Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Techdoc Print Page-140h-5 PDF

Caricato da

FranciscoOliveiraTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Techdoc Print Page-140h-5 PDF

Caricato da

FranciscoOliveiraCopyright:

Formati disponibili

Pgina 140H NA Motor Grader 2ZK00001-UP (MACHINE) POWERED BY 3306 Engine...

1 de 8

Fechar o SIS

Tela anterior

produtos: MOTOR GRADER

Modelo: 140H NA MOTOR GRADER 2ZK

Configurao: 140H NA Motor Grader 2ZK00001-UP (MACHINE) POWERED

BY 3306 Engine

Localizao e Soluo de Problemas

120H, 12H, 135H, 140H, 143H, 160H and 163H Motor Graders Power Train

Nmero de Mdia -SENR8503-03

Data de Publicao -01/12/2005

Data de Atualizao -15/12/2005

i02643819

Power Train

SMCS - 3030-035

Troubleshooting

Performance Check

Problem

The motor grader will not start or stop, and the transmission will not shift into any gear from the

NEUTRAL position.

Note: When you troubleshoot electrical problems or electronic problems, use the most recent electrical

schematic for your machine.

Note: Shift quickly from the NEUTRAL position to the desired gear. Always return the transmission to the

NEUTRAL position between gear selections.

1. Attempt to operate the machine in all gears forward and reverse. Shift the machine from the

NEUTRAL position to the FIRST GEAR FORWARD position. Note the response of the machine

and shift the machine back to the NEUTRAL position.

2. Shift the transmission from the NEUTRAL position to the SECOND GEAR FORWARD position.

Note the response of the machine. Shift the machine back to the NEUTRAL position. Proceed in the

same manner until all gears have been checked.

3. Check the 10 amp transmission control fuse that is located in the fuse panel at the base of the

steering console. If necessary, replace the fuse. Otherwise, proceed to Step 4.

https://127.0.0.1:4435/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 27-10-2016

Pgina 140H NA Motor Grader 2ZK00001-UP (MACHINE) POWERED BY 3306 Engine... 2 de 8

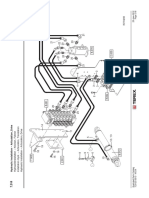

Illustration 1

Transmission Electronic Control Module (ECM)

g00279578

(1) Connector "J1"

(2) Connector "J2"

4. The Electronic Control Module (ECM) is located under the operator seat. While the engine is

running disconnect connector "J1" (1) . Contacts 1, 6 and 40 are common to each other and the

contacts are used to provide system voltage to the ECM. Contacts 2 and 5 are common to each other

and the contacts are used for machine ground. Measure the voltage between the power contacts 1, 6

and 40 to ground in order to check for power to the ECM.

5. If the voltage that is measured in Step 4 is 18 Volts DC to 32 Volts DC, the ECM voltage is

acceptable for proper operation of the ECM. If the voltage that is measured is less than 18 Volts DC,

there is a problem with the charging system. Refer to Special Instruction, "Charging System

Troubleshooting" for information on troubleshooting the charging system. If no voltage was

measured in Step 4, proceed to Step 6.

6. Check the fuse for the Transmission ECM. If the fuse is good, check the 126-PK wires in the

machine harness for an open circuit, or for a poor connection. If a problem is found, repair the

harness or replace the harness.

Problem

The motor grader has lost a single gear.

1. Start the engine. Operate the machine in order to determine the inoperable gear.

2. Stop the machine. Engage the parking brake and turn the key start switch to the OFF position.

3. Check the pressure of the suspect clutch. Refer to Testing and Adjusting, "Transmission Pressures"

for the correct pressure and for the testing procedure. If the clutch pressure is equal to or greater than

the minimum clutch pressure that is given, inspect the suspect clutch. If the clutch pressure is less

than the minimum pressure, proceed to Step 4.

4. Disconnect connectors"J1" (1) and connector"J2" (2) from the Electronic Control Module (ECM).

Measure the resistance between the contact that is associated with the clutch solenoid of the suspect

gear and one of the following contacts:contact 7 of "J1" and contact 3 of "J2"

https://127.0.0.1:4435/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 27-10-2016

Pgina 140H NA Motor Grader 2ZK00001-UP (MACHINE) POWERED BY 3306 Engine... 3 de 8

Note: Refer to the following example. The clutch for the FIRST GEAR FORWARD position does

not engage. The clutch for the FIRST GEAR REVERSE position engages. Measure the resistance

from contact 10 of "J1" (1) to either of the following contacts:contact 7 of "J1" and contact 3 of "J2"

5. If the resistance that is measured in Step 4 was in the range of 20 to 50 ohms, the solenoid valve is

functioning properly. This solenoid valve is controlling the pressure to the suspect clutch. Proceed to

Step 6.

6. If the resistance that is measured in Step 4 is less than 20 ohms, the wiring harness that connects to

the solenoid has a short circuit or the solenoid has a short circuit. If the resistance that is measured in

Step 4 is greater than 50 ohms, the wiring harness has an open circuit or the solenoid has an open

circuit.

7. If the solenoid valve that controls the suspect clutch appears to function but the clutch pressure is

below the minimum pressure, check the supply pressure at high idle with the transmission in the

inoperable gear. Refer to Testing and Adjusting, "Transmission Pressures".

8. If the supply pressure is 3240 kPa (470 psi), inspect the solenoid valve. If the supply pressure is

below 3240 kPa (470 psi), inspect the rotating shaft seals and the piston seals. The rotating seals can

be checked without removing the transmission. Checking the piston seals will require removing the

transmission.

Problem

Loss of a single gear selection in both the forward gear and the reverse gear

1. Start the engine. Operate the machine in order to locate the inoperative gear.

2. Stop the machine. Engage the parking brake and turn the engine start switch to the OFF position.

3. Disconnect connector"J1" (1) . Check the wiring harness that is located between the ECM and the

transmission direction and speed control. The transmission direction and speed control should be in

the position of the lost gear. Use contact 2 or contact 5 of connector "J1" (1) to check the continuity.

Measure the continuity between contact 2 and the contact for the gear that is not working.

4. Check the continuity between contact 29 of connector "J1" (1) and contact 2 of connector "J1" (1) if

FIRST GEAR FORWARD and REVERSE are inoperative. If the continuity exists, proceed to Step

5.

5. Step 4 tested a portion of the machine harness and a portion of the transmission direction and speed

control. The test determined that the transmission direction and speed control is inoperable. Shift the

transmission direction and speed control into a forward gear. Check the continuity between contact

37 and 2 of connector "J1" (1) . If continuity exists, the ECM is not functioning. If continuity does

not exist, the transmission direction and speed control is not functioning.

6. Either the machine harness has failed or the transmission direction and speed control has failed in

Step 4. Remove the 24 contact connector from the transmission direction and speed control. Measure

the continuity at the contact point on the transmission direction and speed control between using

contact 2 of connector "J1" (1) and the contact that is associated with the inoperative gear.

7. Check the continuity between contact 3 of the 24 contact connector and contact 2 of connector

"J1" (1) if FIRST GEAR FORWARD is not operable. If continuity exists, the transmission direction

and speed control is functioning and the machine harness has failed. If continuity does not exist, the

transmission direction and speed control has failed and the machine harness is functioning.

Problem

Slippage of the transmission under load

https://127.0.0.1:4435/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 27-10-2016

Pgina 140H NA Motor Grader 2ZK00001-UP (MACHINE) POWERED BY 3306 Engine... 4 de 8

1. Start the engine. Operate the machine in order to determine the gear that is slipping.

2. Stop the machine and engage the parking brake. Turn the engine start switch to the OFF position.

3. Check the transmission oil level. If the oil level is too high or too low, adjust the oil to the proper

level.

4. If the transmission continues to slip, check the transmission supply pressure. Refer to Testing and

Adjusting, "Transmission Pressures". If the supply pressure is at least 3240 kPa (470 psi) in the

PARK position and at high idle, proceed to Step 5. If the supply pressure is low, proceed to Step 8.

5. The direction clutches are clutch 1, clutch 2 and clutch 3. Direction clutch 1 is controlled by solenoid

(B) . Direction clutch 2 is controlled by solenoid (C) . Direction clutch 3 is controlled by solenoid

(A) . Measure the directional clutch pressure that is associated with the slipping gear. Refer to the

Testing and Adjusting, "Transmission Pressures".

6. For example, if the first gear forward is slipping, clutch 1 (solenoid (B) ) is the associated direction

clutch. Install the pressure port. Start the engine and operate the engine at high idle. Operate the

machine in the slipping gear.

7. Depress the transmission modulator pedal and stop the machine. Slowly release the transmission

modulator pedal. If the direction clutch pressure reaches a minimum pressure of 2080 kPa (302 psi),

inspect the direction clutch. If the directional clutch pressure does not reach a minimum of 2085 kPa

(302 psi), adjust the linkage for the clutch pedal.

8. From Step 4, the transmission control valve is suspect. Inspect the main relief valve for damage. If

necessary, repair the main relief valve. If the main relief valve is functioning correctly, proceed to

Step 9.

9. From Step 6, excessive slippage indicates leakage from the rotating seals or the clutch pistons. If

necessary, inspect or repair these items.

Problem

The Motor grader creeps when the transmission modulator pedal is fully depressed.

1. Start the engine. Operate the engine in order to determine the gears that allow the machine to inch

when the transmission modulator pedal is fully depressed.

2. Stop the machine and engage the parking brake. Turn the engine start switch to the OFF position.

3. Check the adjustment of inching pedal linkage. Refer toTesting and Adjusting, "Clutch Pedal Adjusting" for the correct adjustment procedure.

4. While the transmission modulator pedal is depressed, measure the direction clutch that is associated

with the gear that causes the problem. Refer to Testing and Adjusting, "Transmission Pressures".

https://127.0.0.1:4435/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 27-10-2016

Pgina 140H NA Motor Grader 2ZK00001-UP (MACHINE) POWERED BY 3306 Engine... 5 de 8

Illustration 2

g00925967

5. The direction clutches are clutch 1, clutch 2 and clutch 3. Direction clutch 1 is controlled by solenoid

(B) . Direction clutch 2 is controlled by solenoid (C) . Direction clutch 3 is controlled by solenoid

(A) .

6. For example, if first speed forward is inching, clutch 1 (solenoid (B) ) is the associated direction

clutch. Install the pressure gauge in the associated pressure port. Start the engine. Operate the engine

at high idle and in the suspect gear.

7. Depress the transmission modulator pedal and stop the machine. If the directional clutch pressure

exceeds 30 kPa (4 psi), repeat Step 3. If the directional clutch pressure is less than 30 kPa (4 psi),

inspect the transmission for warped clutch plates.

Problem

First gear out of neutral is the only working gear.

1. Start the engine. Determine the gears that are working.

2. Stop the machine. Engage the parking brake. Turn the engine start switch to the OFF position.

3. Use a jumper wire in order to bypass the pressure switch for manual modulation. The pressure switch

for manual modulation is the same switch as the pressure switch for the inching pedal. This will

determine if the pressure switch is working. The pressure switch for manual modulation is located on

the transmission control valve.

4. Disconnect the 2 contact connector at the pressure switch. This connector will be located close to the

pressure switch. Place a jumper wire between contact 1 and contact 2 of the receptacle on the

machine wiring harness. Proceed to Step 5.

5. Start the machine and attempt to operate the machine in all gears. If the machine has more than one

gear out of neutral then the pressure switch has failed. If first gear out of neutral is the only available

gear , proceed to Step 6.

6. The wiring harness between the manual modulation pressure switch (inching pressure switch) and

the transmission Electronic Control Module (ECM) is suspect. Disconnect connector "J1" (1) and

https://127.0.0.1:4435/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 27-10-2016

Pgina 140H NA Motor Grader 2ZK00001-UP (MACHINE) POWERED BY 3306 Engine... 6 de 8

connector "J2" (2) at the ECM. Check the continuity between contact 11 of "J2" connector (2) and

contact 2 of connector "J1" (1) .

7. The Electronic Control Module has failed if continuity is obtained with the jumper wire in place. The

wiring harness between the Electronic Control Module and the pressure switch has failed if

continuity is not obtained.

Problem

The Transmission Output Speed TOS signal is incorrect.

1. Stop the machine. Engage the parking brake. Turn the engine start switch to the OFF position.

2. The transmission output speed sensor (TOS) is located at the rear of the transmission. Locate the 2

contact connector at the sensor. Disconnect the TOS sensor from the machine wiring harness. Use a

voltmeter in order to measure the voltage between contacts. Connect the voltmeter to contact 4 (202BK) and connect the voltmeter to contact 1 (710-GN) of the machine wiring harness.

3. Operate the machine in FIRST gear at HIGH idle. If the measured voltage at high idle is less than 10

volts AC, replace the TOS sensor. If the measured voltage is greater than 10 volts AC, the TOS

sensor is functioning.

4. Remove the Electronic Control Module that is located under the operator seat. Then, disconnect

connector "J1" (1) . Replace the TOS sensor with a jumper wire. Measure continuity between

contacts 2 and 9 at connector "J1" (1) . If continuity is obtained the transmission is not functioning. If

continuity is not obtained, proceed to step 5.

5. The wiring harness between the ECM and the TOS sensor is suspect. Connect connector "J1" (1) at

the ECM and move back the TOS sensor. Remove the jumper wire from the receptacle and measure

the voltage between contact 2 710-GN and the frame. If any voltage (AC) exists, then repair wire

202-BK in the wiring harness. If voltage does not exist, repair wire 710-GN on the wiring harness.

Problem

The parking brake does not function properly.

1. Start the engine. Operate the machine in order to determine if the parking brake is functioning.

2. Stop the machine. Engage the parking brake. Turn the engine start switch to the OFF position.

3. The parking brake solenoid valve is located under the right side of the cab.

4. Start the engine. Use a screwdriver and lightly touch the end of the parking brake solenoid valve in

order to determine the presence of a electromagnetic force. If the screwdriver is drawn to the

solenoid, the solenoid is functioning.

5. To further test the solenoid, turn the engine key start switch from STOP to RUN and back to STOP.

The parking brake solenoid valve will click when the position of the key has changed. If the solenoid

is functioning proceed to Step 6. If the solenoid is not functioning, proceed to Step 10.

6. Check the mechanical parking brake valve in the transmission direction and speed control for proper

adjustment. Start the engine. Allow the brake pressure to increase to the normal operating pressure of

at least 800 kPa (115 psi). Depress the service brake. Shift the transmission direction and the speed

lever to the NEUTRAL position. Engage the parking brake. When the parking brake is engaged, the

operator should briefly hear air that is venting.

https://127.0.0.1:4435/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 27-10-2016

Pgina 140H NA Motor Grader 2ZK00001-UP (MACHINE) POWERED BY 3306 Engine... 7 de 8

7. When the transmission direction and speed control is placed in the PARKING BRAKE position and

the parking brake vents, the mechanical parking brake valve is properly adjusted. Proceed to Step 8,

if the parking brake does not vent. Adjust the mechanical parking brake valve.

8. Stop the engine. Place blocks in front of the wheels and behind the wheels. Install a 1000 kPa (145

psi) pressure gauge in the parking brake.

9. Start the engine. Depress the service brake pedal. Move the transmission direction and speed control

from the PARKING BRAKE position to the NEUTRAL position and back to the PARKING

BRAKE position. When the transmission direction and speed control is not in the PARK position,

the brake pressure should be 800 to 930 kPa (115 to 135 psi). If the brake pressure is 0 kPa (0 psi),

inspect the brakes. Brake pressure should be relieved to 0 kPa (0 psi) when the transmission direction

and speed control is in the PARK position. Inspect the air lines if the brake pressure does not go to 0

kPa (0 psi).

10. From Step 5, the parking brake valve is suspect. When the engine key start switch is in the RUN

position and the engine is OFF, the parking brake solenoid will be energized.

11. Disconnect the 2 contact connector at the parking brake solenoid. Measure the voltage across contact

1 (126-PK) and contact 2 (200-BK) at the machine harness. If battery voltage is measured at this

point the solenoid has failed. If no voltage or reduced voltage is measured at this point proceed to

Step 12.

12. Measure the voltage at the parking brake solenoid valve between contact 1 (126-PK) and the frame.

If the battery voltage is present, repair wire 200-BK. If the battery voltage is not present repair wire

126-PK.

Problem

The backup alarm does not sound.

1. Stop the engine. Engage the parking brake. Turn the engine key start switch to the OFF position.

Disconnect connector "J1" (1) and the "J2" connector (2) from the ECM. On the machine harness,

check for continuity between contact 2 of connector "J1" (1) and contact 37 of the connector

"J2" (2) . If continuity exists, the wiring to the backup alarm and the alarm is operational. Proceed to

Step 2.

2. Check the continuity between contact 2 of connector "J1" (1) and contact 31 of connector "J1" (1)

with the transmission in a REVERSE GEAR position. If continuity exists, the transmission ECM has

failed. If continuity does not exist, connect the "J1" and "J2" connectors to the correct position at the

transmission ECM and proceed to Step 3.

3. Disconnect the 24 contact connector at the transmission direction and speed control. With the

transmission direction and speed control in the REVERSE position, check the continuity between

contact 2 and contact 12 of the 24 contact connector. If continuity is obtained, repair the wiring

harness between the controller and the transmission direction and speed control. If continuity is not

obtained, replace the transmission direction and speed control.

4. In Step 2, the wiring harness between the transmission ECM and the backup alarm is suspect.

Disconnect the 6 contact connector from the back alarm. This connector will be located at the left

rear of the machine. While the transmission direction and speed control is in the REVERSE position,

measure the voltage between contact 5 (321-BR) and contact 6 (200-BK) of the machine harness

connector. If system voltage is present, the backup alarm has failed. If voltage is not present, the

harness has failed. Proceed to Step 5.

5. While the transmission direction and speed control is in the REVERSE position, measure the voltage

between contact 5 (321-BR) and the frame. If the 24 VDC exists, repair the 200-BK. If voltage does

not exist, repair wire 321-BR.

https://127.0.0.1:4435/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 27-10-2016

Pgina 140H NA Motor Grader 2ZK00001-UP (MACHINE) POWERED BY 3306 Engine... 8 de 8

Problem

The power train oil filler tube assembly is cracking at the base.

The power train oil filler tube assembly is used as a grab handle. The tube failure is most common on

machines with the snow wing attachment. A bracket can be added in order to support the tube assembly.

1. Inspect the power train filler tube at the base for cracks or leaks.

2. If there are cracks or leaks, the tube will need to be replaced.

3. The broken tube will need to be removed.

4. The new filler tube will need to be installed.

Refer to Service Magazine19 April 2004, "A New Support Bracket for the Filler Tube for the Power

Train Oil Is Now Available" in order to install the bracket assembly.

Direitos Autorais 1993 - 2016 Caterpillar Inc.

Todos os Direitos Reservados.

Rede Particular Para Licenciados SIS.

Thu Oct 27 2016 09:25:36 GMT+0100 (Hora de Vero de GMT)

https://127.0.0.1:4435/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 27-10-2016

Potrebbero piacerti anche

- S60 Service ManualDocumento2.117 pagineS60 Service ManualJustiniano Moreno95% (40)

- 140H Test de PresionesDocumento7 pagine140H Test de PresionesJose Jaramillo90% (10)

- 140 HDocumento33 pagine140 HAlex Castillo75% (4)

- Techdoc Print Page-140h-5 PDFDocumento8 pagineTechdoc Print Page-140h-5 PDFFranciscoOliveira100% (1)

- 2013 Infiniti G37 Sedan Service Repair Manual PDFDocumento18 pagine2013 Infiniti G37 Sedan Service Repair Manual PDFfjjsjekdmme0% (1)

- 938GDocumento8 pagine938GUbaldo Enrique Caraballo Estrada100% (3)

- Diagnostic ET. Transmision 140H - DocxDocumento38 pagineDiagnostic ET. Transmision 140H - Docxjorgemorales416100% (2)

- Sistema Electronico 140H TransDocumento10 pagineSistema Electronico 140H TransRodolfo Acosta Martinez100% (7)

- Cat 140H Wiring Diagram ColDocumento10 pagineCat 140H Wiring Diagram Coldominicparramore78% (9)

- Manual Electronically Controlled Transmission Caterpillar H Series Motor Graders PDFDocumento48 pagineManual Electronically Controlled Transmission Caterpillar H Series Motor Graders PDFRached Douahchua100% (8)

- Safety manual for EF494T tractorDocumento239 pagineSafety manual for EF494T tractorbudy kurniawan100% (1)

- Testing & Adjusting Cat - Dcs.sis - Controller PDFDocumento179 pagineTesting & Adjusting Cat - Dcs.sis - Controller PDFmnlar100% (7)

- Serv1824 950H 962H PDFDocumento248 pagineServ1824 950H 962H PDFWALTHERSITO97% (33)

- Transmission Pressures - Test and AdjustDocumento8 pagineTransmission Pressures - Test and Adjustjuankielec100% (3)

- ClutchDocumento200 pagineClutchAlex Castillo100% (6)

- Troubleshooting 966H WL POWERTRAINDocumento12 pagineTroubleshooting 966H WL POWERTRAINAhmet100% (1)

- Cat Transmission 950F PDF - PDFDocumento43 pagineCat Transmission 950F PDF - PDFMehdi Chakroune100% (1)

- Maintenance Interval Schedule: Operation and Maintenance ManualDocumento11 pagineMaintenance Interval Schedule: Operation and Maintenance ManualAHMED2ALI100% (1)

- AVS Manual - Testing and Adjusting Initial PressuresDocumento7 pagineAVS Manual - Testing and Adjusting Initial PressuresAntonio Mejicanos67% (6)

- Transmission Electronic Control for Motor GradersDocumento12 pagineTransmission Electronic Control for Motor GradersBrahim Salah100% (3)

- Transmission Control Valve - Disassemble... 12H, 140H and 160H Motor Graders Power Train Caterpillar - Spare PartsDocumento24 pagineTransmission Control Valve - Disassemble... 12H, 140H and 160H Motor Graders Power Train Caterpillar - Spare Partsabdelrhmangbr86100% (6)

- D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - DocumentationDocumento29 pagineD8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - Documentationdedy imranNessuna valutazione finora

- Control Manifold (Brake, Hydraulic Fan 966Documento15 pagineControl Manifold (Brake, Hydraulic Fan 966Ahmed RezkNessuna valutazione finora

- Testing and Adjusting d6NDocumento7 pagineTesting and Adjusting d6NClaudionorGomesFilho100% (1)

- 320C PDFDocumento160 pagine320C PDFApri Alhaddad100% (1)

- 854F-Testing and AdjustingDocumento96 pagine854F-Testing and AdjustingFranciscoOliveiraNessuna valutazione finora

- Solenoid Valve - Test: 966H, 972H and 980H Wheel Loaders Power Train Electronic Control SystemDocumento8 pagineSolenoid Valve - Test: 966H, 972H and 980H Wheel Loaders Power Train Electronic Control SystemMarco Olivetto100% (1)

- 740B Transmission Electronic SystemDocumento6 pagine740B Transmission Electronic SystemRajan Mullappilly100% (4)

- d7r Solenide de ControlDocumento12 pagined7r Solenide de ControlDavid Ceron100% (6)

- 966h Main Control System OperationDocumento17 pagine966h Main Control System Operationesternocleido24100% (3)

- Cat 315 GiroDocumento4 pagineCat 315 GiroFranciscoOliveira100% (1)

- Mega 250-VDocumento684 pagineMega 250-VЕвгений100% (1)

- Transmission Fault CodesDocumento9 pagineTransmission Fault CodesFranciscoOliveira83% (6)

- Implement Hydraulic System WL 950h 962h 966h 972hDocumento51 pagineImplement Hydraulic System WL 950h 962h 966h 972hElvis Gonzalez Huerta100% (1)

- 14g Motor Grader 96u04298 07045 Machine Powered by 3306 Engine Sebp1263 02 Documentacion PDFDocumento13 pagine14g Motor Grader 96u04298 07045 Machine Powered by 3306 Engine Sebp1263 02 Documentacion PDFjude tallyNessuna valutazione finora

- Deutz ManualDocumento76 pagineDeutz Manualdim4erema60% (5)

- Transmission Control ValveDocumento12 pagineTransmission Control ValveEdwar Julian100% (5)

- Valvula de Control Trans. 140HDocumento13 pagineValvula de Control Trans. 140HRCA09100% (6)

- Test de Presiones de Transmision 938g2Documento12 pagineTest de Presiones de Transmision 938g2cristian chuquicondor torres100% (2)

- 140H Motor GraderDocumento2 pagine140H Motor Graderjose24100% (2)

- CVT CalculationsDocumento7 pagineCVT CalculationsNimitesh SinghNessuna valutazione finora

- D8r Hydraulic SystemDocumento69 pagineD8r Hydraulic SystemKibrom hilufNessuna valutazione finora

- Operação Dos Sistemas 12G, 120G, 130G & 140G MOTOR GRADERS POWER TRAINDocumento37 pagineOperação Dos Sistemas 12G, 120G, 130G & 140G MOTOR GRADERS POWER TRAINLeandro SalNessuna valutazione finora

- 140h 5hm Pruebas y Ajustes de Transmision ElectronicaDocumento28 pagine140h 5hm Pruebas y Ajustes de Transmision ElectronicaSebastian Bonello100% (1)

- 1104D 2 PDFDocumento52 pagine1104D 2 PDFFranciscoOliveira100% (1)

- FTR 900 Singular Cab y Crew Cab Australia PDFDocumento4 pagineFTR 900 Singular Cab y Crew Cab Australia PDFdionymackNessuna valutazione finora

- Fill Time For The Transmision Clutch - CalibrateDocumento8 pagineFill Time For The Transmision Clutch - CalibrateTarwedi Tartor100% (1)

- 320B Excavator Hydraulic SystemDocumento4 pagine320B Excavator Hydraulic Systemjohn ayengah100% (2)

- 140 HDocumento31 pagine140 HAlex Castillo100% (2)

- A 960 EautDocumento20 pagineA 960 EautJan Eklund100% (1)

- Diagnostic Code List: TroubleshootingDocumento7 pagineDiagnostic Code List: Troubleshootingmiguelfpinto100% (1)

- (Oto-Hui - Com) Caterpillar 966H Wheel Loader HYDRAULIC SYSTEMDocumento33 pagine(Oto-Hui - Com) Caterpillar 966H Wheel Loader HYDRAULIC SYSTEMFernando Sabino100% (2)

- 950g Test Pressure RobelloDocumento10 pagine950g Test Pressure RobelloMiguel Angel Garrido Cardenas100% (2)

- 950H, 962H and IT62H Wheel Loader Hydraulic System: Command Control SteeringDocumento2 pagine950H, 962H and IT62H Wheel Loader Hydraulic System: Command Control SteeringRodrigo Chacca100% (2)

- Transmission Control Valve: Shutdown SISDocumento11 pagineTransmission Control Valve: Shutdown SIStallerNessuna valutazione finora

- Bma4723 Vehicle Dynamics Chap 22Documento35 pagineBma4723 Vehicle Dynamics Chap 22Fu HongNessuna valutazione finora

- Pilot Valve (Command Control Steering) 966Documento16 paginePilot Valve (Command Control Steering) 966Ahmed RezkNessuna valutazione finora

- CATERPILLAR Calibracion de TransmisionDocumento6 pagineCATERPILLAR Calibracion de TransmisionJUAN CARLOS PAZ67% (3)

- Esquema Electrico It24fDocumento2 pagineEsquema Electrico It24fSan Gabriel Representaciones100% (1)

- D8R T&aDocumento37 pagineD8R T&aRajan Mullappilly100% (2)

- 938F TRANSMISSION ControlDocumento47 pagine938F TRANSMISSION ControlIbrahim Awad88% (8)

- Transmission Pressures - Test - 084203Documento5 pagineTransmission Pressures - Test - 084203Juan Lopez100% (1)

- Sistema Control Trans 140hDocumento7 pagineSistema Control Trans 140hFernando Ortiz86% (7)

- Ajustes Trans 140GDocumento13 pagineAjustes Trans 140GDomingo Cruz Garcia100% (3)

- CS563Documento44 pagineCS563Jose Luis Garcia BlancoNessuna valutazione finora

- 851 TorcingDocumento270 pagine851 TorcingFrancisco Santiago Gallardo100% (1)

- Self-Propelled Lift Ha 20Px - Ha 26Px: Operating and Maintenance InstructionsDocumento72 pagineSelf-Propelled Lift Ha 20Px - Ha 26Px: Operating and Maintenance InstructionsFranciscoOliveiraNessuna valutazione finora

- 854F-Disassembly and AssemblyDocumento204 pagine854F-Disassembly and AssemblyZIBA KHADIBI100% (2)

- Cat 936eDocumento5 pagineCat 936eAlberto Ferradás100% (1)

- V A25d-A40d D10, D12 PDFDocumento28 pagineV A25d-A40d D10, D12 PDFBEEMK_01Nessuna valutazione finora

- Solenoid Valve (Proportional Reducing) - Calibrate - Number 1 Relief Valve and Number 2 Relief Valve - 084521Documento9 pagineSolenoid Valve (Proportional Reducing) - Calibrate - Number 1 Relief Valve and Number 2 Relief Valve - 084521Juan LopezNessuna valutazione finora

- 325D Excavator Hydraulic System: Fluid Power SymbolsDocumento2 pagine325D Excavator Hydraulic System: Fluid Power SymbolsDennis Olaya100% (3)

- Cce TC35 PDFDocumento260 pagineCce TC35 PDFFranciscoOliveira100% (1)

- JCB Js 220 22 Tonne Tracked Excavator 2 PDFDocumento32 pagineJCB Js 220 22 Tonne Tracked Excavator 2 PDFsergios stamatiouNessuna valutazione finora

- JCB Js 220 22 Tonne Tracked Excavator 2 PDFDocumento32 pagineJCB Js 220 22 Tonne Tracked Excavator 2 PDFsergios stamatiouNessuna valutazione finora

- Haulotte HA16 18PXDocumento74 pagineHaulotte HA16 18PXtiagomacviva100% (1)

- Pulverizer Maintenance Guide Volume 3 - Ball Mills PDFDocumento364 paginePulverizer Maintenance Guide Volume 3 - Ball Mills PDFshubham vermaNessuna valutazione finora

- 12G, 130G & 140G Hydraulic System and Steering PRUBASDocumento24 pagine12G, 130G & 140G Hydraulic System and Steering PRUBASF Labio Alex100% (2)

- Telelift 3713 SX - 11321Documento122 pagineTelelift 3713 SX - 11321FranciscoOliveiraNessuna valutazione finora

- Telelift 4017 - 4514 - 19296Documento212 pagineTelelift 4017 - 4514 - 19296FranciscoOliveiraNessuna valutazione finora

- Specifications: 854E-E34TA, 854F-E34T and 854F-E34TA Industrial EnginesDocumento60 pagineSpecifications: 854E-E34TA, 854F-E34T and 854F-E34TA Industrial EnginesZIBA KHADIBINessuna valutazione finora

- Modulating Valve (Transmission Clutch) 966Documento3 pagineModulating Valve (Transmission Clutch) 966Ahmed Rezk100% (3)

- Service Manual h21 h23t (X) h23tp (X) h25tp (X)Documento265 pagineService Manual h21 h23t (X) h23tp (X) h25tp (X)Radoi RaduNessuna valutazione finora

- Doosan Daewoo D1146Documento147 pagineDoosan Daewoo D1146FranciscoOliveira100% (2)

- Switch (Continuous Flow) : TroubleshootingDocumento5 pagineSwitch (Continuous Flow) : TroubleshootingjimNessuna valutazione finora

- Simonazzi Motorized ValveDocumento6 pagineSimonazzi Motorized Valveronal553Nessuna valutazione finora

- PROCEDURES FOR OIL LEVEL, LEAK AND PRESSURE CHECKSDocumento6 paginePROCEDURES FOR OIL LEVEL, LEAK AND PRESSURE CHECKSD VI MINessuna valutazione finora

- El 200b ExcavadoraDocumento8 pagineEl 200b Excavadoradinny blancoNessuna valutazione finora

- Troubleshooting The ETR Full Protective System (OP, WT, OS)Documento14 pagineTroubleshooting The ETR Full Protective System (OP, WT, OS)Richard ChuaNessuna valutazione finora

- 4) Brochure Air Conditioning CompressorsDocumento16 pagine4) Brochure Air Conditioning CompressorsFranciscoOliveiraNessuna valutazione finora

- Manitou Attachments EN PDFDocumento148 pagineManitou Attachments EN PDFkamaleon dorado100% (1)

- 854F-Operation and MaintenanceDocumento122 pagine854F-Operation and MaintenanceZIBA KHADIBI100% (1)

- G Force3 InstuctionsDocumento20 pagineG Force3 InstuctionsFranciscoOliveiraNessuna valutazione finora

- 4TNV94LDocumento378 pagine4TNV94LFranciscoOliveira100% (1)

- Operating Instructions: Level Ground CutterDocumento32 pagineOperating Instructions: Level Ground CutterFranciscoOliveiraNessuna valutazione finora

- TC125francisco 1Documento1 paginaTC125francisco 1FranciscoOliveiraNessuna valutazione finora

- Techdoc Print Page-140h-3 PDFDocumento2 pagineTechdoc Print Page-140h-3 PDFFranciscoOliveiraNessuna valutazione finora

- Operating Instructions: Level Ground CutterDocumento32 pagineOperating Instructions: Level Ground CutterFranciscoOliveiraNessuna valutazione finora

- MICROMAT single-shaft shredder efficiently granulates plasticsDocumento2 pagineMICROMAT single-shaft shredder efficiently granulates plasticskarnakesNessuna valutazione finora

- Ferramentas CATDocumento4 pagineFerramentas CATMarco OlivettoNessuna valutazione finora

- 2016 PreCut PowerLine FineCut EnglishDocumento16 pagine2016 PreCut PowerLine FineCut Englishrcaleta0% (1)

- Caja 7600 Fro-11210cDocumento34 pagineCaja 7600 Fro-11210cGUSTAVONessuna valutazione finora

- Alat BeratDocumento16 pagineAlat BeratAdji Dwi SaputraNessuna valutazione finora

- Torque Monitoring: Prüftechnik Condition Monitoring GMBH Seite 1Documento17 pagineTorque Monitoring: Prüftechnik Condition Monitoring GMBH Seite 1SunnyNessuna valutazione finora

- C15-20 Gen-2 PDFDocumento6 pagineC15-20 Gen-2 PDFJan HendriksNessuna valutazione finora

- Donax TDLDocumento3 pagineDonax TDLaj912589Nessuna valutazione finora

- Unit 1-At6402 Automotive ChassisDocumento39 pagineUnit 1-At6402 Automotive ChassisSathis KumarNessuna valutazione finora

- Conditions For Implementing Trolleybuses in Public Urban TransportDocumento8 pagineConditions For Implementing Trolleybuses in Public Urban TransportSorin ScutarasuNessuna valutazione finora

- 1890 - Double Rotating ChannelDocumento51 pagine1890 - Double Rotating Channelkar_simNessuna valutazione finora

- 12 - HMCVT Report of SMTDocumento25 pagine12 - HMCVT Report of SMTYundi GaoNessuna valutazione finora

- Electric Vehicle With Multi-Speed Transmission: A Review On Performances and ComplexitiesDocumento15 pagineElectric Vehicle With Multi-Speed Transmission: A Review On Performances and Complexities1ere année ingNessuna valutazione finora

- Generic Network Trouble CodesDocumento11 pagineGeneric Network Trouble Codesspidi75Nessuna valutazione finora

- Escorts India Pvt. Ltd. Crank Shaft & Hydrolic Plant GROUP, FARIDABADDocumento33 pagineEscorts India Pvt. Ltd. Crank Shaft & Hydrolic Plant GROUP, FARIDABADYogeshGargNessuna valutazione finora

- Titan R50 Wagon LeafletDocumento24 pagineTitan R50 Wagon Leafletinfo48260% (1)

- Design, Analysis and Performance Evaluation of A Mechanical GyratorDocumento7 pagineDesign, Analysis and Performance Evaluation of A Mechanical GyratorijrdtNessuna valutazione finora

- LMV 311 Poster - 091316 PDFDocumento1 paginaLMV 311 Poster - 091316 PDFDelio Manuel Moreno AyazoNessuna valutazione finora

- Pump TheoryDocumento167 paginePump Theoryjitendrashukla10836100% (2)

- T11 4WD Service Manual PDFDocumento40 pagineT11 4WD Service Manual PDFAxlesNessuna valutazione finora

- Maxiforce 2009 CatalogDocumento166 pagineMaxiforce 2009 CatalogAminadavNessuna valutazione finora