Los Alamos, New MexicobarnamalaNessuna valutazione finora

- Multi-Particle Collision Dynamics: Flow Around A Circular and A Square CylinderDocumento9 pagineMulti-Particle Collision Dynamics: Flow Around A Circular and A Square CylinderEwerton AvlisNessuna valutazione finora

- A Numerical Study On Concentration Polarization and System Zhou2006Documento9 pagineA Numerical Study On Concentration Polarization and System Zhou2006inara2160Nessuna valutazione finora

- Numerical Simulation of Naturally Fractured Reservoirs: F. Sonier, Souillard, BlaskovichDocumento9 pagineNumerical Simulation of Naturally Fractured Reservoirs: F. Sonier, Souillard, BlaskovichHamidreza AnjidaniNessuna valutazione finora

- SPE 114591 Rate Transient Analysis in Naturally Fractured Shale Gas ReservoirsDocumento17 pagineSPE 114591 Rate Transient Analysis in Naturally Fractured Shale Gas ReservoirsIbrahim ElsawyNessuna valutazione finora

- Reservoir simulation on geological gridsDocumento8 pagineReservoir simulation on geological gridsAbdulrahman HelalNessuna valutazione finora

- The Optimisation of Flotation Networks: International Journal of Mineral ProcessingDocumento21 pagineThe Optimisation of Flotation Networks: International Journal of Mineral ProcessingAli HassanzadehNessuna valutazione finora

- A Non-Standard Statistical Approach To The Silo Discharge: T E P JDocumento8 pagineA Non-Standard Statistical Approach To The Silo Discharge: T E P JA94leo14hsetmaNessuna valutazione finora

- Spe 116575 Ms P Tim WhiitleDocumento9 pagineSpe 116575 Ms P Tim WhiitleglsancorNessuna valutazione finora

- Double Porosity Model With Transient Interporosity Flow For The Response of Tracers in Naturally Fractured Reservoirs, Considering Constant Mass Flux InjectionDocumento13 pagineDouble Porosity Model With Transient Interporosity Flow For The Response of Tracers in Naturally Fractured Reservoirs, Considering Constant Mass Flux InjectionJuanNessuna valutazione finora

- Monte Carlo Moves: For Solids Energy DeterminationDocumento8 pagineMonte Carlo Moves: For Solids Energy DeterminationIndra Prakash JhaNessuna valutazione finora

- Capecelatro Desjardins 2013 An Euler-Lagrange Strategy For Simulating Particle-Laden Flows PDFDocumento31 pagineCapecelatro Desjardins 2013 An Euler-Lagrange Strategy For Simulating Particle-Laden Flows PDFAbgail PinheiroNessuna valutazione finora

- Chapter 2Documento72 pagineChapter 2Seun Sam AdetolaNessuna valutazione finora

- SPE, Phillips Petdeum Co. SPE. Phillips Pctrdeum Co. SPE, Phillips Petmieum CoDocumento13 pagineSPE, Phillips Petdeum Co. SPE. Phillips Pctrdeum Co. SPE, Phillips Petmieum CoQi ZhangNessuna valutazione finora

- Usms 019215 Supplement To SPE 12777, Use of Pressure Derivative in Well-Test Interpretation D. Bourdet, Kappa EngineeringDocumento17 pagineUsms 019215 Supplement To SPE 12777, Use of Pressure Derivative in Well-Test Interpretation D. Bourdet, Kappa EngineeringCrisca FumeNessuna valutazione finora

- M. de Boissieu - Stability of Quasicrystals: Energy, Entropy and Phason ModesDocumento11 pagineM. de Boissieu - Stability of Quasicrystals: Energy, Entropy and Phason ModesPomac232Nessuna valutazione finora

- Ideaz - Cellular Automata For Flow Simulation - Transport PhenomenaDocumento4 pagineIdeaz - Cellular Automata For Flow Simulation - Transport PhenomenamohitladduNessuna valutazione finora

- Assessment of A New Fluent Model For Particle Dispersion in Turbulent FlowsDocumento18 pagineAssessment of A New Fluent Model For Particle Dispersion in Turbulent FlowsgarridolopezNessuna valutazione finora

- Flow in 3D Packed Bed Reactors COMSOLDocumento10 pagineFlow in 3D Packed Bed Reactors COMSOLBenedictEkowPrahNessuna valutazione finora

- Kinetic Modeling of Liquid-Phase Adsorption of Reactive Dyes On Activated CarbonDocumento10 pagineKinetic Modeling of Liquid-Phase Adsorption of Reactive Dyes On Activated CarbonTobias De SomerNessuna valutazione finora

- Modeling Aspects of Wellbore Stability IDocumento8 pagineModeling Aspects of Wellbore Stability IAhmed GharbiNessuna valutazione finora

- The Front Tracking AlgorithmDocumento27 pagineThe Front Tracking AlgorithmZohre AlinejadNessuna valutazione finora

- Column Flotation Process 4172Documento14 pagineColumn Flotation Process 4172Gabriel BartoloneNessuna valutazione finora

- Phase Equilibria in The Polydisperse Zwanzig Model of Hard RodsDocumento14 paginePhase Equilibria in The Polydisperse Zwanzig Model of Hard RodsGilberto RuizNessuna valutazione finora

- P. Angelino Et Al - Role of Plasma Elongation On Turbulent Transport in Magnetically Confined PlasmasDocumento4 pagineP. Angelino Et Al - Role of Plasma Elongation On Turbulent Transport in Magnetically Confined PlasmasMsdsxNessuna valutazione finora

- Shape Relaxation of An Elongated Viscous Drop: K. Moran, A. Yeung, and J. MasliyahDocumento11 pagineShape Relaxation of An Elongated Viscous Drop: K. Moran, A. Yeung, and J. MasliyahClaudio BiaginiNessuna valutazione finora

- Journal of Chromatography A: David Pfister, Fabian Steinebach, Massimo MorbidelliDocumento9 pagineJournal of Chromatography A: David Pfister, Fabian Steinebach, Massimo MorbidelliJames EdwardsNessuna valutazione finora

- A New Concept For The Correlation of Relative Permeability Data and Capillary Pressure For Microfissured RocksDocumento12 pagineA New Concept For The Correlation of Relative Permeability Data and Capillary Pressure For Microfissured RocksRosa K Chang HNessuna valutazione finora

- Flows and Chemical Reactions in Heterogeneous MixturesDa EverandFlows and Chemical Reactions in Heterogeneous MixturesNessuna valutazione finora

- Stochastic Dynamics. Modeling Solute Transport in Porous MediaDa EverandStochastic Dynamics. Modeling Solute Transport in Porous MediaNessuna valutazione finora

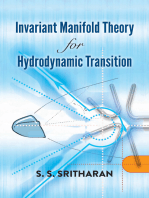

- Invariant Manifold Theory for Hydrodynamic TransitionDa EverandInvariant Manifold Theory for Hydrodynamic TransitionNessuna valutazione finora

- Hydrothermal Analysis in Engineering Using Control Volume Finite Element MethodDa EverandHydrothermal Analysis in Engineering Using Control Volume Finite Element MethodNessuna valutazione finora

- 00000800Documento13 pagine00000800Bahman MatouriNessuna valutazione finora

- Proper Selection OF Drill Bits AND Their USE: Sent To The Society ofDocumento12 pagineProper Selection OF Drill Bits AND Their USE: Sent To The Society ofBahman MatouriNessuna valutazione finora

- Underground Combustion 01L-Rec0Ver% Experiment in The Venango First Sand, Warren County, PaDocumento47 pagineUnderground Combustion 01L-Rec0Ver% Experiment in The Venango First Sand, Warren County, PaBahman MatouriNessuna valutazione finora

- 00000681Documento5 pagine00000681Bahman MatouriNessuna valutazione finora

- 00000787Documento24 pagine00000787Bahman MatouriNessuna valutazione finora

- 00000613Documento13 pagine00000613Bahman MatouriNessuna valutazione finora

- 00000774Documento31 pagine00000774Bahman MatouriNessuna valutazione finora

- Permeabilities and Po-ItiesDocumento12 paginePermeabilities and Po-ItiesBahman MatouriNessuna valutazione finora

- 00000768Documento50 pagine00000768Bahman MatouriNessuna valutazione finora

- 00000768Documento50 pagine00000768Bahman MatouriNessuna valutazione finora

- 00000667Documento7 pagine00000667Bahman MatouriNessuna valutazione finora

- 00000705Documento9 pagine00000705Bahman MatouriNessuna valutazione finora

- 00000569Documento12 pagine00000569Bahman MatouriNessuna valutazione finora

- Su. Ts In: M R12s VDocumento20 pagineSu. Ts In: M R12s VBahman MatouriNessuna valutazione finora

- Su. Ts In: M R12s VDocumento20 pagineSu. Ts In: M R12s VBahman MatouriNessuna valutazione finora

- A. and M. DivisionDocumento17 pagineA. and M. DivisionBahman MatouriNessuna valutazione finora

- 00000569Documento12 pagine00000569Bahman MatouriNessuna valutazione finora

- 00000613Documento13 pagine00000613Bahman MatouriNessuna valutazione finora

- Reservoirs With Gas and Walter: SimpleDocumento6 pagineReservoirs With Gas and Walter: SimpleBahman MatouriNessuna valutazione finora

- Pressure Build-Up Analysis, Variable-Rate Case: S+?s - RX' """Documento5 paginePressure Build-Up Analysis, Variable-Rate Case: S+?s - RX' """Bahman MatouriNessuna valutazione finora

- 00000542Documento25 pagine00000542Bahman MatouriNessuna valutazione finora

- !pedmical I'?Ote: Some LmlmowDocumento19 pagine!pedmical I'?Ote: Some LmlmowBahman MatouriNessuna valutazione finora

- Evaluation of Scale-Up Laws For Two-Phase Flow (Through Porous MediaDocumento13 pagineEvaluation of Scale-Up Laws For Two-Phase Flow (Through Porous MediaBahman MatouriNessuna valutazione finora

- 00000545Documento8 pagine00000545Bahman MatouriNessuna valutazione finora

- A Review of Diffusion and Dispersion in Porous MediaDocumento15 pagineA Review of Diffusion and Dispersion in Porous MediaBahman MatouriNessuna valutazione finora

- PDFDocumento6 paginePDFBahman MatouriNessuna valutazione finora

- 00000532Documento52 pagine00000532Bahman MatouriNessuna valutazione finora

- Experimental Study of Crater Formation in Plastically Deforming Synthetic RocksDocumento6 pagineExperimental Study of Crater Formation in Plastically Deforming Synthetic RocksBahman MatouriNessuna valutazione finora

- Spes - : Some Experiments On The Flow of Miscible Fluids of Unequal Density Through Porous MediaDocumento4 pagineSpes - : Some Experiments On The Flow of Miscible Fluids of Unequal Density Through Porous MediaBahman MatouriNessuna valutazione finora

- Heat Equation 1 DDocumento3 pagineHeat Equation 1 Djohndo3Nessuna valutazione finora

- BOSL Controllers Standard-1Documento82 pagineBOSL Controllers Standard-1Anonymous bnhNfqZXaNessuna valutazione finora

- SuperOhm 3754 (3748-11) - Technical Data Sheet - ECC - Rev 2 - 2016-09Documento2 pagineSuperOhm 3754 (3748-11) - Technical Data Sheet - ECC - Rev 2 - 2016-09igor brocaNessuna valutazione finora

- Reaction kinetics and reactor design conceptsDocumento43 pagineReaction kinetics and reactor design conceptsnoelNessuna valutazione finora

- EBARA Company ProfileDocumento11 pagineEBARA Company ProfileMohamed IbrahimNessuna valutazione finora

- Steam Turbines Basic Information - Power Generation in PakistanDocumento12 pagineSteam Turbines Basic Information - Power Generation in Pakistannomi607Nessuna valutazione finora

- IAEA-SM-346/113 Regional Safeguards Arrangements: The Argentina-Brazil ExperienceDocumento13 pagineIAEA-SM-346/113 Regional Safeguards Arrangements: The Argentina-Brazil ExperiencePeter AngeloNessuna valutazione finora

- World Jet Fuel Specifications 2005Documento51 pagineWorld Jet Fuel Specifications 2005Richo Crb100% (2)

- Lightweight Telescopic MastsDocumento39 pagineLightweight Telescopic MastspnsanatNessuna valutazione finora

- Wipro CSR BBDocumento35 pagineWipro CSR BBYogesh GomsaleNessuna valutazione finora

- Robert T. Knowlton JR.: Local Address: 301 S. Pugh ST, Apt. 409, State College, Pa 16801 Permanent Address: ObjectiveDocumento1 paginaRobert T. Knowlton JR.: Local Address: 301 S. Pugh ST, Apt. 409, State College, Pa 16801 Permanent Address: Objectivertk5025Nessuna valutazione finora

- Calculate Specific Heat of MetalDocumento2 pagineCalculate Specific Heat of MetalIsabelNessuna valutazione finora

- DXXXX-QSOP - Well Control Procedure For Non - Routine OperationsDocumento6 pagineDXXXX-QSOP - Well Control Procedure For Non - Routine Operationsharry mulyafitNessuna valutazione finora

- Gates em Ingles 2010Documento76 pagineGates em Ingles 2010felipeintegraNessuna valutazione finora

- Documents - MX - Absorption Exercises Treybal PDFDocumento6 pagineDocuments - MX - Absorption Exercises Treybal PDFJvson Vens Sance100% (1)

- Brine ZLD Process-GEDocumento7 pagineBrine ZLD Process-GEvijayendra100% (1)

- Thermiculite BrochureDocumento8 pagineThermiculite BrochureXuan TruongNessuna valutazione finora

- Accurate Power Demand Forecasting MethodsDocumento15 pagineAccurate Power Demand Forecasting MethodsRathinaKumarNessuna valutazione finora

- OCDE Toolkit de ConstrucciónDocumento54 pagineOCDE Toolkit de ConstrucciónALBERTO GUAJARDO MENESESNessuna valutazione finora

- Air Compressor Presentation 1.1Documento20 pagineAir Compressor Presentation 1.1ROBERTO FELIX RUEDASNessuna valutazione finora

- Calculating monthly electricity consumptionDocumento2 pagineCalculating monthly electricity consumptionStella KazanciNessuna valutazione finora

- A380-LEVEL III - ATA 26 Fire - Smoke DetectionDocumento42 pagineA380-LEVEL III - ATA 26 Fire - Smoke DetectionAbolfazl Mazloomi100% (2)

- HYpact Compact HybridDocumento24 pagineHYpact Compact HybridMateo Alvez100% (1)

- Dynamis MaxxDocumento14 pagineDynamis MaxxJas SumNessuna valutazione finora

- High Speed AerodynamicsDocumento62 pagineHigh Speed AerodynamicsDavid Bond100% (2)

- Monbat 12V200AhDocumento1 paginaMonbat 12V200AhMaria MuresanNessuna valutazione finora

- Philips XOP-15 - DatasheetDocumento3 paginePhilips XOP-15 - DatasheetGiovani AkNessuna valutazione finora

- Climate Change The Facts (Annotated)Documento3 pagineClimate Change The Facts (Annotated)api-276929919Nessuna valutazione finora

- Accuspin 1 120V 230VDocumento60 pagineAccuspin 1 120V 230VAndrew HolmesNessuna valutazione finora

- Elec Engg Exit Exam 2018 (Part 9)Documento10 pagineElec Engg Exit Exam 2018 (Part 9)Master JaguarNessuna valutazione finora