Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

005 TS Hardox Hituf Wearplate For Tough Situation UK

Caricato da

jakalae52630 valutazioniIl 0% ha trovato utile questo documento (0 voti)

24 visualizzazioni2 pagineHardox

Titolo originale

005 TS Hardox Hituf Wearplate for Tough Situation UK

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoHardox

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

24 visualizzazioni2 pagine005 TS Hardox Hituf Wearplate For Tough Situation UK

Caricato da

jakalae5263Hardox

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

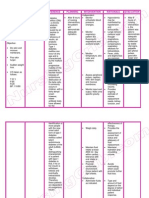

HARDOX HiTuf

wear plate for tough situations

HARDOX HiTuf is an abrasion resistant plate with

extremely high impact toughness in order to

provide excellent crack resistance. The HARDOX

HiTuf is intended for applications with extra high

demands on the combination of crack and wear

resistance.

What is HARDOX HiTuf?

In HARDOX HiTuf we have focused

on making the best wear plate available

for heavy section wear applications,

with extra high demands on crack

resistant and structural integrity.

Due to the way HARDOX HiTuf is

manufactured certain benefits can be

obtained compared to other 400 HBW

steel.

40-70 mm

400 HBW

Steel

HARDOX HiTuf

HARDOX HiTuf

HARDOX HiTuf vs. 400 HBW Steel

A typical steel used for heavy section

wear parts is the 400 Brinell quenched

and tempered wear plates. In some

cases a 400 HBW steel is not sufficient,

and a boost in toughness is needed to

manage the forces.

This is the case in production

and service of heavy section wear

parts subjected to structural loads.

HARDOX HiTuf would be of benefit

especially if there is a need to facilitate

maintenance work involving welding

and thermal cutting. The crack

susceptibility, when welding or cutting,

tends to increase with increasing plate

thickness and plate hardness. Here

HARDOX HiTuf can have a lot to

offer.

Impact Toughness

HARDOX Hituf vs. 400 HBW steel

400 HBW

Steel

To obtain the desired impact toughness

and thus a high crack resistance, many

manufacturers of heavy gauges wear

parts today use structural quenched

and tempered steels in hardness of

260290 Brinell. By increasing the steel

hardness up to 350 Brinell an increase

in wear life of about 1020% can be

reached. This can easily be achieved by

an up grading to the HARDOX HiTuf

wear plate.

High Impact toughness

High impact toughness allows the

steel to resist failure by cracking when

exposed to heavy impact. The higher the

toughness the better the crack resistance,

meaning a greater versatility in applying

the HARDOX HiTuf in thick wear

components subjected to structural loads.

Impact toughness J/-40 C

HARDOX HiTuf is produced by roller

quenching followed by subsequent

tempering and is supplied in the

thickness range of 40120 mm. The

average surface hardness is 350 Brinell.

Improved weldability (lower

preheating)

Improved thermal cutting, (lower

preheating requirements)

Improved temperature stability

(less risk of softening at high service

temperatures.)

HARDOX HiTuf applications

Due to the well balanced properties in

respect to crack and wear resistance

the HARDOX HiTuf fulfils its place

both as a wear plate and as a structural

member. The application segments

where the HARDOX HiTuf is mainly

intended to be used are thick cutting

edges, demolition tools and rippers.

Due to the low preheat requirements

when welding, HARDOX HiTuf is

also an excellent steel to be used for

maintenance work.

71-120 mm

Structural characteristics

The HARDOX HiTuf is the wear plate

with the most structural steel features

of all the wear plates in the HARDOX

product programme. A yield stress of

850900 MPa, an impact toughness of

7095 J/-40 C and an elongation of 16%

ensures a reliable ductility to the steels

structural integrity.

Demolition tools is a typical application

where HARDOX HiTuf exellent performance is utilised.

Welding, low preheat requirements

HARDOX HiTuf can be welded with all

conventional welding methods. Preheat

recommendations for welding with basic

ferritic electrodes is according to the table

below. The use of filler material with

low hydrogen content (HD < 5 ml/100g)

is recommended. If preheating prior to

welding can not be performed welding with

austenitic stainless consumables can be

utilized.

Cutting, low preheating

HARDOX HiTuf can be profiled by any

conventional thermal cutting methods.

Preheating to 125 150o C is recommended

when cutting plates in thickness 100 mm.

More information on how HARDOX

HiTuf should be handled can be found in

HARD FACTS 15 HARDOX HiTuf in the

workshop

Download at www.ssabox.com/techsupport

HARDOX HiTuf can be welded with all conventional welding methods available.

Recommended preheat temperature

Combined plate thickness (mm)

Preheat requirement (oC)

8090

75

90100

100

>100

150

TS-05-HiTuf-uk-01-2003/sterbergs & Srmlandstryck,27965

If preheating can not be fully performed austenitic stainless consumables are

recommended to be used.

HARDOX wear plate only from SSAB Oxelsund

HARDOX is a registered trademark of SSAB Oxelsund.

SSAB Oxelsund AB

SE-613 80 Oxelsund

Sweden

Phone +46 155 25 40 00

Fax +46 155 25 40 73

www.ssabox.com

www.hardox.com

The latest version of this document can be downloaded from www.ssabox.com/techsupport

Potrebbero piacerti anche

- UPD301B/C: Stand-Alone USB Type-C™ Power Delivery 3.0 ControllerDocumento45 pagineUPD301B/C: Stand-Alone USB Type-C™ Power Delivery 3.0 Controllerjakalae5263Nessuna valutazione finora

- Medical Imaging Principles Detectors and Electronics: Table of ContentDocumento2 pagineMedical Imaging Principles Detectors and Electronics: Table of Contentjakalae5263Nessuna valutazione finora

- Ar Doc 238704Documento1 paginaAr Doc 238704jakalae5263Nessuna valutazione finora

- VI Vgpu GuideDocumento1 paginaVI Vgpu Guidejakalae5263Nessuna valutazione finora

- High Resolution RGB LED Color Mixing Application NoteDocumento14 pagineHigh Resolution RGB LED Color Mixing Application Notejakalae5263Nessuna valutazione finora

- SHV0 G12Documento1 paginaSHV0 G12jakalae5263Nessuna valutazione finora

- Modell GZ10Documento2 pagineModell GZ10jakalae5263Nessuna valutazione finora

- Electronic Service Tool (Est) Software Update - Version 9.2.0.0Documento3 pagineElectronic Service Tool (Est) Software Update - Version 9.2.0.0jakalae5263Nessuna valutazione finora

- 308.8308.3.4-5 C9000 enDocumento48 pagine308.8308.3.4-5 C9000 enjakalae5263Nessuna valutazione finora

- Technical Data Sheet: Features FeaturesDocumento11 pagineTechnical Data Sheet: Features Featuresjakalae5263Nessuna valutazione finora

- Optical Mouse Sensor: M16183 (A2703) Series Data SheetDocumento11 pagineOptical Mouse Sensor: M16183 (A2703) Series Data Sheetjakalae5263Nessuna valutazione finora

- MMA WELDING PRODUCT REPAIR PROCESS OF GYSMI 160P 1 - 16. Auteur - Alexis Gillet Date - 30 - 06 - 2016.Documento16 pagineMMA WELDING PRODUCT REPAIR PROCESS OF GYSMI 160P 1 - 16. Auteur - Alexis Gillet Date - 30 - 06 - 2016.jakalae5263Nessuna valutazione finora

- Flasher IC With 18-m Shunt U6043B: FeaturesDocumento8 pagineFlasher IC With 18-m Shunt U6043B: Featuresjakalae5263Nessuna valutazione finora

- General Purpose Type General Purpose Type General Purpose Type General Purpose Type General Purpose Type Photocoupler Photocoupler Photocoupler Photocoupler PhotocouplerDocumento7 pagineGeneral Purpose Type General Purpose Type General Purpose Type General Purpose Type General Purpose Type Photocoupler Photocoupler Photocoupler Photocoupler Photocouplerjakalae5263Nessuna valutazione finora

- έδρας HAWEDocumento54 pagineέδρας HAWEjakalae5263Nessuna valutazione finora

- Pan3204 Low Cost Wireless Mouse Sensor: Key SpecificationDocumento27 paginePan3204 Low Cost Wireless Mouse Sensor: Key Specificationjakalae5263Nessuna valutazione finora

- Agilent ADNS-3080 High-Performance Optical Mouse Sensor: Data SheetDocumento41 pagineAgilent ADNS-3080 High-Performance Optical Mouse Sensor: Data Sheetjakalae5263Nessuna valutazione finora

- Accelerating Innovation in A Changing World: Syngenta Sustainable Business ReportDocumento56 pagineAccelerating Innovation in A Changing World: Syngenta Sustainable Business Reportjakalae5263Nessuna valutazione finora

- Double-Pendulum Dynamics: Created in COMSOL Multiphysics 6.0Documento40 pagineDouble-Pendulum Dynamics: Created in COMSOL Multiphysics 6.0jakalae5263Nessuna valutazione finora

- Data Sheet: ADNS-7530Documento37 pagineData Sheet: ADNS-7530jakalae5263Nessuna valutazione finora

- JCB Telehandlers Spec 4024d5Documento28 pagineJCB Telehandlers Spec 4024d5jakalae5263Nessuna valutazione finora

- Optical Mouse Sensor: M16191 Series DatasheetDocumento11 pagineOptical Mouse Sensor: M16191 Series Datasheetjakalae5263Nessuna valutazione finora

- Series: Air CylinderDocumento6 pagineSeries: Air Cylinderjakalae5263Nessuna valutazione finora

- Air Cylinder: Are Added To The Mounting TypesDocumento124 pagineAir Cylinder: Are Added To The Mounting Typesjakalae5263Nessuna valutazione finora

- CJP2-CJP EuDocumento32 pagineCJP2-CJP Eujakalae5263Nessuna valutazione finora

- Mini Free Mount Cylinder: SeriesDocumento40 pagineMini Free Mount Cylinder: Seriesjakalae5263Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Watt AC-DC Converters: FeaturesDocumento3 pagineWatt AC-DC Converters: FeatureskofidNessuna valutazione finora

- Sponsor and Principal Investigator: Responsibilities of The SponsorDocumento10 pagineSponsor and Principal Investigator: Responsibilities of The SponsorNoriNessuna valutazione finora

- Cosmology Questions and Answers - SanfoundryDocumento9 pagineCosmology Questions and Answers - SanfoundryGopinathan MNessuna valutazione finora

- Power - of - Suffering 2Documento21 paginePower - of - Suffering 2jojiNessuna valutazione finora

- Lesson 3: Letters of RequestDocumento4 pagineLesson 3: Letters of RequestMinh HiếuNessuna valutazione finora

- Micromine TutorialDocumento5 pagineMicromine TutorialFerdinand Siahaan100% (1)

- PQS Catalogue 4 2Documento143 paginePQS Catalogue 4 2sagarNessuna valutazione finora

- January 2014 QP - Paper 1 Edexcel (B) Maths IGCSEDocumento24 pagineJanuary 2014 QP - Paper 1 Edexcel (B) Maths IGCSEStevenstrange001 CattyNessuna valutazione finora

- POLAR BEARS-Biology ProjectDocumento16 paginePOLAR BEARS-Biology Projectserwaa21Nessuna valutazione finora

- Rubber Stamp BusinessDocumento4 pagineRubber Stamp BusinessvasantsunerkarNessuna valutazione finora

- Boomer L2 D - 9851 2586 01Documento4 pagineBoomer L2 D - 9851 2586 01Pablo Luis Pérez PostigoNessuna valutazione finora

- Good Data Won't Guarantee Good DecisionsDocumento3 pagineGood Data Won't Guarantee Good DecisionsAditya SharmaNessuna valutazione finora

- Tugas Farmasi Klinis: Feby Purnama Sari 1802036Documento9 pagineTugas Farmasi Klinis: Feby Purnama Sari 1802036Feby Purnama SariNessuna valutazione finora

- BRB Personal Care Cost Effictive Guide Formulation Edition 2019Documento28 pagineBRB Personal Care Cost Effictive Guide Formulation Edition 2019Abdulrahman HamdanNessuna valutazione finora

- Siemens 6SL31622AA000AA0 CatalogDocumento20 pagineSiemens 6SL31622AA000AA0 CatalogIrfan NurdiansyahNessuna valutazione finora

- MikroekonomiDocumento1 paginaMikroekonomiYudhaPrakosoIINessuna valutazione finora

- Azure Arc DoccumentDocumento143 pagineAzure Arc Doccumentg.jithendarNessuna valutazione finora

- Algorithm Design TechniquesDocumento24 pagineAlgorithm Design TechniquespermasaNessuna valutazione finora

- REF615 PG 756379 ENs PDFDocumento96 pagineREF615 PG 756379 ENs PDFandi mulyanaNessuna valutazione finora

- Computer Forensics ReportDocumento7 pagineComputer Forensics ReportMatias IacobuzioNessuna valutazione finora

- Tasha Giles: WebsiteDocumento1 paginaTasha Giles: Websiteapi-395325861Nessuna valutazione finora

- Five Star Env Audit Specification Amp Pre Audit ChecklistDocumento20 pagineFive Star Env Audit Specification Amp Pre Audit ChecklistMazhar ShaikhNessuna valutazione finora

- Nursing Care Plan Diabetes Mellitus Type 1Documento2 pagineNursing Care Plan Diabetes Mellitus Type 1deric85% (46)

- 1) About The Pandemic COVID-19Documento2 pagine1) About The Pandemic COVID-19محسين اشيكNessuna valutazione finora

- LPP - Problem Number 2Documento9 pagineLPP - Problem Number 2CT SunilkumarNessuna valutazione finora

- Acute Conditions of The NewbornDocumento46 pagineAcute Conditions of The NewbornCamille Joy BaliliNessuna valutazione finora

- TCC Number 153-4-4Documento1 paginaTCC Number 153-4-4jeremie gamonNessuna valutazione finora

- Gulfpub Wo 201805Documento81 pagineGulfpub Wo 201805Patricia.PNessuna valutazione finora

- Copper For BusbarDocumento60 pagineCopper For BusbarSunil Gadekar100% (3)

- Make or Buy - ProblemDocumento4 pagineMake or Buy - ProblemTk KimNessuna valutazione finora