Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DYNAPOL BADGE Free Alternativs

Caricato da

AlptekinCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

DYNAPOL BADGE Free Alternativs

Caricato da

AlptekinCopyright:

Formati disponibili

Evonik Degussa (China) Co.Ltd.

Shanghai Branch

55 Chundong Road,

Xinzhuang Industry Park,

Shanghai 201108

P.R. China

Conclusion

phone +86 21 6119-1771

fax +86 21 6119-1168

Polyester-phenolic coatings based on DYNAPOL LH 318-02 perform adequately to standard qualities of

epoxy-phenolics

Polyester based lacquers provide equal or better flexibility and higher solids than epoxy-phenolics

Polyester-phenolic lacquers show migration levels below regulatory limits

Polyesters do not show estrogenic activity

Polyester systems are BADGE, BPA and PVC free and free of taste

Evonik provides a wide range of various alternatives for epoxies in food contact coatings

Evonik Degussa Corporation

Coatings & Additives

379 Interpace Parkway

Parsppany, NJ 07054-0677

USA

phone +1 973 541-8462

fax +1 973 541-8450

This information and all further technical advice is

based on our present knowledge and experience.

However, it implies no liability or other legal responsibility on our part, including with regard to existing

third party intellectual property rights, especially

patent rights. In particular, no warranty, whether

express or implied, or guarantee of product properties in the legal sense is intended or implied. We

reserve the right to make any changes according to

technological progress or further developments.

The customer is not released from the obligation to

conduct careful inspection and testing of incoming

goods. Performance of the product described herein

should be verified by testing, which should be carried out only by qualified experts in the sole responsibility of a customer. Reference to trade names used

by other companies is neither a recommendation,

nor does it imply that similar products could not be

used.

(April 2008)

DYNAPOL Polyester Resins

BADGE free alternatives for epoxies in food

contact coatings

Evonik Degussa GmbH

Coatings & Additives

Paul-Baumann-Strae 1

45764 Marl

Germany

02/ 2010

phone +49 2365 49-7628

fax +49 2365 49-5030

dynapol@evonik.com

www.evonik.com/dynapol

BADGE free alternatives for

epoxies in food contact coatings

Background

Epoxy based coatings intended to come into contact with food enhance attention regarding the release of critical migrate into packed food during processing and storage. Substances under sus

picion to be hazardous to health when exceeding migration limits are Bisphenol A Diglycidyl Ether

H3C

CH3

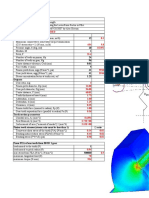

Comparison of interior can coating based on polyester

DYNAPOL LH 318-02 with epoxy-phenolic paint

Product information

Saturated, medium and high molecular weight, hydroxylated polyester resins.

[BADGE]

O

and its associated hydrolysis and hydrochlorination products as well as some migrating oligomers.

Unacceptable high migrate levels did not arise by the use of BADGE as base monomer of heat

cured lacquers, but often from its use as additive for hydrochlorine scavangers during heat curing

of PVC based lacquers (organosols), as additive for the improvement of lacquer adhesion at plate

deformations (e.g. stamping, deep drawing of can material) or as constituent of plastic laminate

adhesives migrating into food through barrier films. Additionally, there is an ongoing discourse

about the extent of estrogenic activity of Bisphenol A - a precursor of the epoxies.

H3C

With a suitable guide formulation (table 1) the polyester was evaluated and compared to an industrial standard epoxy

phenol lacquer (table 2). Higher solids, better flexibility and better adhesion on deformed areas after sterilization were

obtained with the system based on DYNAPOL LH 318-02.

Table 1. Polyester formulation

Resin / Crosslinker ratio

75 : 25

Solid content (0,5 h / 160 C)

48 +/- 1 %

Viscosity, DIN cup 4 mm, (20 C)

120 10 s

Substrate

Tinplate (ETP 2,8/2,8 T 52 0,20)

Curing condition

10 minutes / 200 C (PMT)

Dry film thickness

5,8 g / m

CH3

[Bisphenol A]

HO

OH

Thus, industrial efforts aim to substitute epoxy type adhesives and lacquers for food contact to

avoid any legal problems and health issues.

Especially modified polyester type lacquers are known for low migrate levels and are chosen

for the replacement but polyester resin lacquer formulations and process conditions need to be

adapted to achieve many of the advantageous properties of epoxy type lacquers.

Evoniks research and developmental work so far resulted in the design of a new medium

molecular weight, saturated polyester, DYNAPOL LH 318-02, as a potential epoxy replacement

in phenolic resin crosslinked interior protection finishes with direct food contact.

Table 2. Lacquer comparison

Epoxy-Phenol

Polyester-Phenol

Solid content

39 %

48 %

Viscosity ( DIN 4 cup)

110 s

106 s

Wedge bend test

43 mm

15 mm

Sterilization in water

2/1/1/1 *)

1/1/1/1 *)

Sterilization in 3% acetic acid

4/1/1/1 *)

2/1/1/1 *)

Solvent

FDA

status

Glass transition

temperature

C

Molecular

weight Mn

g/mol

Product

Type

DYNAPOL LH 318-02

medium molecular

saturated polyester

polyester-phenolic systems

55

Solvent Naphtha 150/

Butylglycol

+ *)

20

5.000

DYNAPOL LH 815-05

medium molecular

saturated polyester

good cost/performance

ratio

50

Solvent Naphtha 150/

Solvent Naphtha 200

+ *)

55

7.000

DYNAPOL L 490

high molecular saturated

polyester

excellent flexibility

100

solid

+ **)

40

15.000

DYNAPOL L 651

high molecular saturated

polyester

good flexibility

100

solid

+ *)

40

15.000

DYNAPOL L 658

high molecular saturated

polyester

good flexibility

100

solid

+ *)

40

20.000

DYNAPOL L 411

high molecular saturated

polyester

good hardness/ flexibility

balance

100

solid

+ *)

47

16.000

DYNAPOL L 205

high molecular saturated

polyester

good sterilization resistance

100

solid

+ *)

67

15.000

DYNAPOL L 206

high molecular saturated

polyester

good sterilization resistance

100

solid

+ *)

67

20.000

DYNAPOL L 952

high molecular saturated

polyester

excellent sterilization

resistance

100

solid

+ *)

70

18.000

DYNAPOL L 912

high molecular saturated

polyester

super sterilization and acid

resistance

100

solid

+ *)

105

15.000

*) in compliance with FDA 175.300 (restriction: only for non alcoholic goods)

**) in full compliance with FDA 175.300

Guide formulations for interior can coatings are available on request.

*)Test can (20mm deep drawing, edge radius 5/10/15/20 mm) absorption after 30 min 129 C sterilization:

1=no, 4=strong damage

Solid

content

%

Advantages/

Application

Potrebbero piacerti anche

- Resins For: Vehicle Refinish & Commercial Transportation CoatingsDocumento6 pagineResins For: Vehicle Refinish & Commercial Transportation CoatingsEmilio HipolaNessuna valutazione finora

- Brochure PAP SolvayDocumento24 pagineBrochure PAP Solvaysrushti100% (1)

- Pluronic PE TypesDocumento16 paginePluronic PE TypesMehul KhimaniNessuna valutazione finora

- Renolit Medical Brochure 04-2018Documento13 pagineRenolit Medical Brochure 04-2018Kai HarukaNessuna valutazione finora

- Organic ChemDocumento113 pagineOrganic ChemTrúc Hồ0% (1)

- OMG Americas - Additives BrochureDocumento8 pagineOMG Americas - Additives BrochureUsama AwadNessuna valutazione finora

- EDM - 012 Additives For Wood and Furniture Coatings PDFDocumento8 pagineEDM - 012 Additives For Wood and Furniture Coatings PDFEugene PaiNessuna valutazione finora

- Arcosolv TPNBDocumento4 pagineArcosolv TPNBamiller1987Nessuna valutazione finora

- NUPLEX Plastics NU 006 Resins Automotive Plastics 14-15Documento6 pagineNUPLEX Plastics NU 006 Resins Automotive Plastics 14-15Emilio HipolaNessuna valutazione finora

- Munzing Masterbatch AdditivesDocumento8 pagineMunzing Masterbatch AdditivesThea Athalia CandraNessuna valutazione finora

- Oxylink - Technical Product Information: Additive For Waterborne Resin SystemsDocumento32 pagineOxylink - Technical Product Information: Additive For Waterborne Resin SystemsAPEX SONNessuna valutazione finora

- Shieldex Wash Primer - AC 3Documento2 pagineShieldex Wash Primer - AC 3nanoNessuna valutazione finora

- Dow Surfactants: Reference ChartDocumento5 pagineDow Surfactants: Reference CharttmlNessuna valutazione finora

- Sulphonation Technology in The Detergent IndustryDocumento5 pagineSulphonation Technology in The Detergent IndustryСергей КубахNessuna valutazione finora

- Dehypon LS 45 PDFDocumento2 pagineDehypon LS 45 PDFarguij0% (1)

- Tomadol - Air ProdutsDocumento36 pagineTomadol - Air ProdutsRudney Bonin Herkenhoff50% (2)

- Joncryl 1687: PropertiesDocumento2 pagineJoncryl 1687: PropertiesHiba NaserNessuna valutazione finora

- Stepan Formulation 1220Documento2 pagineStepan Formulation 1220Devesh KumarNessuna valutazione finora

- DAPRO DefoamersDocumento5 pagineDAPRO Defoamerspipaporn kanjanapipatkulNessuna valutazione finora

- Akzonobel Formulation 2C 75 01Documento1 paginaAkzonobel Formulation 2C 75 01culiniNessuna valutazione finora

- SC2042Documento4 pagineSC2042A MahmoodNessuna valutazione finora

- Auto Polish Introduction and Formulation Tips (Đã DịchDocumento8 pagineAuto Polish Introduction and Formulation Tips (Đã DịchTuan TranNessuna valutazione finora

- DS TEGO Polish Additiv WE 50 e 1112 PDFDocumento3 pagineDS TEGO Polish Additiv WE 50 e 1112 PDFSunny D bhoglaNessuna valutazione finora

- Starting 1K floor coating formulationDocumento1 paginaStarting 1K floor coating formulationForeverNessuna valutazione finora

- SC2889 PDFDocumento15 pagineSC2889 PDFA MahmoodNessuna valutazione finora

- AkzoNobel Paint Eng Tcm54-18194Documento20 pagineAkzoNobel Paint Eng Tcm54-18194a2009sNessuna valutazione finora

- Automotive Coatings Product Guide: Resins, Polymers, Dispersants & AdditivesDocumento7 pagineAutomotive Coatings Product Guide: Resins, Polymers, Dispersants & AdditivesAmado ElzNessuna valutazione finora

- Acronal Ps 713 APDocumento2 pagineAcronal Ps 713 APCarlos100% (1)

- Dow PDFDocumento8 pagineDow PDFVeliYunusKavalciNessuna valutazione finora

- Nuosperse FA 196Documento2 pagineNuosperse FA 196Sandra Rojas100% (1)

- Diagram 1: Gibbs Equation On ElasticityDocumento8 pagineDiagram 1: Gibbs Equation On ElasticityManoj Lalita GoswamiNessuna valutazione finora

- StepanFormulation335 PDFDocumento2 pagineStepanFormulation335 PDFDiplomadoEnTecnicasCromatograficasNessuna valutazione finora

- Evonik Home Care Product CatalogueDocumento6 pagineEvonik Home Care Product Catalogue李雷Nessuna valutazione finora

- Brochure Matting Agents EDocumento60 pagineBrochure Matting Agents Efrox123Nessuna valutazione finora

- HDCS010 Heavy Duty Engine CleanerDocumento2 pagineHDCS010 Heavy Duty Engine CleanerTinasheNessuna valutazione finora

- Aerosol 101 Formulation Considerations Allen PriceDocumento48 pagineAerosol 101 Formulation Considerations Allen PriceAmalia RahmasariNessuna valutazione finora

- Benzoik Asit - Sodyum BenzoatDocumento16 pagineBenzoik Asit - Sodyum Benzoatferhat karaağaçNessuna valutazione finora

- TERGITOL Nonyphenol EthoxylateDocumento4 pagineTERGITOL Nonyphenol Ethoxylatevanhung68100% (1)

- Duroftal VPE 7186 Coil - e PDFDocumento24 pagineDuroftal VPE 7186 Coil - e PDFPratik MehtaNessuna valutazione finora

- Stabilized Chlorine Bleach in Alkaline Detergent Composition and Method of Making and Using The Same Us20060089285a1Documento21 pagineStabilized Chlorine Bleach in Alkaline Detergent Composition and Method of Making and Using The Same Us20060089285a1aranionNessuna valutazione finora

- Profil EngDocumento52 pagineProfil EngReza RhiNessuna valutazione finora

- Alcohol Ethoxylate GuideDocumento24 pagineAlcohol Ethoxylate GuideFadhli KusumaNessuna valutazione finora

- 1DS REWOPOL SB CS 50 K e 0211Documento2 pagine1DS REWOPOL SB CS 50 K e 0211Florentina OlaruNessuna valutazione finora

- 0901 B 8038091 CFC 5Documento6 pagine0901 B 8038091 CFC 5ForeverNessuna valutazione finora

- Rhodoline Ote 500Documento2 pagineRhodoline Ote 500ReginaldojoaquimNessuna valutazione finora

- Stepan Formulation 1166Documento2 pagineStepan Formulation 1166kus2002inNessuna valutazione finora

- Propylene Carbonate at Dow ChemicalsDocumento6 paginePropylene Carbonate at Dow Chemicalsjangri1098Nessuna valutazione finora

- Architectural EN-VINAVIL PDFDocumento36 pagineArchitectural EN-VINAVIL PDFSeafar YachtingNessuna valutazione finora

- Supreme: Premium Opacifying Mineral For Titanium Dioxide ExtensionDocumento2 pagineSupreme: Premium Opacifying Mineral For Titanium Dioxide Extensionkensley oliveiraNessuna valutazione finora

- Specialty Clarification & Coagulation Solutions: Chemistry For A Greener WorldDocumento6 pagineSpecialty Clarification & Coagulation Solutions: Chemistry For A Greener Worldnithinc10100% (1)

- Stepan Vehicle Care BrochureDocumento5 pagineStepan Vehicle Care BrochureRafael Santo SilvaNessuna valutazione finora

- US - Surfactants Nonionic - Specialty Ethoxylates Based On Short Chain AlcoholsDocumento20 pagineUS - Surfactants Nonionic - Specialty Ethoxylates Based On Short Chain AlcoholsARTHA -LESTARINessuna valutazione finora

- Multifunctional Additives: For Paints and CoatingsDocumento2 pagineMultifunctional Additives: For Paints and Coatingspandep22Nessuna valutazione finora

- Rheology Modifiers Product Recommendations For EuropeDocumento2 pagineRheology Modifiers Product Recommendations For EuropeHamood AbdoNessuna valutazione finora

- TDS-955 Noverite AD 810 Polymer BrochureDocumento4 pagineTDS-955 Noverite AD 810 Polymer BrochureJulian David Leal Acosta100% (1)

- Polymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3Da EverandPolymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3Nessuna valutazione finora

- Handbook of Vinyl FormulatingDa EverandHandbook of Vinyl FormulatingRichard F GrossmanValutazione: 3 su 5 stelle3/5 (1)

- Issue #9 Printing and Graphics Science Group NewsletterDa EverandIssue #9 Printing and Graphics Science Group NewsletterNessuna valutazione finora

- Self-Cleaning Materials and Surfaces: A Nanotechnology ApproachDa EverandSelf-Cleaning Materials and Surfaces: A Nanotechnology ApproachWalid A. DaoudValutazione: 5 su 5 stelle5/5 (1)

- Modified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975Da EverandModified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975A. RomanovValutazione: 5 su 5 stelle5/5 (1)

- Reactol 5145 ADocumento1 paginaReactol 5145 AAlptekinNessuna valutazione finora

- VADocumento6 pagineVAAlptekinNessuna valutazione finora

- Dimethyl Carbonate Di Methyl EsterDocumento24 pagineDimethyl Carbonate Di Methyl EsterAlptekinNessuna valutazione finora

- Fatty Acid Oil CompositionDocumento10 pagineFatty Acid Oil CompositionĀĥMệd HĀşşanNessuna valutazione finora

- Dispers 628Documento1 paginaDispers 628AlptekinNessuna valutazione finora

- BASF Aerospace Materials OverviewDocumento2 pagineBASF Aerospace Materials OverviewAlptekinNessuna valutazione finora

- Polyurethane Amine Catalysts Guidelines For Safe Handling Amp Disposal EnglishDocumento19 paginePolyurethane Amine Catalysts Guidelines For Safe Handling Amp Disposal EnglishAlptekinNessuna valutazione finora

- Fats Oils PDFDocumento2 pagineFats Oils PDFAlptekinNessuna valutazione finora

- SynoliteDocumento3 pagineSynoliteAlptekinNessuna valutazione finora

- Easaqua TolonateDocumento11 pagineEasaqua TolonateAlptekinNessuna valutazione finora

- Conductive Coatings: Using Carbon NanotubesDocumento3 pagineConductive Coatings: Using Carbon NanotubesAlptekinNessuna valutazione finora

- TRFA MontRealDocumento11 pagineTRFA MontRealAlptekinNessuna valutazione finora

- CS1 Epoxy Curing AgentsDocumento21 pagineCS1 Epoxy Curing AgentsAlptekin100% (1)

- Honeywell ACumistA12 TdsDocumento1 paginaHoneywell ACumistA12 TdsAlptekinNessuna valutazione finora

- Paints and CoatingsDocumento22 paginePaints and CoatingsFatima LiaquatNessuna valutazione finora

- Sikalatex Pds enDocumento2 pagineSikalatex Pds ennidandiniNessuna valutazione finora

- Edexcel IAL Chemistry Organic Chem ReactionsDocumento3 pagineEdexcel IAL Chemistry Organic Chem ReactionsAyesha TauseefNessuna valutazione finora

- Plastic Processing TechniquesDocumento13 paginePlastic Processing TechniquesSagar DhageNessuna valutazione finora

- Liquid Thermoplastic Resinfor Tougher CompositesDocumento6 pagineLiquid Thermoplastic Resinfor Tougher Compositeshaolanwang.ac96gNessuna valutazione finora

- Finishes Brochure PDFDocumento5 pagineFinishes Brochure PDFrajatesh1Nessuna valutazione finora

- Duraline: Cleveland Coil For High Rise FirefightingDocumento2 pagineDuraline: Cleveland Coil For High Rise FirefightingBoyke SaptaNessuna valutazione finora

- No: Excipient Number of Times Excipients Used in Tablets Out of 200 UseDocumento22 pagineNo: Excipient Number of Times Excipients Used in Tablets Out of 200 UseSrikanth MNessuna valutazione finora

- Resource Responsible Use of Recycled Tire Rubber in Asphalt PavementsDocumento41 pagineResource Responsible Use of Recycled Tire Rubber in Asphalt PavementsKY PengNessuna valutazione finora

- Mil H 25579Documento22 pagineMil H 25579Senthil KumarNessuna valutazione finora

- Abrasive Wear Behavior of Graphite Filled E-Glass Fibre Reinforced Polyester CompositesDocumento4 pagineAbrasive Wear Behavior of Graphite Filled E-Glass Fibre Reinforced Polyester Compositesmsudheerm2002Nessuna valutazione finora

- What Is Petroleum ?: Introduction To Petroleum ChemistryDocumento5 pagineWhat Is Petroleum ?: Introduction To Petroleum ChemistryhatiniNessuna valutazione finora

- Lifting Supervisor and Engineer-Cranes SafetyDocumento43 pagineLifting Supervisor and Engineer-Cranes SafetyLan Tian100% (7)

- Spur - Gears - Metric - XLS: Tooth Normal ForceDocumento5 pagineSpur - Gears - Metric - XLS: Tooth Normal ForceTigistuNessuna valutazione finora

- Uranox™ EE4 X-50 - DSM PDFDocumento2 pagineUranox™ EE4 X-50 - DSM PDFمحمد مقلدNessuna valutazione finora

- 14.biomolecules KCET PYQsDocumento1 pagina14.biomolecules KCET PYQsPunith kumarNessuna valutazione finora

- Philips Phthalates ListDocumento21 paginePhilips Phthalates Listliang102009Nessuna valutazione finora

- There Is A Difference Between Tank MaterialsDocumento3 pagineThere Is A Difference Between Tank MaterialsReza KhajeNessuna valutazione finora

- p12 PDFDocumento1 paginap12 PDFRonal J Clavijo RNessuna valutazione finora

- Subject: Pharmacognosy: PHD Admission Test 2017 Question PaperDocumento10 pagineSubject: Pharmacognosy: PHD Admission Test 2017 Question PaperManish BudhrajaNessuna valutazione finora

- Hanser Publications - Bonten, Christian - Plastics Technology Introduction and Fundamentals-Hanser Publications (2019)Documento487 pagineHanser Publications - Bonten, Christian - Plastics Technology Introduction and Fundamentals-Hanser Publications (2019)hkiri aymenNessuna valutazione finora

- Estimating Architectural Works: Building Technology 4Documento28 pagineEstimating Architectural Works: Building Technology 4Joyse CabilingNessuna valutazione finora

- 10.short Questions and AnswersDocumento41 pagine10.short Questions and Answersananda narayanan100% (1)

- Organic Chemistry Questions and Answers - Volume I: July 2020Documento166 pagineOrganic Chemistry Questions and Answers - Volume I: July 2020Simona ButanNessuna valutazione finora

- (Materiales) Productos CNFDocumento18 pagine(Materiales) Productos CNFNicolás Felipe Reyes CerdaNessuna valutazione finora

- H2o2 20 70 ConcetrationDocumento3 pagineH2o2 20 70 Concetrationdaniel_12Nessuna valutazione finora

- Airo24 en WebDocumento8 pagineAiro24 en WebLievenVerraestNessuna valutazione finora

- ZMorph Materials LibraryDocumento101 pagineZMorph Materials Libraryaskey69Nessuna valutazione finora