Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sop Store Room Safety

Caricato da

amirDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sop Store Room Safety

Caricato da

amirCopyright:

Formati disponibili

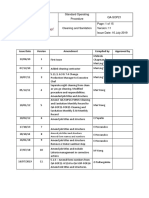

Rev 4-10

TMC

SOP: FOOD STORAGE AND STOREROOM SAFETY

SOP Procedure No.

NS-105-S

Effective Date: 4/1/10

Program Area: Nutrition / CACFP

Replaces Procedure No. NS-105-A

FOOD STORAGE AND SAFETY

PURPOSE:

All TMC-Migrant Seasonal Head Start (MSHS) centers must have yearly inspections by state

and local health authorities. These guidelines are for complying with federal, state and local

health regulations for food preparation in licensed food service establishments. All food,

chemicals, and supplies should be stored in a manner that ensures quality and maximizes

safety of the food served to all.

SCOPE:

Food service staff will comply with inventory and/or storeroom safety procedures to ensure

the personnel safety of all center staff and visitors.

The HACCP Team is the same as the Center Safety (Risk Management) Team.

INSTRUCTIONS:

A member or members of the HACCP Team will:

1. Train on all Hazard Analysis Critical Control Points (HACCP) SOPs including this

procedure. Training will be ongoing to ensure food service staff are aware of food and

personnel safety.

2. All food service staff must comply with the MSHS HACCP program and follow

inventory and/or storeroom safety procedures to ensure the personnel safety of all

center children, staff and visitors.

Follow Food Safety Guidelines for Storing

Dry storage = longer holding of less perishable items; optimum temperature 60-70

Refrigerator = shortterm storage of perishable items

Deep chilling unit = specific foods for short periods

Freezer = long-term storage of perishable foods

Milk Coolers = short-term storage of milk containers

Storage Upon Receiving:

1. Employees receiving and storing food must maintain the storage areas clean, including

dry, refrigerated, and freezer storage;

2. Place foods in the proper storage area (refrigerator or freezer) quickly to avoid

bacterial growth.

a) 41F or lower refrigerator temperatures

b) 26F to 32F or below deep chill storage temperatures

c) 0F or below freezer temperatures

1

Regulatory

References:

1. Texas Food Establishment Rules, # 229.163 (I)

2. HS Performance Standards Guidance CFR # 1304.23 (e)

Page 1 of 4

Rev 4-10

TMC

SOP: FOOD STORAGE AND STOREROOM SAFETY (continued)

d) 50F to 70F at 50 to 60% humidity dry storage temperatures

3. Place foods into appropriate storage areas immediately upon receipt in the

following order:

a) REFRIGERATED FOOD: Store foods in designated refrigerators; follow the

guidelines below to storage foods in refrigerators:

i) TOP SHELF

(1) Prepared or ready-to-eat items

ii) BOTTOM SHELF

(1) Fish and raw seafood items

(2) Whole cuts of raw beef

(3) Whole cuts of raw pork

(4) Ground or processed meats

(5) Raw poultry

b) FROZEN FOOD: Frozen meats, poultry, seafood, fruits, vegetables and some

dairy products, such as ice cream, should be stored in a freezer at 0F to 10 F to

keep them fresh and safe for an extended period of time.

c) DRY FOOD:

i) Canned goods, baking products (such as flour, salt and sugar), grain products

(such as pasta, rice and cereals) and other dry items (such as beans);

ii) Fruit (such as fresh bananas, avocados, and pears) which ripen best at room

temperature; optimum temperature 60-70

iii) Vegetables (such as fresh onions, potatoes, and tomatoes) which store best in

dry storage; optimum temperature 60-70

iv) Keep all food items on shelves that are at least 6 above the floor to facilitate air

circulation and proper cleaning.

v) Store food out of direct sunlight.

vi) Place chemicals and supplies in appropriate storage areas, away from food.

vii) Use First -In-First-Out (FIFO) rotation of products in all storage areas to assure

that oldest products are used first. Products with the earliest use-by or

expiration dates are stored in front of products with later dates. Mixing old food

with new food is not acceptable.

viii)Make sure all goods are dated with receiving date and use-by date (should

already be on the product from manufacturer in most cases). However, if a

calendar date is on the product it should state the month and day (and the year

for shelf-stable and frozen products). If a calendar date is shown, immediately

next to the date must be a phrase explaining the meaning of that date such as

"sell-by" or "use before."

ix) Store food in original container if the container is clean, dry, and intact. If

necessary, repackage food in clean, well-labeled, airtight containers. This can

also be done after a package is opened. Food is NEVER put in chemical

containers and chemicals are NEVER placed in food storage containers.

x) Store potentially hazardous foods no more than 3 - 4 days at 41F from date of

opening containers.

xi) Store pesticides and chemicals away from food handling and storage areas.

Pesticides and chemicals must be stored in original, labeled containers.

2

Regulatory

References:

1. Texas Food Establishment Rules, # 229.163 (I)

2. HS Performance Standards Guidance CFR # 1304.23 (e)

Page 2 of 4

Rev 4-10

TMC

SOP: FOOD STORAGE AND STOREROOM SAFETY (continued)

Storeroom Sanitation:

1. Maintain clean and uncluttered storage areas. Storage areas should be separated

from where garbage is kept to prevent contamination.

2. Dispose of items that are beyond the expiration or use by dates.

3. Store all items on shelves that are at least 6 above the floor to help clean area

safely.

4. Check for signs of rodents or insects; notify the center manager If you suspect they

are present.

Storage Temperature Control:

1. Check the temperature of all refrigerators, freezers, and dry storerooms at the

beginning and at the end of each shift. This includes both internal and external

thermometers, where appropriate.

a. Refrigerator temperatures should be between 36 and 41F.

b. Freezer temperatures should be between -10 and 0F.

c. Storeroom (dry storage) temperatures should be between 50 and 70F.

2. Record temperatures on the appropriate temperature log with employee initials.

3. Notify HACCP Team member immediately of any unacceptable temperatures.

4. Limit overloading refrigerated storage areas, as this prevents air flow and makes

the unit work harder to stay cold.

5. Use caution when cooling hot food in the refrigerator, as this warms the unit and

can put other foods into the temperature danger zone.

6. Keep units closed as much as possible to maintain proper temperatures.

7. Defrost all units as needed and as part of a regular schedule to aid in proper

maintenance and air circulation.

General Storerooms:

1. Classroom and office supplies must be stored on sturdy shelves. The shelving

material must not have:

Pointed, splintered, sharp angles or corner edges or surfaces

2. A sturdy stepstool or ladder must be used to reach high surfaces.

3. Store heavy loads approximately waist high for easier lifting.

4. Store light items on upper shelves.

5. Avoid storing boxes or cartons so portions stick out into aisle.

6. Storage areas need to have good lighting.

7. Organize the aisles in the storeroom so they are wide enough to lift and carry

cases without hitting shelves.

8. Employees and/or regular volunteers must be trained on how to use the squat lift

for heavy loads.

9. Visual aids, diagrams and labels should be placed to assist in proper organization

of storage areas.

3

Regulatory

References:

1. Texas Food Establishment Rules, # 229.163 (I)

2. HS Performance Standards Guidance CFR # 1304.23 (e)

Page 3 of 4

Rev 4-10

TMC

SOP: FOOD STORAGE AND STOREROOM SAFETY (continued)

Cleaning Supplies Storage:

1. All cleaning supplies must be stored and locked or out of reach of the TMC-MSHS

center children and clearly labeled.

2.

3.

Cleaning supplies must be kept separate from food, dishes, cooking equipment

and eating utensils.

Poisonous and toxic substances (including insect and rodent repellants) should be

stored under lock and key with the janitorial/custodian cleaning supplies. Material

Safety Data Sheets (MSDS) must be available for review by the center personnel.

MONITOR:

A member or members of the HACCP Team will:

Visually inspect storage areas for safety and sanitation (i.e., cleaning supplies, infant,

food service area inventories, etc.)

Review training records to ensure food safety and HACCP training was provided to

new employees and ongoing for existing food service personnel.

Monitor temperature logs of storage rooms, refrigerators, and freezers.

Observe Staff to ensure they demonstrate food safety.

Follow up as necessary.

CORRECTIVE ACTION:

Retrain any foodservice employee, supervisor or coordinator not implementing this

HACCP SOP.

Document all corrective action taken on all appropriate forms.

Use outside resources, such as extension specialists, nutrition consultants, vendors,

health inspectors, or qualified trainers to provide food safety and HACCP follow-up

training.

Follow-up on corrective action.

VERIFICATION AND RECORD KEEPING:

HACCP team members will record monitoring activities and corrective action taken on:

Site Visit forms

CACFP Monitoring Forms

Food Safety Checklist

Additional records:

Temperature Logs

Inventory Forms

Food and nonfood invoices

DATE IMPLEMENTED: 4/1/10

BY: All Staff

DATE REVIEWED: _____________________ BY: _______________________

DATE REVISED: _______________________ BY: _______________________

http://www.fsis.usda.gov/Fact_Sheets/Food_Product_Dating/index.asp

4

Regulatory

References:

1. Texas Food Establishment Rules, # 229.163 (I)

2. HS Performance Standards Guidance CFR # 1304.23 (e)

Page 4 of 4

Potrebbero piacerti anche

- SOP StorageDocumento2 pagineSOP StorageAnikBudiany0% (1)

- Food Product Flow: Objective: in This Chapter The Student Will Able ToDocumento15 pagineFood Product Flow: Objective: in This Chapter The Student Will Able ToRosiee Salazar TejadaNessuna valutazione finora

- SOP StorageDocumento3 pagineSOP StorageJessNessuna valutazione finora

- The Food Production FlowDocumento120 pagineThe Food Production FlowTrisha RachoNessuna valutazione finora

- SOP Receiving-DeliveriesDocumento2 pagineSOP Receiving-DeliveriesErdinan SetiawanNessuna valutazione finora

- Food Product FlowDocumento55 pagineFood Product FlowAli Nah100% (1)

- Sanitation Procedures and PracticesDocumento14 pagineSanitation Procedures and PracticesButters AJNessuna valutazione finora

- SOP For Receiving of Food and Raw Materials in KitchenDocumento2 pagineSOP For Receiving of Food and Raw Materials in KitchenAmgad saqr100% (1)

- Fifo PolicyDocumento2 pagineFifo PolicySatya TripathiNessuna valutazione finora

- Standard Operating ProceduresDocumento36 pagineStandard Operating ProceduresAhmed DuraibiNessuna valutazione finora

- Sample Food Safety Audit ChecklistDocumento11 pagineSample Food Safety Audit Checklistgkiyer7Nessuna valutazione finora

- Thawing FoodDocumento2 pagineThawing FoodAddress HotelNessuna valutazione finora

- Restaurants Checklist V3Documento7 pagineRestaurants Checklist V3AzharNessuna valutazione finora

- HACCP ManualDocumento24 pagineHACCP ManualSanchit kanwar100% (1)

- Locker ChecklistDocumento8 pagineLocker ChecklistkamalsalmanNessuna valutazione finora

- 08 HFSC Personal Hygiene Checklist 2019 PDFDocumento1 pagina08 HFSC Personal Hygiene Checklist 2019 PDFRobin100% (1)

- Sunnyside HACCP Plan 2012V1.2Documento42 pagineSunnyside HACCP Plan 2012V1.2fisherkiddNessuna valutazione finora

- Appendix A Suggested Content For Program DescriptionDocumento21 pagineAppendix A Suggested Content For Program Descriptionmohd_shaarNessuna valutazione finora

- Supplier EvaluationDocumento7 pagineSupplier EvaluationK S KumaraNessuna valutazione finora

- sSOP Pre-ProductionDocumento4 paginesSOP Pre-ProductionAlfred RangelNessuna valutazione finora

- Cleaning and Sanitizing Food Contact SurfacesDocumento4 pagineCleaning and Sanitizing Food Contact SurfacesAnna Liza R. Mercado100% (1)

- Sanitation & Food Safety Standard Operating Procedure ManualDocumento15 pagineSanitation & Food Safety Standard Operating Procedure ManualPong CanosaNessuna valutazione finora

- Receiving Deliveries Standard Operating Procedures: Revised 3/2020 1Documento2 pagineReceiving Deliveries Standard Operating Procedures: Revised 3/2020 1Marichelle PaloNessuna valutazione finora

- Quality SOP Manual in Catering and RestaurantsDocumento88 pagineQuality SOP Manual in Catering and RestaurantsMohamed100% (4)

- SOP Facility and Equipment HygieneDocumento6 pagineSOP Facility and Equipment HygieneHenry Taguma100% (1)

- Production SOP - RIODocumento8 pagineProduction SOP - RIOabu naym100% (1)

- Glass and Plastic Breakage PolicyDocumento1 paginaGlass and Plastic Breakage PolicyKriston EdwardNessuna valutazione finora

- HACCP Plan PDFDocumento13 pagineHACCP Plan PDFAnonymous qfCJwxib7Nessuna valutazione finora

- H.7 Supplier Approval QuestionnaireDocumento4 pagineH.7 Supplier Approval QuestionnairePrabhu Prabhu100% (1)

- QM 001 Food Safety Quality Management SystemDocumento5 pagineQM 001 Food Safety Quality Management SystemVikram PathrikarNessuna valutazione finora

- Supplier Evaluation FormDocumento11 pagineSupplier Evaluation FormMATTHEW MUNGAINessuna valutazione finora

- Food TraceabilityDocumento14 pagineFood Traceabilitydwivanjava100% (1)

- Sop HaccpDocumento28 pagineSop HaccpPrashant TripathiNessuna valutazione finora

- Food Safety Training ManualDocumento15 pagineFood Safety Training Manualmohd sharique100% (2)

- SOP Cleaning and Sanitizing - 2!15!16Documento3 pagineSOP Cleaning and Sanitizing - 2!15!16Kenneth Paul OlinanNessuna valutazione finora

- Standard Operating Procedure Index - Food Hygiene & SafetyDocumento1 paginaStandard Operating Procedure Index - Food Hygiene & SafetyBAlaNessuna valutazione finora

- Personal Hygiene, Food Safety and SanitationDocumento14 paginePersonal Hygiene, Food Safety and SanitationCess Dae Lim100% (1)

- ThawingDocumento15 pagineThawingSamiksha SinghNessuna valutazione finora

- Checklist For Kitchen AuditDocumento11 pagineChecklist For Kitchen AuditkiruthikaNessuna valutazione finora

- Washing Fruits and VegetablesDocumento2 pagineWashing Fruits and VegetablesSaravana KumarNessuna valutazione finora

- Food Audit Checklist For KitchenDocumento2 pagineFood Audit Checklist For KitchenArush BhatnagarNessuna valutazione finora

- Self Checklist For Food and Beverage Industry PDFDocumento3 pagineSelf Checklist For Food and Beverage Industry PDFImee S. YuNessuna valutazione finora

- Sop Food Safety and Hygeine VR PDFDocumento51 pagineSop Food Safety and Hygeine VR PDFVinglic Peter RebelloNessuna valutazione finora

- GMP's For Ice MakingDocumento6 pagineGMP's For Ice MakingmailmeaeNessuna valutazione finora

- Food Safety Checklist: Personal HygieneDocumento4 pagineFood Safety Checklist: Personal Hygienegulloque50% (2)

- SOP Food ProductionDocumento10 pagineSOP Food ProductionAnandh67% (3)

- 46 For Review 7.18.4.9 SOP Managing Allergens in FoodDocumento4 pagine46 For Review 7.18.4.9 SOP Managing Allergens in FoodMohamed ShabirNessuna valutazione finora

- Sop KitchenDocumento14 pagineSop Kitchenpolicecollege sihalaNessuna valutazione finora

- Restaurant Opening and Closing Checklist PDFDocumento7 pagineRestaurant Opening and Closing Checklist PDFNiniNessuna valutazione finora

- Vegetable Sanitizing - Control SheetDocumento2 pagineVegetable Sanitizing - Control Sheetsyed zia ul hassanNessuna valutazione finora

- Sop - Kitchen DepartmentDocumento11 pagineSop - Kitchen DepartmentChef Chef100% (3)

- Food Allergen PlanDocumento11 pagineFood Allergen PlanManuelito Maratas AndayaNessuna valutazione finora

- 01 Safety and HygieneDocumento16 pagine01 Safety and Hygienerode1234100% (1)

- Food Safety ChecklistDocumento4 pagineFood Safety Checklistjalali007Nessuna valutazione finora

- Food Defense A Complete Guide - 2020 EditionDa EverandFood Defense A Complete Guide - 2020 EditionValutazione: 1 su 5 stelle1/5 (1)

- Tandard Perating Rocedure: StorageDocumento2 pagineTandard Perating Rocedure: StorageJessa Mae AlgarmeNessuna valutazione finora

- Standard Operating Procedure: StorageDocumento2 pagineStandard Operating Procedure: Storagesunny mgxNessuna valutazione finora

- SOP StorageDocumento3 pagineSOP Storagedickson86100% (3)

- House of Food-Health and Safety PolicyDocumento10 pagineHouse of Food-Health and Safety PolicyEmmanuel YaoNessuna valutazione finora

- Kitchen Garden CookbookDocumento15 pagineKitchen Garden CookbookWeldon Owen PublishingNessuna valutazione finora

- Grape CureDocumento3 pagineGrape Cureestancescu_1Nessuna valutazione finora

- Progress Test 4, Units 10-12Documento2 pagineProgress Test 4, Units 10-12Claudia L Mendoza CarrilloNessuna valutazione finora

- Business ProposalDocumento5 pagineBusiness Proposaljulie anne mae mendozaNessuna valutazione finora

- TDS LPS Brewingyeast Verdant Eng A4Documento2 pagineTDS LPS Brewingyeast Verdant Eng A4bondo2011Nessuna valutazione finora

- Ulangan Harian Bahasa InggrisDocumento3 pagineUlangan Harian Bahasa InggrisSinta7 NingratNessuna valutazione finora

- There Is There Are Fruit VocabularyDocumento2 pagineThere Is There Are Fruit VocabularyaxecaiforaNessuna valutazione finora

- Organic FarmingDocumento192 pagineOrganic FarmingUNIVERSAL-CREATIONSNessuna valutazione finora

- 455 1850 1 PBDocumento8 pagine455 1850 1 PBRosy HutamiNessuna valutazione finora

- WW2 British National Loaf RecipeDocumento1 paginaWW2 British National Loaf RecipeAutumnalMonkNessuna valutazione finora

- No - Suratberanak .Angkagiliran : Bahasa Inggeris 014/1 Feb 2013 50 MinitDocumento13 pagineNo - Suratberanak .Angkagiliran : Bahasa Inggeris 014/1 Feb 2013 50 MinitRodziah IsmailNessuna valutazione finora

- Farmers InterviewDocumento5 pagineFarmers Interviewjay jariwalaNessuna valutazione finora

- How To Make Quick and Easy Stromboli Recipe The Recipe CriticDocumento1 paginaHow To Make Quick and Easy Stromboli Recipe The Recipe CriticAnne O’NimousNessuna valutazione finora

- Sbm-201nz Recipe BookDocumento24 pagineSbm-201nz Recipe BookfadilaNessuna valutazione finora

- Sensory Evaluation of Concentrated Milk Products FinalDocumento41 pagineSensory Evaluation of Concentrated Milk Products Finalhauvu75% (4)

- Cook em HornsDocumento463 pagineCook em Hornscahalan187167% (3)

- Garde Manger RecipesDocumento9 pagineGarde Manger Recipesapi-296847894Nessuna valutazione finora

- Plant Based FoodsDocumento13 paginePlant Based FoodssharathchandraNessuna valutazione finora

- Beer Better Than MilkDocumento1 paginaBeer Better Than Milkmavis16Nessuna valutazione finora

- Essay 3Documento2 pagineEssay 3Carolina HueteNessuna valutazione finora

- (Đề thi gồm: 08 trang) .: Môn thi: TIẾNG ANH (Đề chuyên)Documento3 pagine(Đề thi gồm: 08 trang) .: Môn thi: TIẾNG ANH (Đề chuyên)BTanh MaiNessuna valutazione finora

- Cuisinart CBK-100Documento12 pagineCuisinart CBK-100Ramon GarciaNessuna valutazione finora

- Introductory Catering Theory and PracticeDocumento17 pagineIntroductory Catering Theory and PracticeFuture Managers Pty Ltd100% (4)

- AlerTox Sticks Total Milk Validation ReportDocumento6 pagineAlerTox Sticks Total Milk Validation ReportLuis Miguel Matos OteroNessuna valutazione finora

- Research Questionnaire: Direction: Put A Check Under The Column That Best Suit Your ExperienceDocumento2 pagineResearch Questionnaire: Direction: Put A Check Under The Column That Best Suit Your ExperienceChloie Marie RosalejosNessuna valutazione finora

- Oreo Cookies & Cream Cake Recipe - Sugar & SparrowDocumento2 pagineOreo Cookies & Cream Cake Recipe - Sugar & SparrowBintNessuna valutazione finora

- 5.2 Cupcake ChallengeDocumento294 pagine5.2 Cupcake ChallengeNhlanhla MpofuNessuna valutazione finora

- f2f SFPD Coc Report 2022 DanoneDocumento2 paginef2f SFPD Coc Report 2022 DanoneStefan OarzaNessuna valutazione finora

- PROFILE Settings: Go To InputDocumento21 paginePROFILE Settings: Go To InputcadsultanNessuna valutazione finora

- 6 Week Budget Shred WomenDocumento87 pagine6 Week Budget Shred WomenLuis SanchezNessuna valutazione finora