Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

References Cited Robiatiorlial Movergents. Pat Least One Elaitigallybexaatrlid

Caricato da

mohammadreza91Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

References Cited Robiatiorlial Movergents. Pat Least One Elaitigallybexaatrlid

Caricato da

mohammadreza91Copyright:

Formati disponibili

Unlted States Patent [191

[11] Patent Number:

Mody

[45]

Date of Patent:

4,979,570

Dec. 25, 1990

[54] INFLATABLE TOOL WITH RIB EXPANSION

SUPPORT

Primary Examiner-William P. Neuder

Attorney, Agent, or FirmJackson & Walker

[75] Inventor:

[73] Assignee:

[57]

ABSTRACT

An apparatus, such as a packer or bridge plug, and

Rustom K. Mody, Houston, Tex.

Bake! Hughes Inwqmmted,

Houston Tel

[21] APPL No_; 442,169

_

[22] Flled

[51]

method of use, are provided for introduction into a

subterranean well on a conduit. The apparatus has a

cylindrical housing which may have upper and lower

No" 28 1989

Int. Cl. .......................................... .. E213 33/127

collars. An elastomeric seal is disposed around the exte

rior of the housing with a series of longitudinally ex

[52] US. Cl. .................................. .. 166/387; 166/187;

277/34

[58] Field of Search ................ .. 166/387, 187; 277/34,

277/34-6

tending ribs radially positioned around the housing. The

ribs are outwardly and ?exibly movable from retracted

to expanded positions to anchor the apparatus in the

well thereby resisting at least one of longitudinal and

[56]

References Cited

U's' PATENT DOCUMENTS

3,289,761 12/1966 Smith et al. ................... .. 166/187 X

2223,32

,

x39 -------- -one

robiatiorlial movergents. Pat least one elaitigallybexaatrlid

e etiscame

t eextenoro t en s.

en

body, is moved for sealing engagement within the well

by applicat?m of ?uid, the belt expands and radially

........ ..

4,413,653 11/1983 Carter Jr. ......

aroun

the sealing element, which includes a tubular elastic

conforms the ?exing movement of the nbs.

4,768,590

4,832,120 9/1988

5/1989 Sanford

Coronadoet ....................

al.

.. 277/ 34 X

9 Claims, 2 Drawing Sheets

:03

120A

I20

IOOB

US. Patent

Dec. 25, 1990

Sheet 2 of2

4,979,570

4,979,570

tive to the conduit which carries the apparatus into the

INFLATABLE TOOL WITH RIB EXPANSION

SUPPORT

BACKGROUND OF THE INVENTION

1. Field of the Invention

The invention relates to in?atable devices, such as

packers or bridge plugs, for use in subterranean wells.

2. Brief Description of the Prior Art

In the drilling, completion or workover operations of

subterranean wells, it often becomes desirable to isolate

one section of the well bore from another section of the

well bore. In such event, a sealing tool, commonly re

ferred to as a well packer, bridge plug, or the like, is

used. Those skilled in the art are well familiar with such

tools which have varying con?gurations.

One type of such well packer is an in?atable well

packer which is run in the well on tubing wire line, or

well. An elastomeric sealing element is disposed around

the exterior of the housing. Typically, the apparatus

will also include an inner tubular elastic body longitudi

5 nally extending between the collars. Anchoring means

are provided comprising a series of longitudinally ex

tending rib-like members which are radially positioned

around the housing and extending between the collar

members. The anchoring means may extend from one of

the collar members to the sealing element, or may ex

tend from each of the collars to the scaling element.

Alternatively, the anchoring means may extend from

each of the collars through the sealing element, or from

each of the collars between the sealing element and the

tubular elastic body. The anchoring means is outwardly

?exibly movable from a ?rst retracted position during

running in of the apparatus into the well to a second

expanded position during sealing of the apparatus

the like, and is sealingly engagable with the interior of

within the well for anchoring engagement of the appa

easing set within the well, or, if the well is not set with 20 ratus at a location within the well to thereby resist at

casing, with the interior well bore wall, by means of

least one of longitudinal and rotational movements of

application of well or other ?uid under pressure to

the apparatus at that location.

cause a tubular elastic body to expand radially out

Elastically expandable belt means are carried around

wardly. Such bodies are typically reinforced with a

the exterior of the anchoring means and are spaced

reinforcing sheath which has, in turn, secured around its 25 between the in?atable elastomeric element at each of

exterior, approximate medial portion, a hardened rub

the collars, whereby upon in?ation of the elastomeric

ber element which is the packing component, itself.

element, the belt means expands and radially conforms

Representative of such con?gurations can be found in

the ?exing movement of the anchoring means from the

patents assigned to Lynes, Inc., such as U.S. Pat. Nos.

retracted to the expanding positions to abate the ten

3,604,732, and 3,837,947.

In recent years, some in?atable tools have been pro

dency of the anchoring means to kink or cut or other

wise cause abrasive action relative to the surface and/or

vided in designs in which the reinforcing ribs do not

interior of the tubular elastic body and/or the sealing

carry around their exterior the hardened rubber packer

element.

'

component such that when the apparatus is in?ated to

The

apparatus

is run into the well on a tubular con

35

set the device within the well bore, the reinforcing

duit to a pre-determined location. Thereafter, an in?a

component radially expands to act as an anchor against

tion ?uid is introduced into the apparatus in a known

longitudinal and/or rotational movements of the appa

manner to in?ate the apparatus to cause the anchoring

ratus in the well. In many such con?gurations, it has

means to radially expand outwardly whereby the belt

been found that the inflation of the tubular elastic body

will cause the reinforcing component to radially expand 40 means conforms the ?exing movement of the anchoring

means. In?ation is continued until the elastomeric seal

such that the reinforcing component kinks as the ribs

ing element is sealingly engaged with the interior wall

move outwardly such as do petals of a ?ower. Also, the

of the well bore or, when casing has been run, the inter

in?ation of tubular elastic body will cause uneven cir

nal diameter of the casing, to thereby isolate one portion

cumferential overlap of the reinforcing components

such that some of the reinforcing components may not 45 of the well from another portion of the well.

overlap as the ribs move outwardly creating an extru

BRIEF DESCRIPTION OF THE DRAWINGS

sion gap between the reinforcing components. When

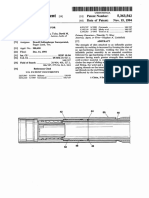

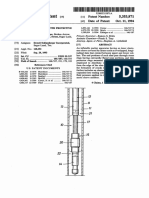

FIG. 1 is a longitudinally extending sectional view

this occurs, the tubular elastic body will become vulner

showing the apparatus run into the well prior to the

able to cutting extrusion and abrasion if it is disposed

setting action.

between ribs during such action, resulting in a loss or

FIG. 2 is a view similar to that of FIG. 1 showing the

decrease in in?ation pressure and, in turn, he integrity

apparatus as it is being moved to its set position.

of the seal established by the setting of the packer at

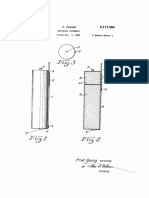

FIG. 3 is a perspective view of the elastic sealing

such position within the well bore.

The present invention is directed toward an abate

ment of such problem by providing an apparatus and

method wherein the expansion of the ribs is assisted by

element and the belt means in the position of the tool as

55 shown in FIG. 1.

FIG. 4 is a view similar to that of FIG. 3, illustrating

means of an expansion control belt surrounding the

exterior of the ribs to conform their radial expansion

the action of the tubular elastic body, the anchoring

movements.

position shown in FIG. 2.

means and the belt means as the tool is moved to the

DESCRIPTION OF THE PREFERRED

EMBODIMENTS

With reference to the drawings, there is disclosed an

apparatus 10 positioned within a well bore WB and

troduceable into a subterranean well on a tubular con

duit. The well may be cased or uncasecl hole. The appa 65 carried thereon on a tubular conduit TC. The apparatus

10 is comprised of a mandrel 100 together with an upper

ratus has a housing which may be de?ned with upper

circumferentially extending collar member 101 at its

and lower collar members. Means, such as threads, are

provided for securing the housing of the apparatus rela

uppermost end and a companion collar 102 at its lower

SUMMARY OF THE INVENTION

The present invention provides an apparatus and

method of use thereof with the apparatus being in

4,979,570

the strips and their arrangement in forming the anchor

most end. The top collar 101, has threads 104, for

threadably engaging the apparatus 10 to members ex

tending a tubular conduit TC. Additionally, the top of

the mandrel 100 is also threadably engaged to the tubu

lar conduit connection TC at connection 100a. The

mandrel 100 also has a series of injection portions 100c

the strips will overlap the next adjacent strip when the

inflatable elastic body 105 is de?ated and each strip will

overlap the next adjacent strip when the in?atable

member 105 is in?ated, thus forming the reinforcing

for communicating in?ation ?uid during setting of the

sheath-like structure at all times.

ing means or reinforcing sheath 108 is such that each of

apparatus 10.

As discussed earlier, the length of the ribs 108a and

their comparative thinness may result in a tendency to

The lower collar 102 normally is attached to a seal

sub 120 having seal 120a which slides up the mandrel 0 kink during in?ation of the tubular elastic body 105

thus permitting the body 105 to come in between re

100 as the apparatus 10 is being set within the well.

Threads 100b are provided on the lower end of the

spective rib members 108a, thus causing punctures

mandrel 100 for securement to an additional section of

within the elastic body 105 and a loss in the integrity of

tubing conduit or another tool.

the sealing element 113 as the in?ation of the apparatus

It will, of course, be appreciated that the apparatus 10 5 10 is adversely effected.

Depending upon the use for which the apparatus 10 is

constructed, the base material of the ribs 1080 may be of

flat braided wire impregnated with elastomer or plastic,

strips of plain woven fiberglass which may or may not

be impregnated with elastomer or plastic, strips of plain

or woven nylon, strips of spring steel, strips of metal,

such as ordinary mild steel, stainless steel, or other per

may be carried at the lowermost end of the tubular

conduit TC, and if there are no other tools to be carried

into the well bore WB below the apparatus 10, the

threads 100b will not be used. Alternatively, the appara

tus 10 may be disposed on the tubular conduit TC be

tween members thereof, such that the threads 1000

secure the apparatus 10 to the tubular conduit TC and a

tubular member of the conduit TC extends below the

apparatus 10 and is secured thereby at threads 100b.

Around the mandrel 100 is carried a longitudinally 25

extending tubular elastic body member 105 secured

within the upper collar 101 at its uppermost end by

means of an upper securing ring 106 snugly engaging

the body 105 in combination with an upper lock ring

member 109. Likewise, the lowermost end of the tubu

lar elastic body 105 is secured at its lowermost end by

means of a companion lower securing ring 107 juxtapo

sitioning the lowermost end of the tubular elastic body

105 within the lower collar 102 by means of the lower

> lock ring 110.

Implaced circumferentially around the tubular elastic

manently deformable material, strips of other plain or

woven material, such as te?on or other plastics, depend

ing upon the pressure to which the in?atable apparatus

10 is to be in?ated.

The sealing element 113 is of known construction,

and may be any hardened rubber or other sealing mate

rial, such as plastic, which is bonded or otherwise per

manently secured around the anchoring means 108.

As shown, the apparatus 10 contains upper and lower

donut shaped circumferentially extending belt members

111, 112 respectively positioned adjacent the sealing

element 113 and between the upper and lower collar

35 members 101, 102. The belts 111, 112 should be formed

of a rubber or other elasticized material which will

body 105 is an anchoring means 108 comprised of rib

conform to the radial expansion of the rib members 1080

as the anchoring means 108 is ?exed outwardly during

elements 1080. As shown, the anchoring means 108 has

in?ation of the tubular elastic body 105. By use of the

its uppermost end extending within the interior of the

upper collar 101 and secured relative thereto by weld

belt members 111, 112, the kinking of the ribs 1080 is

ing or other conventional securing means to the lock

resisted to permit conformed and uniformed radial out

ring 109. The lowermost end of the anchoring means

ward expansion of the ribs 120 without cutting or tear

108 is snugly secured within the interior of the lower

ing into the elastic body 105.

collar 102 and is likewise affixed to the lower lock ring

Although preferable, it is not necessary that the belts

110. The anchoring means 108 is shown with a sealing 45 111, 112 be placed medially between the sealing element

element 113 or packer implaced in the medial position

113 and the respective collars 101, 102. The belts 111,

112 may be placed at any position along the anchoring

of the anchoring means 108. As shown, each of the ribs

108a longitudinally extend from the interior of the

means 108 but, preferably, will be positioned adjacent

the medial point between the sealing element 113 and

upper collar 101 to the interior of the lower collar 102

and through or interior of the sealing element 113.

the respective collar 101, 102.

It will be appreciated that the ribs 108a need not be

The belts may be placed on the tool in any desired

one continuous length and could be positioned such that

number and may be positioned thereon as desired. The

they extend from the upper collar 101 to the sealing

construction, number and location of the belts 111, 112

should be such that they will not adversely affect the

element 113 or, alternatively, from the lower collar 102

integrity of the seal provided by the sealing element 113

to the sealing element 113, depending upon the anchor

with the well bore WB.

ing and/or other objectives to be served by actuation of

the means 108.

During setting, the ribs may expand sufficient to pro

The anchoring means 108 may be formed of any

vide anchoring contact with the well bore, although the

suitable material to accomplish the results desired and

view depicted in FIG. 2 does not illustrate such ribs

which will withstand the temperatures encountered

completed extended to such position.

during operation of the apparatus 10 within the well

During the setting of the apparatus 10, ?uid will be

bore WB. The anchoring means 108 is also a reinforcing

introduced through the tubular elastic body 105 in a

sheath for the tubular elastic body 105 and is preferably

known manner. The belts 111, 112, urge the anchoring

formed of longitudinally extending strips or ribs 1080

means 108 into the retracted, or running position as

which are of a suitable length so that they extend be 65 shown in FIG. 1, while expansion of the tubular elastic

body 105 urges the anchoring means 108 outwardly.

tween each of the collars 101, 102. It will be noted that

each of the longitudinally extending ribs 108a circum

The combination of these two forces assist the anchor

ferentially overlap an adjacent rib 1080. The width of

ing means 108 during the setting procedure such that

4,979,570

(e) elastically expandable belt means carried around

the ribs 108a will not ?ex or bend and are thereby sup

ported to prevent kinking, Le. a ?exing or bending

the exterior of said anchoring means, whereby

upon in?ation of said elastomeric element, the belt

means expands and radially conforms the ?exing

action which includes some axial rotation of the rib 1080

which might cause the tubular elastic body 105 to be

urged in between rib members 108a and pinched to

cause a hole or slight in?ection in the body 105 ulti

mately resulting in a puncture or leak.

Although the invention has been described in terms

of speci?ed embodiments which are set forth in detail, it

should be understood that this is by illustration only and

that the invention is not necessarily limited thereto,

movement of the anchoring means from the re

tracted to the expanded positions.

4. The apparatus of claim 3 wherein the anchoring

means comprises a series of thin metal strips.

5. Apparatus for introduction into a subterranean

well on a conduit, comprising:

since alternative embodiments and operating techniques

(a) a cylindrical housing including upper and lower

collar members;

will become apparent to those skilled in the art in view

of the disclosure. Accordingly, modi?cations are con

(b) means for securing said housing relative to said

templated which can be made without departing from 15

(c) an in?atable elastomeric element disposed around

the exterior of said housing;

(d) anchoring means comprising a series of longitudi

the spirit of the described invention.

What is claimed and desired to be secured by Letters

Patent is:

1. Apparatus for introduction into a subterranean

20

well on a conduit, comprising:

(a) a cylindrical housing including upper and lower

collar members;

(b) means for securing said housing relative to said

conduit;

(c) an inflatable elastomeric element disposed around

the exterior of said housing;

(d) anchoring means comprising a series of longitudi

conduit;

nally extending rib members and outwardly ?exi

bly movable from a ?rst retracted position during

running in of said apparatus into said well to a

second expanded position during setting of said

apparasis within said well, for anchoring engage

ment 0 said apparatus at a location within said well

25

nally extending rib members radially positioned

around said housing and extending between said 30

collar members and through said elastomeric ele

ment and outwardly ?exibly movable from a ?rst

to thereby resist at least one of longitudinal and

rotational movements of said apparatus at said lo

cation; and

(e) elastically expandable belt means carried around

the exterior of said anchoring means whereby upon

in?ation of said elastomeric element the belt means

expands and radially conforms a ?exing movement

of the anchoring means from the retracted to the

retracted position during running in of said appara

expanded positions.

tus into said well to a second expanded position

6. The apparatus of claim 5 wherein the anchoring

during setting of said apparatus within said well, 35 means comprises a series of thin metal strips.

for anchoring engagement of said apparatus at a

7. Apparatus for introduction into a subterranean

location within said well to thereby resist at least

well on a conduit, comprising:

one of longitudinal and rotational movements of

said apparatus at said location; and

(a) upper and lower collar members;

(e) elastically expandable belt means carried around 40

the exterior of said anchoring means and spaced

between said inflatable elastomeric element and

anchoring means from the retracted to the ex

nally extending rib members radially positioned

panded positions.

2. The apparatus of claim 1 wherein the anchoring

means comprises a series of thin metal strips.

3. Apparatus for introduction into a subterranean 50

well on a conduit, comprising:

(a) a cylindrical housing including upper and lower

(b) means for securing said housing relative to said

55

(c) an in?atable elastomeric element disposed around

the exterior of said housing;

(d) anchoring means comprising a series of longitudi

nally extending rib members radially positioned

around said housing and extending from at least

one of said collar members and outwardly ?exibly

movable from a first retracted position during run

ning in of said apparatus into said well to a second

expanded position during setting of said apparatus

within said well, for anchoring engagement of said 65

apparatus at a location within said well to thereby

resist at least one of longitudinal and rotational

movements of said apparatus at said location; and

around said apparatus and extending from at least

one of said collar members to said elastomeric seal

ing element and outwardly ?exibly movable from a

?rst retracted position during running in of said

apparatus into said well to a second expanded posi

tion during setting of said apparatus within said

well for anchoring engagement of said apparatus at

conduit;

conduit;

(0) an inner tubular elastic body longitudinally ex

tending between said collars;

(d) elastomeric sealing means disposed around the

exterior of said apparatus;

(e) anchoring means comprising a series of longitudi

each of said collars, whereby upon in?ation of said

elastomeric element, the belt means expands and

radially conforms the flexing movement of the

collar members;

(b) means for securing said apparatus relative to said

a location within said well to thereby resist at least

one of longitudinal and rotational movements of

said apparatus at said location; and

(f) elastically expandable belt means carried around

the exterior of said anchoring means whereby,

upon in?ation of said inner elastic body, the belt

means expands and radially conforms the ?exing

movement of the anchoring means from the re

tracted to the expanded positions and resists cut~

ting of said tubular elastic body.

8. The apparatus of claim 7 wherein the anchoring

means comprises a series of thin metal strips.

9. Method of sealing a portion of a subterranean well,

comprising the steps of:

4,979,570

8

one of longitudinal and rotational movements of

said apparatus at said location; and

(l) assembling at the top of the well a conduit having

af?xed thereon a sealing apparatus, said sealing appa

ratus comprising:

(a) upper and lower collar members;

(b) means for securing said apparatus relative to said

(f) elastically expandable belt means carried around

the exterior of said anchoring means whereby,

upon in?ation of said inner elastic body, the belt

means expands and radially conforms the ?exing

conduit;

movement of the anchoring means from the re

(c) an inner tubular elastic body longitudinally ex

tracted to the expanded positions and resists cut

tending between said collars;

ting

of said tubular elastic body;

(d) elastomeric sealing means disposed around the

10 (2) running said apparatus on said conduit within said

exterior of said apparatus;

well to a pre-determinable position within said well;

(e) anchoring means comprising a series of longitudi

(3) actuating said sealing apparatus by introduction of

nally extending rib members radially positioned

?uid to expand said tubular elastic body whereby the

around said apparatus and extending from at least

belt means expands to radially conform the ?exing

one of said collar members to said elastomeric seal

ing element and outwardly ?exibly movable from a

?rst retracted position during running in of said

apparatus into said well to a second expanded posi

tion during setting of said apparatus within said

well for anchoring engagement of said apparatus at

movement of the anchoring means from the retracted

to the expanded positions to anchor the apparatus to

resist at least one of longitudinal and rotational move

ments of said apparatus, and said elastomeric sealing

20

element is in sealing position relative to said well bore

at said position.

i

a location within said well to thereby resist at least

25

30

35

45

50

55

65

Potrebbero piacerti anche

- Polish Top LinerDocumento12 paginePolish Top LinerLenis CeronNessuna valutazione finora

- Viii/Ii/Ii": United States Patent (191 (11) Patent Number: 4,708,208Documento9 pagineViii/Ii/Ii": United States Patent (191 (11) Patent Number: 4,708,208mohammadreza91Nessuna valutazione finora

- United States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985Documento5 pagineUnited States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985mohammadreza91Nessuna valutazione finora

- Us 5531545Documento10 pagineUs 5531545Mark EdowaiNessuna valutazione finora

- Us 5271461Documento18 pagineUs 5271461ask101Nessuna valutazione finora

- Ullltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992Documento7 pagineUllltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992mohammadreza91Nessuna valutazione finora

- US5303813Documento7 pagineUS5303813AdailsonNessuna valutazione finora

- 11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555Documento5 pagine11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555mohammadreza91Nessuna valutazione finora

- Us 4676137Documento6 pagineUs 4676137fghdfjerNessuna valutazione finora

- H!!!!! - EEHHE) : Nonononononon Niinin 'Documento4 pagineH!!!!! - EEHHE) : Nonononononon Niinin 'Hadi KoraniNessuna valutazione finora

- 螺栓枪口装步枪 PDFDocumento7 pagine螺栓枪口装步枪 PDFJin SongNessuna valutazione finora

- Us 5988287Documento14 pagineUs 5988287mohammadreza91Nessuna valutazione finora

- Inflatable Packer Reinforcement MethodDocumento5 pagineInflatable Packer Reinforcement Methodmohammadreza91Nessuna valutazione finora

- Conveyor Belt Transfers Ice Bodies From Storage to Dispensing AreaDocumento6 pagineConveyor Belt Transfers Ice Bodies From Storage to Dispensing AreaRodrigoPomaNessuna valutazione finora

- United States "Patents PDFDocumento17 pagineUnited States "Patents PDFTien Nguyen VanNessuna valutazione finora

- United States Patent: BittnerDocumento8 pagineUnited States Patent: BittneronlyaqmalNessuna valutazione finora

- Method of Increasing Strength of Welded Slat Assembly for Inflatable PackersDocumento6 pagineMethod of Increasing Strength of Welded Slat Assembly for Inflatable Packersmohammadreza91Nessuna valutazione finora

- United States Patent: Primary Examiner - (74) Attorney, Agent, or FirmDocumento9 pagineUnited States Patent: Primary Examiner - (74) Attorney, Agent, or FirmAdriana Daniela SanduNessuna valutazione finora

- United States Patent (19) (11) 4,298,078Documento9 pagineUnited States Patent (19) (11) 4,298,078lfilippiniNessuna valutazione finora

- 915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWDocumento15 pagine915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWMetin MehelNessuna valutazione finora

- United States Patent (19) 11) Patent Number: 4,811,792Documento8 pagineUnited States Patent (19) 11) Patent Number: 4,811,792MuhammadNessuna valutazione finora

- Tug Boat Cover Rolling Apparatus Optimized for SEODocumento5 pagineTug Boat Cover Rolling Apparatus Optimized for SEOاحمد عبدالكريمNessuna valutazione finora

- Vde 8C: MJWJDLZMDocumento7 pagineVde 8C: MJWJDLZMAmlan DasNessuna valutazione finora

- Filed Oct. 22, 1951: P. C. HuttonDocumento5 pagineFiled Oct. 22, 1951: P. C. HuttonGalo YambayNessuna valutazione finora

- J. H. Wilson: Inventor.Documento6 pagineJ. H. Wilson: Inventor.lfilippiniNessuna valutazione finora

- United States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f PatentDocumento10 pagineUnited States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f Patentmohammadreza91Nessuna valutazione finora

- Title: Bedsheet TensionerDocumento6 pagineTitle: Bedsheet TensionerRA Mikael Master MindNessuna valutazione finora

- Us2996100 PDFDocumento8 pagineUs2996100 PDFerzrzretgertfertgeNessuna valutazione finora

- Deç. 7, 1948. F, A, Gaspar ' - 2,455,469: Filed Oct. 1, 1946Documento3 pagineDeç. 7, 1948. F, A, Gaspar ' - 2,455,469: Filed Oct. 1, 1946david19775891Nessuna valutazione finora

- United States: (12) Patent Application Publication (10) Pub. No.: US 2006/0253080 A1Documento5 pagineUnited States: (12) Patent Application Publication (10) Pub. No.: US 2006/0253080 A1seansotoNessuna valutazione finora

- United States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,121Documento7 pagineUnited States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,12112348Nessuna valutazione finora

- United States Patent (19) : 11) Patent Number: 5,181,477 45 Date of Patent: Jan. 26, 1993Documento10 pagineUnited States Patent (19) : 11) Patent Number: 5,181,477 45 Date of Patent: Jan. 26, 199312348Nessuna valutazione finora

- LL L'L///"/"Z//: (12) United States PatentDocumento4 pagineLL L'L///"/"Z//: (12) United States PatentwewewewNessuna valutazione finora

- CH10Documento17 pagineCH10ylj dsNessuna valutazione finora

- USRX52Documento3 pagineUSRX52nmfzkwy2rNessuna valutazione finora

- Conveyor Belt Maintenance Manual 2010 PDFDocumento46 pagineConveyor Belt Maintenance Manual 2010 PDFkhuong_uno100% (3)

- System For Shooting Using Compressed Gas - US Patent 5909000Documento21 pagineSystem For Shooting Using Compressed Gas - US Patent 5909000Aride4everNessuna valutazione finora

- 'Fr'Edlyqqj/G' Inventor.: Aug. 29, 1939. F - Young 2,171,384Documento5 pagine'Fr'Edlyqqj/G' Inventor.: Aug. 29, 1939. F - Young 2,171,384kahj juliNessuna valutazione finora

- US5513743Documento6 pagineUS5513743AdailsonNessuna valutazione finora

- Tube Saport PDFDocumento4 pagineTube Saport PDFjr110livecomNessuna valutazione finora

- Us 6131519Documento4 pagineUs 6131519dgfhjsdg hfsdhyjNessuna valutazione finora

- SO1210 CALM Buoy: The MONOBUOY Company LTDDocumento12 pagineSO1210 CALM Buoy: The MONOBUOY Company LTDgladimar100% (2)

- Us 4812080Documento10 pagineUs 4812080JonNessuna valutazione finora

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Documento7 pagineSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaNessuna valutazione finora

- United States Patent (191: Durand Et AlDocumento8 pagineUnited States Patent (191: Durand Et AlCarter TatumNessuna valutazione finora

- United States Patent (19) 11 Patent Number: 5,626,614: Hart 45 Date of Patent: May 6, 1997Documento10 pagineUnited States Patent (19) 11 Patent Number: 5,626,614: Hart 45 Date of Patent: May 6, 1997Alex KattamisNessuna valutazione finora

- US Patent 7090236 Land SailingDocumento8 pagineUS Patent 7090236 Land SailingDimas MaulanaNessuna valutazione finora

- Aerial Gunnery Target (1980)Documento9 pagineAerial Gunnery Target (1980)CAP History LibraryNessuna valutazione finora

- United States Patent (19) : ZollingerDocumento8 pagineUnited States Patent (19) : Zollingermohammad dehghanfarsiNessuna valutazione finora

- Umted States Patent (19) (11) Patent Number: 4 957 424: Mitchell Et A1. (45) Date of Patent: Sep. 18, 1990Documento17 pagineUmted States Patent (19) (11) Patent Number: 4 957 424: Mitchell Et A1. (45) Date of Patent: Sep. 18, 1990adrianomc25Nessuna valutazione finora

- Filed Sept. 30, 1963: C. C. BrownDocumento8 pagineFiled Sept. 30, 1963: C. C. BrownyasamanNessuna valutazione finora

- Annex - A Search Report TitleDocumento3 pagineAnnex - A Search Report TitleJOHN STEPHEN NALUGONNessuna valutazione finora

- Method and Means For Adjusting The Elevation of Manhole Covers - MCCOY ARCHIBADocumento5 pagineMethod and Means For Adjusting The Elevation of Manhole Covers - MCCOY ARCHIBALandel SmithNessuna valutazione finora

- DEEP DRILLING TECHNIQUESDocumento4 pagineDEEP DRILLING TECHNIQUESTamara Muñoz SánchezNessuna valutazione finora

- United States Patent (19) : Putnam, Jr. Et Al. (11) 4,171,605Documento13 pagineUnited States Patent (19) : Putnam, Jr. Et Al. (11) 4,171,605kartikkeyyanNessuna valutazione finora

- Us4171605 PDFDocumento13 pagineUs4171605 PDFkartikkeyyanNessuna valutazione finora

- Definisi Komponen Wellhead Dan XtreeDocumento7 pagineDefinisi Komponen Wellhead Dan XtreeLuthfan Desmono Silalahi100% (1)

- Weaving Instruct I 01 AmerDocumento84 pagineWeaving Instruct I 01 Amersanyu33333Nessuna valutazione finora

- Shafting, Pulleys, Belting and Rope TransmissionDa EverandShafting, Pulleys, Belting and Rope TransmissionNessuna valutazione finora

- Us 20050077053Documento16 pagineUs 20050077053mohammadreza91Nessuna valutazione finora

- Us 5988287Documento14 pagineUs 5988287mohammadreza91Nessuna valutazione finora

- Us5353871 PDFDocumento4 pagineUs5353871 PDFmohammadreza91Nessuna valutazione finora

- Us 4406461Documento5 pagineUs 4406461mohammadreza91Nessuna valutazione finora

- Packer Sealing Element With Shape Memory MaterialDocumento8 paginePacker Sealing Element With Shape Memory Materialmohammadreza91Nessuna valutazione finora

- United States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f PatentDocumento10 pagineUnited States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f Patentmohammadreza91Nessuna valutazione finora

- Ullltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992Documento7 pagineUllltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992mohammadreza91Nessuna valutazione finora

- Us 4406461Documento5 pagineUs 4406461mohammadreza91Nessuna valutazione finora

- Us 2843208Documento7 pagineUs 2843208mohammadreza91Nessuna valutazione finora

- US5439053 Thickness PDFDocumento6 pagineUS5439053 Thickness PDFmohammadreza91Nessuna valutazione finora

- Inflatable Packer Reinforcement MethodDocumento5 pagineInflatable Packer Reinforcement Methodmohammadreza91Nessuna valutazione finora

- 0 - Rank One Convexification Approach For The Modeling of Magnetic Shape Memory Response PDFDocumento2 pagine0 - Rank One Convexification Approach For The Modeling of Magnetic Shape Memory Response PDFmohammadreza91Nessuna valutazione finora

- Method of Increasing Strength of Welded Slat Assembly for Inflatable PackersDocumento6 pagineMethod of Increasing Strength of Welded Slat Assembly for Inflatable Packersmohammadreza91Nessuna valutazione finora

- Ullltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992Documento7 pagineUllltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992mohammadreza91Nessuna valutazione finora

- 1286 - Giant Magnetic-field-Induced Strain in NiMnGa Seven-Layered Martensitic PhaseDocumento3 pagine1286 - Giant Magnetic-field-Induced Strain in NiMnGa Seven-Layered Martensitic Phasemohammadreza91Nessuna valutazione finora

- Unlted States Patent (10) Patent No.: US 7,621,322 B2Documento9 pagineUnlted States Patent (10) Patent No.: US 7,621,322 B2mohammadreza91Nessuna valutazione finora

- 79 - Magnetic - Eld-Induced Superelasticity of Ferromagnetic Thermoelastic Martensites Experiment and Modeling PDFDocumento8 pagine79 - Magnetic - Eld-Induced Superelasticity of Ferromagnetic Thermoelastic Martensites Experiment and Modeling PDFmohammadreza91Nessuna valutazione finora

- 268-Giant Field-Induced Reversible Strain in Magnetic Shape Memory NiMnGa Alloy PDFDocumento3 pagine268-Giant Field-Induced Reversible Strain in Magnetic Shape Memory NiMnGa Alloy PDFmohammadreza91Nessuna valutazione finora

- 86 - Voltage Generation Induced by Mechanical Straining in Magnetic Shape Memory Materials PDFDocumento5 pagine86 - Voltage Generation Induced by Mechanical Straining in Magnetic Shape Memory Materials PDFmohammadreza91Nessuna valutazione finora

- 11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555Documento5 pagine11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555mohammadreza91Nessuna valutazione finora

- 55 - Stress-And Magnetic-Field-Induced Variant Rearrangement in Ni-Mn-Ga Single Crystals With Seven-Layered Martensitic Structure PDFDocumento4 pagine55 - Stress-And Magnetic-Field-Induced Variant Rearrangement in Ni-Mn-Ga Single Crystals With Seven-Layered Martensitic Structure PDFmohammadreza91Nessuna valutazione finora

- 75 - Modelling Detwinning of Martensite Platelets Under Magnetic and (Or) Stress Actions On Ni-Mn-Ga Alloys PDFDocumento3 pagine75 - Modelling Detwinning of Martensite Platelets Under Magnetic and (Or) Stress Actions On Ni-Mn-Ga Alloys PDFmohammadreza91Nessuna valutazione finora

- 142 - Quantitative Model of Large Magnetostrain Effect in Ferromagnetic Shape Memory Alloys PDFDocumento10 pagine142 - Quantitative Model of Large Magnetostrain Effect in Ferromagnetic Shape Memory Alloys PDFmohammadreza91Nessuna valutazione finora

- 1577 - Energy Harvesting Vibration Sources For Microsystems ApplicationsDocumento21 pagine1577 - Energy Harvesting Vibration Sources For Microsystems Applicationsmohammadreza91Nessuna valutazione finora

- 18 - A Three Dimensional Phenomenological Model For Magnetic Shape Memory AlloysDocumento7 pagine18 - A Three Dimensional Phenomenological Model For Magnetic Shape Memory Alloysmohammadreza91Nessuna valutazione finora

- 967 - 6% Magnetic-Field-Induced Strain by Twin-Boundary Motion in Ferromagnetic Ni-Mn-GaDocumento4 pagine967 - 6% Magnetic-Field-Induced Strain by Twin-Boundary Motion in Ferromagnetic Ni-Mn-Gamohammadreza91Nessuna valutazione finora

- 1286 - Giant Magnetic-field-Induced Strain in NiMnGa Seven-Layered Martensitic PhaseDocumento3 pagine1286 - Giant Magnetic-field-Induced Strain in NiMnGa Seven-Layered Martensitic Phasemohammadreza91Nessuna valutazione finora

- DMDave - Dungeons & Lairs 43 - Vampire Undercroft - Free VersionDocumento10 pagineDMDave - Dungeons & Lairs 43 - Vampire Undercroft - Free VersionFrédéric GenestNessuna valutazione finora

- Hesmon 64 Instruction Manual PDFDocumento20 pagineHesmon 64 Instruction Manual PDFa sNessuna valutazione finora

- YLE Practice Tests Plus Starter SB 2nd EdDocumento79 pagineYLE Practice Tests Plus Starter SB 2nd EdAli Raza100% (17)

- Magic Treehouse Carnival at Candlelight WorksheetDocumento21 pagineMagic Treehouse Carnival at Candlelight Worksheetsarah_jcfreak3767100% (2)

- JR HydrantBroch - spm2147 1411Documento36 pagineJR HydrantBroch - spm2147 1411perezismaelNessuna valutazione finora

- IsoDocumento8 pagineIsochandramohanNessuna valutazione finora

- Java™ Speech Grammar Format Specification: Version 1.0 - October 26, 1998Documento37 pagineJava™ Speech Grammar Format Specification: Version 1.0 - October 26, 1998letsdoitmailboxNessuna valutazione finora

- Creativecommons What Is Creative Commons EngDocumento1 paginaCreativecommons What Is Creative Commons EngCreative Commons95% (19)

- Motion To File Amicus in Intel v. Fortress 3nov2020Documento5 pagineMotion To File Amicus in Intel v. Fortress 3nov2020Jennifer M GallagherNessuna valutazione finora

- IEEE Standard For Configuration Management in Systems and Software EngineeringDocumento71 pagineIEEE Standard For Configuration Management in Systems and Software EngineeringDevaraj Sathasivam100% (1)

- Burnette Sonny - Jazzscapes N°5 - We Be Beboppin'Documento18 pagineBurnette Sonny - Jazzscapes N°5 - We Be Beboppin'olivier giraudNessuna valutazione finora

- Adaptive Sonics v. GN Resound A/S Et. Al.Documento8 pagineAdaptive Sonics v. GN Resound A/S Et. Al.PriorSmartNessuna valutazione finora

- CD Process Concepts GuideDocumento166 pagineCD Process Concepts GuideLuis140108Nessuna valutazione finora

- IIPRD Sample Valuation ReportDocumento34 pagineIIPRD Sample Valuation ReportAba JifarNessuna valutazione finora

- IconicsoloDocumento23 pagineIconicsoloartlabor1001Nessuna valutazione finora

- Module 4 - Lesson 2 Student Sample Projects Using Open-Ended ToolsDocumento25 pagineModule 4 - Lesson 2 Student Sample Projects Using Open-Ended ToolsLorelle S. Cagande100% (1)

- Permatex Prussian Blue Technical Data SheetDocumento1 paginaPermatex Prussian Blue Technical Data SheetMartin LundeenNessuna valutazione finora

- Touareg Body Manual: Student ReferenceDocumento39 pagineTouareg Body Manual: Student Referenceovidiu19686867% (3)

- Creating New Portal Display RulesDocumento14 pagineCreating New Portal Display RulesAnonymous Yw2XhfXvNessuna valutazione finora

- Lion QueenDocumento37 pagineLion Queenmaba rrNessuna valutazione finora

- US1826727.PDF Energy From AirDocumento2 pagineUS1826727.PDF Energy From AirMihai DanielNessuna valutazione finora

- ASTM C 289 ASR Aggregates Chemical MethodDocumento7 pagineASTM C 289 ASR Aggregates Chemical Methodsattiric100% (1)

- Shadowrun 6th World MapDocumento1 paginaShadowrun 6th World MapCalvin JamesNessuna valutazione finora

- Coursedescription PY RX2540M5 MNT WBTDocumento1 paginaCoursedescription PY RX2540M5 MNT WBTMỹ Linh NguyễnNessuna valutazione finora

- AQA Foundation SB AnswersDocumento85 pagineAQA Foundation SB AnswersFrancesco ZanettiNessuna valutazione finora

- The Life and Death of Andy Warhol PDFDocumento424 pagineThe Life and Death of Andy Warhol PDFIgor Ivković100% (3)

- AP Calculus 2003 FRQDocumento6 pagineAP Calculus 2003 FRQvkNessuna valutazione finora

- Jcpenney Portraits Digital Images: Copy Authorization FormDocumento1 paginaJcpenney Portraits Digital Images: Copy Authorization Formkaten3574Nessuna valutazione finora

- Chapter 7 Introduction To Intectual PropertyDocumento12 pagineChapter 7 Introduction To Intectual PropertyDaisy Jane Beltran Lulab100% (1)

- ABS CBN Vs GOZONDocumento2 pagineABS CBN Vs GOZONMikoNessuna valutazione finora