Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Oxidation Paths of A Coking Coal and PDF

Caricato da

d1360sdfggfbdmllTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Oxidation Paths of A Coking Coal and PDF

Caricato da

d1360sdfggfbdmllCopyright:

Formati disponibili

Fuel Vol. 76, No. 12, pp.

1137-1142, 1997

1997 Elsevier Science Ltd. All rights reserved

Printed in Great Britain

0016-2361/97 $17.00+0,00

Plh S0016-2361(97)00115-4

ELSEVIER

Oxidation paths of a coking coal and

comparison of its oxidized product

with a non-caking coal

Jose E. S~nchez and Jos(~ M. Rinc6n

Departamento de Ouimica, Laboratorio de Investigaci6n en Combustibles, Universidad Nacional,

Bogota, Colombia

(Received 30 August 1996; revised 21 March 1997)

A coking coal was rendered non-caking by air oxidation at 125C. The oxidation process was followed by free

swelling index, dilatometry, FT-i.r and e.s.r. It was found that the oxidation could be divided into two steps. The

main feature observed in the first step was loss of coking properties. In addition there were increases in phenolic

hydroxyl content and e.s.r, spin concentration, and a decrease in volatiles in the dilatometric test. In the second

step, the caking properties were lost and the rate of carbonyl formation increased. The FT-i.r spectra of the

oxidized coal and a non-caking coal were very similar, indicating that the presence of oxygenated groups is

related to the absence of plastic properties. A mechanism of the oxidation process is proposed. 1997 Elsevier

Science Ltd.

(Keywords: coking coal; aerial oxidation; plastic p r o p e r t i e s )

It is well known that mild oxidation changes physical and

chemical properties of coal. The loss of plastic properties

and self-heating in piles are two of the technological

properties most frequently studied 1-8. None of the many

proposed theories explains the mechanism of the changes

produced in coking coals as a consequence of oxidation 9-11.

Mild oxidation impairs the plastic properties ~'2'6, lowers the

liquid yield from liquefaction and the volatile matter from

pyrolysis 5, and chan~es the extractability 6'12 and free

radical concentration 5 '1 3 1' 4 . The oxidation process increases

the concentration of reactive oxygen groups such as - O H ,

-COOH, - C = O and C - O - O and decreases aliphatic

hydrogen 5,6,9A2,15.

Ignasiak et al. 16.17 reported that the formation of reactive

oxygen functional groups such as hydroxyl and carboxyl

was responsible for the loss of coking properties through

oxidation. Painter et al. ~8 attributed the loss of caking

properties on oxidation to the formation of ester cross-links.

Liotta et al. 19 considered the formation of ether bonds to be

responsible for the loss of coking properties. Larsen et al. 12

detected changes in cross-linking after low-temperature

oxidation but argued that these were not responsible for the

observed decrease in free swelling index (FSI). Rhoads et

al. 15 explained this phenomenon by the loss of aliphatic

hydrogen during oxidation. All these different explanations

may arise from differences in experimental conditions, such

as oxidation time, temperature and type of coal sample.

The mechanism of coal oxidation has been the subject of

considerable study 4'5'12'18-22. It is generally accepted that

the initial stage of oxidation involves the attack of molecular

oxygen on certain aliphatic species, generally methylene

groups ~ to aromatic rings or to - O R groups, producing

peroxides and hydroperoxides which decompose to form

oxygenated groups 5,22-25.

In this work, to elucidate the structural changes during

oxidation of a bituminous coal and its influence on the

coking and caking porperties the oxidation process was

monitored by spectroscopic analysis and weight loss.

EXPERIMENTAL

Materials

Two types of coal were used: La Vega (LV) with coking

properties and Tres Bancos (TB) without caking properties.

Both coals belong to the same basin. The samples were

taken directly from the seam and kept under nitrogen during

the present study. The raw coals were ground to < 250 #m.

Oxidation

About 10 g of crushed coal LV was spread in a layer

- 5 mm thick on an aluminium plate and placed in an oven

at 125 ___ IC. Oxidation was achieved by introducing air

into the oven until the caking and coking properties were

lost as measured by standard FSI and dilatometer test

methods.

Spectroscopic analysis

FT-i.r. and e.s.r, measurements were performed to

investigate chemical changes on oxidation. The FT-i.r

spectra were taken by diffuse reflectance.

RESULTS AND DISCUSSION

The properties of the coals used are shown in Table 1. Coal

Fuel 1997 Volume 76 Number 12

1137

Oxidation paths of a coking coal: J. E. S~nchez and J. M. Rinc6n

Table

1 Properties of coals used

Coal

LV

Proximate analysis (wt%)

Ash (db)

Moisture

Volatile matter (daf)

Ultimate analysis (wt% daf)

C

H

N

S

O(diff.)

H/C atomic ratio

Plastic properties

FS!

Max. dilatation (%)

Max. contraction (%)

T~oft (C)

Max. fuidity (ddpm)

OLV

TB

10.8

0.9

36.0

12.1

1.4

35.2

12.0

5.2

46.2

86.9

5.6

1.8

0.6

5.1

0.77

85.4

5.0

1.7

0.5

7.3

0.70

82.2

5.6

1.8

0.9

9.5

0.82

8.5

200

30

360

1900

1.0

FT-i.r. spectroscopy

--32

380

--

-8

437

--

2ooT

o,

:o

;o

!

80

I

100

80

I00

Oxidation time ( h )

-100 1

20

40

60

Oxidation time (h)

30

2,o

I~ ~

0

0

i

40

20

,

6'0

80

of 1 was reached. The change in plastic properties with

oxidation time is shown in Figure 1. At 24 h, the dilatation

of LV was lost (Figure la) and the FSI had decreased from

8.5 to 6 (Figure lb). At 84 h of oxidation the FSI had

decreased to 1. The FSI and contraction (Figure lb,c)

showed similar profiles. The softening temperature (Figure

ld) increased during the first 24 h and then remained

constant. From the preceding observations the oxidation

process could be divided into two steps: (1) loss of coking

properties in the first 24 h; (2) destruction of caking

properties as measured by the FSI.

100

Oxidation time (h)

450

FT-i.r results for oxidized coals have been reported in

many papers 17,26,27. Figure 2 shows the FT-i.r. spectra of

LV, other Colombian coking coals CH057, CH089 and

CH107 for comparison, and the non-caking coals OLV and

TB. The four coking coals show similar spectra. The main

differences between LV and OLV are present in the regions

3600-3100, 3000-2700 and 1800-1600 cm -[ due to -OH,

C - H and C = O stretching bands respectively (Figure 3).

The oxidation path was followed by measuring the area of

the peaks related to these groups, Figure 4. During the first

step there was an increase in absorption at 3600-3100 cmdue to phenolic groups. Then the intensity of the band

decreased and finally remained constant during the second

step (Figure 4a). The carbonyl group content, as measured

by the absorption band at 1800-1600 cm -1, did not change

appreciably in the first step but increased during the second

step (Figure 4b). The aliphatic - C H groups, at 30002700 cm -1, decreased continuously in both steps (Figure

4c). From the above, it is concluded that the presence of

phenolic groups influences the loss of coking properties.

Caking properties are more related to the formation of

carbonyl groups.

Different authors4'12'15'18'21'28 suggest that oxidation of

alkyl-aromatic species in coals starts at the a position, so the

carbonyl groups found in this work probably belong to ct

groups that could be acids, esters, aldehydes or ketones.

These groups cause polarity in the aromatic rings, and as a

consequence the molar absorptivity of the aromatic rings at

1600cm -l strongly increases, as shown by the high

intensity of this band in the OLV and TB spectra (Figure

2). Therefore this high-intensity band, which has been the

subject of controversy in the literature, could be due to

highly aromatic conjugated polar groups which are of

relatively high reactivity and are cross-linking precursors 29.

[

A band at 1735 cm- is usually found as a shoulder on the

intense 1600 cm -1 broad band in the spectra of oxidized

400

350

u

300 1

0

20

40

60

80

I O0

Oxidation time ( h )

T a b l e 2 Free radical concentration and g factor as a function of

oxidation time

Time (h)

Figure 1 Effect of oxidation on plastic properties as a function of

time

LV is currently used as coking coal in industry and OLV

was obtained from LV after 84 h of oxidation. Coal TB is

normally used for combustion.

Coal oxidation

Since there is no criterion to fix the final point of

oxidation, it was decided to continue oxidation until an FSI

1138

Fuel 1997 Volume 76 Number 12

00

06

12

24

30

36

48

54

60

72

84

Spin concentration

(1019 g -I )

Increase (%)

1.65

2.96

3.06

3.10

3.16

3.29

3.37

3.34

3.47

3.66

3.29

0.0

79.7

85.7

87.8

91.3

99.6

104.1

102.7

110.2

122. I

99.7

2.0035

2.0039

2.0045

2.0038

2.0041

2.0050

2.0049

2.0047

2.0045

2.0029

2.0029

Oxidation paths of a coking coal: J. E. Sanchez and J. M. Rincon

2.00

1.00

CH057"

'

2.00

]

CH089"

LV*

1.00

,

2.00

OLV

CHI07*

.oo

4000

3000

2000

1000

cm -1

4000

3000

2000

1000

cm -1

* Coking coals

Figure 2 FT-i.r spectra of Colombian coking coals LV, CH057, CH089, CHI07 and non-caking coals TB, OLV

2.00

1.50

1.00

0.50

Y

-0.50

I

3500

3000

"

2500

2000

1500

1000 '

cm -1

Figure 3 Diffuse reflectance i.r. difference spectra of coals LV and OLV

coals. For identification it has been necesary to use the

second derivative of the spectrum. Fuller et al. 27 used this

absorption, assigned to unconjugated carbonyl groups, as an

index of the loss of coking properties during oxidation. This

peak at 1735 cm -I was also present in the TB spectrum and

as a shoulder in the OLV spectrum; after water extraction of

OLV its presence was clearly identified, and the spectrum of

OLV became very similar to that of TB (Figure 5). The

effect of water extraction has not been previously reported,

and this method may be used to quantify the intensity of the

band to measure the degree of mild oxidation. This

band seems to be very stable, since it remains after

extraction with other solvents 3. The above results

suggest that the presence of carbonyl groups, conjugated

Fuel 1997 Volume 76 Number 12

1139

Oxidation paths of a coking coal: J. E. S~nchez and J. M. Rinc6n

2.00

TB

20

1.00

20

40

60

80

IOO

Oxidation time (h)

3000

4000

2.00

2000

I000

cm-1

LV

14

--

13

10

1.00

/

0

i

20

i

40

n

60

80

q

100

Oxidation time (h)

4000

ZOO,

20

3000

2000

1000

cm-!

3000

2000

1000

cm-1

1.00

20

40

60

80

|

100

Oxidation time (h)

Figure 4 Effect of oxidation on absorption area at 3600-3100,

1800-1600 and 3000-2700 cm -1 as a function of time

4000

Figure 5 FT-i.r spectra of water extraction residues of coals TB,

LV and OLV

and non-conjugated, in oxidized coals and in low-rank coals

is related to the absence of plastic properties.

40

35

E.s.r. data

Previous work z3 showed that the spin concentration

changes according to the oxidation conditions. The spin

concentrations and g factors are shown in Table 2; during

the first step the relative increase in spin concentration was

- 8 8 % and the g value also increased, suggesting that the

free radicals are stabilized over the oxygenated groups.

Weight loss during oxidation

Figure 6 shows the effect of oxidation on weight loss, as

measured in the FSI and dilatometric tests. Under the

conditions of the FSI test the weight loss remained constant,

whereas in the dilatometer it decreased from 27% for the

raw coal to 17% in the first step and then remained constant

in the second step. Similar results were obtained in a

simulated test by thermogravimetry. This means that during

pyrolysis, the oxidized OLV structure is thermally more

stable than the LV structure. This is consistent with the

higher bond dissociation energy for the C~-C~ bond when

there is a carbonyl group at the C~- position 3~. Another

possibility is that the free radicals in the volatiles may be

quenched by oxygenated free radicals to produce oxygenated chars.

1140

Fuel 1997 Volume 76 Number 12

30

--

25

FSI

DILAT

~ 20

~

1o

5

0

0

i

20

i

40

i

60

t

80

i

100

Oxidation time (h)

Figure 6 Effect of oxidation on weight loss in FSI and

dilatometer tests as a function of time

Oxidation mechanism

The mechanisms proposed4"L5'26 are supported by

knowledge of the oxidation mechanisms of model compounds in fluid phases where there are no mass transport

limitations. In solids like coal, there are such limitations, so

the mobile species are the oxygen and derivatives formed

during the process such as OH, HOO" and H" as follows:

Oxidation paths of a coking coal: J. E. Sanchez and J. M. Rinc6n

I: Oxygen reaction with native free radicals and labile

hydrogen

~ "

+ 02

,~ ( ~ 1 - O " O "

VI: Condensation and cross-linking

(16)

(1)

(0-0.

O-H

O,

C)"

+ H-O-O"

II: Hydroperoxide formation

(:~"

+ H-O-O"

<SD-O-O"

C)-O-O-H

+ H-O-O"

O-O-OH

(3)

+ 02

(4)

III: Hydroperoxide decomposition

(~)-O-O-H

~-O-O-H

(~3-O" + "OH thermal

+ Fe~

(~)-O"

>

O-o-O

(17)

(2)

(5)

+ OH- + Fe +'

where ( 8 ) and ( ~

are different entities in coal.

This mechanism is consistent with the results obtained in

this work such as the loss of hydrogen, the presence of

oxygenated free radicals, carbonyl and phenolic groups and

also the formation of H2 detected in other work 32,33.

From the above it can be concluded that the loss of coking

and caking properties in coals during mild oxidation is

related to the accumulation of free radicals, peroxides and

hydroperoxides, carbonyl groups and phenolic groups.

These species are labile at low temperatures and are crosslinking precursors.

(6)

ACKNOWLEDGEMENTS

C)-O=O=H

C)-0-H

+HaO

+ H-O-0H

(7)

IV: B-Elimination

(8)

R-C=O + <:~"

REFERENCES

I

H

H

I

C>-c-o.

The authors are grateful to CINDEC-U.N and FONIC for

financial support for this work.

(~-C=O

R"

(9)

I

R

3

(~C=O

I

R

H"

(10)

V: Carbon oxides formation

C:>c=o

(~

+ 02

6

7

8

> (~C=0

> (~"

-C= 0

+ H00"

(11)

CO

(12)

~-O-H

H

I

OC-X

I

H

13,

O-C-R

I

0-0H

O-

O"

I

C-R (13)

I

0"

9

10

11

12

13

14

15

16

O*

O"

I

-c~

,~,-C=O

R.

(14)

19

20

21

O.

22

O.

~.~,-c=o

17

18

(~.

CO~

(15)

23

Dryden, I. G. C., in Chemistry of Coal Util&ation, Supplementary Volume, ed. H. H. Lowry. Wiley, New York, 1963,

Chapter 6.

Wender, I., Heredy, L. A., Neuworth, M. B. and Dryden, I.

G. C., in Chemistryof Coal Utilization, Second Supplementary Volume, ed. M. A. Elliott. Wiley-Interscience, New

York, 1981, Chapter 8.

Clemens, A. H., Matheson, T. W., Lynch, L. J. and

Sakurovs, R., Fuel, 1989, 68, 1162.

Clemens, A. H., Matheson, T. W. and Rogers, D. E., Fuel,

1991, 70, 215.

Khan, M. R., Usmen, R., Newton, E., Beer, S. and

Chisholm, W., Fuel, 1988, 67, 1668.

Seki, H., Ito, O. and Iino, M., Fuel, 1990, 69, 317.

Nordon, P. and Bainbridge, W., Fuel, 1983, 62, 619.

Krishnaswamy, S., Agarwal, P. K. and Gunn, R. D., Fuel,

1996, 75, 353.

Seki, H., Ito, O. and Iino, M., Fuel, 1990, 69, 1047.

Wheeler, R. V. and Clark, A. H., Journal of the Chemical

Society, 1913, 103, 1704.

Van Krevelen, D. W., van Heerden, C. and Huntjens, F. J.,

Fuel, 1951, 30, 253.

Larsen, J. W., Lee, D., Schmidt, T. and Greent, A., Fuel,

1986, 65, 595.

Yokono, T., Miyazawa, K., Sanada, Y. and Marsh, H., Fuel,

1981, 60, 598.

Ripmeester, J. A., Couture, C., MacPhee, J. A. and Nandi, B.

N., Fuel, 1984, 63, 522.

Rhoads, C. A., Senftle, J. T., Coleman, M. M., Davis, A. and

Painter, P. C., Fuel, 1983, 62, 1387.

Ignasiak, B. S., Szladow, A. J. and Montgomery, D. S., Fuel,

1974, 53, 12.

Szladow, A. J. and Ignasiak, B. S., Fuel, 1976, 55, 253.

Painter, P. C., Sayder, R. W., Pearson, D. E. and Kwong, J.,

Fuel, 1980, 59, 282.

Liotta, R., Brons, G. and Isaacs, J., Fuel, 1983, 62, 781.

Getner, L. S., Fuel, 1987, 66, 1091.

Wachowska, H. M., Nandi, B. N. and Montgomery, D. S.,

Fuel, 1974, 53, 212.

Cronauer, D. C., Ruberto, R. G., Jenkins, R. G., Davis, A.,

Painter, P. C., Hoover, D. S., Starsinic, M. E. and Schlyer,

D., Fuel, 1983, 62, 1124.

Cronauer, D. C., Ruberto, R. G., Silver, R. S., Jenkins, R. G.,

Ismail, Y. M. K. and Schlyer, D., Fuel, 1983, 62, 1116.

Fuel 1997 V o l u m e 76 N u m b e r 12

1141

Oxidation paths of a coking coal: J. E. S~nchez and J. M. Rincon

24

25

26

27

28

29

1142

Kouchi, J. K., Free Radicals, Vol. 1. Wiley, London, 1973,

Chapter 7.

Calemma, V., Rausa, R., Margarit, R. and Girardi, R., Fuel,

1988, 67, 764.

Painter, P. C., Snyder, R. W. and Pearson, D. E., Applied

Spectroscopy, 1981, 35, 106.

Fuller, M. P., Hamadeh, Y. M., Griffiths, P. R. and

Lowenhaupt, D. E., Fuel, 1982, 61, 529.

Huffman, G. P., Huggins, F. E., Dunmyre, G. R., Pignocco,

A. J. and Lin, M., Fuel, 1985, 64, 849.

Niksa, S., Energy and Fuels, 1996, 10, 173.

Fuel 1997 Volume 76 Number 12

30

31

32

33

Sfinchez, J. E. and Rinc6n, J. M., Revista Colombiana de Qu

[mica, 1993, 22(2), 1.

Murata, S., Mori, T., Murakami, A. and Nomura, M.,

Energy and Fuels, 1995, 9, 119.

Grossman, S., David, S., Sokolov, K. and Cohen, H., in Coal

Science, ed. J. A. Pajares and J. M. D. Tasc6n. Elsevier,

Amsterdam, 1995, p. 473.

Grossman, S., David, S., Sokolov, K. and Cohen, H., in Coal

Science, ed. J. A. Pajares and J. M. D. Tasc6n. Elsevier,

Amsterdam, 1995, p. 469.

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Multivariate Statistical Process Control in Product Quality Review Assessment - A Case StudyDocumento10 pagineMultivariate Statistical Process Control in Product Quality Review Assessment - A Case Studyd1360sdfggfbdmllNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Multivariate Statistical Process Control in ChromatographyDocumento12 pagineMultivariate Statistical Process Control in Chromatographyd1360sdfggfbdmllNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Measurement Uncertainty: Veronika R. MeyerDocumento10 pagineMeasurement Uncertainty: Veronika R. Meyerd1360sdfggfbdmllNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Statistical Quality Control Applied To Ion Chromatography CalibrationsDocumento7 pagineStatistical Quality Control Applied To Ion Chromatography Calibrationsd1360sdfggfbdmllNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Linear Least Squares Both ErrorsDocumento2 pagineLinear Least Squares Both Errorsd1360sdfggfbdmllNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Quantifying Uncertainty in Analytical Measurement: Eurachem / Citac Guide CG 4Documento141 pagineQuantifying Uncertainty in Analytical Measurement: Eurachem / Citac Guide CG 4ahmad YaghiNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Calculating Standard Deviations andDocumento5 pagineCalculating Standard Deviations andd1360sdfggfbdmllNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Certificate of Analysis: Certified Reference MaterialDocumento3 pagineCertificate of Analysis: Certified Reference MaterialAnonymous GdWMlV46bUNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

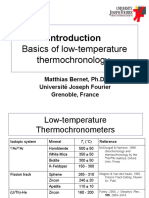

- Basics of Low-Temperature Thermochronology: Matthias Bernet, Ph.D. Université Joseph Fourier Grenoble, FranceDocumento31 pagineBasics of Low-Temperature Thermochronology: Matthias Bernet, Ph.D. Université Joseph Fourier Grenoble, Franced1360sdfggfbdmllNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Tga 1 2010 PDFDocumento384 pagineTga 1 2010 PDFd1360sdfggfbdmllNessuna valutazione finora

- Fission-Track Analysis: Matthias Bernet, Ph.D. Université Joseph Fourier Grenoble, FranceDocumento69 pagineFission-Track Analysis: Matthias Bernet, Ph.D. Université Joseph Fourier Grenoble, Franced1360sdfggfbdmllNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- 2010 - EdisonDocumento13 pagine2010 - Edisond1360sdfggfbdmllNessuna valutazione finora

- EPA Method 3001Documento40 pagineEPA Method 3001d1360sdfggfbdmllNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Bucharest 2013 Ws 4Documento32 pagineBucharest 2013 Ws 4d1360sdfggfbdmllNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- I Hate OrgDocumento13 pagineI Hate Orgjestoni langgidoNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Smith Ch08 Lecture EditDocumento60 pagineSmith Ch08 Lecture EditfaithNessuna valutazione finora

- Essay Questions 91 05Documento3 pagineEssay Questions 91 05Chrisel Joy Dela CruzNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- An Advanced Laboratory Manual of Organic ChemistryDocumento103 pagineAn Advanced Laboratory Manual of Organic Chemistryalkem7100% (1)

- Reactions of AlkenesDocumento14 pagineReactions of AlkenesLara AlhaddadNessuna valutazione finora

- Some Important Reasoning Based Questions of Organic ChemistryDocumento17 pagineSome Important Reasoning Based Questions of Organic ChemistrySourajit Mukherjee100% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Nishimura Sh. Handbook of Heterogeneous Catalytic Hydrogenation For Organic Synthesis (Wiley, 2001) (ISBN 0471396982) (747s) PDFDocumento747 pagineNishimura Sh. Handbook of Heterogeneous Catalytic Hydrogenation For Organic Synthesis (Wiley, 2001) (ISBN 0471396982) (747s) PDFindiomajadero100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Previous Year Questions Carbon & Its CompoundsDocumento41 paginePrevious Year Questions Carbon & Its CompoundsRehan MotiwalaNessuna valutazione finora

- Principles of General Organic and Biological Chemistry 2nd Edition Smith Test BankDocumento24 paginePrinciples of General Organic and Biological Chemistry 2nd Edition Smith Test Bankallisontaylorfnrqzamgks100% (25)

- Torulaspora Delbrueckii and Conversion To Ephedrine byDocumento4 pagineTorulaspora Delbrueckii and Conversion To Ephedrine bysalvia1025100% (1)

- AITS-02 - Hints and Solutions - Lakshya NEET 2024Documento19 pagineAITS-02 - Hints and Solutions - Lakshya NEET 2024shktimahto0238Nessuna valutazione finora

- Physical Science DLP M6Documento6 paginePhysical Science DLP M6Ciel LueNessuna valutazione finora

- Organic Chemistry Notes PDFDocumento58 pagineOrganic Chemistry Notes PDFAzadnikov94% (16)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- List of Straight-Chain AlkanesDocumento6 pagineList of Straight-Chain AlkanesRSLNessuna valutazione finora

- Understanding Organic ReactionsDocumento4 pagineUnderstanding Organic ReactionsSteve MessengerNessuna valutazione finora

- Derivados PetroleoDocumento48 pagineDerivados PetroleoCarlos TimanaNessuna valutazione finora

- Orgemd Post Lab Activity 2 4Documento43 pagineOrgemd Post Lab Activity 2 4Lynette Evangelista100% (3)

- 122 IR ProcedureDocumento24 pagine122 IR ProcedureJohn SepulvedaNessuna valutazione finora

- DPP802Documento2 pagineDPP802anikephantomNessuna valutazione finora

- Dehydration of AlcoholsDocumento2 pagineDehydration of AlcoholsLawrenceDeJesusNessuna valutazione finora

- Reaction Mechanisms GOC BookDocumento84 pagineReaction Mechanisms GOC BookAyushNessuna valutazione finora

- CA2004312C - Production of Allyl Chloride - Google PatentsDocumento5 pagineCA2004312C - Production of Allyl Chloride - Google PatentsTeeTeeXdNessuna valutazione finora

- Chapter 2. Introduction To Organic Chemistry: 2.1 Functional Group and Homologous SeriesDocumento8 pagineChapter 2. Introduction To Organic Chemistry: 2.1 Functional Group and Homologous SeriesDavid PhilipNessuna valutazione finora

- Formal Report: Nucleophilic Acyl Subtitution: The Synthesis of EthersDocumento3 pagineFormal Report: Nucleophilic Acyl Subtitution: The Synthesis of EthersJuris Marie G. GarciaNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Aromatic CompoundsDocumento107 pagineAromatic CompoundsNishantNessuna valutazione finora

- Organic Chemistry Multiple Choice QuestionsDocumento4 pagineOrganic Chemistry Multiple Choice QuestionsRonald Angelo LopezNessuna valutazione finora

- B.Tech I & II Semester Syllabus - 2018-19 PDFDocumento41 pagineB.Tech I & II Semester Syllabus - 2018-19 PDFDatta YallapuNessuna valutazione finora

- Tetrahydrofuran: THF (Disambiguation)Documento12 pagineTetrahydrofuran: THF (Disambiguation)Faris NaufalNessuna valutazione finora

- Anthrone TestDocumento1 paginaAnthrone TestChristine Joy Solatorio33% (3)

- CH307 Inorganic Kinetics: Dr. Andrea Erxleben Room C150 Andrea - Erxleben@nuigalway - IeDocumento50 pagineCH307 Inorganic Kinetics: Dr. Andrea Erxleben Room C150 Andrea - Erxleben@nuigalway - Ieneel721507Nessuna valutazione finora