Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Moment Direction

Caricato da

RajaKuppanCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Moment Direction

Caricato da

RajaKuppanCopyright:

Formati disponibili

Guide to Calculating Extraneous Loads

FUTEK Advanced Sensor Technology strongly believes in providing all of our customers

with reliable data that helps them in determining the right product for their application.

We provide this Extraneous Loads & Coefficients Guide in order to help determine

the adequacy of the sensor in the presence of loads and moments that are not in the

intended direction of the sensor.

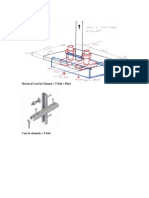

The forces depicted in Figure 1 may be characterized

as following:

Mz

Loads (Fx, Fy, Fz [lbs]). Defined as a load along

each respective axis, these forces are applied by the

customer during or after installation. The direction of

each load is indicated on the specification sheet of

Fy

Fx

Mx

My

each load cell model.

Moments (Mx, My, Mz [in-lb]). Moments (torques) are

forces that cause the structure to either bend or rotate.

To label the axes correctly on each of FUTEKs sensors,

please refer to the individual sensors sheets of each

Fz

specific model.

Most of the time, the project designer should have a

Figure 1: Definition of All Loads & Moments Applied

good idea what forces and/or moments will be acting

on the sensor. Using this information, FUTEK utilizes

an combined stress equation to determine whether or

not a sensor is suitable for the application.

Drawing Number: EL1080-A

Note: In this document all forces, regardless of the load cells capacity, are

in lb. (pounds mass), and all the moments, regardless of capacity, are in

in-lb (inch-pounds).

Sensor Solution Source

Load Torque Pressure Multi-Axis Calibration Instruments Software

www.futek.com

ANSI

ISO

Z540-1

13485

Guide to Calculating Extraneous Loads

CALCULATING THE EXTERNAL LOADS

EXAMPLE

There are four easy steps in determining if the external

We are looking to see if we can use a 500 lb capacity

loads are acceptable on the load cell:

LCM300 inline load cell for an application. The load

cell will experience 300 lb downwards force in the Fz

1. Find the Extraneous Loads Sheets for the desired

direction, a force of 25 lb in the Fx direction, a

load cell (http://www.futek.com/extraneous-load-

2.5 lb force in the Fy direction, and a moment of

factor)

1 in-lb about the z-axis.

2. Determine the extraneous forces and moments

that will be acting on the sensor

3. Select the extraneous load coefficients provided

by the table for the sensors capacity

4. Lastly solve the basic equation for the combined

To calculate if the combined forces and moments will

allow the 500 lb capacity to be used in this application,

we need to refer to the External Load Document of

the specific load cell.

stress due to all the loads from step 2. Your

calculated combined stress should be equal

to or less that the chosen

from step 3. If

TABLE 1: EXTRANEOUS LOAD COEFFICIENT LCM300

CAPACITY (lb)

you exceed the allowable stress value, a higher

25

1200

1200

560

3500

3500

1040

capacity model should be chosen.

50

3500

3500

870

8955

8955

7225

100

3336

3336

530

9050

9050

8345

250

770

770

220

1955

1955

1380

500

665

665

150

1420

1420

1250

1000

475

475

86

1405

1405

1190

max

The basic equation for combined stress is the

following:

max

(A)|Fx| + (B)|Fy| + (C)|Fz| + (D)|Mx| + (E)|My| + (F)|Mz|

We first need to obtain the off axis coefficients

(A,B,C,D,E,F) for the desired capacity. We then place

A, B, C, D, E, F are the coefficients (step 3) determined

the coefficients and forces in the combined stress

by FUTEKs engineers. The units of A, B, and C are

equation.

provided in psi/lbf, whereas the units of D, E, and F

are provided in psi/in-lb. The resulting answer from the

equation above has units of psi.

Guide to Calculating Extraneous Loads

EXAMPLE (continued)

Note that the equation requires the absolute value

All the stresses on the structure should be less than or

of the forces or moments. For example, although the

equal to the maximum stress (

main force in the Fz direction is applied in the negative

how the load cell is being loaded

direction (-300 lb), the force should be entered as 300

lb in the equation (i.e. |-300|=300).

665|25|+665|2.5|+150|-300|+1420|0|+1420|0|+1250|1|

3325+1662.5+45000+0+0+1250

64537.5 psi

Next we need to look at the maximum stress (

that the structure is able to handle.

), depending on the

max

acceptable for if they are static or non-reversing. If

these loads are fully reversing, the structure might

yield, thus a higher capacity unit should be selected.

It should be noted that the fully reversing maximum

stress condition is determined so that the structure

lasts for at least 10 to 20 million cycles. If the load

cell needs to last more than 100 million cycles the

maximum fatigue stress for a reversing load should be

TABLE 2: MAXIMUM STRESSES ON THE STRUCTURE

PARAMETER

VALUE

Material

17-4PH S.S.

Static Load (=60% Y.S.)

87,000

Fatigue (Non Reversing Loads)

78,000

Fatigue (Full Reversing Loads)

62,000*

www.futek.com

max

In our example we see that extraneous loads are

(A)|Fx| + (B)|Fy| + (C)|Fz| + (D)|Mx| + (E)|My| + (F)|Mz|

10 Thomas, Irvine, CA 92618 USA

Tel: (949) 465-0900

Fax: (949) 465-0905

max

max

under

max

0.75 (46,500 psi in our case). In this case,

if we wanted the load cell to last infinite life under

fatigue fully reversing conditions, we will need to look

for a larger load capacity.

ANSI

ISO

Z540-1

13485

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Steel Plate CalculationsDocumento2 pagineSteel Plate CalculationsBolarinwaNessuna valutazione finora

- How To Get The Centerline Symbol C/L Type /U+2104 in The Text FieldDocumento1 paginaHow To Get The Centerline Symbol C/L Type /U+2104 in The Text FieldRajaKuppanNessuna valutazione finora

- A Paper Sizes - A0, A1, A2, A3, A4, A5, A6, A7, A8, A9, A10Documento3 pagineA Paper Sizes - A0, A1, A2, A3, A4, A5, A6, A7, A8, A9, A10RajaKuppanNessuna valutazione finora

- Autocad ShortcutsDocumento13 pagineAutocad ShortcutsKriscel CaraanNessuna valutazione finora

- Table 3.25 Min. % of Reinforcement BS 8110Documento2 pagineTable 3.25 Min. % of Reinforcement BS 8110RajaKuppan100% (1)

- 14 3332013SieveAnalysisDataDocumento2 pagine14 3332013SieveAnalysisDataRajaKuppanNessuna valutazione finora

- Autocad ShortcutsDocumento13 pagineAutocad ShortcutsKriscel CaraanNessuna valutazione finora

- Aaac Astm B All Aluminium Alloy ConductorDocumento5 pagineAaac Astm B All Aluminium Alloy ConductorRajaKuppanNessuna valutazione finora

- Conductor DetailsDocumento12 pagineConductor DetailsmanohargudNessuna valutazione finora

- Beam Design Formulas With Shear and MomentDocumento20 pagineBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- AAC SpecificationDocumento6 pagineAAC SpecificationAdhyartha KerafNessuna valutazione finora

- SCI P252 SecureDocumento114 pagineSCI P252 SecureDan CiucuNessuna valutazione finora

- AAC SpecificationDocumento6 pagineAAC SpecificationAdhyartha KerafNessuna valutazione finora

- Voters, Not Political Parties, Are Responsible For The Criminalization of Politics - Group DiscussionDocumento16 pagineVoters, Not Political Parties, Are Responsible For The Criminalization of Politics - Group DiscussionRajaKuppanNessuna valutazione finora

- Retirement Age For Politicians - Group DiscussionDocumento17 pagineRetirement Age For Politicians - Group DiscussionRajaKuppanNessuna valutazione finora

- What India Needs Is A Dictatorship - Group DiscussionDocumento22 pagineWhat India Needs Is A Dictatorship - Group DiscussionRajaKuppanNessuna valutazione finora

- The Way Forward For India Is To Join Hands With Pakistan On Nuclear Matters - Group DiscussionDocumento5 pagineThe Way Forward For India Is To Join Hands With Pakistan On Nuclear Matters - Group DiscussionRajaKuppanNessuna valutazione finora

- Should We Pursue Our Policy of Dialogue With Pakistan - Group DiscussionDocumento11 pagineShould We Pursue Our Policy of Dialogue With Pakistan - Group DiscussionRajaKuppanNessuna valutazione finora

- Presidential V - S Parliamentary Form of Government in India - Group DiscussionDocumento13 paginePresidential V - S Parliamentary Form of Government in India - Group DiscussionRajaKuppanNessuna valutazione finora

- Should Voters Be Given A NOTA (None of The Above) Choice - Group DiscussionDocumento18 pagineShould Voters Be Given A NOTA (None of The Above) Choice - Group DiscussionRajaKuppanNessuna valutazione finora

- Reservations in The Private Sector - Group DiscussionDocumento21 pagineReservations in The Private Sector - Group DiscussionRajaKuppanNessuna valutazione finora

- Should Tainted Ministers Allowed To Contest Elections - Group DiscussionDocumento6 pagineShould Tainted Ministers Allowed To Contest Elections - Group DiscussionRajaKuppanNessuna valutazione finora

- Religion Should Not Be Mixed With Politics - Group DiscussionDocumento18 pagineReligion Should Not Be Mixed With Politics - Group DiscussionRajaKuppanNessuna valutazione finora

- Necessity of Women Quota Bill For Women Empowerment - Group DiscussionDocumento20 pagineNecessity of Women Quota Bill For Women Empowerment - Group DiscussionRajaKuppanNessuna valutazione finora

- Is Our Political System Reason For Our Backwardness - Group DiscussionDocumento22 pagineIs Our Political System Reason For Our Backwardness - Group DiscussionRajaKuppanNessuna valutazione finora

- Need For Good Leaders in India - Group DiscussionDocumento18 pagineNeed For Good Leaders in India - Group DiscussionRajaKuppanNessuna valutazione finora

- Politics Is Run by The Barrel of Gun - Group DiscussionDocumento6 paginePolitics Is Run by The Barrel of Gun - Group DiscussionRajaKuppanNessuna valutazione finora

- India Should Go For The Presidential Form of Democracy - Group DiscussionDocumento15 pagineIndia Should Go For The Presidential Form of Democracy - Group DiscussionRajaKuppanNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Bugatti Type 57SCDocumento10 pagineBugatti Type 57SCjorge Angel Lope100% (1)

- IEEE 802 StandardsDocumento14 pagineIEEE 802 StandardsHoney RamosNessuna valutazione finora

- Skilled Worker Overseas FAQs - Manitoba Immigration and Economic OpportunitiesDocumento2 pagineSkilled Worker Overseas FAQs - Manitoba Immigration and Economic OpportunitieswesamNessuna valutazione finora

- Chalcedony Value, Price, and Jewelry Information - International Gem SocietyDocumento8 pagineChalcedony Value, Price, and Jewelry Information - International Gem Societyasset68Nessuna valutazione finora

- One and Half SindromeDocumento4 pagineOne and Half SindromeYulia DamayantiNessuna valutazione finora

- D.O. 221-A - Application Form (Renewal)Documento1 paginaD.O. 221-A - Application Form (Renewal)Karl PagzNessuna valutazione finora

- The Chassis OC 500 LE: Technical InformationDocumento12 pagineThe Chassis OC 500 LE: Technical InformationAbdelhak Ezzahrioui100% (1)

- NOV23 Nomura Class 6Documento54 pagineNOV23 Nomura Class 6JAYA BHARATHA REDDYNessuna valutazione finora

- Early Christian ArchitectureDocumento38 pagineEarly Christian ArchitectureInspirations & ArchitectureNessuna valutazione finora

- Types of Intermolecular ForcesDocumento34 pagineTypes of Intermolecular ForcesRuschan JaraNessuna valutazione finora

- Science Grade 10 (Exam Prep)Documento6 pagineScience Grade 10 (Exam Prep)Venice Solver100% (3)

- Categories of Cargo and Types of ShipsDocumento14 pagineCategories of Cargo and Types of ShipsVibhav Kumar100% (1)

- Analysis of MMDR Amendment ActDocumento5 pagineAnalysis of MMDR Amendment ActArunabh BhattacharyaNessuna valutazione finora

- ACTIX Basic (Sample CDMA)Documento73 pagineACTIX Basic (Sample CDMA)radhiwibowoNessuna valutazione finora

- Invoice ApprovalDocumento54 pagineInvoice ApprovalHamada Asmr AladhamNessuna valutazione finora

- Coc 1 ExamDocumento7 pagineCoc 1 ExamJelo BioNessuna valutazione finora

- Serenity RPG Firefly Role Playing Game PDFDocumento225 pagineSerenity RPG Firefly Role Playing Game PDFNathaniel Broyles67% (3)

- Ict's - 2022 - Mentorship - Summarized - Thread - by - Trader - Theory - Sep 22, 22 - From - RattibhaDocumento11 pagineIct's - 2022 - Mentorship - Summarized - Thread - by - Trader - Theory - Sep 22, 22 - From - RattibhaChristiana OnyinyeNessuna valutazione finora

- Diazonium Salts Azo DyesDocumento8 pagineDiazonium Salts Azo DyesAnthony Basanta100% (1)

- TABEL Sifat Uap Jenuh Tabel Suhu Dan TekananDocumento8 pagineTABEL Sifat Uap Jenuh Tabel Suhu Dan Tekanan21-002 Alditua sinabaribaNessuna valutazione finora

- Heat Pyqs NsejsDocumento3 pagineHeat Pyqs NsejsPocketMonTuberNessuna valutazione finora

- SQLDocumento13 pagineSQLRadhakrishnan__7263Nessuna valutazione finora

- Newsela Teacher Review - Common Sense EducationDocumento1 paginaNewsela Teacher Review - Common Sense EducationJessicaNessuna valutazione finora

- Nuttall Gear CatalogDocumento275 pagineNuttall Gear Catalogjose huertasNessuna valutazione finora

- A Tall Order - Cooling Dubai's Burj Khalifa: FeatureDocumento2 pagineA Tall Order - Cooling Dubai's Burj Khalifa: FeatureMohsin KhanNessuna valutazione finora

- H.mohamed Ibrahim Hussain A Study On Technology Updatiing and Its Impact Towards Employee Performance in Orcade Health Care PVT LTD ErodeDocumento108 pagineH.mohamed Ibrahim Hussain A Study On Technology Updatiing and Its Impact Towards Employee Performance in Orcade Health Care PVT LTD ErodeeswariNessuna valutazione finora

- Presentación de Power Point Sobre Aspectos de La Cultura Inglesa Que Han Influido en El Desarrollo de La HumanidadDocumento14 paginePresentación de Power Point Sobre Aspectos de La Cultura Inglesa Que Han Influido en El Desarrollo de La HumanidadAndres EduardoNessuna valutazione finora

- Steve Jobs TalkDocumento3 pagineSteve Jobs TalkDave CNessuna valutazione finora

- Pepperberg Notes On The Learning ApproachDocumento3 paginePepperberg Notes On The Learning ApproachCristina GherardiNessuna valutazione finora

- Catch Up RPHDocumento6 pagineCatch Up RPHபிரதீபன் இராதேNessuna valutazione finora