Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ER5554

Caricato da

Anonymous stV08Js44V0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

24 visualizzazioni1 paginaThis document provides technical information about aluminum and copper welding wire and electrodes from Weldwire Company, including:

- Alloy WW5554 conforms to AWS A5.10 and ASME SFA A5.10 standards for welding processes including MIG, TIG, electron beam, and oxyfuel gas.

- The chemical composition requirements for alloy ER5554 including the maximum amounts of elements like silicon, chromium, iron, zinc, and copper.

- The welding rod parameters depend on the actual welding process used and deposited chemistry and properties can vary depending on multiple factors.

- Alloy ER5554 can be used to weld base materials 5454 and 5456 with inert gas,

Descrizione originale:

ER5554 aluminium welding rod

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document provides technical information about aluminum and copper welding wire and electrodes from Weldwire Company, including:

- Alloy WW5554 conforms to AWS A5.10 and ASME SFA A5.10 standards for welding processes including MIG, TIG, electron beam, and oxyfuel gas.

- The chemical composition requirements for alloy ER5554 including the maximum amounts of elements like silicon, chromium, iron, zinc, and copper.

- The welding rod parameters depend on the actual welding process used and deposited chemistry and properties can vary depending on multiple factors.

- Alloy ER5554 can be used to weld base materials 5454 and 5456 with inert gas,

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

24 visualizzazioni1 paginaER5554

Caricato da

Anonymous stV08Js44VThis document provides technical information about aluminum and copper welding wire and electrodes from Weldwire Company, including:

- Alloy WW5554 conforms to AWS A5.10 and ASME SFA A5.10 standards for welding processes including MIG, TIG, electron beam, and oxyfuel gas.

- The chemical composition requirements for alloy ER5554 including the maximum amounts of elements like silicon, chromium, iron, zinc, and copper.

- The welding rod parameters depend on the actual welding process used and deposited chemistry and properties can vary depending on multiple factors.

- Alloy ER5554 can be used to weld base materials 5454 and 5456 with inert gas,

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

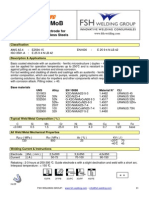

WELDWIRE COMPANY, INC.

Technical Information

Aluminum & Copper Welding Wire & Electrodes

Alloy: WW5554

Conforms to Certification: AWS A5.10

Class: ER5554

ASME SFA A5.10

Alloy: ER5554

Weld Process: Mig, Tig, Electron bead, Oxyfuel gas

AWS Chemical Composition Requirements

Si = 0.25 max

Cr = 0.05 - 0.20

Fe = 0.40 max

Zn = 0.25 max

Cu = 0.10 max

Ti = 0.05 - 0.20 max

Mn = 0.50 1.0

Al = Remainder

Mg = 2.4 - 3.0

Be = 0.0003

Recommended Operation of Welding Rods

Weld parameters are dependent upon the actual weld process

being utilized.

Other = 0.05 each - 0.15 max total

Application

Deposited Chemical Composition % (Typical)

Deposited chemistry is influenced by many factors so no

typical analysis can be recorded.

Deposited All Weld Metal Properties %

As-Welded

Deposited all weld metal properties are influenced by many

factors such as weld process used, so no typical weld metal

properties can be reported.

This material can be used to weld base material types 5454 and

5456. All inert gas processes, electron beam and oxyfuel gas

welding processed can be used.

- The proper choice of aluminum filler metal mainly depends

on the base metal properties to be achieved and Welding

technique. Post weld cracking, corrosion resistance and

behavior under elevated temperature also need to be taken into

consideration.

- Cracking usually can be minimized by choosing a filler metal

alloy of higher alloy content then the base metal.

Deposited Charpy-V-Notch Impact Properties %

Not applicable

If additional information is needed Contact Weldwire Company, Inc. 800-523-1266

Potrebbero piacerti anche

- Avesta Welding: How To Weld Fully Austenitic Stainless SteelsDocumento0 pagineAvesta Welding: How To Weld Fully Austenitic Stainless SteelsMoosewanger01Nessuna valutazione finora

- Applied Welding Engineering: Processes, Codes, and StandardsDa EverandApplied Welding Engineering: Processes, Codes, and StandardsNessuna valutazione finora

- Concrete Mix Design (35 MPa)Documento3 pagineConcrete Mix Design (35 MPa)Chileshe Mulenga Phiri100% (1)

- Elettrodo Per Alluminio e Sue Leghe AWS A5.3 - E4043 (Selectarc - Eurosald Mod. AL105)Documento1 paginaElettrodo Per Alluminio e Sue Leghe AWS A5.3 - E4043 (Selectarc - Eurosald Mod. AL105)Eraldo MigliavaccaNessuna valutazione finora

- ACUWELD MIG &TIG Welding WiresDocumento38 pagineACUWELD MIG &TIG Welding WiresALOKE GANGULYNessuna valutazione finora

- CHP 1 ProjectDocumento11 pagineCHP 1 ProjectDhyey KalariyaNessuna valutazione finora

- AFM ER308 Afm Er308LDocumento9 pagineAFM ER308 Afm Er308LKH NgNessuna valutazione finora

- Welding: Presented by Robert Pelton & Tyson Baker Meen 372 December 10, 2001Documento17 pagineWelding: Presented by Robert Pelton & Tyson Baker Meen 372 December 10, 2001manoj_005Nessuna valutazione finora

- AH MergedDocumento6 pagineAH MergedReginaldo SantosNessuna valutazione finora

- ENiFe CIDocumento1 paginaENiFe CIakashmalayiNessuna valutazione finora

- ER90S-B9 Electrode SpecDocumento1 paginaER90S-B9 Electrode SpecfaizalzolNessuna valutazione finora

- SmawDocumento14 pagineSmawali_halimeNessuna valutazione finora

- Welding Process and ConsumableDocumento64 pagineWelding Process and Consumablenizar_ikmps100% (1)

- Unit V: Design of Weld Joints, Weldability and Testing of WeldmentsDocumento24 pagineUnit V: Design of Weld Joints, Weldability and Testing of WeldmentsparthibankNessuna valutazione finora

- Welding Duplex Stainless SteelDocumento44 pagineWelding Duplex Stainless SteelTran Thanh HaoNessuna valutazione finora

- Class: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageDocumento2 pagineClass: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageAditya PrajasNessuna valutazione finora

- How To Weld Fully Austenitic Stainless SteelsDocumento20 pagineHow To Weld Fully Austenitic Stainless SteelsCarlos Bermejo AlvarezNessuna valutazione finora

- Selectarc Selectarc Selectarc Selectarc: Inox 2509mobDocumento1 paginaSelectarc Selectarc Selectarc Selectarc: Inox 2509mobGogo PNessuna valutazione finora

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocumento1 paginaL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55Nessuna valutazione finora

- Advanced Welding TechnologyDocumento60 pagineAdvanced Welding TechnologySwati AgarwalNessuna valutazione finora

- Welding ProcedureDocumento38 pagineWelding ProcedureRicardo Ceballos100% (1)

- Weld Wire CatalogDocumento50 pagineWeld Wire CatalogMurdock Howling MadNessuna valutazione finora

- Analysis of Tig Welding Weldment and Defect Identification Using Non Destructive Testing NDTDocumento48 pagineAnalysis of Tig Welding Weldment and Defect Identification Using Non Destructive Testing NDTRebecca KelleyNessuna valutazione finora

- 38965Documento50 pagine38965RedFahimNessuna valutazione finora

- ER70S-2 Mild SteelDocumento1 paginaER70S-2 Mild SteelNadeemNessuna valutazione finora

- Mechanical Engineering Design Presentation Bsme01183097Documento30 pagineMechanical Engineering Design Presentation Bsme01183097Waqar KhanNessuna valutazione finora

- Dual Shield 7000a1Documento1 paginaDual Shield 7000a1Gokul RajanNessuna valutazione finora

- MATPR EES TemplateDocumento10 pagineMATPR EES TemplatevijayNessuna valutazione finora

- 05042016000000A - Avesta 904L - CeDocumento1 pagina05042016000000A - Avesta 904L - CeJorge Uribe RochaNessuna valutazione finora

- Afrox Ferroloid1 tcm282-30151 PDFDocumento1 paginaAfrox Ferroloid1 tcm282-30151 PDFsatnamNessuna valutazione finora

- Aluminum Bronze A2 Welding Wire and Rod: Cert # 05-R0925Documento1 paginaAluminum Bronze A2 Welding Wire and Rod: Cert # 05-R0925Valli RajuNessuna valutazione finora

- ERCUDocumento1 paginaERCURogério JuniorNessuna valutazione finora

- A 4043 TdsDocumento2 pagineA 4043 Tdssajeev27Nessuna valutazione finora

- Alloy 5556 Weld Data Sheet: Typical ApplicationsDocumento2 pagineAlloy 5556 Weld Data Sheet: Typical Applicationsvishal bailurNessuna valutazione finora

- Low Fuming Bronze: (Rbcuzn-C)Documento1 paginaLow Fuming Bronze: (Rbcuzn-C)Marcelino Navarrete EvaristoNessuna valutazione finora

- Lecture-1, Maraging SteelsDocumento30 pagineLecture-1, Maraging Steelssatish chinthamNessuna valutazione finora

- 5183 Aluminum Welding WireDocumento1 pagina5183 Aluminum Welding Wiresank79Nessuna valutazione finora

- Data Sheet E308L-17Documento2 pagineData Sheet E308L-17Shaik Nizam UddinNessuna valutazione finora

- FSW On Aluminium 5052-H112 by Hose SitumorangDocumento10 pagineFSW On Aluminium 5052-H112 by Hose SitumorangHose GamalielNessuna valutazione finora

- Welding Report PDFDocumento10 pagineWelding Report PDFAsheeshSharmaNessuna valutazione finora

- 14-WIS5 Consumables 2006Documento76 pagine14-WIS5 Consumables 2006Rob WillestoneNessuna valutazione finora

- Wel 12 DDocumento7 pagineWel 12 DWilly UioNessuna valutazione finora

- ENiCrFe 2Documento1 paginaENiCrFe 2briang-2Nessuna valutazione finora

- Lesson X Specification No. DescriptionDocumento1 paginaLesson X Specification No. DescriptioncrysNessuna valutazione finora

- Ok 347 AutrodDocumento2 pagineOk 347 Autrodjoao guilhermeNessuna valutazione finora

- Bavaria en BA-TIG 310Documento1 paginaBavaria en BA-TIG 310cocoNessuna valutazione finora

- L6 - Joining ProcessesDocumento22 pagineL6 - Joining ProcessesDinesh MahalaNessuna valutazione finora

- Alloy 625 Wire & Rod: U.S. Alloy CoDocumento1 paginaAlloy 625 Wire & Rod: U.S. Alloy CowinstonsequeiraNessuna valutazione finora

- AUTROD 316LSiDocumento2 pagineAUTROD 316LSijoao guilhermeNessuna valutazione finora

- 4 Lead and Its AlloysDocumento36 pagine4 Lead and Its AlloysmohansaiNessuna valutazione finora

- FAQ For 9Cr MaterialsDocumento10 pagineFAQ For 9Cr MaterialsmanasikarthikNessuna valutazione finora

- 10.3 The American Welding Society (Aws) : Lesson XDocumento1 pagina10.3 The American Welding Society (Aws) : Lesson XcrysNessuna valutazione finora

- Afrox Ferroloid2 Tcm282-30152Documento1 paginaAfrox Ferroloid2 Tcm282-30152satnamNessuna valutazione finora

- Multimaterial Joining Gould EwiDocumento11 pagineMultimaterial Joining Gould Ewirpadhra8803Nessuna valutazione finora

- E309LMo 16Documento1 paginaE309LMo 16faiz oeNessuna valutazione finora

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDa EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNessuna valutazione finora

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDa EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNessuna valutazione finora

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesDa EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNessuna valutazione finora

- Lorch PDFDocumento12 pagineLorch PDFAnonymous stV08Js44V100% (1)

- Continuum™ Advanced MIG Welder - MillerWeldsDocumento8 pagineContinuum™ Advanced MIG Welder - MillerWeldsAnonymous stV08Js44VNessuna valutazione finora

- Die Penetrant ProcedureDocumento3 pagineDie Penetrant ProcedureAnonymous stV08Js44VNessuna valutazione finora

- Wps ExampleDocumento2 pagineWps ExampleAnonymous stV08Js44VNessuna valutazione finora

- Inequality SymbolsDocumento2 pagineInequality SymbolsAnonymous stV08Js44VNessuna valutazione finora

- eUP TKDocumento47 pagineeUP TKAshley JacksonNessuna valutazione finora

- Sifphosphor Bronze No8Documento1 paginaSifphosphor Bronze No8Anonymous stV08Js44VNessuna valutazione finora

- Suportes Comentados MC-S60-003Documento10 pagineSuportes Comentados MC-S60-003celonevesNessuna valutazione finora

- Aluminr Contemprory DoorsDocumento76 pagineAluminr Contemprory Doorscatalogue dekorNessuna valutazione finora

- Astm C1186Documento47 pagineAstm C1186Corrado Sirianni100% (2)

- REO Range CatalogueDocumento8 pagineREO Range CatalogueSURAJ PratapNessuna valutazione finora

- Whirlpool w77Documento56 pagineWhirlpool w77Walter RizzatoNessuna valutazione finora

- Sliding Thermal BreakDocumento64 pagineSliding Thermal BreakSaud AffanNessuna valutazione finora

- Instructions For Installation, Operation, Care and MaintenanceDocumento10 pagineInstructions For Installation, Operation, Care and MaintenanceAdi HardiansyahNessuna valutazione finora

- TOTO Sanitary Catalog July 2021Documento40 pagineTOTO Sanitary Catalog July 2021Yansen HardjokoNessuna valutazione finora

- Cherlopalli Vakulamatha Temple RoadDocumento39 pagineCherlopalli Vakulamatha Temple Roadharsha vickyNessuna valutazione finora

- CHB Back-Up ComputationDocumento36 pagineCHB Back-Up Computationkhim tugasNessuna valutazione finora

- Advanced Composite Materials CHM-790 Lec # 11: ReinforcementsDocumento11 pagineAdvanced Composite Materials CHM-790 Lec # 11: ReinforcementsKhawaja TaimoorNessuna valutazione finora

- 100 Terms and 50 Symbols Foundation EngineeringDocumento7 pagine100 Terms and 50 Symbols Foundation EngineeringHrv Aquino100% (1)

- Materials AlturasDocumento66 pagineMaterials AlturasDonald ToledoNessuna valutazione finora

- Rebar Drawing Check ListDocumento1 paginaRebar Drawing Check Listalok100% (1)

- SITE BOOK Quantity Take Off Details PDFDocumento20 pagineSITE BOOK Quantity Take Off Details PDFkumaravajiraNessuna valutazione finora

- General HydraulicsDocumento52 pagineGeneral HydraulicsEdgarNessuna valutazione finora

- Furring For Gypsum Board CeilingsDocumento4 pagineFurring For Gypsum Board Ceilingsjack.simpson.changNessuna valutazione finora

- Thermoplastic PolyurethaneDocumento4 pagineThermoplastic PolyurethanepepeNessuna valutazione finora

- ISO Nominal Diameter of Tool (MM) Tolerance Designation 3-6 6-10 10-18 18-30 30-50 50-80 80-120 120-180 Tolerance (Unit 0.001 MM)Documento1 paginaISO Nominal Diameter of Tool (MM) Tolerance Designation 3-6 6-10 10-18 18-30 30-50 50-80 80-120 120-180 Tolerance (Unit 0.001 MM)Ahmad Shuja100% (1)

- Silo Data SheetDocumento4 pagineSilo Data SheetZoran Danilov100% (1)

- En 1982 Copper and Copper Alloy Ingots and Castings - Compositions, Uses and Typical Properties-Table10Documento1 paginaEn 1982 Copper and Copper Alloy Ingots and Castings - Compositions, Uses and Typical Properties-Table10yw_oulalaNessuna valutazione finora

- Limitations and Exclusions (Walls BS 8110)Documento1 paginaLimitations and Exclusions (Walls BS 8110)dhanya1995Nessuna valutazione finora

- X MGR Data Sheet Technical Information ASSET DOC 2597885Documento5 pagineX MGR Data Sheet Technical Information ASSET DOC 2597885Amirul AfiqNessuna valutazione finora

- Effect of Aggregate Properties On Asphalt Concrete MixesDocumento18 pagineEffect of Aggregate Properties On Asphalt Concrete MixesNgabirano B. JuliusNessuna valutazione finora

- Portland Cement: Wednesday, March 25, 2015Documento35 paginePortland Cement: Wednesday, March 25, 2015EFRA BININessuna valutazione finora

- Fire Resistance Ratings - ANSI/UL 263: Design No. U311Documento3 pagineFire Resistance Ratings - ANSI/UL 263: Design No. U311DavidNessuna valutazione finora

- 4.1. Nquiriquele Health Center - General Plan Materniy + External Services - StructureDocumento6 pagine4.1. Nquiriquele Health Center - General Plan Materniy + External Services - StructuredevisguibsonNessuna valutazione finora

- PC750-7 S/N 20001-UP (Overseas Version)Documento2 paginePC750-7 S/N 20001-UP (Overseas Version)АлександрNessuna valutazione finora

- Bladder Accumulators Standard Model: 1. DescriptionDocumento8 pagineBladder Accumulators Standard Model: 1. DescriptionbarryNessuna valutazione finora