Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hot-Dip Galvanized vs. Aluminum: Design and Installation

Caricato da

ahmodahTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hot-Dip Galvanized vs. Aluminum: Design and Installation

Caricato da

ahmodahCopyright:

Formati disponibili

Cabletrays Institute Technical Bulletin

1 of 2

Hot-Dip Galvanized vs. Aluminum

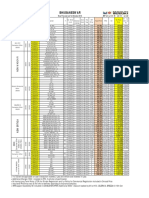

One of the most important choices when designing a cable tray system for corrosive or outdoor environments

is the material. Steel cable tray with a Hot-Dip Galvanized after Fabrication (ASTM A123) finish has been

used successfully for many years. Increasingly, however, aluminum is becoming the material of choice for

cable tray systems. In these days of shrinking construction budgets, why would engineers, contractors, and

end users choose aluminum cable tray, which typically has a slightly higher initial cost, over Hot-Dip

galvanized steel cable tray? The answer lies in aluminum's many advantages in design, installation, delivery,

performance and total cost over the lifetime of the installation.

Design and Installation

Most people know of aluminum's superior strength-to-weight ratio For example, a 36" wide, 24-foot section of

ladder cable tray with a 6" side rail, NEMA 20C hot-dip galvanized steel cable tray weighs about 200 lbs,

whereas the same cable tray in aluminum weighs only about 100 lbs When installers must carry and put

cable tray sections into place, which may be 30' or more above ground, aluminum's lighter weight can mean

the difference between needing just two installers instead of four.

Field cuts are also much easier with aluminum cable trays, not only because aluminum is easier to cut,

punch, and drill, but there is no need to apply a protective coating to the exposed edges. The hot-dip

galvanized coating on steel must be repaired with a zinc rich paint (also called cold galvanizing) which is

inferior to the original galvanizing, leaving a chink in the steel's armor against corrosion. Of course, there is

always the chance that some contractors may not repair the cuts at all, further impairing the cable tray's

corrosion resistance.

Because aluminum cable tray components are extruded, material can be used more efficiently and tolerances

remain tighter. Some manufacturers have used this to the contractor's advantage by creating splice joints and

other features which offer better performance and require less labor to install. And when using cable tray as

an equipment grounding conductor (EGC), aluminum's superior current carrying capacity reduces the need to

purchase and install a separate EGC (in qualifying industrial installations) and also increases the safety of the

installation by providing a better fault current path.

Delivery and Availability

Aluminum cable tray systems can normally be shipped from the factory in a short period of time. Small orders

can ship in just a few days, depending on the manufacturer's work-load. Hot-dip galvanized cable tray

systems typically take several days to fabricate, hot-dip galvanize, and prepare for final shipment.

All cable tray manufacturers must ship their cable trays to a third party to have them galvanized. This requires

that the cable tray be manufactured, packed and shipped to the galvanizer. Some manufacturers return the

material to their plants after galvanizing to inspect and deburr the product prior to packing and final shipment.

Other manufacturers rely on the hot-dip galvanizer to inspect, deburr, and pack the material for shipment.

The cost of a delay in getting material to the jobsite is many times the cost of the material itself and using

aluminum cable tray helps to minimize the chance of delays.

Hot-dip galvanized steel cable tray covers pose another problem. Placing thin gauge steel covers in a hot

zinc bath will often cause the covers to warp. To avoid this problem, thicker material is used and the covers

are limited to six feet long. The extra material and the extra labor required to install shorter covers has a

significant impact on the cost of the entire cable tray system.

Cabletrays Institute Technical Bulletin

2 of 2

Performance

Aluminum cable tray has excellent corrosion resistance in many chemical environments and has been used

for over thirty years in petro-chemical plants and paper mills along the gulf coast from Texas to Florida. The

aluminum alloy used by American cable tray manufacturers is 6063-T6, which is considered copper-free and

sometimes referred to as marine grade aluminum. Although copper-free aluminum may experience some

chloride pitting in a marine environment, this corrosion is limited and does not affect the structural integrity of

the system.

Galvanizing on steel cable trays is designed to slowly wear away as it protects the steel; any place where the

coating is thin or has been removed can prematurely limit the product's service life. Since aluminum cable

trays are homogenous material throughout, their service life is unaffected by scratches and field

modifications. When aluminum cable trays are used with stainless steel hardware, the system can perform

indefinitely, with little or no degradation over time, making it ideal for many chemical and marine

environments.

Total Cost

Aluminum's many advantageous features like its corrosion resistance, superior strength-to-weight ratio, ease

of field modification, fast delivery and availability, and labor saving installation all add up to a system well

worth the extra 10% to 15% in initial price. Recently, the relative cost of aluminum to steel has been

decreasing, making the choice between aluminum and steel no contest.

Potrebbero piacerti anche

- Bicycle ProjectDocumento4 pagineBicycle Projectgaming channelNessuna valutazione finora

- Type of Cable TrayDocumento6 pagineType of Cable TraywalaaNessuna valutazione finora

- How Does Galvanizing Protect Steel From Corrosion?Documento12 pagineHow Does Galvanizing Protect Steel From Corrosion?jnshreyNessuna valutazione finora

- Advantages & Disadvantages of Aluminium. Connection of Aluminium To SteelDocumento7 pagineAdvantages & Disadvantages of Aluminium. Connection of Aluminium To SteelDeepti Shrimali0% (1)

- PVC and GMSDocumento9 paginePVC and GMSwickedsinner7Nessuna valutazione finora

- Metal Roofing Fundamentals - Rob HaddockDocumento8 pagineMetal Roofing Fundamentals - Rob HaddockNimish PrabhukhanolkarNessuna valutazione finora

- Mats. Forum Page 164 - 169Documento6 pagineMats. Forum Page 164 - 169Meriam KetataNessuna valutazione finora

- CS Assignment/studyDocumento7 pagineCS Assignment/studyAshwin AnilNessuna valutazione finora

- GALVALUME Sheet Carbon Steel SpecsDocumento6 pagineGALVALUME Sheet Carbon Steel SpecsHarshith Rao Vadnala100% (1)

- Type of Cable TrayDocumento10 pagineType of Cable TrayregistraraNessuna valutazione finora

- D031181002 - Introduction-EnglishDocumento3 pagineD031181002 - Introduction-EnglishTaufik QurahmanNessuna valutazione finora

- MM 352 CEP, Group No 8Documento5 pagineMM 352 CEP, Group No 8jawad arifNessuna valutazione finora

- Aluminum Vs COPPERDocumento4 pagineAluminum Vs COPPERTapi SkNessuna valutazione finora

- Aluminum Vs Copper in TrafoDocumento6 pagineAluminum Vs Copper in TrafosamuraivickyNessuna valutazione finora

- Astm A123 PDFDocumento2 pagineAstm A123 PDFবিপ্লব পাল67% (6)

- Cable TrayDocumento5 pagineCable Traykxalxo7637Nessuna valutazione finora

- Aluminum vs. Copper Conductors A Serious AlternativeDocumento7 pagineAluminum vs. Copper Conductors A Serious Alternativemhomar_2006339Nessuna valutazione finora

- Aleaciones de Aluminio MarinoDocumento4 pagineAleaciones de Aluminio MarinoreurriNessuna valutazione finora

- Aluminium Alloy - Wikipedia, The Free EncyclopediaDocumento12 pagineAluminium Alloy - Wikipedia, The Free EncyclopediaAshishJoshi100% (1)

- Tool and MoldDocumento4 pagineTool and MoldWilmar MattesNessuna valutazione finora

- Aluminium AlloyDocumento22 pagineAluminium AlloyAashish Gharde0% (1)

- 55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Documento2 pagine55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Syed Raja AdeelNessuna valutazione finora

- Cs Assignment (Sc20b011)Documento7 pagineCs Assignment (Sc20b011)Ashwin AnilNessuna valutazione finora

- Internal Floating RoofDocumento7 pagineInternal Floating Roofzackii90Nessuna valutazione finora

- 1 - Volumen 1 - Fittings PDFDocumento168 pagine1 - Volumen 1 - Fittings PDFjuan_octoberNessuna valutazione finora

- Catalogue Cable Tray RevDocumento40 pagineCatalogue Cable Tray RevhardiyantodonniNessuna valutazione finora

- 03 Web Xlpe Guide enDocumento8 pagine03 Web Xlpe Guide endes1982100% (1)

- GALV - Cut Edge ProtectionDocumento5 pagineGALV - Cut Edge ProtectionHarry Aldous100% (1)

- Equipment and Procedures For Welding AlumDocumento6 pagineEquipment and Procedures For Welding AlumAmilcar AndradeNessuna valutazione finora

- Aluminium and Its Alloys Used in Electrical EngineeringDocumento7 pagineAluminium and Its Alloys Used in Electrical EngineeringTigrilloNessuna valutazione finora

- Aluminum SolderingDocumento14 pagineAluminum SolderingChris De La TorreNessuna valutazione finora

- Corrosion Protection BoltingDocumento4 pagineCorrosion Protection BoltingachmaddachNessuna valutazione finora

- TRACO ReportDocumento11 pagineTRACO ReportKinginiKingini100% (1)

- Copper-Clad Aluminum (CCA) : Indoor Wiring Solutions GuideDocumento6 pagineCopper-Clad Aluminum (CCA) : Indoor Wiring Solutions GuideOscar ValdésNessuna valutazione finora

- Astm A123pdf CompressDocumento2 pagineAstm A123pdf CompressYugandharNessuna valutazione finora

- Midal Cable ReportDocumento9 pagineMidal Cable ReportFaYzYNessuna valutazione finora

- 2013 How Much Does Galvanizing CostDocumento2 pagine2013 How Much Does Galvanizing CosttassanaiNessuna valutazione finora

- EngineeringWithCladSteel2ndEd PDFDocumento24 pagineEngineeringWithCladSteel2ndEd PDFUNIISCRIBDNessuna valutazione finora

- Fastener Design ManualDocumento10 pagineFastener Design ManualJohn PaulsyNessuna valutazione finora

- Corrugated Metal Culverts - Durability in New Zealand ConditionsDocumento3 pagineCorrugated Metal Culverts - Durability in New Zealand Conditionslouis donyNessuna valutazione finora

- John Harvey and Samantha Birch: Important Factors in The Selection of Steel Ladle Lining MaterialsDocumento8 pagineJohn Harvey and Samantha Birch: Important Factors in The Selection of Steel Ladle Lining MaterialssadhuNessuna valutazione finora

- Engineering MaterialsDocumento46 pagineEngineering MaterialsAdil FarooqNessuna valutazione finora

- Metallurgy and Processing of Ultralow Carbon Bake Hardening SteelsDocumento14 pagineMetallurgy and Processing of Ultralow Carbon Bake Hardening SteelsvictorNessuna valutazione finora

- Thinking Thin With Green Sand Cast IronDocumento3 pagineThinking Thin With Green Sand Cast Ironmecaunidos7771Nessuna valutazione finora

- Steel Connection Solutions: A Kee Safety CompanyDocumento44 pagineSteel Connection Solutions: A Kee Safety CompanytylerstearnsNessuna valutazione finora

- HTLS (HPC) IEEMA Seminar BrianWareingDocumento69 pagineHTLS (HPC) IEEMA Seminar BrianWareingJose ValdiviesoNessuna valutazione finora

- Metals Polymers Ceramics: U.S. Navy Ship New York Contains Steel From Ground ZeroDocumento3 pagineMetals Polymers Ceramics: U.S. Navy Ship New York Contains Steel From Ground ZeroAlejandroSalxixonNessuna valutazione finora

- Aming Members Sept 04Documento16 pagineAming Members Sept 04Edison BecerraNessuna valutazione finora

- Hot Dip GalvanizedDocumento4 pagineHot Dip GalvanizedD SRINIVASNessuna valutazione finora

- Olex Arial CatalogueDocumento15 pagineOlex Arial CatalogueMike WesleyNessuna valutazione finora

- ZINCALUME Steel Technical Bulletins 2018Documento32 pagineZINCALUME Steel Technical Bulletins 2018HerdisNessuna valutazione finora

- Report On Self Supported Roofing System 08.4.15Documento40 pagineReport On Self Supported Roofing System 08.4.15Gaddam Padmaja Reddy100% (1)

- Mechanical Plating and GalvanizingDocumento2 pagineMechanical Plating and GalvanizingUntung Ari WibowoNessuna valutazione finora

- ASTM Specifications - American Galvanizers AssociationDocumento9 pagineASTM Specifications - American Galvanizers Associationwinarnob100% (1)

- Bake Hardening SteelDocumento15 pagineBake Hardening SteelAnoop KizhakathNessuna valutazione finora

- AISI tn-d100-13Documento4 pagineAISI tn-d100-13Edison BecerraNessuna valutazione finora

- Copper Flashings And Weatherings - A Practical HandbookDa EverandCopper Flashings And Weatherings - A Practical HandbookNessuna valutazione finora

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkDa EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNessuna valutazione finora

- Cabletrays Institute Technical Bulletin9Documento4 pagineCabletrays Institute Technical Bulletin9ahmodahNessuna valutazione finora

- Chapter 5 Contents: 5 - Electrical Design 5 - 3 - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . .Documento2 pagineChapter 5 Contents: 5 - Electrical Design 5 - 3 - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . .ahmodahNessuna valutazione finora

- Cabletrays Institute Technical Bulletin7Documento1 paginaCabletrays Institute Technical Bulletin7ahmodahNessuna valutazione finora

- Cabletrays Institute Technical BulletinDocumento3 pagineCabletrays Institute Technical BulletinahmodahNessuna valutazione finora

- Life Time - DR ShadyDocumento1 paginaLife Time - DR ShadyahmodahNessuna valutazione finora

- Cabletrays Institute Technical Bulletin8Documento2 pagineCabletrays Institute Technical Bulletin8ahmodahNessuna valutazione finora

- Prkglot Ped GraphicDocumento1 paginaPrkglot Ped GraphicahmodahNessuna valutazione finora

- Cramolin Urethane Red (Lacquer) : Technical Data SheetDocumento2 pagineCramolin Urethane Red (Lacquer) : Technical Data SheetahmodahNessuna valutazione finora

- Distrbtn GraphicDocumento1 paginaDistrbtn GraphicahmodahNessuna valutazione finora

- Gland Chart For BS5308Documento1 paginaGland Chart For BS5308ahmodahNessuna valutazione finora

- Cabletrays Institute Technical Bulletin3Documento2 pagineCabletrays Institute Technical Bulletin3ahmodahNessuna valutazione finora

- Gland Chart For BS6724: Booklet CablesDocumento1 paginaGland Chart For BS6724: Booklet CablesahmodahNessuna valutazione finora

- Earthing: Earth Rod To Cable ClampsDocumento1 paginaEarthing: Earth Rod To Cable ClampsahmodahNessuna valutazione finora

- Conductors: Bare Copper TapeDocumento1 paginaConductors: Bare Copper TapeahmodahNessuna valutazione finora

- Gland Chart For BS5467: Booklet CablesDocumento1 paginaGland Chart For BS5467: Booklet CablesahmodahNessuna valutazione finora

- Cabletrays Institute Technical Bulletin2Documento2 pagineCabletrays Institute Technical Bulletin2ahmodahNessuna valutazione finora

- Cabletrays Institute Technical Bulletin10Documento2 pagineCabletrays Institute Technical Bulletin10ahmodahNessuna valutazione finora

- Page 28Documento1 paginaPage 28ahmodahNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Lightning Protection: Tape ClipsDocumento1 paginaLightning Protection: Tape ClipsahmodahNessuna valutazione finora

- Lightning Protection: Flexible Braid BondDocumento1 paginaLightning Protection: Flexible Braid BondahmodahNessuna valutazione finora

- Earthing: Coupling - For Threaded Copperbond Earth RodDocumento1 paginaEarthing: Coupling - For Threaded Copperbond Earth RodahmodahNessuna valutazione finora

- Earthing: Earth Rods - Copperbond ThreadedDocumento1 paginaEarthing: Earth Rods - Copperbond ThreadedahmodahNessuna valutazione finora

- A Step by Step Explanation of Principal Component AnalysisDocumento7 pagineA Step by Step Explanation of Principal Component AnalysisVaibhav YadavNessuna valutazione finora

- LP 3rd QUARTER EIM XDocumento3 pagineLP 3rd QUARTER EIM XLuis John VillamagnoNessuna valutazione finora

- D T Ra, Attt-440 006 (Htet) : PojepasthDocumento5 pagineD T Ra, Attt-440 006 (Htet) : PojepasthMick DelantorNessuna valutazione finora

- Recruitment SystemDocumento23 pagineRecruitment SystemGoverthanan3350% (6)

- HPE ProLiant DL380 Gen10 Server UKDoC HSTNS-5200-a50005003enwDocumento3 pagineHPE ProLiant DL380 Gen10 Server UKDoC HSTNS-5200-a50005003enwhesmaileeNessuna valutazione finora

- Mtcna Training Materials (2013-01)Documento432 pagineMtcna Training Materials (2013-01)Tekno VlogNessuna valutazione finora

- Valleyview - T CR Soc: Bulldog Atmxt1664T3-C2Ur Galway Atmxt1667T2-C2UrDocumento44 pagineValleyview - T CR Soc: Bulldog Atmxt1664T3-C2Ur Galway Atmxt1667T2-C2Urserrano.flia.co100% (1)

- How To Integrate Cisco Unity Connection With CUCMDocumento32 pagineHow To Integrate Cisco Unity Connection With CUCMmandeepmailsNessuna valutazione finora

- Dictionary - Alcatel Lucent - AaaDocumento3 pagineDictionary - Alcatel Lucent - AaaluisNessuna valutazione finora

- 175 012200 PDFDocumento2 pagine175 012200 PDFAbu Anas M.SalaheldinNessuna valutazione finora

- SFTPDocumento3 pagineSFTPmace13370% (1)

- 132P ITT Pressure SwitchsDocumento2 pagine132P ITT Pressure Switchsjcdavid24Nessuna valutazione finora

- Indra-Doppler VHF Omnidirectional Range 0Documento6 pagineIndra-Doppler VHF Omnidirectional Range 0nemyaNessuna valutazione finora

- ISO 14001 All-in-One Package PDFDocumento39 pagineISO 14001 All-in-One Package PDFArga KrisnaNessuna valutazione finora

- VLAN Ip SubnetDocumento3 pagineVLAN Ip SubnetVane Duarte GonzalezNessuna valutazione finora

- Dealer Price List Oct 2019Documento2 pagineDealer Price List Oct 2019Pranab Kumar NayakNessuna valutazione finora

- INNOVA OBD2 Scanner-Manual 3030g EDocumento60 pagineINNOVA OBD2 Scanner-Manual 3030g EgoogleheadNessuna valutazione finora

- ISO External Audit ChecklistDocumento2 pagineISO External Audit ChecklistdeshankarunarathneNessuna valutazione finora

- 5-6 Univer PDFDocumento2 pagine5-6 Univer PDFGLITZ ELEKTRO BUILDERS CDO BRANCHNessuna valutazione finora

- QCS-2010 Section 21 Part 6 Cables and Small WiringDocumento16 pagineQCS-2010 Section 21 Part 6 Cables and Small Wiringbryanpastor106100% (1)

- Istartek VT600 Vehicle Tracker USER MANUALDocumento22 pagineIstartek VT600 Vehicle Tracker USER MANUALIstartek Vehicle Gps TrackerNessuna valutazione finora

- Process Engineer Job Des.Documento2 pagineProcess Engineer Job Des.Donesh VarshneyNessuna valutazione finora

- Network Architectures: Layers of OSI Model and TCP/IP ModelDocumento5 pagineNetwork Architectures: Layers of OSI Model and TCP/IP ModelLvly AngelNessuna valutazione finora

- Nokia E72 User Guide (En)Documento141 pagineNokia E72 User Guide (En)jeff slaterNessuna valutazione finora

- Windows Management Framework 4 0 Release NotesDocumento22 pagineWindows Management Framework 4 0 Release NotesJohn RofinNessuna valutazione finora

- Superterm AceleratorDocumento12 pagineSuperterm AceleratorFernando Estrada ZapataNessuna valutazione finora

- 530 - Dryers ManualDocumento4 pagine530 - Dryers ManualmecambNessuna valutazione finora

- SAP NetWeaver Gateway Developer Center..Documento57 pagineSAP NetWeaver Gateway Developer Center..mundeckeNessuna valutazione finora

- Deo Spray SamplesDocumento8 pagineDeo Spray SamplesVaibhav KaushikNessuna valutazione finora

- First Article Inspection (FAI) AS9102 PresentationDocumento28 pagineFirst Article Inspection (FAI) AS9102 Presentationcucho31Nessuna valutazione finora