Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Acoustic 15 Nor PDF

Caricato da

Nagarjuna KonduruTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Acoustic 15 Nor PDF

Caricato da

Nagarjuna KonduruCopyright:

Formati disponibili

Sains Malaysiana 40(4)(2011): 379384

Effect of Aluminum Hydroxide Loading on the Compression Stress and Modulus,

Thermal Conductivity and Acoustic Properties of Palm-Based

Polyurethane Hybrid Composite

(Kesan Penambahan Aluminium Hidroksida Terhadap Tegasan dan Modulus Mampatan,

Kekonduksian Terma dan Sifat Akustik Komposit Hibrid Poliuretana Berasaskan Sawit)

NOR RABBIATUL ADAWIYAH NORZALI, KHAIRIAH HAJI BADRI* & MOHD ZAKI NUAWI

ABSTRACT

The effect of adding aluminum hydroxide (ATH) in the palm-based polyurethane hybrid composite was studied. The

compression stress and modulus, thermal conductivity and acoustic property were determined. The hybrid composite

was prepared by adding 10 wt% of oil palm empty fruit bunch fibre (EFB) followed by ATH at varying amount of 2, 4

and 6 wt% of the overall mass of the resin. The compression stress and modulus gave the highest values of 575 kPa and

2301 kPa, respectively at 2 wt% ATH. At 4 wt% ATH, the compression stress and modulus decreased to 431 kPa and 1659

kPa, respectively and further decreased at 6 wt% ATH to 339 kPa and 1468 kPa respectively. The k-value increased with

the increment of the ATH loading exhibited a poor thermal conductivity. Sound absorption analysis indicated that the

absorption coefficient was higher at higher frequency (4000 Hz) for all samples with PU-EFB/ATH with 4% ATH showed

the highest absorption coefficient.

Keywords: Acoustic property; aluminum hydroxide; palm-based polyurethane; thermal conductivity

ABSTRAK

Kesan penambahan aluminum hidroksida (ATH) ke dalam komposit hibrid poliuretana (PU) berasaskan sawit telah dikaji.

Tegasan dan modulus mampatan, kekonduksian terma dan sifat akustiknya ditentukan. Komposit hibrid PU disediakan

dengan menambahkan 10% bt serabut tandan kosong kelapa sawit (EFB) diikuti dengan penambahan ATH pada peratus

penambahan divariasikan pada 2, 4 dan 6% bt mengikut berat keseluruhan resin. Tegasan dan modulus mampatan

adalah pada nilai tertinggi pada penambahan 2% bt ATH iaitu masing-masing 338 kPa dan 2209 kPa. Pada 4% bt ATH,

tegasan dan modulus mampatan menurun kepada masing-masing 431 kPa dan 1659 kPa dan semakin menurun dengan

penambahan 6% bt ATH kepada masing-masing 379 kPa dan 1468 kPa. Nilai k meningkat dengan penambahan ATH

dan mempamerkan sifat kekonduksian terma yang lemah. Analisis serapan bunyi menunjukkan koefisien serapan yang

tinggi pada frekuensi tinggi (4000 Hz) untuk semua sampel dengan PU-EFB/ATH (4% ATH) menunjukkan pekali serapan

tertinggi.

Kata kunci: Aluminum hidroksida; kekonduksian terma; poliuretana berasaskan sawit; sifat akustik

INTRODUCTION

Polyurethane (PU) has been widely used in many fields

such as aerospace, construction, sports and furniture.

PU has many advantages for instance; high abrasion

resistance, tear strength, excellent shock absorption and

low density (Xu et al. 2008). PU foam has also been

widely used as a thermal insulator. Addition of natural

fibers as reinforcing fillers in polymeric materials has

been widely used recently because of their properties

which is environmental-friendly and cost effective.

These lignocellulosic fibers offer low cost, low density,

nonabrasive and enhanced energy recovery (Khairul

Anuar Mat Amin & Khairiah Haji Badri 2007) as well as

enhancing the mechanical strength of the bio-composites

formed (Badri et al. 2004; Badri et al. 2005; Rozman et

al. 2003).

Bio-composite is an organic material that is easily

caught fire. Even though the addition of EFB in the PU

system enhanced its mechanical properties, it will also

weaken the thermal properties. EFB can also decrease the

fire-resistivity due to its property that is easily ignited. In

order to increase not only the mechanical property but

also the thermal property of palm-based PU, fire retardant

namely, aluminum hydroxide is added besides EFB.

Aluminum trihydroxide (ATH) which is also known

as aluminum hydroxide has a molecular structure of

Al(OH)3. Besides low cost, other benefits from ATH also

include odorless, easy to handle, non-toxic, chemically

inert and non-volatile (Bonsignore 1981; Wu et al. 2004).

When composites filled with ATH is being heated and

subsequently burned, the ATH can absorb the heat which

is being applied to it. The absorbed heat is dispersed

380

uniformly in the ATH particles and reduced the heating rate

of the composites. The decomposition of ATH will form

alumina and water vapor as follow:

(1)

This is an endothermic reaction with absorbed heat of

1.97 kJg-1. The water vapor produced during the reaction

will dilute any combustible gaseous substable evolved.

Due to its ability to dilute combustible gases and slows

down fire, ATH is used as flame retardant.

In this paper, the effect of ATH loading on the

compression stress and modulus, thermal conductivity

and acoustic properties of the palm-based polyurethane

was carried out as a preliminary study in determining

its capability as a fire-retardant. The PU was prepared

by reacting the palm kernel oil-based (PKO) monoester

(polyol) with 2, 4-diphenylmethane diisocyanate and

loaded with a fixed amount of EFB at 10 wt%.

MATERIALS AND METHODS

MATERIALs

The RBD PKO -based polyol was prepared using

method described by Badri et al. (2001). The 2,4diphenylmethane diisocyanate (MDI) was obtained from

Cosmopolyurethane (M) Sdn Bhd, Port Klang, Malaysia.

Additives for the polymerization of the polyurethane

were glycerol ( BHD Laboratory Supplies, England),

silicon surfactant (Niax L5440) (Witco Ltd, Singapore)

and also tetramethylhexanediamine ( TMHDA ) and

pentamethyldiethylenetriamine (PMDETA) as catalysts

which were obtained from Cosmopolyurethane (M) Sdn

Bhd, Port Klang, Malaysia. Oil palm empty fruit bunch

fibre (EFB) was obtained from Malaysian Palm Oil Board

(MPOB) Dengkil, Malaysia. Aluminum hydroxide (ATH)

was obtained from Fluka, Switzerland. The PU system

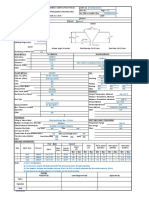

Table

developed used water as the blowing agent to replace

chlorofluorocarbon, CFC.

METHODs

The hybrid composites were prepared using the formulation

given in Table 1. The PKO-based polyol and the PU additives

were blended with water using an overhead stirrer with

a speed of 1000 rpm for 10 s. The EFB and ATH were

added based on weight percentage of the overall weight

of polyol resin. The EFB was added at fixed amount (10

wt%) while ATH was varied at 2, 4 and 6 wt%. The blend

was then mixed with MDI at a ratio of 100:115 (resin

to MDI). The mixture was then poured into a mould. It

was then demoulded after 15 min. The composites were

conditioned at room temperature for 16 h before further

characterizations.

CHARACTERIZATION OF THE PU HYBRID

COMPRESSION TEST

The compression test was conducted according to the

standard of BS 4370: Part 1: 1988 (Method of Test for

Rigid Cellular Material): Method 3 (Compression).

Samples were cut into dimension of 50 mm 50 mm

50 mm. The test was carried out using Instron Universal

Testing Machine model 5566 at cross-head speed of 50

mm min-1 until the thickness was reduced to 90% of its

original thickness. The compression stress and modulus

were recorded as average of five readings.

THERMAL CONDUCTIVITY TEST

Thermal conductivity was carried out using thermal

conductivity analyzer model Anacon. Samples were cut

into 160 mm 160 mm 30 mm. Thermal conductivity

was calculated based on the formula:

(2)

1. Formulation for the preparation of the control PU and hybrid PU composites

Ingredients, pbw*

0 wt%

90

PKO-based polyol

Glycerol

Niax L5440

TMHDA

PMDETA

Water

Total pbw

EFB

ATH

Ratio resin: MDI

10

3

2 wt% ATH

90

10

3

10 wt% EFB

4 wt% ATH

90

10

3

6 wt% ATH

90

10

3

0.46

0.46

0.46

0.46

4.00

4.25

4.30

4.35

0.49

107.95

-

100:115

Note: *pbw: part by weight of the overall ingredients

0.49

108.20

10.82

2.16

100:115

0.49

108.25

10.82

4.33

100:115

0.49

108.30

10.83

6.50

100:115

where t is thickness of the sample (m), Q is the rate of heat

flow (W), A is the tested surface area of the sample (m2)

and T is the temperature gradient between the hot plate

and the cold plate (K).

ACOUSTIC TEST

The acoustic test was performed using impedance tube

Model SCS9020B/K according to ASTM E1050-98

(Standard Test Method for Impedance and Absorption of

Acoustical Materials Using Tube, Two Microphones and

a Digital Frequency Analysis System) and ISO 10534-2

(Acoustics-Determination of sound absorption coefficient

and impedance in the impedance tubes-Part 2: Transferfunction method). The acoustic absorption coefficient ()

is defined as the ratio of the acoustic energy absorbed by

the foam (Iincident - Ireflected) to the acoustic energy incident

(Iincident) on the surface and is dependent on frequency. The

tested frequency range was 125 4000 Hz.

SEM ANALYSIS

The SEM analysis was used to study the distribution of ATH

in hybrid composites. The analysis was carried out using

SEM chamber model Phillips XL-30. The dried samples

were pre-coated with gold using gold sputter coater model

SC500.

RESULTS AND DISCUSSION

MECHANICAL PROPERTIES

The stress put onto the PU system creates energy that

is absorbed by the EFB. This energy is transferred to

the PU matrix and ATH subsequently and uniformly

being dispersed in the system. At higher loading of ATH

(more than 2 wt%), the compression stress and modulus

decreased. Further addition of the fire retardant (ATH) to

the composites reduced the ability of the composites to

absorb and disperse the energy. Mechanically, addition

of rigid particles leads to an increase in the brittleness of

the composites as observed by Dvir et al. (2003). Loading

of ATH in the PU system has caused disruption in the PU

system. It creates disorder to the cellular structure. The

same observation was encountered by Nachtigall et al.

(2006) when ATH was blended in polypropylene. There

was a tendency for the ATH to weaken the mechanical

strength of the composites due to the rigidity nature

of the ATH particulates. Khairul Anuar Mat Amin &

Khairiah Haji Badri (2007) has reported in their study

using kaolinite as filler that the presence of the kaolinite

disturbed the interfacial adhesion of PU matrix and EFB.

These supported the findings in this study where there

was reduction in the compression stress and modulus at

4 and 6 wt% ATH. Further explanation was verified by

the SEM micrographs.

Figure 2 shows the SEM micrographs of the control PU

and the hybrid PU composites at ATH loading of 2, 4 and

6 wt%. Figures 2 (a) shows the structure of the unfilled

PU. The micrograph indicated uniform hexagonal cellular

structure of PU. At 2 wt% ATH, the ATH was adhered to the

cell wall together with the EFB. During compression testing,

the stress transferred continuously from the matrix to the

EFB and to the ATH. This resulted in a uniform dispersion of

the stress. Figures 2 (c) and (d) shows ruptured cell walls

of the PU composites. These created stress concentration

point where it produced discontinuity in the matrix (Khairul

Anuar Mat Amin & Khairiah Haji Badri 2007).

Compression stress, kPa

Compression modulus, kPa

Figure 1 shows the trend in compression stress and

modulus of hybrid composites with 0, 2, 4 and 6 wt% ATH.

Addition of 2 wt% ATH increased the compression stress

and modulus to 575.2 kPa and 2301.8 kPa, respectively but

decreased with further addition of ATH to the composites.

381

ATH loading, wt%

Figure

1. Compression stress and modulus of the control PU and the hybrid PU composites

382

(a)

(b)

(c)

(d)

Figure 2. SEM

micrographs of the (a) control PU, hybrid PU composites filled with (b) 2 wt% ATH

(c) 4 wt% ATH and (d) 6 wt% ATH

THERMAL CONDUCTIVITY

Figure 3 shows the thermal conductivity (Wm-1K-1) of the

hybrid PU composites at various ATH loading (wt%). The

thermal conductivity increased with increasing ATH loading

in the system but decreased at 6 wt% ATH. This indicated

that the addition of ATH in the PU system contributes to poor

thermal conductivity. The disability of ATH to dissipate the

energy in term of heat flow resulted in higher k-value at

higher ATH loading. Benli et al. (1998) reported that fine

incorporation of filler particles in the matrix enhanced

the thermal conductivity. When heat was introduced to

the hybrid composites, ATH as rigid particles absorb an

amount of heat and transfer it to the nearest ATH in the

system. Modesti et al. (2002) also reported that addition

of solid particles in the composites leads to higher thermal

conductivity. The thermal conductivity of the hybrid PU

system at 6 wt% ATH decreased maybe due to random

dispersion of the ATH particles in the PU-EFB matrix as

reported by Kumlutas et al. (2003). It might also be due

to the ruptured cell wall that increased the diffusion rate

of carbon dioxide out and air inside the system. Since

air has lower k-value compared to the carbon dioxide,

the whole hybrid PU composites exhibited an improved

thermal conductivity.

ACOUSTIC PROPERTY

The acoustic property (Figure 4) showed that at lower

frequencies (125 500 Hz), poor sound absorption was

observed. The absorption coefficient () was the highest

at 4 wt% ATH compared to 2 and 6 wt% ATH. All hybrid

PU composites indicated higher absorption coefficient at

frequency ranges at 2000-4000 Hz. When the incident

sound wave hit the ATH, the sound energy is dispersed

in the composites due to the attenuation of air viscosity

in the cell pore. Interaction between the vibrated ATH

increased the low frequency attenuation thus increase the

absorption coefficient (Zhou et al. 2006).

CONCLUSIONs

The effect of aluminum hydroxide in the mechanical,

thermal conductivity and acoustic property of the palmbased polyurethane composites has been studied. The

hybrid PU composites with 2 wt% ATH showed higher

properties for compression stress and modulus, thermal

conductivity and acoustical characteristics. However, the

acoustic study indicated that loading at 4 wt% ATH showed

higher absorption coefficient at the range of 2000-4000

Hz. The loading of ATH is able to improve the mechanical,

thermal and acoustic properties of the composites.

However, it is suggested that treatment of ATH shall be

carried out to improve the properties. Treatment of ATH

with titanate as a coupling agent might be able to improve

the mechanical properties of the composites.

383

Thermal Conductivity, Wm-1K-1

ATH loading, wt%

3. Thermal conductivity of the hybrid PU composites (with fixed amount of EFB at 10 wt%)

Absorption coefficient (a), Arbitrary

Figure

Frequency, Hz

Figure

REFERENCES

4. Acoustic property of the hybrid PU composites

Badri, K.H., Othman, Z. & Mohd Razali, I. 2005. Mechanical

properties of polyurethane composites from oil palm

resources. Iranian Polymer Journal 14(5): 987-993.

Badri, K.H., Othman, Z. & Ahmad, S.H. 2004. Rigid Polyurethane

Foams From Oil Palm Resources. Journal Of Materials

Science 39(16-17): 5541-5542.

Badri, K.H., Ahmad, S.H. & Zakaria, S. 2001. The production of

a high-functionality RBD palm kernel-based polyester polyol.

Journal of Applied Polymer Science 82: 827-832.

Benli, S., Yilmazer, ., Pekel, F. & zkar, S. 1998. Effect of

fillers on thermal and mechanical properties of polyurethane

elastomer. Journal of Applied Polymer Science 68: 10571065.

Bonsignore, P.V. 1981. Alumina Trihydarate as a Flame Retardant

for Polyurethane Foams. In Advances in Urethane Science

and Technology, edited by Frisch, K.C. & Klempner, D. 8:

253-262. Pennsylvania: Technomic Publishing Co. Inc.

Dvir, H., Gottlieb, M., Daren, S. & Tartakovsky, E. 2003.

Optimization of a flame-retarded polypropylene composite.

Composites Science and Technology 63: 1865-1875.

Khairul Anuar Mat Amin & Khairiah Haji Badri 2007. Palmbased bio-composites hybridized with kaolinite. Journal of

Applied Polymer Science 105: 2488-2496.

Kumlutas, D., Tavman, I.H. & Coban, M.T. 2003. Thermal

conductivity of particle filled polyethylene composite

materials. Composites Science and Technology 63: 113117.

Modesti, M., Lorenzetti, A., Simioni, F. & Camino, G. 2002.

Expandable Graphite as an Intumescent Flame Retardant

in PolyisocyanuratePolyurethane Foams. Polymer

Degradation and Stability 77: 195-202.

384

Nachtigall, S.M.B., Miotto, M., Schneider, E.E., Mauler, R.S.

& Camargo Forte, M.M. 2006. Macromolecular coupling

agents for flame retardant materials. European Polymer

Journal 42: 990-999.

Rozman, H.D., Saad, M.J. & Mohd Ishak, Z.A. 2003. Flexural

and impact properties of oil palm empty fruit bunch (EFB)propylene composite-the effect of maleic anhydride chemical

modification of EFB. Polymer Testing 22(3): 335-341.

Wu, C.P., Lee, J.S. & Liao, Y.J. 2004. Thermal analysis of

aluminium trihydroxide. In Proceedings of the NATAS Annual

Conference on Thermal Analysis and Application: 79-85.

Xu, Z., Tang, X. & Zheng, J. 2008. Thermal stability and

flame retardancy of rigid polyurethane foams/organoclay

nanocomposites. Polymer-Plastics Technology and

Engineering 47: 1136-1141.

Zhou, H., Li, B. & Huang, G. 2006. Sound absorption

characteristics of polymer microparticles. Journal of Applied

Polymer Science 101: 2675-2679.

Nor Rabbiatul Adawiyah Norzali & Khairiah Haji Badri*

School of Chemical Sciences & Food Technology

Faculty of Science & Technology

Universiti Kebangsaan Malaysia

43600 UKM Bangi

Selangor D.E.

Malaysia

Mohd Zaki Nuawi

Department of Civil and Mechanical Engineering

Faculty of Engineering and Built Environment

Universiti Kebangsaan Malaysia

43600 UKM Bangi

Selangor D.E.

Malaysia

*Correspondence author; email: kaybadri@ukm.my

Received: 9 December 2009

Accepted: 15 July 2010

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- 41 - BT - Readmit (r13 To r16)Documento3 pagine41 - BT - Readmit (r13 To r16)Nagarjuna KonduruNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- 7W 11bt11202022 PDFDocumento22 pagine7W 11bt11202022 PDFNagarjuna KonduruNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Gear ParametersDocumento12 pagineGear Parametersmahesh_547Nessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Gujarat Technological UniversityDocumento2 pagineGujarat Technological UniversityNagarjuna KonduruNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Merritt EtdDocumento140 pagineMerritt EtdNagarjuna KonduruNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Non-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2Documento242 pagineNon-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2darqm589% (18)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Environmental StudiesDocumento8 pagineEnvironmental StudiessudheerNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Jawaharlal Nehru Technological University Kakinada: Revised Time TableDocumento1 paginaJawaharlal Nehru Technological University Kakinada: Revised Time TableNagarjuna KonduruNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Strength of Materials Parts I&II-TimoshenkoDocumento450 pagineStrength of Materials Parts I&II-Timoshenkoapi-370842873% (11)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- KinematicsofMachinery PDFDocumento10 pagineKinematicsofMachinery PDFNagarjuna KonduruNessuna valutazione finora

- 2 2 1st Mid Mech Day 2 BitsDocumento2 pagine2 2 1st Mid Mech Day 2 BitsNagarjuna KonduruNessuna valutazione finora

- 3-2 1st Mid Mech Day-2Documento19 pagine3-2 1st Mid Mech Day-2Nagarjuna KonduruNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Prediction of The Elastic Modulus of Wood Flour/Kenaf Fibre/Polypropylene Hybrid CompositesDocumento8 paginePrediction of The Elastic Modulus of Wood Flour/Kenaf Fibre/Polypropylene Hybrid CompositesNagarjuna KonduruNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Automotive AlDocumento9 pagineAutomotive Aljpar378Nessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- 08 Chapter1Documento63 pagine08 Chapter1Inam Ul Haq100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- 33Documento10 pagine33Nagarjuna KonduruNessuna valutazione finora

- 9 IJAEST Vol No.4 Issue No.1 Effect of Fibre Volume Fraction On The Tensile Strength of Banana Fibre Reinforced Vinyl Ester Resin Composites.089 091 PDFDocumento3 pagine9 IJAEST Vol No.4 Issue No.1 Effect of Fibre Volume Fraction On The Tensile Strength of Banana Fibre Reinforced Vinyl Ester Resin Composites.089 091 PDFNagarjuna KonduruNessuna valutazione finora

- Mechanical Properties of Short Random Oil Palm Fibre Reinforced Epoxy CompositesDocumento6 pagineMechanical Properties of Short Random Oil Palm Fibre Reinforced Epoxy CompositesNagarjuna KonduruNessuna valutazione finora

- Mechanical Properties of Short Random Oil Palm Fibre Reinforced Epoxy CompositesDocumento6 pagineMechanical Properties of Short Random Oil Palm Fibre Reinforced Epoxy CompositesNagarjuna KonduruNessuna valutazione finora

- Cement Materials PaperDocumento41 pagineCement Materials PaperSairam Venkat0% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- JourLignocellulose-based Hybrid Bilayer Laminate Compositenal of Composite Materials 2005 Hariharan 663 84Documento23 pagineJourLignocellulose-based Hybrid Bilayer Laminate Compositenal of Composite Materials 2005 Hariharan 663 84Nagarjuna KonduruNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- 1 s2.0 S0261306912000295Documento5 pagine1 s2.0 S0261306912000295Nagarjuna KonduruNessuna valutazione finora

- IJERTV1IS6085Documento3 pagineIJERTV1IS6085Nagarjuna KonduruNessuna valutazione finora

- GATE ME Solved Question Paper 2011 1Documento15 pagineGATE ME Solved Question Paper 2011 1Amit Singh DehuryNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Materials For Entertainment EngineeringDocumento51 pagineMaterials For Entertainment EngineeringAkash RsNessuna valutazione finora

- A Comparative Study On The Mechanical Properties of Jute and Sisal Fiber Reinforced Polymer Composites - SpringerDocumento4 pagineA Comparative Study On The Mechanical Properties of Jute and Sisal Fiber Reinforced Polymer Composites - SpringerNagarjuna KonduruNessuna valutazione finora

- 2011 Effect of Alkali Treatment On Interfacial and Mechanical Properties of Coir Fiber Reinforced Poly (Butylene Succinate) Biodegradable Composites Composites Part B Engineering Nam T.HDocumento9 pagine2011 Effect of Alkali Treatment On Interfacial and Mechanical Properties of Coir Fiber Reinforced Poly (Butylene Succinate) Biodegradable Composites Composites Part B Engineering Nam T.Hmora14167Nessuna valutazione finora

- JourLignocellulose-based Hybrid Bilayer Laminate Compositenal of Composite Materials 2005 Hariharan 663 84Documento23 pagineJourLignocellulose-based Hybrid Bilayer Laminate Compositenal of Composite Materials 2005 Hariharan 663 84Nagarjuna KonduruNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- MEPDG Manual of PracticesDocumento209 pagineMEPDG Manual of PracticesSri RamyaNessuna valutazione finora

- Bundel Soal Kimia TPBDocumento210 pagineBundel Soal Kimia TPBElen Mustika100% (1)

- Strut and Tie Model Analysis of Prestressed Deep BeamsDocumento24 pagineStrut and Tie Model Analysis of Prestressed Deep BeamsKannan Chandrabhanu100% (1)

- Bayer Process Diagram ExplainedDocumento6 pagineBayer Process Diagram ExplainednatsmdNessuna valutazione finora

- Jeppesen CHAPTER 4 Aircraft Welding PDFDocumento30 pagineJeppesen CHAPTER 4 Aircraft Welding PDFDavid SchkolnikNessuna valutazione finora

- The Optical Properties of Magnesium Oxide ContainiDocumento6 pagineThe Optical Properties of Magnesium Oxide ContainiAbdulbar kelilNessuna valutazione finora

- Asme b31.3 InterpretationsDocumento18 pagineAsme b31.3 InterpretationsMallela Sampath KumarNessuna valutazione finora

- Rheological Properties of Some Oil Based Muds Used in Reservoirs in The Niger Delta, NigeriaDocumento6 pagineRheological Properties of Some Oil Based Muds Used in Reservoirs in The Niger Delta, NigeriaNurfatini CheNessuna valutazione finora

- Styrene Acrylic FTIRDocumento9 pagineStyrene Acrylic FTIRDesi Rahma PrihandiniNessuna valutazione finora

- Piston RingDocumento43 paginePiston RingSudath Kularathna67% (3)

- Route 34 PlansDocumento1 paginaRoute 34 PlansThe Valley IndyNessuna valutazione finora

- Balancing Chemical Equations: For Advanced Chemistry Special Science High School in Grade 10 Quarter 3/ Week 2Documento9 pagineBalancing Chemical Equations: For Advanced Chemistry Special Science High School in Grade 10 Quarter 3/ Week 2Venice Gwyn ChavezNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Chapter 10 Solution Lecture Solution Ecture NotesDocumento37 pagineChapter 10 Solution Lecture Solution Ecture NotesLiew KahJiannNessuna valutazione finora

- Wivacryl As 50: Styrene Acrylic Paint BinderDocumento7 pagineWivacryl As 50: Styrene Acrylic Paint Bindermahesh.nakNessuna valutazione finora

- Petroleum Equipment Assembly & Metal Structure JSC: N/A N/ADocumento2 paginePetroleum Equipment Assembly & Metal Structure JSC: N/A N/AKhôi ĐàoNessuna valutazione finora

- WRC 107 Stress Calculation For Sustained Loads:: Dimensionless Loads For Cylindrical Shells at Attachment JunctionDocumento5 pagineWRC 107 Stress Calculation For Sustained Loads:: Dimensionless Loads For Cylindrical Shells at Attachment JunctionmsmrizhwanNessuna valutazione finora

- Mix Proportioning of M80 Grade Self-Compacting ConDocumento3 pagineMix Proportioning of M80 Grade Self-Compacting ConfaseehNessuna valutazione finora

- Lintels and ArchesDocumento49 pagineLintels and Arches18 Architects50% (2)

- 04 Nowy-Styl-Group Price-List Office-Furniture EXP-CZ-SK en BNOS-RG E06 2018Documento420 pagine04 Nowy-Styl-Group Price-List Office-Furniture EXP-CZ-SK en BNOS-RG E06 2018Marin IonutNessuna valutazione finora

- Optiflo RC: Pulse-Jet Cylindrical Cartridge Dust CollectorDocumento6 pagineOptiflo RC: Pulse-Jet Cylindrical Cartridge Dust CollectorJuan Manuel Bedoya AcevedoNessuna valutazione finora

- Aci 318-14 RC-BM-001Documento7 pagineAci 318-14 RC-BM-001Bunkun15Nessuna valutazione finora

- Lab 4-Measurement of Plastic Viscosity of Different Mud Samples by Viscometer.Documento20 pagineLab 4-Measurement of Plastic Viscosity of Different Mud Samples by Viscometer.Sunny BbaNessuna valutazione finora

- VMC-Haj House - Final Estimate 09.01.19Documento787 pagineVMC-Haj House - Final Estimate 09.01.19Patan Abdul Mehmood Khan100% (1)

- AVK Check ValvesDocumento4 pagineAVK Check ValvesgdpNessuna valutazione finora

- Estimation of Undrained Shear Strength For Peat Using CPTDocumento4 pagineEstimation of Undrained Shear Strength For Peat Using CPTLaura RossNessuna valutazione finora

- DIY Homemade HHO Hydrogen Generator - RMCyberneticsDocumento6 pagineDIY Homemade HHO Hydrogen Generator - RMCyberneticsharisaryono100% (1)

- X17CrNi16 2Documento2 pagineX17CrNi16 2madodandembeNessuna valutazione finora

- HUMITECHDocumento1 paginaHUMITECHtimNessuna valutazione finora

- Zimbabwe School Examinations Council Chemistry 6031/3Documento12 pagineZimbabwe School Examinations Council Chemistry 6031/3takundavs100% (2)

- Items To Review at Hostel CHC ZAMKODocumento1 paginaItems To Review at Hostel CHC ZAMKOHumphrey OnyejegbuNessuna valutazione finora

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- Guidelines for Chemical Process Quantitative Risk AnalysisDa EverandGuidelines for Chemical Process Quantitative Risk AnalysisValutazione: 5 su 5 stelle5/5 (1)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksDa EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksValutazione: 5 su 5 stelle5/5 (1)

- Guidelines for the Management of Change for Process SafetyDa EverandGuidelines for the Management of Change for Process SafetyNessuna valutazione finora

- Advanced Process Control: Beyond Single Loop ControlDa EverandAdvanced Process Control: Beyond Single Loop ControlNessuna valutazione finora

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDa EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationValutazione: 4 su 5 stelle4/5 (18)