Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cleaning

Caricato da

Biljana TausanovicTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cleaning

Caricato da

Biljana TausanovicCopyright:

Formati disponibili

Application Guide

To find out more and download our

published papers visit our website at

www.genesysro.com

G

I N T E R N A T I O N A L

Application Guide 7

Cleaning of reverse osmosis (RO) and

nanofiltration (NF) membranes

Membrane cleaning

All RO/NF installations experience

a degree of membrane fouling

which will impact on operational

efficiency and cost.

The consequences of fouling include a decrease in permeate

production, increased differential pressure (dP) and or a decrease

in permeate quality. In practical terms cleaning frequency and

duration increases, membrane life may decrease and both

operational input and downtime increase. The type and the quality

of feed water, the effectiveness of the pre-treatment regime and

also other factors relating to system design and operating practices

determine the degree and type of fouling.

The types of contamination most commonly detected can be

classified as:

Organics and biofouling: Feed water

with high organic matter content is the

cause of these deposits. The presence

of such compounds also facilitates

biofilm formation on the surface of the

membranes, and is the most commonly

occurring type of fouling.

present

Colloidal Fouling: Colloids

in the feed water should normally

be removed by the pre-treatment

system; failure or poor design of pretreatment systems may lead to colloidal

membrane fouling.

Inorganic scale deposits: The most

common types of scale found in

membranes are calcium carbonate

and calcium sulphate with bariumand

strontium sulphate occurring less

frequently. Scale can often be attributed

to incorrect antiscalant selection or poor

antiscalant control. In addition it is also common to find iron and

silica deposits.

The cleaning strategies and products used will be different for each

type of foulant. The following are general recommendations and

tips to consider when designing a membrane cleaning programme.

Each cleaning situation is different; therefore,

specific cleaning recommendations are dependent

on the type of foulant.

Most effective cleaning allows longer system

operating time between cleanings and results in

the lowest operating costs.

(DOW FilmTec Technical manual)

General Recommendations

When to clean?

All membranes must be cleaned periodically; as a minimum at least

one routine clean per year is required. Although the symptoms

of contamination are not always immediately detectable, the

membranes should be cleaned whenever there are variations of 1015% of normalised data for the parameters of: differential pressure,

product flow or permeate quality.

What equipment is needed to clean?

Most RO/NF systems include a clean-in-place (CIP) system. The

basic design consists of a tank for preparation and mixing of

cleaning solutions, heating element and a centrifugal pump for

re-circulating the cleaning solution throughout the system. It

should also incorporate control instrumentation for the process

parameters (flow, pressure, temperature) and points for sampling.

It is also advisable to install a simple filtration system (cartridge

filters) in the recirculation loop in order to prevent suspended solids

from re-entering the system and damaging the membranes.

How to clean?

The general cleaning procedure for RO /NF membranes comprises

four main stages:

1. preparation of cleaning solution

2. recirculation of cleaning solution in the system

3. removal and rinsing of the used cleaning solution

4. start of production once the process is complete.

Application Guide 7 : Introduction to fouling and cleaning of reverse osmosis (RO) and nanofiltration (NF) membranes

www.genesysro.com

Application Guide

Preparation of the cleaning solution

Removing the cleaning solution and rinsing.

The volume of cleaning solution is calculated using the number

of membranes to clean (volume in each pressure vessel) and the

volume of the cleaning circuit and pipe work. As accurate data is

sometimes difficult to ascertain, a rule of thumb is to use between

1.2 and 1.5 volumes of cleaning solution per volume of membranes.

Membrane manufacturers recommend using 30-50 litres per 8

membrane.

After cleaning (often sequential cleaning steps are necessary with

different chemicals) the membranes should be rinsed with product

water (flushing at high flow rates may be required to remove

suspended particles loosened by the cleaning process) to fully

displace the cleaning solution (until the pH in the feed and reject are

the same).

Production Start up.

Cleaning solutions should be prepared with good quality chlorine

free water (permeate water). The chemicals used should be added

to the water ensuring that changes in pH and temperature (heating

of the cleaning solution is often essential) are carried out gradually.

If necessary adjust the pH to the membrane manufacturers

specification using hydrochloric acid or sodium hydroxide. Removal

of organic foulants is dependent on achieving the optimum

temperature and pH.

Following the rinse and before the plant is returned to production,

discard the initial production volume to ensure the total elimination

of chemicals used in cleaning, preventing contamination of the

product water. Always follow the membrane manufacturers

guidelines.

Cleaning products

The choice of cleaning products used in each case depends on the

type of membrane fouling. We recommend performing a membrane

autopsy to determine the

exact nature and extent of

contamination. For membranes

contaminated with different

foulants it may be necessary

to use a combination of

different products in one or

more stages of cleaning to

ensure efficient removal.

Re-circulation of cleaning solution

For optimal cleaning use the maximum flow recommended by

the manufacturer of the membranes and the pressure must be

between 1.5 - 4.0 bar. In order to optimise the contact between the

cleaning solution and the deposits and successfully remove them it

is recommended to alternate periods of recirculation and soaking.

Throughout the cycle, monitor changes in pH and colour of the

cleaning solution. If the pH changes by >1.0 pH unit or the solution

becomes discoloured then discard and prepare a fresh solution. This

helps avoid membrane abrasion and improves cleaning efficiency.

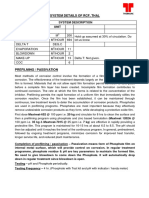

Selection of Genesol Cleaning Products

Product

Description

Genesol 30

Fast Acting Biocide

CaCO3

CaSO4

BaSO4

Genesol 32

Preserving Biocide

Genesol 34

Alkaline chelant

Genesol 36

Surfactant

Genesol 37

Strong acid

Genesol 38

Liquid acid

SiO2

CaPO4

Mg(OH)2

Organic

Colloids

Genesol 40

Alkaline cleaner

Genesol 50

Alkaline chelant

Genesol 703

Powdered alkaline cleaner

Fe/Mn

Hints For The Selection Of Cleaning Products

Ideally always start cleaning with alkaline products and finish

with acid products.

Deposits of organic matter and biofilm form in the first

membranes and can be difficult to remove, use a combination of

biocides and alkaline cleaners.

Colloidal matter (aluminosilicates) is also cleaned with alkaline

formulations. Genesol 703 is especially effective against this

type of deposit

Calcium carbonate scales are formed very quickly in the final

membranes. Genesol 37 is the most effective product

Calcium sulphate is also formed in the final membranes, this is

especially difficult to clean, although Genesol 34, a chelating

agent is a good option.

Genesol 40 is a highly effective in cleaning silica.

Iron deposits are easily cleaned with acid cleaners, such as

Genesol 38

YEARS

YEARS

Genesys International Limited 3A Aston Way, Middlewich, Cheshire, UK, CW10 0HS

t: +44(0)1606 837 605 f: +44(0)1606 837 558 e: info@genesysro.com

Potrebbero piacerti anche

- Analytical Methods for Drinking Water: Advances in Sampling and AnalysisDa EverandAnalytical Methods for Drinking Water: Advances in Sampling and AnalysisNessuna valutazione finora

- Membrane Cleaning 101 PDFDocumento5 pagineMembrane Cleaning 101 PDFsamrickyNessuna valutazione finora

- Adv 885 Ro Pac M QuickrefguideDocumento8 pagineAdv 885 Ro Pac M QuickrefguideAlejandroOdioCastilloNessuna valutazione finora

- Filmtec RO Membrane CleaningDocumento2 pagineFilmtec RO Membrane Cleaningzulmas100% (1)

- Foulants and Cleaning Procedures of RO MembraneDocumento7 pagineFoulants and Cleaning Procedures of RO MembranesushantNessuna valutazione finora

- Pre Treatment PresentationDocumento183 paginePre Treatment PresentationHamza RaoNessuna valutazione finora

- Cooling Tower RO SystemDocumento7 pagineCooling Tower RO SystemAbdul SamadNessuna valutazione finora

- Exp 3Documento15 pagineExp 3mjunaidNessuna valutazione finora

- CIP Procedure of RO MembraneDocumento2 pagineCIP Procedure of RO MembraneImran Ahmed Jewel100% (2)

- Water Treatment Brochure PDFDocumento8 pagineWater Treatment Brochure PDFmathesis-2Nessuna valutazione finora

- Cleaning OverviewDocumento32 pagineCleaning Overviewnash100% (3)

- Coagulants For Water Treatment: Application FeaturesDocumento1 paginaCoagulants For Water Treatment: Application FeaturesSIVAPATHASEKARANNessuna valutazione finora

- Ecolab FS Brochure 2016 - EN PDFDocumento39 pagineEcolab FS Brochure 2016 - EN PDFkaduwdNessuna valutazione finora

- Effluent Treatment PlantDocumento16 pagineEffluent Treatment PlantVishal guptaNessuna valutazione finora

- Raw Water TreatmentDocumento85 pagineRaw Water TreatmentHeru PramudyaNessuna valutazione finora

- Case History - MBR Plant Achieves Higher Flow With PermaCareDocumento4 pagineCase History - MBR Plant Achieves Higher Flow With PermaCareSandeep K TiwariNessuna valutazione finora

- Water Chemistry IN Thermal Power Plants (An Overview) : O.P.RangwaniDocumento24 pagineWater Chemistry IN Thermal Power Plants (An Overview) : O.P.RangwaniAbhishek Prakash Srivastava100% (1)

- SWTP Operation ManualDocumento131 pagineSWTP Operation ManualKASHIFNessuna valutazione finora

- Chem-Aqua Corp BrochureDocumento8 pagineChem-Aqua Corp BrochureQuốc Anh KhổngNessuna valutazione finora

- Wastewater TrainDocumento3 pagineWastewater TrainLester Mercado100% (1)

- Revotech Sewage Treatment Opt PDFDocumento5 pagineRevotech Sewage Treatment Opt PDFPrashant Singh ChauhanNessuna valutazione finora

- Sewage Treatment Plant PDF in Hindi 1Documento64 pagineSewage Treatment Plant PDF in Hindi 1Pankaj Gogoi100% (1)

- Thermax Chemical Division Brochure PDFDocumento24 pagineThermax Chemical Division Brochure PDFmathesis-2Nessuna valutazione finora

- UC2 - Water Treatment System (Group3)Documento166 pagineUC2 - Water Treatment System (Group3)Banjo MirandillaNessuna valutazione finora

- Innovative Offerings For Membrane and Thermal Desalination PlantsDocumento24 pagineInnovative Offerings For Membrane and Thermal Desalination Plantscvolkan1Nessuna valutazione finora

- Cleaning Spiral Wound MembranesDocumento4 pagineCleaning Spiral Wound MembranesBhavik ZalaNessuna valutazione finora

- Tannin BasedDocumento5 pagineTannin BasedVinod SindhavNessuna valutazione finora

- Norit Ac Potable Water BrochureDocumento9 pagineNorit Ac Potable Water BrochureNermeen ElmelegaeNessuna valutazione finora

- Cleaning and Sanitizing in The Milk Processing Industry 2010Documento28 pagineCleaning and Sanitizing in The Milk Processing Industry 2010John WaweruNessuna valutazione finora

- 2000 LPH Reverse Osmosis Plant FRPDocumento20 pagine2000 LPH Reverse Osmosis Plant FRPt m murshedNessuna valutazione finora

- Effluent Treatment Plant-In Ahmedabad Gujarat IndiaDocumento8 pagineEffluent Treatment Plant-In Ahmedabad Gujarat IndiaShubham India - Sewage Treatment PlantNessuna valutazione finora

- 500 LPH Ro SystemDocumento9 pagine500 LPH Ro SystemAbdul SamadNessuna valutazione finora

- New Updated Profile Bimal WaterDocumento25 pagineNew Updated Profile Bimal WaterJaved HasanNessuna valutazione finora

- NOH-ASSE BasicsofWaterPurificationSessionDocumento61 pagineNOH-ASSE BasicsofWaterPurificationSessionNector Jr. GuevarraNessuna valutazione finora

- Determination of Ca Sequestration ValueDocumento3 pagineDetermination of Ca Sequestration ValueGovindanayagi PattabiramanNessuna valutazione finora

- Argentina Membrane Filtration JCD PDFDocumento42 pagineArgentina Membrane Filtration JCD PDFjpsingh75Nessuna valutazione finora

- For Water & Waste Water Treatment: Cleaner TechnologiesDocumento33 pagineFor Water & Waste Water Treatment: Cleaner Technologieskrishan kumar AgarwalNessuna valutazione finora

- ECOLab FactBook 01Documento85 pagineECOLab FactBook 01Roy Ellison100% (1)

- CIP PresentationDocumento28 pagineCIP PresentationVictor LeiNessuna valutazione finora

- Water QuotationDocumento12 pagineWater Quotationanand sahuNessuna valutazione finora

- Activated Carbon For Waste Water Treatment v2 NDocumento8 pagineActivated Carbon For Waste Water Treatment v2 NMohammed A. Helal100% (1)

- Cooling Water Problems and Solutions CouDocumento56 pagineCooling Water Problems and Solutions CouBanvari GurjarNessuna valutazione finora

- Uf Tech ManualDocumento18 pagineUf Tech ManualVemulapalli SaibabuNessuna valutazione finora

- Metito - TSE RO Presentation KM DC WorkshopDocumento24 pagineMetito - TSE RO Presentation KM DC WorkshopMohamed TahounNessuna valutazione finora

- Hydrex 4101Documento6 pagineHydrex 4101Bere SnchzNessuna valutazione finora

- Demin + Boiler - Standard Internet PDFDocumento87 pagineDemin + Boiler - Standard Internet PDFRudyNessuna valutazione finora

- How DMI 65 WorksDocumento7 pagineHow DMI 65 Worksashry09Nessuna valutazione finora

- HYDRAcap MAX Presentation - Abril 2012Documento32 pagineHYDRAcap MAX Presentation - Abril 2012PC VSNessuna valutazione finora

- INDION Ion Exchange ResinsDocumento8 pagineINDION Ion Exchange ResinsvinonaguNessuna valutazione finora

- UF TORAY PresentationDocumento27 pagineUF TORAY PresentationAlfonso José García Laguna100% (1)

- Volume 5 Phosphonate TestingDocumento4 pagineVolume 5 Phosphonate TestingMiguel GonzalezNessuna valutazione finora

- SLESDocumento5 pagineSLESAllyana TiemsimNessuna valutazione finora

- What Is Wastewater Treatment?: EnvironmentDocumento9 pagineWhat Is Wastewater Treatment?: EnvironmentAli JawwadNessuna valutazione finora

- Pass I VationDocumento1 paginaPass I VationSankar100% (1)

- Aventura Iron Removal MediaDocumento2 pagineAventura Iron Removal MediaAkshay NarayankarNessuna valutazione finora

- WTE-ENDOM2021001505-R12-AS Cooling-SSF and DSDocumento26 pagineWTE-ENDOM2021001505-R12-AS Cooling-SSF and DSDeepak Patil100% (1)

- MSDS - Polyelectrolyte, CleartechDocumento7 pagineMSDS - Polyelectrolyte, CleartechBazil BoliaNessuna valutazione finora

- Boiler Chemical FormulaDocumento5 pagineBoiler Chemical Formulasaif asqalanyNessuna valutazione finora

- Cleaning Procedure HydranauticsDocumento5 pagineCleaning Procedure Hydranauticsmirza_adil99Nessuna valutazione finora

- TSG C 001 Membrane Cleaning Guide Water Application ElementsDocumento5 pagineTSG C 001 Membrane Cleaning Guide Water Application ElementsSaeed DehestaniatharNessuna valutazione finora

- Filternox vs. Sand FiltersDocumento11 pagineFilternox vs. Sand FiltersBiljana TausanovicNessuna valutazione finora

- Filtration Module Gravel Filters Sec - 5 Dec 00Documento6 pagineFiltration Module Gravel Filters Sec - 5 Dec 00Biljana TausanovicNessuna valutazione finora

- Filtration Module Gravel Filters Sec - 5 Dec 00Documento33 pagineFiltration Module Gravel Filters Sec - 5 Dec 00Arun GuptaNessuna valutazione finora

- Bentonite Wastewater Treatment PDFDocumento12 pagineBentonite Wastewater Treatment PDFBiljana TausanovicNessuna valutazione finora

- Alkalinity ConversionsDocumento1 paginaAlkalinity Conversionsahmedmagdi2009Nessuna valutazione finora

- Iso 5814 PDFDocumento5 pagineIso 5814 PDFBiljana TausanovicNessuna valutazione finora

- PVC Chemical ResistantDocumento14 paginePVC Chemical ResistantIndunil Prasanna Bandara WarnasooriyaNessuna valutazione finora

- The Kinetics of Rotating Biological Contactors Treating DomesticDocumento120 pagineThe Kinetics of Rotating Biological Contactors Treating DomesticBiljana TausanovicNessuna valutazione finora

- Membrane AutopsyDocumento2 pagineMembrane AutopsyBiljana TausanovicNessuna valutazione finora

- Lime Softening PDFDocumento16 pagineLime Softening PDFBiljana TausanovicNessuna valutazione finora

- Sludge DisposalDocumento62 pagineSludge Disposalblumunchie100% (2)

- Steps To Design RO SystemDocumento5 pagineSteps To Design RO SystemBiljana TausanovicNessuna valutazione finora

- Rohm&Haas Principles. 1997-2003Documento25 pagineRohm&Haas Principles. 1997-2003Biljana Tausanovic100% (1)

- Potassium PermanganateDocumento15 paginePotassium Permanganatejewettwater100% (1)

- Constant Head Permeability TestDocumento14 pagineConstant Head Permeability Testfuji0% (1)

- Bearing Materials - Engineering Materials & Metallurgy Questions and Answers - SanfoundryDocumento3 pagineBearing Materials - Engineering Materials & Metallurgy Questions and Answers - SanfoundrySample UseNessuna valutazione finora

- Msds Sodium BicarbonateDocumento4 pagineMsds Sodium BicarbonateDeny Aditya PratamaNessuna valutazione finora

- 1 - Biochemistry Notes by Dr. M A Bari Siddiqui: DrmentorsDocumento3 pagine1 - Biochemistry Notes by Dr. M A Bari Siddiqui: DrmentorsShiva KumarNessuna valutazione finora

- Detailed Lesson PlanDocumento5 pagineDetailed Lesson PlanGspr BoJoyNessuna valutazione finora

- VSS, Chem., B.SC - Sem.I, Structure and Bonding NotesDocumento29 pagineVSS, Chem., B.SC - Sem.I, Structure and Bonding NotesKushma KushmaNessuna valutazione finora

- Solid State Physics-Springer (2022)Documento550 pagineSolid State Physics-Springer (2022)Shehnila KarimNessuna valutazione finora

- Usp 665Documento8 pagineUsp 665AdrianaNessuna valutazione finora

- Lecture 1Documento31 pagineLecture 1Yingqi SuNessuna valutazione finora

- NGDocumento23 pagineNGEngr. Md. Tipu SultanNessuna valutazione finora

- DAFTAR PUSTAKA EllaDocumento3 pagineDAFTAR PUSTAKA EllaElla IntanNessuna valutazione finora

- SA Model NasaDocumento9 pagineSA Model NasaMohit GuptaNessuna valutazione finora

- EMF ExercisesDocumento42 pagineEMF ExercisesBEEMI REDDY VENKATA REDDYNessuna valutazione finora

- Solubility of S-Block CompoundsDocumento4 pagineSolubility of S-Block CompoundsNkemzi Elias NzetengenleNessuna valutazione finora

- Experimental Investigation of CI Engine Performance by Nano Additive in BiofuelDocumento5 pagineExperimental Investigation of CI Engine Performance by Nano Additive in BiofuelThiruvasagamoorthy KaNessuna valutazione finora

- GW - MS Series - Quick Installation Guide-POLYDocumento83 pagineGW - MS Series - Quick Installation Guide-POLYWaldemiro AzeredoNessuna valutazione finora

- CH 23 Knight 4thDocumento68 pagineCH 23 Knight 4thIshiCNessuna valutazione finora

- Soil Sience - Chapter 5Documento40 pagineSoil Sience - Chapter 5awokeNessuna valutazione finora

- Gas Treating Products and Services PDFDocumento16 pagineGas Treating Products and Services PDFProcess EngineerNessuna valutazione finora

- Fluid Mechanics - Assignment I-2012-2013Documento6 pagineFluid Mechanics - Assignment I-2012-2013Robert WalusimbiNessuna valutazione finora

- Gate 2005 CyDocumento14 pagineGate 2005 CySumanta- 14Nessuna valutazione finora

- Demystifying Quantum MechanicsDocumento10 pagineDemystifying Quantum Mechanicsmrbubos0% (1)

- Chemistry Grade 11Documento198 pagineChemistry Grade 11Jan92% (24)

- The Chernobyl Disaster - Wil MaraDocumento113 pagineThe Chernobyl Disaster - Wil MaraAgerrle_Isnowon100% (3)

- Rotomolded Tanks - Importance of Rotomolded TanksDocumento3 pagineRotomolded Tanks - Importance of Rotomolded Tanksrotomould03Nessuna valutazione finora

- IGSCE Reviewer Multiple Choice PDFDocumento52 pagineIGSCE Reviewer Multiple Choice PDFAlan Peter50% (2)

- General Properties of MaterialsDocumento24 pagineGeneral Properties of Materials1900651Nessuna valutazione finora

- Metal-Salen Schiff Base Complexes in Catalysis: Practical AspectsDocumento12 pagineMetal-Salen Schiff Base Complexes in Catalysis: Practical Aspects0191710017 JULIAN DAVID QUIMBAYO PARRA ESTUDIANTE ACTIVO100% (1)

- Designing For Pressure Safety Valves in Supercritical ServiceDocumento4 pagineDesigning For Pressure Safety Valves in Supercritical ServiceSrinivas BobbyNessuna valutazione finora

- Canadian Milling Practice 421 FinalDocumento5 pagineCanadian Milling Practice 421 Finalapi-594954613Nessuna valutazione finora

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseDa EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseValutazione: 3.5 su 5 stelle3.5/5 (69)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingDa EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingValutazione: 5 su 5 stelle5/5 (5)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessDa EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNessuna valutazione finora

- The Other End of the Leash: Why We Do What We Do Around DogsDa EverandThe Other End of the Leash: Why We Do What We Do Around DogsValutazione: 5 su 5 stelle5/5 (65)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingDa EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingValutazione: 3.5 su 5 stelle3.5/5 (34)

- Fire Season: Field Notes from a Wilderness LookoutDa EverandFire Season: Field Notes from a Wilderness LookoutValutazione: 4 su 5 stelle4/5 (142)

- The Big, Bad Book of Botany: The World's Most Fascinating FloraDa EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraValutazione: 3 su 5 stelle3/5 (10)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionDa EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionValutazione: 4 su 5 stelle4/5 (811)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsDa EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsValutazione: 4 su 5 stelle4/5 (223)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldDa EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldValutazione: 4.5 su 5 stelle4.5/5 (18)

- Spoiled Rotten America: Outrages of Everyday LifeDa EverandSpoiled Rotten America: Outrages of Everyday LifeValutazione: 3 su 5 stelle3/5 (19)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildDa EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildValutazione: 4.5 su 5 stelle4.5/5 (44)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeDa EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeValutazione: 4.5 su 5 stelle4.5/5 (699)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsDa EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsValutazione: 3.5 su 5 stelle3.5/5 (13)

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldDa EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldValutazione: 4 su 5 stelle4/5 (593)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorDa EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorValutazione: 4.5 su 5 stelle4.5/5 (137)

- Come Back, Como: Winning the Heart of a Reluctant DogDa EverandCome Back, Como: Winning the Heart of a Reluctant DogValutazione: 3.5 su 5 stelle3.5/5 (10)

- When the Sahara Was Green: How Our Greatest Desert Came to BeDa EverandWhen the Sahara Was Green: How Our Greatest Desert Came to BeValutazione: 4.5 su 5 stelle4.5/5 (6)

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderDa EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderValutazione: 4 su 5 stelle4/5 (283)