Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Exceed™ 1018 Series: Metallocene Polyethylene Resin

Caricato da

ChanakyaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Exceed™ 1018 Series: Metallocene Polyethylene Resin

Caricato da

ChanakyaCopyright:

Formati disponibili

Product Datasheet

Exceed1018 Series

Metallocene Polyethylene Resin

Product Description

Exceed 1018 resins are metallocene ethylene-hexene copolymers. Films made from Exceed 1018 resin have outstanding tensile, impact strength

and puncture. These superior strength properties, along with excellent drawability, allow downgauging in bag application.

General

Availability1

Latin America

Additive

Exceed 1018KA: Antiblock: 5000 ppm; Slip: 1000 ppm; Processing Aid: Yes; Thermal Stabilizer: Yes

Exceed 1018MK: Antiblock: 5000 ppm; Slip: 1000 ppm; Processing Aid: Yes; Thermal Stabilizer: Yes

Exceed 1018LA: Antiblock: 4500 ppm; Slip: 450 ppm; Processing Aid: Yes; Thermal Stabilizer: Yes

Exceed 1018JA: Antiblock: 4500 ppm; Slip: No; Processing Aid: Yes; Thermal Stabilizer: Yes

Applications

Agricultural Film

Bag in Box

Barrier Food Packaging

Blown Film

Bread Bags

Food packaging

Form Fill And Seal Packaging

Revision Date

12/01/2012

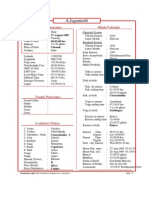

Resin Properties

Density

Melt Index (190C/2.16 kg)

Peak Melting Temperature

Film Properties

North America

Typical Value (English)

0.918 g/cm

1.0 g/10 min

247 F

Typical Value (English)

Freezer Film

General Packaging

Heavy Duty Bags

Industrial Packaging

Lamination Film

Multilayer Packaging Film

Overwrap Film

Packaging Films

Premium Trash Bags

Stand Up Pouches

Trash Bags

Trash Can Liners

Typical Value (SI)

0.918 g/cm

1.0 g/10 min

119 C

Typical Value (SI)

Test Based On

ExxonMobil

Method

ASTM D1238

ExxonMobil

Method

Test Based On

Tensile Strength at Yield MD

1400 psi

9.4 MPa

ASTM D882

Tensile Strength at Yield TD

1400 psi

9.4 MPa

ASTM D882

Tensile Strength at Break MD

7900 psi

50 MPa

ASTM D882

Tensile Strength at Break TD

6200 psi

43 MPa

ASTM D882

Elongation at Break MD

500 %

500 %

ASTM D882

Elongation at Break TD

600 %

600 %

ASTM D882

Secant Modulus MD - 1% Secant

27000 psi

190 MPa

ASTM D882

Secant Modulus TD - 1% Secant

28000 psi

190 MPa

ASTM D882

Dart Drop Impact

460 g

460 g

ASTM D1709A

Elmendorf Tear Strength MD

250 g

250 g

ASTM D1922

Elmendorf Tear Strength TD

470 g

470 g

ASTM D1922

Puncture Force

8 lbf

36 N

ExxonMobil

Method

Puncture Energy

16 inlb

1.8 J

ExxonMobil

Method

Optical Properties

Typical Value (English)

Typical Value (SI)

Test Based On

Gloss (45)

39

39

ASTM D2457

Haze

18 %

18 %

ASTM D1003

Legal Statement

Contact your ExxonMobil Chemical Customer Service Representative for potential food contact application compliance (e.g. FDA, EU, HPFB).

This product is not intended for use in medical applications and should not be used in any such applications.

Effective Date: 12/01/2012

ExxonMobil

Page: 1 of 2

Product Datasheet

Exceed1018 Series

Metallocene Polyethylene Resin

Processing Statement

Film (1 mil/25.4 micron) made from Exceed 1018KA on a 2.5 inch (63.5 mm) blown film line with a 2.5:1 blow-up ratio, a melt temperature of

403F (206C), a 60 mil (1.52 mm) die gap at a rate of 10 lbs/hr/in die circumference (1.79 kg/hr/cm).

Notes

Typical properties: these are not to be construed as specifications.

1Product

may not be available in one or more countries in the identified Availability regions. Please contact your Sales Representative for

complete Country Availability.

For additional technical, sales and order assistance: www.exxonmobilchemical.com/ContactUs

2016 ExxonMobil. ExxonMobil, the ExxonMobil logo, the interlocking X device and other product or service names used herein are trademarks of

ExxonMobil, unless indicated otherwise. This document may not be distributed, displayed, copied or altered without ExxonMobil's prior written

authorization. To the extent ExxonMobil authorizes distributing, displaying and/or copying of this document, the user may do so only if the document

is unaltered and complete, including all of its headers, footers, disclaimers and other information. You may not copy this document to or reproduce it

in whole or in part on a website. ExxonMobil does not guarantee the typical (or other) values. Any data included herein is based upon analysis of

representative samples and not the actual product shipped. The information in this document relates only to the named product or materials when

not in combination with any other product or materials. We based the information on data believed to be reliable on the date compiled, but we do not

represent, warrant, or otherwise guarantee, expressly or impliedly, the merchantability, fitness for a particular purpose, freedom from patent

infringement, suitability, accuracy, reliability, or completeness of this information or the products, materials or processes described. The user is solely

responsible for all determinations regarding any use of material or product and any process in its territories of interest. We expressly disclaim liability

for any loss, damage or injury directly or indirectly suffered or incurred as a result of or related to anyone using or relying on any of the information in

this document. This document is not an endorsement of any non-ExxonMobil product or process, and we expressly disclaim any contrary implication.

The terms we, our, "ExxonMobil Chemical" and "ExxonMobil" are each used for convenience, and may include any one or more of ExxonMobil

Chemical Company, Exxon Mobil Corporation, or any affiliate either directly or indirectly stewarded.

exxonmobilchemical.com

Effective Date: 12/01/2012

ExxonMobil

Page: 2 of 2

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- 07-GB Column BasesDocumento14 pagine07-GB Column BasesAUNGPSNessuna valutazione finora

- CM Dashboard Arunachal PradeshDocumento8 pagineCM Dashboard Arunachal PradeshDebashish Goswami100% (1)

- Tattva IIDocumento8 pagineTattva IIVisti LarsenNessuna valutazione finora

- Cycle CountDocumento58 pagineCycle CountPJ190275% (4)

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocumento3 pagineContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction Manualmalika_00Nessuna valutazione finora

- 24-Bhrighu Saral Paddathi - 5Documento14 pagine24-Bhrighu Saral Paddathi - 5SaptarishisAstrology100% (1)

- Failure Mechanisms of C-Steels (API 571)Documento90 pagineFailure Mechanisms of C-Steels (API 571)Abdul Gafoor Shaikh50% (2)

- 4 MivDocumento19 pagine4 Mivpavankumar001Nessuna valutazione finora

- Report - MillingDocumento8 pagineReport - MillingMaarij Anjum50% (2)

- 36-Bhrighu Saral Paddathi - 7Documento8 pagine36-Bhrighu Saral Paddathi - 7SaptarishisAstrologyNessuna valutazione finora

- Deep Sea Research Submarine Report PDFDocumento128 pagineDeep Sea Research Submarine Report PDFy_596688032Nessuna valutazione finora

- BETA-2 Pancake Geiger TubeDocumento4 pagineBETA-2 Pancake Geiger TubeqqazertyNessuna valutazione finora

- Understanding ZTPFDocumento41 pagineUnderstanding ZTPFsanjivrmenonNessuna valutazione finora

- ModelsGuidelines v5Documento37 pagineModelsGuidelines v5Martin NolanNessuna valutazione finora

- Schemes of Maharashtra State Agricultural Marketing Board (Msamb)Documento2 pagineSchemes of Maharashtra State Agricultural Marketing Board (Msamb)ChanakyaNessuna valutazione finora

- IASbaba Prelims 60 Days PlanDocumento58 pagineIASbaba Prelims 60 Days PlanAmit MeherNessuna valutazione finora

- Lotryl: Ethylene - Methyl Acrylate CopolymerDocumento2 pagineLotryl: Ethylene - Methyl Acrylate CopolymerChanakyaNessuna valutazione finora

- Medieval Class 7 Chapter 10Documento18 pagineMedieval Class 7 Chapter 10ChanakyaNessuna valutazione finora

- Case Adhesives BrochureDocumento6 pagineCase Adhesives BrochureChanakyaNessuna valutazione finora

- Clariant FRDocumento28 pagineClariant FRChanakyaNessuna valutazione finora

- Design Unlimited: Baydur & BayflexDocumento12 pagineDesign Unlimited: Baydur & BayflexChanakyaNessuna valutazione finora

- Executive Director Rahul Sharma PDFDocumento2 pagineExecutive Director Rahul Sharma PDFjpsmu09Nessuna valutazione finora

- Bioadimide 100 en RCRDocumento2 pagineBioadimide 100 en RCRChanakyaNessuna valutazione finora

- Ebrochure EnglishDocumento13 pagineEbrochure Englishrandykotra100% (1)

- All Horoscope-Dasha-Varshapala Charts and CalculationsDocumento88 pagineAll Horoscope-Dasha-Varshapala Charts and CalculationsChanakyaNessuna valutazione finora

- US India Composite and Plastic OpportunitiesDocumento4 pagineUS India Composite and Plastic OpportunitiesChanakyaNessuna valutazione finora

- Marketing of Agriculture InputsDocumento18 pagineMarketing of Agriculture InputsChanakyaNessuna valutazione finora

- Marketing of Agriculture InputsDocumento18 pagineMarketing of Agriculture InputsChanakyaNessuna valutazione finora

- Odisha Current Affairs 2019 by AffairsCloudDocumento27 pagineOdisha Current Affairs 2019 by AffairsCloudTANVEER AHMEDNessuna valutazione finora

- ASTM D1265-11 Muestreo de Gases Método ManualDocumento5 pagineASTM D1265-11 Muestreo de Gases Método ManualDiana Alejandra Castañón IniestraNessuna valutazione finora

- Samsung SSD 850 EVO M2 Data Sheet Rev2Documento4 pagineSamsung SSD 850 EVO M2 Data Sheet Rev2Piyush ShrivastavaNessuna valutazione finora

- Eletrical Motor OffshoreDocumento38 pagineEletrical Motor OffshoreandreisraelNessuna valutazione finora

- Silabus Reading VDocumento4 pagineSilabus Reading VAndi AsrifanNessuna valutazione finora

- The Sims 4 Cheats For PC: Platform. If You've DiscoveredDocumento2 pagineThe Sims 4 Cheats For PC: Platform. If You've DiscoveredDean Joyce AlborotoNessuna valutazione finora

- Table UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3Documento7 pagineTable UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3MechanicalNessuna valutazione finora

- Himmlischer Adventjodler StringsDocumento2 pagineHimmlischer Adventjodler StringsSibille HuberNessuna valutazione finora

- Activities Pm.Documento13 pagineActivities Pm.jona llamasNessuna valutazione finora

- 20140630-A2384 ALTRONIXDocumento30 pagine20140630-A2384 ALTRONIXRicardo MercadoNessuna valutazione finora

- Xample Program in C++ Using File Handling To Perform Following OperationsDocumento6 pagineXample Program in C++ Using File Handling To Perform Following OperationsNamita SahuNessuna valutazione finora

- Xiaopan OS InstallationDocumento6 pagineXiaopan OS InstallationMuhammad SyafiqNessuna valutazione finora

- Dokumen - Tips Cfm56 7 B AnswerbookDocumento75 pagineDokumen - Tips Cfm56 7 B AnswerbookOnur YayNessuna valutazione finora

- TableauDocumento5 pagineTableaudharmendardNessuna valutazione finora

- Practice Questions PneumaticsDocumento13 paginePractice Questions Pneumaticssamer07hd100% (3)

- Pre-Disciplinary and Post-Disciplinary Perspectives: Bob Jessop & Ngai-Ling SumDocumento13 paginePre-Disciplinary and Post-Disciplinary Perspectives: Bob Jessop & Ngai-Ling SumMc_RivNessuna valutazione finora

- Android Chapter13 Multi ThreadingDocumento42 pagineAndroid Chapter13 Multi ThreadingPrasad G. Kulkarni50% (2)

- Novell Course 3076 SUSE Upgrading To Certified Linux Engineer 10Documento362 pagineNovell Course 3076 SUSE Upgrading To Certified Linux Engineer 10Legioner LegionerovNessuna valutazione finora