Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

M. H. Butler &. C. A. Larson.: (No Model.)

Caricato da

Kosmas StefanidesTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

M. H. Butler &. C. A. Larson.: (No Model.)

Caricato da

Kosmas StefanidesCopyright:

Formati disponibili

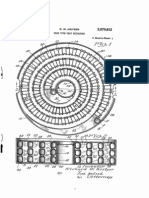

'No. 7l0,422.

'

Patanted 001:; 7, I902.

,M. H. BUTLER &. C. A. LARSON.

VEGETABLE WASHER.

(Application ?led Sept. 17, 1900.)

(No Model.)

I'm: mmius vn'zns 50.. Pkomuma. wxsmncwu, o. c.

UNITED STATES PATENT OFFICE;

MILTON H. BUTLER AND CARL A. LARSON,v OF CHERRYCREEK, NEW YORK.

VEGETABLE-WASHER.

SPECIFICATION forming part of Letters Patent No. 710,422, dated October 7, 1902.

Application ?led September 17, 1900. Serial No. 30,825. (No-model.)

der to afford spaces for the introduction of

Be it knownthat we,MILTON H. B UTLER and the vegetables or fruit to the space between

To ctZZ whom it may concern.

CARL A.LARSON, citizens of theUnitedStates, the two cylinders. From the opposite end of

residing at Oherrycreek, in the county of the closed cylinder 10, which is considerably

Chautauqua and State of New York, have in shorter than the cylinder 13, extend a series

vented a new and useful Vegetable-\Vasher, of spokes 16, secured to both cylinders and

10

of which the following is a speci?cation.

Our invention relates to certain improve

ments in vegetable-washers, and has for its

object to provide a device of simple and eco'-

nomical construction by which fruit and vege

tables may be thoroughly washed without

injury and automatically drained andvdis

serving as asupport for the outer cylinder,

that portion of the outer cylinder projecting

beyond the end of the cylinder 10 being of

sufficient strength to support the end disk 14,

the latter being closed to prevent the escape

of fruit or vegetables from the outer cylinder

except at the central portion, where a small

charged from the machine into _a suitable opening is provided for the introduction of

a discharge-chute 18, which is partly sup

receptacle.

With these and other objects-in view the in_ ported in position by the shaft 8, the latter

vention consists in the novel construction and passing through an opening 19 near the in

combination of parts hereinafter described, ner end of said chute. At the opposite end 70

illustrated in the accompanying drawings,and of the machine is arranged a suitable feed

20 particularly pointed out in the appended hopper or chute17, adapted to deliver the

fruit or vegetables into the space between

claim.

A

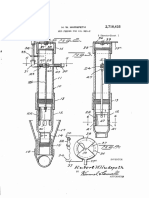

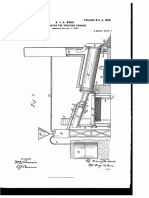

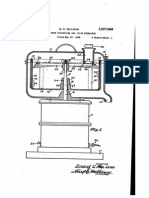

In the drawings, Figure 1 is a plan View of the two cylinders.

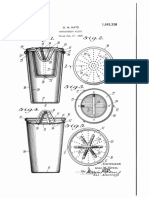

At the discharge end of the machine are ar 75

a vegetable-washing machine constructed in

accordance with our invention, a portion of ranged a number of buckets 20, each consist

the

outer foraminous cylinder being broken ing of a section of foraminous material bent

25

away in order to more clearly illustrate the into scoop shape and having its opposite sides

interior parts. Fig. 2 is a longitudinal sec-. secured, respectively, to the inner surface of

tional elevation of the same. Fig. 3 is a the disk 14 and one of the spokes 16, said

transverse sectional elevation of the machine buckets being of sufficient length to extend

from the periphery of the inner cylinder 10

on the line 3 3 of Fig. 2.

Similar numerals of reference are employed to the outer cylinder 13 and serving to ele

to indicate corresponding parts throughout vate the fruit or vegetables from the water

and discharge the same into the chute 18, the

the several ?gures of the drawings.

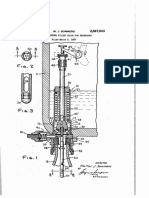

5 designates a suitable tank or trough hav water being drained from the vegetables

35 ing at its opposite ends bearings 6 and 7 for

the support of a horizontally-disposed shaft

8, the latter being provided at one end with a

driving-pulley 9. On the shaft 8 is secured a

closed cylinder 10, having a perfectly smooth

exterior surface to prevent injury to the fruit

during the movement above the water-line.

At one end of the tank, preferably at the

feed end, is a water-supply pipe 22, and at

the discharge end is a water-discharge 23, the

latter being arranged in about the horizontal

plane of the closed cylinder for the purpose

or vegetables, said cylinder being somewhat of maintaining a constant level of water at a

shorter than the tank and so arranged that point slightly above the extreme lower edge

its lower portion will be slightly below the of said cylinder, so that the fruit or vegeta 95

bles which may rise to the top of the water

will be prevented from ?oating from one side

from one'end of the cylinder to the other, and of the cylinder to the other.

The helical ?ange 12 extends from the closed

this helical ?ange supports a cylindrical fo

raminous casing 13, the opposite ends of cylinder to the outer foraminous cylinder and

which are secured to circular end pieces let forms what may be considered a series of

water-line. On the cylinder 10 is secured a

45 helical flange or screw 12, which progresses

50 and 14.

The end piece 14 is inthe form of chambers along the length of the shorter cyl

a ring and is supported by spokes 15, extend

ing radially from the closed cylinder in or

inder, there being no passage for the fruit or

Vegetables except that afforded by following

710,422

the helical line of the ?ange. In this man face, a smooth-surfaced helical ?ange secured

ner the vegetables may be retained -in the to the periphery of the cylinder and extend

water for any desired length of time and sub ing throughout its length, a foraminous cyl 35

jected to a longer or shorter washing action inder secured to the peripheral edge of said

in accordance with the character and condi ?ange and projecting beyond its discharge

tion of the fruit or vegetables being treated. end, a disk 14 to which the delivery end of

As both the inner cylinder and the helical the outer cylinder is secured, a series of ra

?ange have perfectly smooth surfaces, there dial spokes connecting the end of the closed

will be no abrading or grating action what cylinder with the outer cylinder, radial f0

IO

ever on any of the ?oating fruits or vege

raminous delivery- buckets extending from

tables, and those which by reason of their the inner to the outer cylinder and having

greater speci?c gravity sink to the lower por their opposite edges connected to the spokes

I tion of the outer cylinder will be rolled to and the disk 14 respectively, a discharge-spout 45

some extent by the cylinder, but will be pro extending through a central opening in the

15 tected from abrasion by the water. At the ' disk and receiving the drained product from

end of the closed cylinder the vagetables are the foraminous buckets, a water-supply at

discharged into the space occupied by the the feed end of the tank, and a water-dis

buckets 20 and are carried by said buckets charge provided at- the discharge end of the

up above the water-line and drained and tank in about the horizontal plane of the

20 thence discharged into the chute v18.

lower portion of the closed cylinder, for main

In order to thoroughly wash the vegetables taining a constant water-level and a constant

or fruit, we prefer to maintain a constant flow ?ow in the direction of travel of the vegeta

of Water from end to end of the tank and in bles.

55

the same direction as that followed by the

In testimony that we claim the foregoing as

vegetables during their travel through the

our own we have hereto affixed our signa

machine.

tures in the presence of two witnesses. ,

Having thus described our invention, what

MILTON H. BUTLER.

CARL A. LARSON.

we clairnis

In a machine for washing vegetables and

fruit, the combination of a water-tank, a hori

zontal shaft, a closed cylinder carried by the

shaft and presenting a smooth peripheral sur

Witnesses:

GEO. W. OSWILL,

L. O. LANGWORTHY.

Potrebbero piacerti anche

- Scientific American Supplement, No. 611, September 17, 1887Da EverandScientific American Supplement, No. 611, September 17, 1887Nessuna valutazione finora

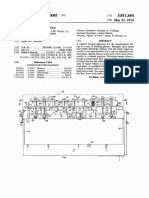

- Sept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LDocumento4 pagineSept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LRakeshNessuna valutazione finora

- Scientific American Supplement, No. 365, December 30, 1882Da EverandScientific American Supplement, No. 365, December 30, 1882Nessuna valutazione finora

- June 7, 1955 A, D. Kinser Et Al 2,710,071: Fi'iled Nov. 17. 1951Documento3 pagineJune 7, 1955 A, D. Kinser Et Al 2,710,071: Fi'iled Nov. 17. 1951محمود محمدNessuna valutazione finora

- Apparatus For Treating Sewage.: No. 659,503. I Patented Oct. 9, I900Documento4 pagineApparatus For Treating Sewage.: No. 659,503. I Patented Oct. 9, I900Abdullah SimpsonNessuna valutazione finora

- Apparatus For Disintegrating and Dewatering Fibrous MaterialDocumento5 pagineApparatus For Disintegrating and Dewatering Fibrous MaterialLaorenciaNessuna valutazione finora

- United States Patent: SchwartzmanDocumento4 pagineUnited States Patent: SchwartzmanJames LindonNessuna valutazione finora

- Us1955360 PDFDocumento8 pagineUs1955360 PDFRodrigoPomaNessuna valutazione finora

- Flower v. Detroit, 127 U.S. 563 (1888)Documento7 pagineFlower v. Detroit, 127 U.S. 563 (1888)Scribd Government DocsNessuna valutazione finora

- Us 2409624Documento6 pagineUs 2409624Giovanni BlancoNessuna valutazione finora

- Jan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1Documento5 pagineJan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1luiscremaschiNessuna valutazione finora

- Wa0012.Documento3 pagineWa0012.Ramos DavidNessuna valutazione finora

- US2900999-metal SealDocumento3 pagineUS2900999-metal Sealasen tsaiNessuna valutazione finora

- W.J. Sommers: Counter-Pressure Filler Valve For Beverages Filed March 5, 1957Documento3 pagineW.J. Sommers: Counter-Pressure Filler Valve For Beverages Filed March 5, 1957bimalishaNessuna valutazione finora

- March 6, 1928. 1,661,336: Jods Attor VeyDocumento3 pagineMarch 6, 1928. 1,661,336: Jods Attor VeyOscar Lora SiñaniNessuna valutazione finora

- 1,018,037 ... Patented Feb. 20, 1912.: .??? Coax/K Wyùkkevaoma ????Documento3 pagine1,018,037 ... Patented Feb. 20, 1912.: .??? Coax/K Wyùkkevaoma ????fernando Ancaya AncayaNessuna valutazione finora

- 1,138,232. Patented May 4, 1915,: 0, J, McgannDocumento3 pagine1,138,232. Patented May 4, 1915,: 0, J, McgannVyacheslavNessuna valutazione finora

- Sept. 2, 1.930. W. Wxlson 1,774,955: Filed De'C. 7, 1929 2 Sheets-Sheet L ADocumento5 pagineSept. 2, 1.930. W. Wxlson 1,774,955: Filed De'C. 7, 1929 2 Sheets-Sheet L Aاحمد عبدالكريمNessuna valutazione finora

- Nov. 9, 1965 R. C. Frampton Etal 3,216,663: Filed Nov. 15, 1963 2 Sheets-Sheet 1Documento5 pagineNov. 9, 1965 R. C. Frampton Etal 3,216,663: Filed Nov. 15, 1963 2 Sheets-Sheet 1Anggara T NugrahaNessuna valutazione finora

- Bottle Filler and Capper Unit: June 24, 1930. G. E. Strandt 1,766,962Documento8 pagineBottle Filler and Capper Unit: June 24, 1930. G. E. Strandt 1,766,962Luis Enrique Barreto GarciaNessuna valutazione finora

- Us 3378330Documento5 pagineUs 3378330James LindonNessuna valutazione finora

- Fish LadderDocumento5 pagineFish LadderKabuyaya DanNessuna valutazione finora

- Filed July 30, 1923: Pedal of Erator For Flush ValvesDocumento3 pagineFiled July 30, 1923: Pedal of Erator For Flush ValvesmarlondijiNessuna valutazione finora

- Guizlzarafngstrazzd: G1 C. EngstrandDocumento4 pagineGuizlzarafngstrazzd: G1 C. EngstrandAdhithya SriniNessuna valutazione finora

- LL-LLL'LL-FLL: 31, 1940. E. C. MmleanDocumento7 pagineLL-LLL'LL-FLL: 31, 1940. E. C. MmleanKrozeNessuna valutazione finora

- Us 1001260Documento5 pagineUs 1001260mehdi parsNessuna valutazione finora

- Another Corn Dog Machine PatentDocumento14 pagineAnother Corn Dog Machine PatentMinnesota Public RadioNessuna valutazione finora

- United States Patent (191: ReilingDocumento5 pagineUnited States Patent (191: ReilingTannyVaneNessuna valutazione finora

- Nov. 9, 1965 G. C. Molotzak 3,216,390Documento5 pagineNov. 9, 1965 G. C. Molotzak 3,216,390احمد عبدالكريمNessuna valutazione finora

- Us 2109297Documento6 pagineUs 2109297lfilippiniNessuna valutazione finora

- Dau TomDocumento6 pagineDau TomPham LoiNessuna valutazione finora

- United States Patent (191: McguganDocumento6 pagineUnited States Patent (191: McguganJamesStenhouseNessuna valutazione finora

- March 8, 1960 Y H. A. Longino 2,927,383: Filed June 3, 1958 2 Sheets-Sheet 1Documento5 pagineMarch 8, 1960 Y H. A. Longino 2,927,383: Filed June 3, 1958 2 Sheets-Sheet 1david19775891Nessuna valutazione finora

- 'Inveiqtori': Filed Dec. 21, 1953Documento9 pagine'Inveiqtori': Filed Dec. 21, 1953Vashish RamrechaNessuna valutazione finora

- 9 Q /N - /ENTOR:: May 9, 1931 T. B. Modine 2,983,508Documento3 pagine9 Q /N - /ENTOR:: May 9, 1931 T. B. Modine 2,983,508احمد عبدالكريمNessuna valutazione finora

- Break Pressure Tank DocumentDocumento19 pagineBreak Pressure Tank DocumentAbdul Rauf MukaddamNessuna valutazione finora

- US3230974 E61 PatentDocumento3 pagineUS3230974 E61 Patentspanglish6969Nessuna valutazione finora

- H. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Documento4 pagineH. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Josh FullerNessuna valutazione finora

- United States Patent 1191: KosiskyDocumento4 pagineUnited States Patent 1191: Kosiskycyndigrace_mNessuna valutazione finora

- Sept? 15, 1964: Filed Aug. 31, 1962Documento5 pagineSept? 15, 1964: Filed Aug. 31, 1962احمد عبدالكريمNessuna valutazione finora

- John /AL/QQ: Filed May 19, 71922 4 Sheets-Sheet 1Documento9 pagineJohn /AL/QQ: Filed May 19, 71922 4 Sheets-Sheet 1sukanta60Nessuna valutazione finora

- United States PatentDocumento5 pagineUnited States PatentJagannathan ArumugamNessuna valutazione finora

- Us1223254 PDFDocumento7 pagineUs1223254 PDFRodrigoPomaNessuna valutazione finora

- 1895 - Us570025Documento5 pagine1895 - Us570025Enrico Bruce GioloNessuna valutazione finora

- Filed March 20, 1943Documento8 pagineFiled March 20, 1943Andrés RamírezNessuna valutazione finora

- Buoyancy: The "Hidro" Self-Powered Generator of James KwokDocumento14 pagineBuoyancy: The "Hidro" Self-Powered Generator of James KwokAlboresha RafidNessuna valutazione finora

- Byyeqwla: 2 I / I I VDocumento5 pagineByyeqwla: 2 I / I I VaegosmithNessuna valutazione finora

- Us2277566 1Documento3 pagineUs2277566 1Priya TiwariNessuna valutazione finora

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Documento7 pagineSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaNessuna valutazione finora

- June 4, 1957 B. Vonnegut - 2,794,341Documento4 pagineJune 4, 1957 B. Vonnegut - 2,794,341Amit PandeyNessuna valutazione finora

- US3317184Documento4 pagineUS3317184Efabind OtNessuna valutazione finora

- (1956), June 14) US2970812 Drum Type Heat ExchangerDocumento4 pagine(1956), June 14) US2970812 Drum Type Heat ExchangeraegosmithNessuna valutazione finora

- Intersecting Spherical Pressure TankDocumento25 pagineIntersecting Spherical Pressure TankLuci Oktaria SitorusNessuna valutazione finora

- Rasa SystemDocumento5 pagineRasa SystemShan SinghNessuna valutazione finora

- Wellhead Connector H4 TypeDocumento9 pagineWellhead Connector H4 Typeste7ieNessuna valutazione finora

- June 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960Documento6 pagineJune 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960RodrigoPomaNessuna valutazione finora

- United States Patent: KiernanDocumento12 pagineUnited States Patent: KiernanharisupayNessuna valutazione finora

- US1562093Documento3 pagineUS1562093priyankaNessuna valutazione finora

- 5 - ?lm/"1% Law - (Wee ? Ma : Gssesr Lure-11760745.' Loaf/lb 110072Documento2 pagine5 - ?lm/"1% Law - (Wee ? Ma : Gssesr Lure-11760745.' Loaf/lb 110072ertsetsetetNessuna valutazione finora

- Us 3811604Documento7 pagineUs 3811604elmatto12Nessuna valutazione finora

- ΣχέδιοDocumento16 pagineΣχέδιοKosmas StefanidesNessuna valutazione finora

- ΣχέδιοDocumento16 pagineΣχέδιοKosmas StefanidesNessuna valutazione finora

- ΣχέδιοDocumento20 pagineΣχέδιοKosmas StefanidesNessuna valutazione finora

- Arranging Techniques For SynthesistsDocumento146 pagineArranging Techniques For SynthesistsKosmas Stefanides100% (1)

- Francis Rocco Prestia - Fingerstyle Funk Bass VideobookletDocumento20 pagineFrancis Rocco Prestia - Fingerstyle Funk Bass VideobookletGuillermo CisnerosNessuna valutazione finora

- Appendix - Pcmc2Documento8 pagineAppendix - Pcmc2Siva PNessuna valutazione finora

- E Flight Journal Aero Special 2018 Small PDFDocumento44 pagineE Flight Journal Aero Special 2018 Small PDFMalburg100% (1)

- Tribal Banditry in Ottoman Ayntab (1690-1730)Documento191 pagineTribal Banditry in Ottoman Ayntab (1690-1730)Mahir DemirNessuna valutazione finora

- What Is TranslationDocumento3 pagineWhat Is TranslationSanskriti MehtaNessuna valutazione finora

- Chapter 3 - Organization Structure & CultureDocumento63 pagineChapter 3 - Organization Structure & CultureDr. Shuva GhoshNessuna valutazione finora

- Prelim Examination MaternalDocumento23 paginePrelim Examination MaternalAaron ConstantinoNessuna valutazione finora

- Tplink Eap110 Qig EngDocumento20 pagineTplink Eap110 Qig EngMaciejNessuna valutazione finora

- Syllabus DresserDocumento2 pagineSyllabus DresserVikash Aggarwal50% (2)

- Waterstop TechnologyDocumento69 pagineWaterstop TechnologygertjaniNessuna valutazione finora

- Presentation 11Documento14 paginePresentation 11stellabrown535Nessuna valutazione finora

- Snapdragon 435 Processor Product Brief PDFDocumento2 pagineSnapdragon 435 Processor Product Brief PDFrichardtao89Nessuna valutazione finora

- MASONRYDocumento8 pagineMASONRYJowelyn MaderalNessuna valutazione finora

- Vendor Information Sheet - LFPR-F-002b Rev. 04Documento6 pagineVendor Information Sheet - LFPR-F-002b Rev. 04Chelsea EsparagozaNessuna valutazione finora

- Chemistry Test 1Documento2 pagineChemistry Test 1shashankNessuna valutazione finora

- Business Plan 3.3Documento2 pagineBusiness Plan 3.3Rojin TingabngabNessuna valutazione finora

- TCL LD24D50 - Chassis MS09A-LA - (TKLE2413D) - Manual de Servicio PDFDocumento41 pagineTCL LD24D50 - Chassis MS09A-LA - (TKLE2413D) - Manual de Servicio PDFFabian OrtuzarNessuna valutazione finora

- Sam Media Recruitment QuestionnaireDocumento17 pagineSam Media Recruitment Questionnairechek taiNessuna valutazione finora

- Washing Machine: Service ManualDocumento66 pagineWashing Machine: Service ManualFernando AlmeidaNessuna valutazione finora

- Existential ThreatsDocumento6 pagineExistential Threatslolab_4Nessuna valutazione finora

- LTE Networks Engineering Track Syllabus Overview - 23 - 24Documento4 pagineLTE Networks Engineering Track Syllabus Overview - 23 - 24Mohamed SamiNessuna valutazione finora

- Chapter13 PDFDocumento34 pagineChapter13 PDFAnastasia BulavinovNessuna valutazione finora

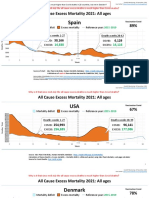

- Countries EXCESS DEATHS All Ages - 15nov2021Documento21 pagineCountries EXCESS DEATHS All Ages - 15nov2021robaksNessuna valutazione finora

- Methods of Recording Retruded Contact Position in Dentate PatientsDocumento15 pagineMethods of Recording Retruded Contact Position in Dentate PatientsYossr MokhtarNessuna valutazione finora

- Spesifikasi PM710Documento73 pagineSpesifikasi PM710Phan'iphan'Nessuna valutazione finora

- Leigh Shawntel J. Nitro Bsmt-1A Biostatistics Quiz No. 3Documento6 pagineLeigh Shawntel J. Nitro Bsmt-1A Biostatistics Quiz No. 3Lue SolesNessuna valutazione finora

- Dialogue Au Restaurant, Clients Et ServeurDocumento9 pagineDialogue Au Restaurant, Clients Et ServeurbanuNessuna valutazione finora

- E0 UoE Unit 7Documento16 pagineE0 UoE Unit 7Patrick GutierrezNessuna valutazione finora

- DNA ReplicationDocumento19 pagineDNA ReplicationLouis HilarioNessuna valutazione finora

- Work ProblemsDocumento19 pagineWork ProblemsOfelia DavidNessuna valutazione finora

- Howard R700X - SPL - INTDocumento44 pagineHoward R700X - SPL - INTJozsefNessuna valutazione finora