Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Thermistor Working Principle Instrumentation Tools

Caricato da

Abarajithan RajendranCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Thermistor Working Principle Instrumentation Tools

Caricato da

Abarajithan RajendranCopyright:

Formati disponibili

Thermistor Working Principle Instrumentation Tools

1 of 8

http://instrumentationtools.com/thermistor-working-principle/

INSTRUMENTATION TOOLS

Thermistor Working Principle

Thermistors

Thermistors are temperature sensitive semiconductors that exhibit a large change

in resistance over a relatively small range of temperature. There are two main

types of thermistors, positive temperature coefficient (PTC) and negative

temperature coefficient (NTC). NTC thermistors exhibit the characteristic of

resistance falling with increasing temperature. These are most commonly used for

temperature measurement.

A thermistor is similar to an RTD, but a semiconductor material is used instead of

a metal. A thermistor is a solid state device and has larger sensitivity than does an

RTD. Unlike RTDs, the temperature-resistance characteristic of a thermistor is

non-linear, and cannot be characterized by a single coefficient. Furthermore,

unlike RTDs, the resistance of a thermistor decreases

temperature.

with

increasing

6/4/2016 4:29 PM

Thermistor Working Principle Instrumentation Tools

2 of 8

http://instrumentationtools.com/thermistor-working-principle/

Thermistors cannot be used to measure high temperatures compared to RTDs. In

fact, the maximum temperature of operation is sometimes only 100 or 200C.

Manufacturers commonly provide resistance-temperature data in curves, tables or

polynomial expressions. Linearizing the resistance-temperature correlation may be

accomplished with analog circuitry, or by the application of mathematics using

digital computation. A typical thermistor circuit is shown below.

From the circuit diagram, it is clear that this is a simple voltage divider. Rs is some

fixed (supply) resistor. Rs and the supply voltage, Vs, can be adjusted to obtain

the desired range of output voltage Vo for a given range of temperature.

Advantages: Large resistance change with temperature, rapid response time,

good stability, High resistance eliminates difficulties caused by lead resistance,

Low cost and interchangeable

Disadvantages: Non-linear, limited operating temperature range, may be

subjected to inaccuracy due to overheating, current source required.

Resistance vs. Temperature Curve

6/4/2016 4:29 PM

Thermistor Working Principle Instrumentation Tools

3 of 8

http://instrumentationtools.com/thermistor-working-principle/

Unlike RTDs and thermocouples, thermistors do not have standards associated

with their resistance vs. temperature characteristics or curves. Consequently,

there are many different ones to choose from.

Each thermistor material provides a different resistance vs. temperature curve.

Some materials provide better stability while others have higher resistances so

they can be fabricated into larger or smaller thermistors.

Many manufactures list a Beta (B) constant between 2 temperatures (Example: [3

0/50 = 3890). This, along with the resistance at 25C (77F) can be used to

identity a specific thermistor curve.

Thermistor is a resistance thermometer, similar to a Resistance Temperature

Detector (RTD) and is used fortemperature measurement. It consists of a

non-metallic resistor that is used as the temperature sensing element.

Thermistor is the short form for Thermal Resistor. The device consists of a bulk

semiconductor device that acts as a resistor with a high and negative temperature

co-efficient of resistance, sometimes as high as -6% per degree Celsius rise in

temperature. Due to this property of high sensitivity (that is, huge resistance

change for a small change in temperature), the thermistor is mainly applicable in

precision temperature measurement, temperature control, and temperature

compensation, especially in a lower temperature range of -100 degree Celsius to

+300 degree Celsius.

Difference between Thermistor and Resistance Temperature Detectors (RTD)

Both devices work on the same principle that a constant current flowing through

the resistor, and its changing resistance due to change in temperature, is

measured as a voltage drop across it. The main difference is that the electrical

resistance of the resistor used in a thermistor varies in a non-linear manner with

respect to temperature. The sensing element used in the thermistor is made up of

either a ceramic or polymer, while RTD uses pure metals as its sensing element.

Another major difference is in its operating range. Due to its high sensitivity,

thermistors are used in narrow span measurements and low temperature ranges

6/4/2016 4:29 PM

Thermistor Working Principle Instrumentation Tools

4 of 8

http://instrumentationtools.com/thermistor-working-principle/

from -20 degree Celsius to +120 degree Celsius. But RTDs are used over wide

and larger temperature ranges.

Construction

The device is manufactured from materials like sintered mixtures of oxides of

metals such as manganese, nickel, cobalt, and iron. Their resistances range from

0.4 ohms to 75 mega-ohms and they may be fabricated in wide variety of shapes

and sizes. Smaller thermistors are in the form of beads of diameter from 0.15

millimeters to 1.5 millimeters. Such a bead may be sealed in the tip of solid glass

rod to form probe which is easier to mount than bead. Alternatively thermistor may

be in the form of disks and washers made by pressing thermistor material under

high pressure into flat cylindrical shapes with diameter from 3 millimeters to 25

millimeters. Washers may be stacked and placed in series or parallel to increase

power disciplining capability.

Characteristic Curve

Resistance Versus Temperature Characteristics of Thermistor

The resistance versus temperature curve is one of the main characteristics that is

used in measurement, control and compensation applications using a thermistor.

The characteristics graph is shown below. From the characteristics graph of a

typical thermistor, we can see that the resistivity changes from 107 to 1 ohm-cm

as the temperature changes from -100 degree Celsius to +400 degree Celsius.

This high negative temperature coefficient of resistance makes thermistor an ideal

temperature transducer.

6/4/2016 4:29 PM

Thermistor Working Principle Instrumentation Tools

5 of 8

http://instrumentationtools.com/thermistor-working-principle/

Thermistor as Temperature Sensor

A thermistor used for the measurement of temperature is shown in the figure

below. The thermistor is designed to have a resistance of 2 kilo-ohms at 25 degree

Celsius and temperature coefficient of -4% per degree Celsius will bring a

reduction of 80 ohms per degree Celsius change in temperature.

The device is connected in series to a battery and a micrometer. A change in

temperature causes a change in the resistance if the thermistor and the

corresponding micrometer current reading is noted. Usually, the meter is

calibrated in terms of temperature with 0.1 degree Celsius resolution. As shown in

the figure, a bridge circuit is also used so as to increase the thermistors sensitivity.

Thermistor Types

For studying about the different types of thermistors, it is important to understand

the formula which shows the linear relationship between resistance and

temperature.

As a 1st order approximation, the change in resistance is equal to the 1st order

temperature co-efficient of resistance times the change in temperature.

dR = k.dT

where, dR Change in Resistance

k 1st Order Temperature Coefficient of Resistance

dT Change in Temperature

If the value of temperature coefficient of resistance (k) is positive, an increase in

temperature increases the resistance. Such a device can be called a Posistor or

Positive Temperature Coefficient Thermistor (PTC). If the value of k is negative, an

increase in temperature will decrease the resistance value. Such a device is called

a Negative Temperature Coefficient Thermistor (NTC).

Posistor/Positive Temperature Coefficient (PTC) Thermistors

PTC Thermistors that are used in industries are broadly classified into two. The

first one is called by the name Silistors, as to Sensitive Silicon Resistors. Silistors

are known to have a positive temperature coefficient of 08% per degree Celsius. If

the temperature goes higher than 175 degree Celsius, the device jumps to a

negative temperature coefficient region. The other classification of PTC

Thermistors is called Switching Type PTC Thermistors. It is made from ceramic

type materials and are known to have a very high resistance from a small change

in temperature. Dopants are also added to the material so that they show a

6/4/2016 4:29 PM

Thermistor Working Principle Instrumentation Tools

6 of 8

http://instrumentationtools.com/thermistor-working-principle/

semi-conductive behavior as well. The device is known to have a transition or

Curie temperature. Until the device reaches that particular point, it shows a

negative temperature co-efficient pattern in its resistance-temperature

characteristics. After this point, it starts to show an increasing positive temperature

coefficient of resistance. At this point, the resistance also begins to develop. The

main difference in the temperature-resistance curve between a silistor and

switching PTC Thermistor is shown below.

Resistance Temperature Characteristic of Silistor and Switching

Type PTC

Applications

1. The device is famous for its application as a circuit protecting device, such as a fuse.

The flow of current through the device causes a heat to build up due to its resistive

property. Thus, if excessive current flows through the device, the device begins to heat

up accordingly and thus increases its resistance. This increase in resistance again

builds up more heat. This creates such an effect that develops more resistance in the

device, and limits the amount of voltage and current in the device.

2. Another major application is as a timer in degaussing coil circuit of CRT monitors. When

a CRT monitor is turned on, an initial current reaches the PTC thermistor and

degaussing coil. The PTC thermistor will be of large size and thus, the resistance of the

device increases as the current flows in. This causes the heat to build up and thus the

degaussing coil shuts off very fast. The degaussing coil is necessary to decrease the

continuous magnetic field in a smooth manner. This help can be provided only by the

PTC thermistor.

Negative Temperature Coefficient (NTC) Thermistors

6/4/2016 4:29 PM

Thermistor Working Principle Instrumentation Tools

7 of 8

http://instrumentationtools.com/thermistor-working-principle/

NTC Thermistors that are used in industries are broadly classified into two. Thus

classification is based on the method by which the electrodes are placed on the

ceramic body. This main category could be further divided depending on the

different types of geometries, shapes and processing methods. One of the main

categories that is most commonly used in the industries is the bead type

thermistors. According to the shape and manufacturing methods, bead

thermistors can be again classified into Bare Beads, Glass Coated Beads,

Ruggedized Beads, and Bead in glass Enclosures and many more.

Another group of NTC Thermistors is the ones with metalized surface contacts.

These thermistors can be mounted using spring contacts or by surface mounting.

Applications

1. NTC thermistors are used for temperature measurements (usually in a narrow span and

low temperature ranges).

2. The device can be used to limit the sudden over current that flows in supply circuits. The

device is known to have a very high value of resistance in the beginning. The resistance

gradually decreases by the heating up of the device. As the resistance decreases, the

usual operation of the circuit is restored and the high current flows through it without

damaging other parts of the circuit.

3. This device is used to measure the temperature of incubators.

4. NTC thermistors are used to measure and monitor batteries while they are kept for

charging.

5. They are used to know the temperature of oil and coolant used inside automotive

engines. This information is sent back to the driver through indirect ways.

PTC & NTC Thermistors Comparison

Thermistor,abbreviated for THERMally sensitive resiSTOR.

PTC, abbreviated for Positive Temperature Coefficient.

NTC, abbreviated for Negative Temperature Coefficient.

PTC thermistor resistance increases with temperature rising.

NTC thermistor resistance decreases with temperature rising.

PTC Thermistor major material BaTio3, NTC thermistor major material is Mn, Ni,

Cu.

PTC thermistor is mainly applied in over-current overload and short circuit

protection, telecom protection, lighting soft switching time delay, motor starting,

temperature sensing & protection, self-regulation heating,etc.

NTC thermistor is mainly applied in inrush current suppressing limiting,

temperature sensing measurement, temperature compensation, temperature

6/4/2016 4:29 PM

Thermistor Working Principle Instrumentation Tools

8 of 8

http://instrumentationtools.com/thermistor-working-principle/

control, etc.

Also Read: RTD Working Principle

POSTED BY S BHARADWAJ REDDY

Instrumentation Professional Working in a reputed Oil & Gas Company.

6/4/2016 4:29 PM

Potrebbero piacerti anche

- Thermistor BasicsDocumento6 pagineThermistor BasicsFreddy LlusionNessuna valutazione finora

- Thermistors Types and ApplicationsDocumento5 pagineThermistors Types and ApplicationsSharmilaNessuna valutazione finora

- Thermistor: Uses of ThermistorsDocumento5 pagineThermistor: Uses of ThermistorsBisma khanNessuna valutazione finora

- Thermistor:: PTC ThermistorsDocumento6 pagineThermistor:: PTC ThermistorsTanveer AliNessuna valutazione finora

- RTD, Thermocouple, Thermistors, Manometer, Bourdon TubeDocumento36 pagineRTD, Thermocouple, Thermistors, Manometer, Bourdon TubeDINESH KUMAR DRAVIDAMANI100% (1)

- Characteristics of ThermocoupleDocumento6 pagineCharacteristics of ThermocouplekusumgdasNessuna valutazione finora

- ThermistorDocumento25 pagineThermistorTerrell LasamNessuna valutazione finora

- NTC ThermistorsDocumento44 pagineNTC Thermistorskn65238859Nessuna valutazione finora

- Temperature, Light & Pressure SensorsDocumento60 pagineTemperature, Light & Pressure SensorsHaider-e-KararNessuna valutazione finora

- Thermocouples: Prepared By: K Krishna Kishore 4 Year ECE 15F41A0440 Presented To: Mr. S. Nanda Kishore (PH.D.)Documento17 pagineThermocouples: Prepared By: K Krishna Kishore 4 Year ECE 15F41A0440 Presented To: Mr. S. Nanda Kishore (PH.D.)k kNessuna valutazione finora

- Temperature Sensor Types For Temperature MeasurementDocumento8 pagineTemperature Sensor Types For Temperature MeasurementcesarinigillasNessuna valutazione finora

- TN 324: Intelligent InstrumentationDocumento43 pagineTN 324: Intelligent InstrumentationAlango Jr Tz100% (1)

- ECG Measurement SystemDocumento10 pagineECG Measurement SystemMary HelenNessuna valutazione finora

- Resistive TransducerDocumento75 pagineResistive TransducerDhineshSKNessuna valutazione finora

- Instrumentation Lab.: RTD Thermistors Thermocoupl eDocumento31 pagineInstrumentation Lab.: RTD Thermistors Thermocoupl eGAURAV SINGHNessuna valutazione finora

- Applications of Transducers MeasuredDocumento24 pagineApplications of Transducers MeasuredDevaki V Devi100% (1)

- Biomedical Instrumentation: Chapter 6 in Introduction To Biomedical Equipment Technology by Joseph Carr and John BrownDocumento106 pagineBiomedical Instrumentation: Chapter 6 in Introduction To Biomedical Equipment Technology by Joseph Carr and John BrownGauri DNessuna valutazione finora

- Lecture 2 Sensors and TransducersDocumento47 pagineLecture 2 Sensors and TransducersdevchithNessuna valutazione finora

- Chapter 6Documento54 pagineChapter 6نورول نضيره رشديNessuna valutazione finora

- Mechanical Measurements and InstrumentationDocumento71 pagineMechanical Measurements and InstrumentationanandakumarmtsNessuna valutazione finora

- Group 1 Experimental and MeasurementDocumento46 pagineGroup 1 Experimental and MeasurementAmir O. OshoNessuna valutazione finora

- Resistive Capacitive TransducerDocumento29 pagineResistive Capacitive Transducersai krishnaNessuna valutazione finora

- RTD Characteristics ChartDocumento10 pagineRTD Characteristics ChartAkshat ChitnisNessuna valutazione finora

- TransducerDocumento37 pagineTransducerHarkirat Singh Walia Singh100% (1)

- Temperature Measurement MethodsDocumento24 pagineTemperature Measurement MethodsVijay Raj PuniaNessuna valutazione finora

- TransducersDocumento66 pagineTransducersAnanya SrivastavaNessuna valutazione finora

- Thermocouple PresentationDocumento15 pagineThermocouple PresentationMantuomNessuna valutazione finora

- Temperature Control SystemDocumento2 pagineTemperature Control SystemNagulapati KiranNessuna valutazione finora

- Temperature Sensing TechniquesDocumento66 pagineTemperature Sensing TechniquesEng RemoonNessuna valutazione finora

- TransducersDocumento70 pagineTransducersaishwarye gaikwad100% (1)

- RTD TutorialsDocumento11 pagineRTD TutorialsjaigodaraNessuna valutazione finora

- Module 6 Temperature SensorsDocumento20 pagineModule 6 Temperature SensorsJyothi SamanthulaNessuna valutazione finora

- Unit 2 Resistance Thermo PDFDocumento31 pagineUnit 2 Resistance Thermo PDFUv sai likithNessuna valutazione finora

- Introduction To Strain GaugesDocumento32 pagineIntroduction To Strain GaugesManjunatha Babu N.s100% (1)

- Sensor Experiment RTDDocumento2 pagineSensor Experiment RTDTheresia Diah ArumNessuna valutazione finora

- Sensors and Transducers GuideDocumento47 pagineSensors and Transducers GuideAbdul Hakeem Semar KamaluddinNessuna valutazione finora

- Micro SensorsDocumento35 pagineMicro SensorssunsrinNessuna valutazione finora

- Thermocouple and RTDDocumento13 pagineThermocouple and RTDrana 13022001Nessuna valutazione finora

- What Is A ThermocoupleDocumento10 pagineWhat Is A Thermocouplekrishnaswamy9Nessuna valutazione finora

- Biomedical Transducers PresentationDocumento44 pagineBiomedical Transducers PresentationDavid TalamNessuna valutazione finora

- Lecure-2 Sensors For Biomedical ApplicationsDocumento98 pagineLecure-2 Sensors For Biomedical ApplicationsDivya Aseeja0% (1)

- Unit - III Transducers and SensorsDocumento54 pagineUnit - III Transducers and Sensorsrameshsme100% (2)

- Difference Between RTD, Thermocouple and ThermistorDocumento3 pagineDifference Between RTD, Thermocouple and ThermistorVenkata Suresh MandavaNessuna valutazione finora

- ThermocouplesDocumento21 pagineThermocouplesAusaf ShaikhNessuna valutazione finora

- Measurement of force and torque instrumentsDocumento38 pagineMeasurement of force and torque instrumentsPalak NaikNessuna valutazione finora

- On Measurement of Non-Electrical QuantitiesDocumento39 pagineOn Measurement of Non-Electrical Quantitiesrao asadNessuna valutazione finora

- TRANSDUCERDocumento11 pagineTRANSDUCERLucks GonzalesNessuna valutazione finora

- Measurement and InstrumentationDocumento45 pagineMeasurement and Instrumentationsamkous100% (1)

- Resistive PotentiometerDocumento7 pagineResistive PotentiometerSouradeep HalderNessuna valutazione finora

- Resistance ThermometerDocumento8 pagineResistance Thermometerapi-263577432100% (1)

- MAE 334 - Temp MeasurementDocumento5 pagineMAE 334 - Temp MeasurementKhoa Ngo NhuNessuna valutazione finora

- Transducers: An SEO-Optimized GuideDocumento26 pagineTransducers: An SEO-Optimized GuideraajitaNessuna valutazione finora

- Electrical Transducer Types & ApplicationsDocumento20 pagineElectrical Transducer Types & ApplicationsSachin K GowdaNessuna valutazione finora

- JJ104 Workshop Technology CHAPTER9 Arc WeldingDocumento14 pagineJJ104 Workshop Technology CHAPTER9 Arc WeldingAh Tiang50% (4)

- Industrial Sensors and Transducers Term PaperDocumento14 pagineIndustrial Sensors and Transducers Term PaperKumater TerNessuna valutazione finora

- Unit 4 Self Generating Sensors PDFDocumento57 pagineUnit 4 Self Generating Sensors PDFHingula100% (1)

- Thermistor Temperature Sensor GuideDocumento14 pagineThermistor Temperature Sensor GuideDheeraj YadavNessuna valutazione finora

- Thermistor Circuit SymbolDocumento4 pagineThermistor Circuit SymbolAkshat GoelNessuna valutazione finora

- Ther Mist orDocumento6 pagineTher Mist orLuthando PuzaNessuna valutazione finora

- Sensors Unit-2Documento20 pagineSensors Unit-2Sri ChandanaNessuna valutazione finora

- Field Remote Instrument Enclosure: JB-001 MR02Documento1 paginaField Remote Instrument Enclosure: JB-001 MR02suhailfarhaanNessuna valutazione finora

- Field Remote Instrument Enclosure: JB-001 MR02Documento1 paginaField Remote Instrument Enclosure: JB-001 MR02suhailfarhaanNessuna valutazione finora

- Field Remote Instrument Enclosure: JB-001 MR02Documento1 paginaField Remote Instrument Enclosure: JB-001 MR02suhailfarhaanNessuna valutazione finora

- Naveen ResumeDocumento4 pagineNaveen ResumeAbarajithan RajendranNessuna valutazione finora

- Membrane area needed to concentrate 10L to 200mL in 2.5h at 50LMHDocumento1 paginaMembrane area needed to concentrate 10L to 200mL in 2.5h at 50LMHAbarajithan RajendranNessuna valutazione finora

- AKSS ASDM-2022: - Internal Safety OrientationDocumento3 pagineAKSS ASDM-2022: - Internal Safety OrientationAbarajithan RajendranNessuna valutazione finora

- Scheduled Courses in 2019 (Singapore) : Course Title Code JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC Duration (DAYS)Documento1 paginaScheduled Courses in 2019 (Singapore) : Course Title Code JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC Duration (DAYS)Abarajithan RajendranNessuna valutazione finora

- Bala ResumeDocumento4 pagineBala ResumeAbarajithan RajendranNessuna valutazione finora

- Ab FFLDDocumento184 pagineAb FFLDNikhilesh MuraleedharanNessuna valutazione finora

- Field Instrument Installation ChecklistDocumento1 paginaField Instrument Installation ChecklistAbarajithan RajendranNessuna valutazione finora

- Sanjay ResumeDocumento4 pagineSanjay ResumeAbarajithan RajendranNessuna valutazione finora

- Trinkets Season 2 - Google SearchDocumento1 paginaTrinkets Season 2 - Google SearchAbarajithan Rajendran0% (1)

- Chp8 3edition PDFDocumento21 pagineChp8 3edition PDFAbarajithan RajendranNessuna valutazione finora

- Agitator Calculation. - SPLDocumento2 pagineAgitator Calculation. - SPLAbarajithan RajendranNessuna valutazione finora

- Calibrate Displacer Level Transmitter in 40 CharactersDocumento6 pagineCalibrate Displacer Level Transmitter in 40 CharactersAbarajithan RajendranNessuna valutazione finora

- 23Documento1 pagina23Abarajithan RajendranNessuna valutazione finora

- HP To WattDocumento4 pagineHP To WattAbarajithan RajendranNessuna valutazione finora

- Sarathi New ResumeDocumento6 pagineSarathi New ResumeAbarajithan RajendranNessuna valutazione finora

- DasaDocumento2 pagineDasaAbarajithan RajendranNessuna valutazione finora

- Design Criteria - External Spin FilterDocumento2 pagineDesign Criteria - External Spin FilterAbarajithan RajendranNessuna valutazione finora

- General Specifications: Daqstation DX1000Documento20 pagineGeneral Specifications: Daqstation DX1000Abarajithan RajendranNessuna valutazione finora

- Jack. Pump Head CalculationDocumento3 pagineJack. Pump Head CalculationAbarajithan RajendranNessuna valutazione finora

- Measure Impulse Line Characteristics Using Cross-CorrelationDocumento4 pagineMeasure Impulse Line Characteristics Using Cross-CorrelationAbarajithan RajendranNessuna valutazione finora

- DFVDocumento1 paginaDFVAbarajithan RajendranNessuna valutazione finora

- B.3.12 - Impulse Piping & TubingDocumento5 pagineB.3.12 - Impulse Piping & TubinggdfsndhgfdvhjzdNessuna valutazione finora

- AD Vigano: 110/127 V and 220/240 V Bi-Pin Fluorescent Luminaires For Non-Armoured CableDocumento1 paginaAD Vigano: 110/127 V and 220/240 V Bi-Pin Fluorescent Luminaires For Non-Armoured CableAbarajithan RajendranNessuna valutazione finora

- Compact Valve Terminal (16-Valves Profibus Master)Documento2 pagineCompact Valve Terminal (16-Valves Profibus Master)Abarajithan RajendranNessuna valutazione finora

- Redapt Hazardous Area GuideDocumento11 pagineRedapt Hazardous Area GuidekarthipetroNessuna valutazione finora

- 12Documento1 pagina12Abarajithan RajendranNessuna valutazione finora

- Custom Ex Control Stations Stainless SteelDocumento17 pagineCustom Ex Control Stations Stainless SteelAbarajithan RajendranNessuna valutazione finora

- 9898 - Immersion Temperature Sensor FT-TP - 100 FT-TP - 400 - enDocumento4 pagine9898 - Immersion Temperature Sensor FT-TP - 100 FT-TP - 400 - enurangtengakNessuna valutazione finora

- PTC PDFDocumento2 paginePTC PDFLeandro Esteban GarciaNessuna valutazione finora

- LG Refrigerator Bottom Freezer LRBC22522 Service ManualDocumento65 pagineLG Refrigerator Bottom Freezer LRBC22522 Service ManualJohn TrippNessuna valutazione finora

- Basic Electronic in Laptop Repairing PDFDocumento43 pagineBasic Electronic in Laptop Repairing PDFRene Ruiz0% (1)

- SCK SeriesDocumento17 pagineSCK SeriestahirianNessuna valutazione finora

- Thermocouples: Advantages DisadvantagesDocumento5 pagineThermocouples: Advantages DisadvantagesAffa YogiswaraNessuna valutazione finora

- SEMIKRON Technical Explanation SEMiX® - IGBT Modules + Bridge Rectifier Family EN 2009-10-14 Rev-03Documento36 pagineSEMIKRON Technical Explanation SEMiX® - IGBT Modules + Bridge Rectifier Family EN 2009-10-14 Rev-03Michael SalcedoNessuna valutazione finora

- General Catalogue WebDocumento84 pagineGeneral Catalogue WebJuanCabañasNessuna valutazione finora

- Module 6 Temperature SensorsDocumento20 pagineModule 6 Temperature SensorsJyothi SamanthulaNessuna valutazione finora

- The Negative Temperature Coefficient (NTC) Thermistor and Light-Dependent Resistor GuideDocumento3 pagineThe Negative Temperature Coefficient (NTC) Thermistor and Light-Dependent Resistor GuideAyman Mohamed Hashim100% (1)

- Energy Auditing: R 2018 Elsevier Inc. All Rights ReservedDocumento934 pagineEnergy Auditing: R 2018 Elsevier Inc. All Rights ReservedVincent PoletNessuna valutazione finora

- Catenary CatlogueDocumento19 pagineCatenary CatlogueSrikantha ThotagamuwaNessuna valutazione finora

- Presentation on electronically controlled Caterpillar enginesDocumento56 paginePresentation on electronically controlled Caterpillar enginesPablo Antonio Figueroa Cuevas100% (11)

- Resistor Capacitor InductorDocumento11 pagineResistor Capacitor InductorLudvig Vahn D. NiepezNessuna valutazione finora

- SMMANDocumento21 pagineSMMANRayssa OliveiraNessuna valutazione finora

- Biomedical Instrumentation: Chapter 6 in Introduction To Biomedical Equipment Technology by Joseph Carr and John BrownDocumento106 pagineBiomedical Instrumentation: Chapter 6 in Introduction To Biomedical Equipment Technology by Joseph Carr and John BrownGauri DNessuna valutazione finora

- Steinhart-Hart Therm Is Tor CalculatorDocumento4 pagineSteinhart-Hart Therm Is Tor CalculatorAuthmane DekNessuna valutazione finora

- Carrier Service ManualDocumento40 pagineCarrier Service ManualMetalloy67% (9)

- Temperature Controlled DC Fan Circuit AnalysisDocumento4 pagineTemperature Controlled DC Fan Circuit Analysisaqib aliNessuna valutazione finora

- 107TD47 DB enDocumento6 pagine107TD47 DB enNaveedNessuna valutazione finora

- MPDFDocumento30 pagineMPDFDriza RabieNessuna valutazione finora

- JUMO Quantrol LC100/LC200/LC300: Universal PID Controller SeriesDocumento12 pagineJUMO Quantrol LC100/LC200/LC300: Universal PID Controller SeriesKenan UzunovicNessuna valutazione finora

- A Hybrid System For Battery Thermal Management For PDFDocumento152 pagineA Hybrid System For Battery Thermal Management For PDFHARSHIT KUMARNessuna valutazione finora

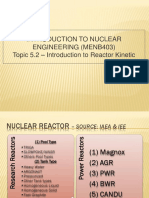

- L5-2 - Intro Reactor KineticDocumento60 pagineL5-2 - Intro Reactor KineticSritaran BalakrishnanNessuna valutazione finora

- 1TNC920204D0201-AO11 User's Guide-En V1Documento18 pagine1TNC920204D0201-AO11 User's Guide-En V1HujiLokoNessuna valutazione finora

- Electrical Potentiometer Data Sheets ML06, ML10, ML25Documento5 pagineElectrical Potentiometer Data Sheets ML06, ML10, ML25Carlos MeloNessuna valutazione finora

- Selection Guide - E300 Electronic Overload Relay - 193-SG010E-En-P - January 2016Documento36 pagineSelection Guide - E300 Electronic Overload Relay - 193-SG010E-En-P - January 2016Nicolás A. SelvaggioNessuna valutazione finora

- ThermistorDocumento4 pagineThermistorjullianagabriel1103Nessuna valutazione finora

- Ferroelectric Devices 2nd EditionDocumento361 pagineFerroelectric Devices 2nd Edition王小飞100% (1)