Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Marshall-Tufflex Product Performance

Caricato da

suresh babuDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Marshall-Tufflex Product Performance

Caricato da

suresh babuCopyright:

Formati disponibili

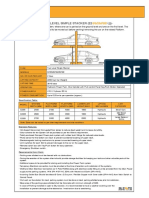

1937-07118 MT CM Prod Benefits.

qxp:MT

6/5/09

13:10

Page 1

MARSHALL-TUFFLEX

PRODUCT PERFORMANCE

Presenting the facts and features on product time and cost saving,

EMC capability, fire performance and environmental issues.

FIRE PERFORMANCE INFORMATION (www.beamainstallation.org.uk)

Full information on the Causes and Process of Fire can be found at www.beamainstallation.org.uk

This is an independent report conducted to ascertain the Fire Performance of PVC-U.

VINYL 2010

The European PVC industry has, over recent years, initiated a number of far reaching

policies that have been incorporated into the Voluntary Commitment to the

European Commission, Vinyl 2010, demonstrating that the whole life cycle of PVC is

sustainable. Marshall-Tufflex is fully committed to meeting and, where possible,

exceeding the requirements of Vinyl 2010.

POLYVINYLCHLORIDE (PVC)

PVC is one of the most successful modern synthetic materials. It makes excellent use

of scarce resources, is long-lasting and safe in production, use and disposal. The

effect of PVC on health and the environment, from manufacture to disposal, has

been more thoroughly researched than almost any other synthetic material. The

properties of PVC can be significantly altered by additives. As a result, different

classifications of PVC exist:

PVC-U: Polyvinylchlorideunplasticised - used in the manufacture of rigid PVC for

products such as conduits, trunking, drainage systems and windows. The fire

rating for PVC-U is excellent.

PVC-P: Polyvinylchlorideplasticised - PVC that uses plasticisers for the

manufacture of flexible products such as electric cables and flexible tubing.

PVC-P is not so fire resistant.

ENVIRONMENTAL BENEFITS OF PVC-U

100% recyclable material

No increase in dioxin emissions from Municipal Waste Incineration

PVC-U products have a long life cycle

Lowest oil content of a commodity plastic - less energy to produce

No painting or repainting

No chemical treatments required

Highly rated in terms of social and economic sustainability

MARSHALL-TUFFLEX

The Company has been recycling PVC-U products for many years with a well

proven performance history and actively pursues a comprehensive programme to

develop formulations based on environmentally acceptable materials, whilst still

maintaining and, where possible, improving on long-term performance properties.

Jim Fletcher, Managing Director

Fire prevention is the key objective when maximising Fire Escape Time. Product factors required are:

Difficult to ignite

Low burning rate

Low heat release

Low smoke production

Low toxicity

Halogens

In the field of flame retarded products, only fluorine, chlorine and bromine are relevant.

Being halogen-free (0H or ZH) does not necessarily equate with low fire hazard, for example:

Polyethylene is halogen-free and burns freely in air. Providing polyethylene with fire retardancy properties requires the

addition of fire retardant chemicals. These can create toxic fumes in combustion.

PVC is not halogen-free as it contains chlorine. However, chlorine is an effective flame retardant, delaying ignition and

resulting in lower heat release and lower flame spread.

Delayed ignition maximises Fire Escape Time. (See above)

Zero Halogen (OH or ZH)

Indicates that a material does not contain more than a trace of halogen.

Does not necessarily mean that product would have any fire retardancy properties.

Low Smoke and Fume (LSF)

LSF is not a specific material but more of a marketing term, indicating that when a product is involved in fire, there is a low level of

smoke and fume when it burns.

The term LSF does not necessarily equate with a low fire hazard or the lack of toxic fumes.

Carbon Monoxide (CO)

The most significant asphyxiant and very dangerous because it has no taste or smell.

May be produced when any carbon-based material is burnt in air.

Approximately 75% of all fire deaths can be attributed to carbon monoxide poisoning.

Carbon Dioxide (CO2)

A major product of almost all fires, its effect, above a volume of about 2%, is to make victims breath faster and increase the dosage

of other fire gases received. In many fire scenarios the 2% threshold is not reached.

Hydrogen Chloride (HCI)

Produced when organochlorine materials are burnt in air.

Classed as a toxic irritant, the irritation caused by HCI has a warning effect at levels far below those that may cause death, unlike

carbon monoxide which can kill people whilst they sleep. Experiments have shown that it is impossible to continue sleeping when

HCI is present, even in harmless concentrations.

Please call +44 (0) 1424 856600 for a copy of this Product Performance Document (EL140) or the Marshall-Tufflex Environmental

Document (EL136) or download from www.marshall-tufflex.com > BROCHURE REQUEST.

MARSHALL-TUFFLEX LTD, Churchfields Industrial Estate, Hastings, East Sussex TN38 9PU Tel: 01424 856600 Fax: 01424 856611

International Tel: +44 (0) 1424 856000 International Fax: +44 (0) 1424 856666 Technical Hotline: +44 (0) 1424 856688 Email: sales@marshall-tufflex.com Web: www.marshall-tufflex.com

1937-07118 MT CM Prod Benefits.qxp:MT

6/5/09

13:10

Page 2

MARSHALL-TUFFLEX PRODUCT PERFORMANCE continued

PVC-U

SYSTEM

Odyssey Trunking

System

Aesthetically designed

trunking with unique

curved profile:

Cat 6 compliant

No need to mitre corners

Easy to cut and install

No sharp edges

No earth bonding

required

Built-in cable tray

INSTALLATION Adjustable or fixed bend

options

Recessed boxes for curved

accessories

ABS moulded fittings

Dado level mounting

Coloured boxes available

to assist with Part M

(Visual Impairment)

Installers quote fast and

easy installation

EMC

PROPERTIES

STEEL

ALUMINIUM

SPECIALIST SYSTEMS

Sterling Trunking

Systems

SnakeWay Cable

Support System

Steel Trunking

Systems

Aluminium

Containment Systems

Multi-compartment group

of systems designed for

commercial, educational

and healthcare applications:

Many different profile

configurations

Some systems Cat 6

compliant

Large range of sizes, cable

capacities, colours and

finishes

Easy to cut and install

No sharp edges

Suitable for skirting or

dado level mounting and

busbar option

Coloured boxes available

to assist with Part M

(Visual Impairment)

Amazing cable support

systems for wall, floor and

ceiling applications:

Can be hand-formed onsite

Up to 85% savings on

installation times

Big project cost savings

No on-site clamping or

assembling

No threading of rods on

ceiling systems

Slow bends for good data

performance

No clamping or

assembling

Very simple installation for a

variety of applications:

Common cover

throughout the range

Cover snaps into body

automatically, establishing

earth continuity

Not so easy to cut as

PVC-U

Requires earth bonding

Can be used in high

ambient temperatures

Ideal for commercial,

industrial, workshop and

laboratory use:

Sterling multicompartment systems

Moulded fittings

Polycarbonate clip-on

fittings

Some systems Cat 6

compliant

Extruded section enables

striking shapes with high

tolerances

Lighter material than steel

Compact 32Amp

connectors providing

pre-wired, pre tested plug

and play system supplying

cabling runs from power

source to accessory box:

Up to 80% faster fitting

times

Big project cost savings

Suitable for underfloor,

trunking, dry-lined and

surface mount

applications

Simple 3-layer construction

with an aluminium tube

sandwiched between

internal and external layers

of polyethylene:

Easy to store, fast to fit

(up to 100 metre lengths

available)

No special tools

necessary

Simple to use on site

lower project costs

Can be installed in screed

Easy to feed through

floor joists and in cavity

walls

Resistant to extremes of

temperature

Some EMC/EMI screening

Steel trunking is an

excellent EMC/EMI

screening material

First class EMC/EMI

screening performance

especially at higher

frequencies

N/A

Aluminium layer provides

excellent EMC/EMI

screening performance

especially at higher

frequencies

Aluminium systems

specified with polycarbonate fittings meet

accepted requirements for

LSOH

Withstands high

temperatures

The MT32 wiring system is

LSOH.

POLYCARBONATE

An LSOH material that

performs well in a fire

situation (MT Supertube

fittings are manufactured in

steel and polycarbonate).

POLYETHYLENE

Halogen free.

MT Supertube FR Plus:

Meets the requirements of

LUL Engineering Standard

2-01001-002:Issue A1.

Material classification EQ/I

(equipment/limited and

dispersed).

MT32 is a completely reusable system. All major

components can be disassembled for re-use.

No special disposal

restrictions.

A unique conductive spray coating can be specified to

offer protection from electromagnetic interference to data

and communications cabling.

Steel screening

Aluminium screening

insert option

insert option

Steel inserts available

Fire rating for PVC-U is excellent (see independent survey at

www.beamainstallation.org.uk). PVC-U has all the

characteristics required for Fire Escape Time (see page 1).

Is highly resistant to ignition

Does little to contribute to the spread of fire and is

classified to Building Regs. Class 0

Has a low rate of smoke production during the early

FIRE

stages of a fire

PERFORMANCE Acts as an effective barrier to flame spread from

malfunctioning electrical components contained within

them

Chars and is self-extinguishing

Does not produce flaming droplets or burning debris

Basic Steel Trunking and SnakeWay systems meet the

accepted requirements for LSOH

Withstands high temperatures

Type and thickness of any coating needs to be

considered as this can affect Fire Performance

Accessory boxes and dividing fillets may be PVC-U (see

PVC-U Fire Performance)

MT32 Power

Connection

POLYCARBONATE

FITTINGS

Fire rated to UL94V0

ABS FITTINGS

Fire rated to UL94V0

ABS FITTINGS

Fire rated to UL94V0

100% recyclable

100% recyclable

Can be recycled many times without loss of quality

Can be recycled many times without loss of quality

No phthalates used in manufacture of PVC-U or FR-ABS Well established recycling facilities

RECYCLING &

Does not increase dioxin emissions in waste

ENVIRONMENTAL incineration

Proven sustainability

Collection schemes established for recovery of PVC-U

Marshall-Tufflex Environmental Document available (EL136)

100% recyclable

Can be recycled many

times without loss of

quality

Well established recycling

facilities

MT Supertube &

MT Supertube FR Plus

MARSHALL-TUFFLEX LTD, Churchfields Industrial Estate, Hastings, East Sussex TN38 9PU Tel: 01424 856600 Fax: 01424 856611

International Tel: +44 (0) 1424 856000 International Fax: +44 (0) 1424 856666 Technical Hotline: +44 (0) 1424 856688 Email: sales@marshall-tufflex.com Web: www.marshall-tufflex.com

EL140/09030

Potrebbero piacerti anche

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDa EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesValutazione: 3.5 su 5 stelle3.5/5 (3)

- CP 601S CP 601S: Elastomeric Firestop SealantDocumento4 pagineCP 601S CP 601S: Elastomeric Firestop Sealantrichard_qrNessuna valutazione finora

- UAE Emergency Lighting Guide Lines - GoodDocumento47 pagineUAE Emergency Lighting Guide Lines - Goodsuresh babuNessuna valutazione finora

- Voltage Drop For Street Light PoleDocumento3 pagineVoltage Drop For Street Light Polesuresh babuNessuna valutazione finora

- Ceramic Breaking DiscDocumento13 pagineCeramic Breaking Discbotan_mihaiNessuna valutazione finora

- Rockwool 159Documento37 pagineRockwool 159ashish2783Nessuna valutazione finora

- Rockwool Rti Product Catalogue ExportDocumento45 pagineRockwool Rti Product Catalogue ExportBeomHee Lee100% (1)

- EcoTherm Structural Insulation Quick Guide Aug 2015Documento40 pagineEcoTherm Structural Insulation Quick Guide Aug 2015harshstoryNessuna valutazione finora

- ArmacellDocumento19 pagineArmacellGiải Pháp Cơ ĐiệnNessuna valutazione finora

- Damival en 20120516Documento8 pagineDamival en 20120516ssingaram1965Nessuna valutazione finora

- Sinorix1230 - EN - A D N FireDocumento18 pagineSinorix1230 - EN - A D N FireakashajmeraNessuna valutazione finora

- CS Corrosion Protection SystemDocumento20 pagineCS Corrosion Protection SystemMichael AlbuquerqueNessuna valutazione finora

- FireStop Catalogue 2015 V4Documento48 pagineFireStop Catalogue 2015 V4Muhidin KozicaNessuna valutazione finora

- Process ManualDocumento183 pagineProcess ManualAnonymous UoHUag100% (5)

- Optima Ceiling Panels High Performance Fiberglass: Committed To SustainabilityDocumento18 pagineOptima Ceiling Panels High Performance Fiberglass: Committed To Sustainabilitya1c2d3Nessuna valutazione finora

- Low Smoke Zero Halogen ConduitDocumento3 pagineLow Smoke Zero Halogen Conduitashitha dilanNessuna valutazione finora

- Polycarbonate (PC) : PetrochemicalsDocumento14 paginePolycarbonate (PC) : PetrochemicalsAhmed MokhtarNessuna valutazione finora

- 2013 FireStop Catalogue V3 Final (SM)Documento48 pagine2013 FireStop Catalogue V3 Final (SM)nt_long76Nessuna valutazione finora

- Climaver Ductwork System BrochureDocumento12 pagineClimaver Ductwork System BrochureFredoMari LCNessuna valutazione finora

- Electrical EquipmentDocumento84 pagineElectrical EquipmentHarthwell CapistranoNessuna valutazione finora

- Fire Protection Industry - UkDocumento6 pagineFire Protection Industry - UkUtsav GoswamiNessuna valutazione finora

- Clean, Protect, Lubricate: Product CatalogueDocumento36 pagineClean, Protect, Lubricate: Product CatalogueAbe KobNessuna valutazione finora

- Firecel - General Catalogue 100 - 2 (English) - Light VersionDocumento36 pagineFirecel - General Catalogue 100 - 2 (English) - Light Versionodemircioglu2Nessuna valutazione finora

- ASFP E-Bulletin Issue 12Documento1 paginaASFP E-Bulletin Issue 12h_militaru7862Nessuna valutazione finora

- Lorient ATG BrochureDocumento24 pagineLorient ATG Brochureodemircioglu2Nessuna valutazione finora

- Enviro Kerb SystemDocumento26 pagineEnviro Kerb SystemΜανος ΦιοράκηςNessuna valutazione finora

- Aircrete Blocks Technical ManualDocumento95 pagineAircrete Blocks Technical Manualpseudosil100% (3)

- Alp General ACCESORIESDocumento74 pagineAlp General ACCESORIESsas_uu100% (1)

- Recotec Rotafil enDocumento16 pagineRecotec Rotafil enJordan RileyNessuna valutazione finora

- Inertec2012 PDFDocumento16 pagineInertec2012 PDFchinitnNessuna valutazione finora

- Fire Protection For Structural SteelDocumento8 pagineFire Protection For Structural SteelcheckshinlNessuna valutazione finora

- Aluminium Composite Panels Article: History of ACPDocumento7 pagineAluminium Composite Panels Article: History of ACPsales7099Nessuna valutazione finora

- Asia Sealant Application Guide Final Version 9-29-04Documento61 pagineAsia Sealant Application Guide Final Version 9-29-04surajit7gupta100% (2)

- Duct Solutions Brochure.12.09Documento6 pagineDuct Solutions Brochure.12.09Nedunuri.Madhav MurthyNessuna valutazione finora

- ISOVER Ultimate Insulation ManuallowDocumento24 pagineISOVER Ultimate Insulation Manuallowytu_makinaNessuna valutazione finora

- TMS 2002Documento3 pagineTMS 2002Daniel StuparekNessuna valutazione finora

- Mesa Ceiling Panels Mineral Fiber: Committed To SustainabilityDocumento18 pagineMesa Ceiling Panels Mineral Fiber: Committed To Sustainabilitya1c2d3Nessuna valutazione finora

- ACO-Stainless Steel Underground PipeDocumento60 pagineACO-Stainless Steel Underground PipeAli BariNessuna valutazione finora

- Passive Fire Protection SystemDocumento33 paginePassive Fire Protection Systemfayis u m100% (1)

- Total Brochure UK LoRes 0609 PDFDocumento32 pagineTotal Brochure UK LoRes 0609 PDFMohammed RayanNessuna valutazione finora

- 1.4 Advanced PFP Seminar 11 2011 PDFDocumento94 pagine1.4 Advanced PFP Seminar 11 2011 PDFfredo405Nessuna valutazione finora

- EPD XCarb Magnelis UpdatedDocumento17 pagineEPD XCarb Magnelis Updatedemail.ysf.ramiNessuna valutazione finora

- Reducing Dioxin Emissions in Electric Steel MillsDocumento4 pagineReducing Dioxin Emissions in Electric Steel MillstedmozbiNessuna valutazione finora

- Proflex CatalogueDocumento8 pagineProflex Catalogueapi-291585305Nessuna valutazione finora

- Product Portfolio 2013Documento292 pagineProduct Portfolio 2013henlopNessuna valutazione finora

- Curs - Gratuit - Online - CPD 12 2015 - Acoustic Design and Flat Roofs - Features - BuildingDocumento9 pagineCurs - Gratuit - Online - CPD 12 2015 - Acoustic Design and Flat Roofs - Features - Buildingandrew_sfiNessuna valutazione finora

- Organic Coated Steel: ArcelorDocumento37 pagineOrganic Coated Steel: ArcelordangmiuNessuna valutazione finora

- Nexanaffgs HanggfafdbookDocumento116 pagineNexanaffgs HanggfafdbookAnonymous ziG2oaNessuna valutazione finora

- Kalzip Facade SystemsDocumento24 pagineKalzip Facade SystemsAndon Setyo WibowoNessuna valutazione finora

- Cat Cabelte EN Web PDFDocumento296 pagineCat Cabelte EN Web PDFJoko Isnanto100% (1)

- FM 200Documento4 pagineFM 200aniketNessuna valutazione finora

- Flame and Smoke Retardants in Vinyl Chloride Polymers - Commercial Usage and Current DevelopmentsDocumento26 pagineFlame and Smoke Retardants in Vinyl Chloride Polymers - Commercial Usage and Current DevelopmentsabiliovieiraNessuna valutazione finora

- Demand For NonDocumento7 pagineDemand For NongganageNessuna valutazione finora

- Technopro CatalogueDocumento20 pagineTechnopro CatalogueAdnan KhanNessuna valutazione finora

- Fire Engineering 2011Documento240 pagineFire Engineering 2011Beto J. Spsilandi100% (1)

- Kalzip Systems Brochure MEDocumento72 pagineKalzip Systems Brochure MEjmcc2Nessuna valutazione finora

- Aero KDocumento2 pagineAero KbmxmmxNessuna valutazione finora

- 2012 Burner Range: Leaders in Combustion TechnologyDocumento5 pagine2012 Burner Range: Leaders in Combustion TechnologyBbaPbaNessuna valutazione finora

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyDa EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNessuna valutazione finora

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Da EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Nessuna valutazione finora

- Issue #9 Printing and Graphics Science Group NewsletterDa EverandIssue #9 Printing and Graphics Science Group NewsletterNessuna valutazione finora

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementDa EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNessuna valutazione finora

- Three Level Puzzle ParkingDocumento1 paginaThree Level Puzzle Parkingsuresh babuNessuna valutazione finora

- BMS in Hospitals PDFDocumento36 pagineBMS in Hospitals PDFsuresh babu100% (1)

- Cable Tray Standards - by LegrandDocumento4 pagineCable Tray Standards - by Legrandsuresh babuNessuna valutazione finora

- White Paper: Electrical Services in Building FiresDocumento2 pagineWhite Paper: Electrical Services in Building Firessuresh babuNessuna valutazione finora

- B3.3 Series: Diesel Generator SetDocumento4 pagineB3.3 Series: Diesel Generator Setsuresh babuNessuna valutazione finora

- Éπ~Ùç Çí∫-Èπ◊Çú≈.. Ejy-®√-´'Çí¬.. E®Ωç-Ûª-®√ߪ'Çí¬.. ´'† £Æ«%ܿߪ'Ç Ææpçc-Ææ÷Høë Öçc! ´'† Éóææç Û√°Æ-Vûª-ߪ'-°Æ-Úø'-Ûª÷Øë Öçc. ´'J Åçûªöà Éã©-Éπ-¢Á'I† Í∫'Çúá Éóææç ´'†Ç Ææpçc-Ææ'H-Ø√O´÷?Documento1 paginaÉπ~Ùç Çí∫-Èπ◊Çú≈.. Ejy-®√-´'Çí¬.. E®Ωç-Ûª-®√ߪ'Çí¬.. ´'† £Æ«%ܿߪ'Ç Ææpçc-Ææ÷Høë Öçc! ´'† Éóææç Û√°Æ-Vûª-ߪ'-°Æ-Úø'-Ûª÷Øë Öçc. ´'J Åçûªöà Éã©-Éπ-¢Á'I† Í∫'Çúá Éóææç ´'†Ç Ææpçc-Ææ'H-Ø√O´÷?suresh babuNessuna valutazione finora

- Phy - Dimensions of TFDocumento13 paginePhy - Dimensions of TFsuresh babuNessuna valutazione finora

- Two Level Simple StackerDocumento1 paginaTwo Level Simple Stackersuresh babuNessuna valutazione finora

- Plastic Bags Vs Paper Bags Which Is More Earth Friendly?Documento6 paginePlastic Bags Vs Paper Bags Which Is More Earth Friendly?Hans Markson TanNessuna valutazione finora

- Catalog SAABDocumento167 pagineCatalog SAABAdriano Beluco100% (6)

- 61JSK-4400 Jack Screw Kit Installation Instructions - English H14727PADocumento4 pagine61JSK-4400 Jack Screw Kit Installation Instructions - English H14727PAnader0123Nessuna valutazione finora

- EVS3020 B50 060142 02 InglêsDocumento20 pagineEVS3020 B50 060142 02 InglêsPaulo RodriguesNessuna valutazione finora

- Adsorption Isotherm of Acetic Acid Solutions On Activated CarbonDocumento7 pagineAdsorption Isotherm of Acetic Acid Solutions On Activated Carboneiddnew67% (6)

- Ppe C PDFDocumento4 paginePpe C PDFrexivyNessuna valutazione finora

- Catalogo Transair Aluminio 8pg 168mm 2015 Ing JDSDocumento8 pagineCatalogo Transair Aluminio 8pg 168mm 2015 Ing JDSNahbi Emilio PerezNessuna valutazione finora

- CycloneDocumento25 pagineCycloneAna Marie AllamNessuna valutazione finora

- Tor 62Documento1 paginaTor 62topoginoNessuna valutazione finora

- Environmental Green Chemistry Applications of Nanoporous CarbonsDocumento24 pagineEnvironmental Green Chemistry Applications of Nanoporous CarbonsIvan AlcomendrasNessuna valutazione finora

- 1/2" Elima-Matic Bolted Plastic - Drum PumpDocumento15 pagine1/2" Elima-Matic Bolted Plastic - Drum PumpWalter LrNessuna valutazione finora

- Acetone: Shell ChemicalsDocumento3 pagineAcetone: Shell ChemicalsUzair BukhariNessuna valutazione finora

- AP-2 Bearing BrochureDocumento6 pagineAP-2 Bearing BrochureLuis Alejandro García JoyaNessuna valutazione finora

- Throttle Learning 2Documento2 pagineThrottle Learning 2Indy RufSanNessuna valutazione finora

- Venmar IAQ Products BrochureDocumento12 pagineVenmar IAQ Products Brochuree-ComfortUSANessuna valutazione finora

- Medium-Voltage CablesDocumento10 pagineMedium-Voltage CablesRa ArNessuna valutazione finora

- SYD-382 Smoke PointDocumento9 pagineSYD-382 Smoke PointFrank.JNessuna valutazione finora

- Rotary Kiln Handbook NEWDocumento56 pagineRotary Kiln Handbook NEWjoseNessuna valutazione finora

- Husqvarna 2003 SM WRE 125 ManualDocumento2 pagineHusqvarna 2003 SM WRE 125 ManualNdae IskandarNessuna valutazione finora

- Ch-8.2 Screw Thread ManufacturingDocumento18 pagineCh-8.2 Screw Thread ManufacturingPrateek Bayal0% (2)

- Car Engine Bearing FunctionsDocumento1 paginaCar Engine Bearing Functionsphutd09Nessuna valutazione finora

- Intro To Green ChemistryDocumento44 pagineIntro To Green ChemistryAmann AwadNessuna valutazione finora

- 4 PDFDocumento4 pagine4 PDFinghoraciorojas5270Nessuna valutazione finora

- Metal Forming & Shaping Processes: Topic 3Documento37 pagineMetal Forming & Shaping Processes: Topic 3afnanhananyNessuna valutazione finora

- Industrial Meter CatalogDocumento84 pagineIndustrial Meter CataloghotnatkapoorNessuna valutazione finora

- DatasheetDocumento10 pagineDatasheetNSFWNessuna valutazione finora

- Color Fastness To Washing Is The Common Quality ParameterDocumento4 pagineColor Fastness To Washing Is The Common Quality Parameterakanksha2006Nessuna valutazione finora

- Force FX Electrosurgical Generator C Service ManualDocumento236 pagineForce FX Electrosurgical Generator C Service ManualIBRAHIMNessuna valutazione finora

- TRIZ MatrixDocumento28 pagineTRIZ MatrixHaslina Hakimi100% (1)