Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Petkus F12 Cleaner

Caricato da

igbnsCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Petkus F12 Cleaner

Caricato da

igbnsCopyright:

Formati disponibili

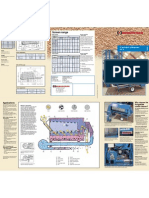

Universal Cleaner F 12 / P 12

justable supply flap. This flap allows for an optimal separation effect.

For both cleaners a combined cleaning method via ball and scraper chain

is used to clean the upper screen. The bottom screens of the P12 are

also cleaned by the ball method whereas the bottom screen of the F12

uses brush cleaning, which regardless of the motor speed, ensures

optimal screen efficiency.

Construction:

The PETKUS F 12 and P 12 cleaners are equipped with an inlet hopper,

a pre and final air separation, with depositing chambers and discharge

auger as well as two counter vibrating screen compartments. The various components of the machine (inlet hopper, discharge auger, scraper

chain, etc.) are operated by drive motors.

Standard Equipment:

Compact, closed and bolted frame made of painted sheet steel

Screen compartments, pre-aspiration and final aspiration made

of galvanized sheet steel

Set of screens for corresponding screening diagram

Individual drive units with gear motors

PETKUS F 12 and P 12 Universal Cleaners are tried and tested and used Options:

Broad range of screens for all types of crops

for the high quality cleaning of cereals, legumes, and above all, grass and

Pin drum in-feed

fine seeds. The compact air-screen cleaner can be used for pre or intensive

Aspiration connection

cleaning, as well as for seed cleaning. Within a specific technological process

the cleaners can also be set up in series.

The P 12 Cleaner is the cleaner of choice for mobile seed cleaning plants

due to its compact, low vibration design. The cleaner is fitted with a standard screen set up consisting of two screen compartments and three

screen layers with ball cleaning. Conversely, the F 12 features a variable

screen configuration, in which the middle screen can be arranged in two

different constellations. The bottom screen is cleaned by brush.

Advantages:

High flexibility through variable screen diagrams and extensive

setting options

High cleaning capacity and quality

Also suitable for the grading of fine seeds

Low mass imbalance due to separate screen compartments,

therefore also suitable for mobile systems

Highly efficient screen cleaning through ball cleaning and

scraper chain

Only the F 12:

Bottom screens can be run in sequence or parallel

Brush cleaning ensures screen efficiency independent of

motor speed

Seed cleaning for grain

1-30-1/2 08-2015

Description:

The in-feed consists of a weight-loaded cylindrical roller. For poor flowing

products, one can opt to use a pin drum. This in-feed guarantees a broad

and uniform dispersion over the complete screen surface independent

of the product and capacity. In the air-separator light dust particles are

separated and then deposited into the discharge chamber and removed

via a screw auger.

The separation of coarse or large particles is carried out by the upper

screen. Smaller particles and impurities are separated with the middle

and bottom screens. In the P 12, the middle and bottom screens are arranged in parallel. In the F 12, with the help of an additional sliding floor

and product flow distributor, the bottom screens can be arranged either

in parallel or sequentially. Arranged sequentially, the middle screen acts

as a relief screen for the bottom separation screen. The overflow then

reaches the PETKUS dual channel final air separator, which has an ad-

Seed cleaning for fine seed

PETKUS Technologie GmbH|Roeberstr. 8|99848 Wutha-Farnroda|Germany|Phone:+49 36921-980|E-mail: info@petkus.com|www.petkus.com

Universal Cleaner F 12 / P 12

2325

2105

70

2050

2355

220

1520x2 60

224x35 5

2010

450

200

1200x 200

160

6 7

2305

8 9

Technical Data

Capacity (Based on: wheat)

Pre-cleaning

Seed cleaning

Intensive cleaning

Capacity (Based on: Italian Rye Grass)

Pre-cleaning

Seed cleaning

Length

Width

Height

Weight

Electrical power, without fan

Volume with built in fan

Volume with built in fan, rail or road transport

F 12 / P 12

t/h

t/h

t/h

t/h

t/h

mm

mm

mm

kg

kW

m

m

60

6

25

4

1

2325

2350

2355

1750

1.1 / 0.37

12.86

16

Technical Data

F 12 / P 12

Working width

mm

1200

No. of screen layers

pcs.

3

Inclination of the upper screen

5

Inclination of the middle/lower screen

7

Screen area, total

m

5.04

Fan

kW

5.5 - 11.0

Contact surface area

cm

1014

Static ground pressure

kN/m

187

Revolution

Hz

5.3 / 5.7

Horizontal dynamic load

kN

0.5

Vertical dynamic load in f

kN

1.3

Technical changes reserved.

PETKUS Technologie GmbH|Roeberstr. 8|99848 Wutha-Farnroda|Germany|Phone:+49 36921-980|E-mail: info@petkus.com|www.petkus.com

Potrebbero piacerti anche

- K 542Documento2 pagineK 542igbnsNessuna valutazione finora

- Petkus A12 CleanerDocumento2 paginePetkus A12 CleanerigbnsNessuna valutazione finora

- Mobile Grain CleanerDocumento2 pagineMobile Grain CleanerDulguunkherlen BudkhandNessuna valutazione finora

- FSP PresentationDocumento35 pagineFSP PresentationAshwani KumarNessuna valutazione finora

- Brochure Husker RollsDocumento2 pagineBrochure Husker RollsEmerson OliveiraNessuna valutazione finora

- Seed Processing and Handling CompleteDocumento291 pagineSeed Processing and Handling CompleteEncargado Proyectos NUTRIOILNessuna valutazione finora

- Buhler Pulse RollDocumento8 pagineBuhler Pulse RollBest BetterNessuna valutazione finora

- Brochure MDDP MDDQ Roller Mill Dolomit 2013 enDocumento6 pagineBrochure MDDP MDDQ Roller Mill Dolomit 2013 enelgin gineteNessuna valutazione finora

- Presentation For FAMSUN DryerDocumento51 paginePresentation For FAMSUN Dryerjose david rios mezaNessuna valutazione finora

- Cimbria DELTA 121: Data Sheet 121Documento1 paginaCimbria DELTA 121: Data Sheet 121Roginer VazNessuna valutazione finora

- Flyer Sewage Sludge DryingDocumento6 pagineFlyer Sewage Sludge Dryingkosmc123Nessuna valutazione finora

- 04 Grinding GD Hammer Mill V002Documento4 pagine04 Grinding GD Hammer Mill V002Ewin Septian GunturNessuna valutazione finora

- Food Grains MachineryDocumento39 pagineFood Grains MachinerykarthiNessuna valutazione finora

- User Manual: Steam MixerDocumento28 pagineUser Manual: Steam MixerCA PCNessuna valutazione finora

- THIELE Catalog Bucket-Elevator-Chains E 2014 PDFDocumento20 pagineTHIELE Catalog Bucket-Elevator-Chains E 2014 PDFNuzuliana EnuzNessuna valutazione finora

- SMA LACB Flyer Update BID21 ENDocumento4 pagineSMA LACB Flyer Update BID21 ENadilsonrodriguesNessuna valutazione finora

- MPARDocumento4 pagineMPARgolesfredyNessuna valutazione finora

- Screen OneDocumento2 pagineScreen OneMtyghm Tymmt100% (1)

- Huber - Folleto - Deshidratador - RoS 3QDocumento4 pagineHuber - Folleto - Deshidratador - RoS 3Qenzo_kcrs2787109Nessuna valutazione finora

- BSXY-13206-001 - 02 S Preparation of The Machine ESDocumento68 pagineBSXY-13206-001 - 02 S Preparation of The Machine ESJulisa LombardoNessuna valutazione finora

- Van Aarsen Mix Datasheet MultiMix Twin Shaft Paddle Mixer V001Documento2 pagineVan Aarsen Mix Datasheet MultiMix Twin Shaft Paddle Mixer V001TienQuan DoNessuna valutazione finora

- Westrup BrochureDocumento36 pagineWestrup BrochureADS ADSNessuna valutazione finora

- Cimbria Mega CleanerDocumento12 pagineCimbria Mega CleanerMohammad AinuddinNessuna valutazione finora

- BTA en OperatingInstructionS3Documento292 pagineBTA en OperatingInstructionS3evgenNessuna valutazione finora

- Attachment Chain Selection GuideDocumento4 pagineAttachment Chain Selection Guidemanoj6189Nessuna valutazione finora

- Donaldson UK Manual TDS PDFDocumento19 pagineDonaldson UK Manual TDS PDFPatricio TamayoNessuna valutazione finora

- Canning Technology: Can Seamer ExchangeDocumento2 pagineCanning Technology: Can Seamer Exchange高金辉Nessuna valutazione finora

- Andritz Pellet Dies PDFDocumento4 pagineAndritz Pellet Dies PDFgrupa2904Nessuna valutazione finora

- BE Manual 1600.2400.3000 MSD19087ADocumento152 pagineBE Manual 1600.2400.3000 MSD19087AIle Jie100% (1)

- Bucket Elevators, Bucket Conveyors and MoreDocumento22 pagineBucket Elevators, Bucket Conveyors and MoreDilnesa EjiguNessuna valutazione finora

- Zamboanga Pet Line 110419Documento1 paginaZamboanga Pet Line 110419PAul JoHn MeNdozaNessuna valutazione finora

- 94-Chain Conveyors & ElevatorsDocumento6 pagine94-Chain Conveyors & ElevatorsWuttSuNessuna valutazione finora

- 1-Tiffany, (B) Quotation 5TPH Animal Feed Line, ZONSTAR RICHI PDFDocumento14 pagine1-Tiffany, (B) Quotation 5TPH Animal Feed Line, ZONSTAR RICHI PDFAnonymous oRXzylDPNNessuna valutazione finora

- Spare Part List: PMV 919 (W-XW-TW)Documento51 pagineSpare Part List: PMV 919 (W-XW-TW)m100% (1)

- Sifter RS 3 EDocumento4 pagineSifter RS 3 EjunnelNessuna valutazione finora

- Rotary ConditionerDocumento7 pagineRotary ConditionerMiguel OrhlNessuna valutazione finora

- AUMUND Asia (H.K.) Limited: Cockburn Cement Limited AustraliaDocumento14 pagineAUMUND Asia (H.K.) Limited: Cockburn Cement Limited AustraliaNicolas Recio Fdez-Tresguerres100% (1)

- UM10705 01 00 Screw ConveyorDocumento1 paginaUM10705 01 00 Screw ConveyorDADAIRESENDENessuna valutazione finora

- Shallow, Rounded Buckets Din 15232: FoldedDocumento1 paginaShallow, Rounded Buckets Din 15232: Foldedmkiani2Nessuna valutazione finora

- Imagebroschüre eDocumento13 pagineImagebroschüre eSavin TimofteNessuna valutazione finora

- Disc Fertilizer Granulator - Huaqiang Pellet MachineDocumento1 paginaDisc Fertilizer Granulator - Huaqiang Pellet Machineluna leNessuna valutazione finora

- Alapala Technical PDFDocumento164 pagineAlapala Technical PDFMoh Al Basher Babiker100% (1)

- OM CT 002 01 Chain Transfer Owners Manual PDFDocumento33 pagineOM CT 002 01 Chain Transfer Owners Manual PDFMujibur RahmanNessuna valutazione finora

- O'Brien Met-Track Workstation Bridge CranesDocumento16 pagineO'Brien Met-Track Workstation Bridge Cranesdf_campos3353Nessuna valutazione finora

- Katalog Spareparts Bpm2&3Documento85 pagineKatalog Spareparts Bpm2&3Arif Abu FarhanaNessuna valutazione finora

- GravitySeparator GB WebDocumento8 pagineGravitySeparator GB WebAndreea Florentina SimaNessuna valutazione finora

- Bucket ElevatorsDocumento2 pagineBucket ElevatorsCarlos SolerNessuna valutazione finora

- Newsletter Weaving July-13Documento13 pagineNewsletter Weaving July-13dineshkeswaniNessuna valutazione finora

- SPAREPARTS 9600 Don PDFDocumento201 pagineSPAREPARTS 9600 Don PDFNataliNessuna valutazione finora

- Bucket Elevator: Owner/Operator's Manual and Installation/Maintenance GuideDocumento130 pagineBucket Elevator: Owner/Operator's Manual and Installation/Maintenance Guideimvp5640Nessuna valutazione finora

- Bucket Elevators Catalogue: Gambarotta GschwendtDocumento64 pagineBucket Elevators Catalogue: Gambarotta GschwendtRICARDOALEXBORGESNessuna valutazione finora

- TDTG Bucket ElevatorDocumento20 pagineTDTG Bucket ElevatorVictor Julio Torres Daza0% (1)

- Allgaier Apt Tro Dryingtechnologiesformineralrawmaterials enDocumento12 pagineAllgaier Apt Tro Dryingtechnologiesformineralrawmaterials enesteNessuna valutazione finora

- Cyclone SeparatorDocumento22 pagineCyclone SeparatorVANDINI BANSALNessuna valutazione finora

- Hengyang Rotary DryerDocumento8 pagineHengyang Rotary DryerLi GaryNessuna valutazione finora

- Bucket Elevator ConveyorDocumento7 pagineBucket Elevator ConveyorJuan Carlos RNessuna valutazione finora

- Krones AirCo The Air Conveyor For PET BottlesDocumento10 pagineKrones AirCo The Air Conveyor For PET BottlesfadyNessuna valutazione finora

- K 531Documento2 pagineK 531igbnsNessuna valutazione finora

- Pre-Cleaner DELTA 142: Data Sheet 142Documento1 paginaPre-Cleaner DELTA 142: Data Sheet 142Madalina MenteaNessuna valutazione finora

- K 541Documento2 pagineK 541igbnsNessuna valutazione finora

- PETKUS Destoner G05Documento2 paginePETKUS Destoner G05igbnsNessuna valutazione finora

- PETKUS MultiCoater CM100Documento2 paginePETKUS MultiCoater CM100igbnsNessuna valutazione finora

- PETKUS OptoSelector OS F ClassDocumento2 paginePETKUS OptoSelector OS F ClassigbnsNessuna valutazione finora

- De-Awner Type K322Documento2 pagineDe-Awner Type K322igbnsNessuna valutazione finora

- PETKUS Trockner DWUDocumento2 paginePETKUS Trockner DWUigbnsNessuna valutazione finora

- PETKUS Chemical Batch Treater C100 - C200Documento2 paginePETKUS Chemical Batch Treater C100 - C200igbnsNessuna valutazione finora

- Dust Extraction SystemDocumento2 pagineDust Extraction SystemigbnsNessuna valutazione finora

- DB Pendelbecherelevator PB400Documento2 pagineDB Pendelbecherelevator PB400igbnsNessuna valutazione finora

- PETKUS Chemical BatchTreater C50Documento2 paginePETKUS Chemical BatchTreater C50igbnsNessuna valutazione finora

- K 531Documento2 pagineK 531igbnsNessuna valutazione finora

- Petkus Buffer Bin VksDocumento2 paginePetkus Buffer Bin VksigbnsNessuna valutazione finora

- K 541Documento2 pagineK 541igbnsNessuna valutazione finora

- K 532Documento2 pagineK 532igbns0% (1)

- 2 - Updates For RCM 2.2Documento19 pagine2 - Updates For RCM 2.2The Municipal AgriculturistNessuna valutazione finora

- Millet Grain StructureDocumento4 pagineMillet Grain StructureAAO DasamantpurNessuna valutazione finora

- Coconut Oil: Bailey's Industrial Oil and Fat Products, Sixth Edition, Six Volume SetDocumento25 pagineCoconut Oil: Bailey's Industrial Oil and Fat Products, Sixth Edition, Six Volume SetErdanisa Aghnia IlmaniNessuna valutazione finora

- Nursery Design: Exercise #1Documento3 pagineNursery Design: Exercise #1Orlan AmbaNessuna valutazione finora

- NurseryDocumento6 pagineNurseryRONALD PACOLNessuna valutazione finora

- Dispersal of Seed by Various Agencies: Biology Investigatory ProjectDocumento12 pagineDispersal of Seed by Various Agencies: Biology Investigatory Projectalan Chacko100% (5)

- Introduction Contains The Topics: Introduction of Seed ProductionDocumento37 pagineIntroduction Contains The Topics: Introduction of Seed ProductionSheelendra Mangal BhattNessuna valutazione finora

- Seed Germination ProjectDocumento7 pagineSeed Germination ProjectHamid Khan57% (7)

- Investigating Plant Systems: Unit ProjectDocumento5 pagineInvestigating Plant Systems: Unit ProjectKathleen DennisNessuna valutazione finora

- Dodea Science Content Standards-Glencoe Integrated Science Correlation 6th GradeDocumento10 pagineDodea Science Content Standards-Glencoe Integrated Science Correlation 6th Gradeapi-232424041Nessuna valutazione finora

- Exploring The Relative Advantages of Local Innovation in AgroforestryDocumento12 pagineExploring The Relative Advantages of Local Innovation in Agroforestryfajar hilmiNessuna valutazione finora

- AGR112Documento8 pagineAGR112Rashidatulazwani Mohd Nazari0% (1)

- C1 CQSQPuwc LDocumento84 pagineC1 CQSQPuwc LSYLVIENessuna valutazione finora

- Commercial Poultry NutritionDocumento413 pagineCommercial Poultry NutritionVijay Kumar Anumolu100% (5)

- SalinityDocumento5 pagineSalinityhemant8988100% (1)

- Agriculture Past Paper-1Documento2 pagineAgriculture Past Paper-1sehrishhaji91Nessuna valutazione finora

- Practical Work Reports Plant Morphology "The Development of Taproot System and Fibrous Root System"Documento21 paginePractical Work Reports Plant Morphology "The Development of Taproot System and Fibrous Root System"Kamilatul KhoirohNessuna valutazione finora

- MaizeDocumento100 pagineMaizeDidier SanonNessuna valutazione finora

- Monday Tuesday Wednesday Thursday Friday: GRADES 1 To 12 Daily Lesson LogDocumento7 pagineMonday Tuesday Wednesday Thursday Friday: GRADES 1 To 12 Daily Lesson LogIra Kryst BalhinNessuna valutazione finora

- Agrifarming - In-Curry Leaves Farming A Profitable Business Kadi PattaDocumento5 pagineAgrifarming - In-Curry Leaves Farming A Profitable Business Kadi PattaMoolam RaoNessuna valutazione finora

- Endosperm 1Documento27 pagineEndosperm 1Pratibha SharmaNessuna valutazione finora

- Some Beautiful Indian Climbers and ShrubsDocumento493 pagineSome Beautiful Indian Climbers and ShrubsMathew YoyakkyNessuna valutazione finora

- Sunflower 2Documento20 pagineSunflower 2Aastha DubeyNessuna valutazione finora

- Q4 Elem AFA 6 Week1Documento4 pagineQ4 Elem AFA 6 Week1Irene BaquiranNessuna valutazione finora

- The Structure of Dicot Seed:: Icse Class:9 Biology GerminationDocumento3 pagineThe Structure of Dicot Seed:: Icse Class:9 Biology GerminationjaswanthNessuna valutazione finora

- PRE-BOARD EXAMINATION, January 2015 Class XII Biology (044) : G.G.N. Public School, Rose Garden, LudhianaDocumento5 paginePRE-BOARD EXAMINATION, January 2015 Class XII Biology (044) : G.G.N. Public School, Rose Garden, LudhianaSamita BhallaNessuna valutazione finora

- Crop ScienceDocumento87 pagineCrop ScienceArjay Mendoza100% (1)

- Plant Structure and FunctionDocumento73 paginePlant Structure and FunctionHIRA ALTEYA AYOPNessuna valutazione finora

- Bio 212 Physiology 2021Documento17 pagineBio 212 Physiology 2021Bello AjetayoNessuna valutazione finora

- 31 Plant Hormones-SDocumento6 pagine31 Plant Hormones-SLeo Ding0% (1)