Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Desalination of Bore Water

Caricato da

adalcayde2514Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Desalination of Bore Water

Caricato da

adalcayde2514Copyright:

Formati disponibili

Desalination of Bore Water

March 2014 Primefact 1338 first edition

Agriculture NSW Water Unit

Many producers may have access to a supply of water from a bore; however, this water is too high in salts

for use either in the house or garden, or for their stock to consume. Desalination of this water is an option

which some producers may consider feasible in order to utilise their water resources most effectively.

What is desalination?

Desalination is most often considered to be the process of removing salts from water. There are several

methods of desalination; however, this Primefact is focused on reverse osmosis desalination.

The process of desalination does not always completely remove all salts from the water. Sometimes very

low levels of salts remain in the water after desalination. The salinity of the water before desalination

influences how much salt can be removed. You should always check this with the manufacturer of the

unit.

What is reverse osmosis?

In order to understand reverse osmosis, it is important to understand osmosis. Osmosis is a natural

process where liquid will flow from a dilute source to a solution of greater concentration, across a semipermeable membrane in order to establish a nil gradient of concentration (or equilibrium). The semipermeable membrane only allows passage of water (solvent) and not the salts.

Osmosis is a process which can work in reverse. If the bore water (salty solution) is placed under an

external pressure which is greater than the osmotic pressure then the water will move in the opposite

direction, from the solution of greater concentration to the dilute source. As the salts cannot pass through

the semi-permeable membrane they are left behind. The result is potable water on one side of the osmotic

membrane, and very salty water (brine) on the other side, where the pressure was applied.

This is what a reverse osmosis desalination unit does. The diagram below outlines how a reverse osmosis

unit works.

Water quality

There are several ways to refer to the salinity of water; however, in this Primefact, all references to salinity

are made on the basis of total dissolved solids (TDS), represented by the unit of milligrams of salt per

litre of water (mg/L). This is a reference to how salty the water is, and not to what the particular salts are

that are present in the water, or how they behave chemically (or electrically).

For more information about water quality measurements and parameters, please refer to Primefact 1337

Farm water quality and treatment.

Desalination of Bore Water

Figure1. How a reverse osmosis unit works.

Table 1. Total Dissolved Solids (TDS) mg/L for stock drinking water.

Stock Type

Desirable maximum

concentration for healthy

growth

Maximum concentration

at which good condition

might be expected*

Maximum concentration

that may be safe for

limited periods*

Sheep

5000

5000 to 10 000

10 000 to 13 000

Beef Cattle

4000

4000 to 5000

5000 to 10 000

Dairy Cattle

2500

2500 to 4000

4000 to 7000

Horses

4000

4000 to 6000

6000 to 7000

Pigs

4000

4000 to 6000

6000 to 8000

Poultry

2000

2000 to 3000

3000 to 4000

* The tolerance level particularly depends on the type of feed available.

NSW Department of Primary Industries, July 2014

Desalination of Bore Water

Stock water quality

Stock water requirements and maximum advisable levels of salinity vary widely according to season, stock

type and type of feed on offer. Table 1 outlines the maximum TDS for water suitable for optimum and

below-optimum growth/conditions for livestock.

Primefact 326 Water requirements for sheep and cattle gives more detailed information about all aspects

of watering stock (see address at the end of this Primefact).

Domestic water quality

Many rural households use bore water in their homes for domestic purposes, including drinking. The

Australian Drinking Water Guidelines (1996) state that 500 mg/L is the upper value for TDS; however,

levels up to 1000 mg/L are acceptable. Above 1000 mg/L may be associated with excessive scaling,

corrosion (of pipes etc), and unacceptable taste.

What to do next

If you have water which exceeds the recommended levels of total dissolved solids (TDS), for either your

stock water or domestic water, desalination may be worth considering for your situation.

There are important issues to consider when investigating the feasibility of this technology for your

situation:

1. Find a supplier of desalination equipment, and discuss your situation and plans. This will assist

you in making some informed decisions, as well as making sure that you are aware of any

processes that are important to follow.

2. Obtain a detailed laboratory test of your bore water. This test will need to be extensive, to

determine the TDS, as well as the breakdown of the different types of salt present in your water.

The presence of some elements may require pre-treatment of your water so as to prevent scaling

and damage to the osmotic membrane.

3. Once you know the TDS of your water you should work out what your daily maximum water

requirements are. Table 2 outlines the water requirement for the various classes of stock.

Indicative household consumption rates are given in the section on domestic water.

4. Seek quotes from suppliers who will design a system specifically for your situation.

5. Cost the process of desalination.

6. Plan for the disposal of the waste product (brine) from desalination.

Please note that stock water consumption may be increased significantly under extremely hot conditions.

Consumption may increase by up to 80% under these conditions.

Sheep can drink 40% more in summer than in winter, and 5080% more if their water contains more than

2000 mg/L in TDS.

For more information on stock water please refer to Primefact 269, Stock water a limited resource. (see

address at the end of this Primefact)

Primefact 1337 Farm water quality and treatment also provides information on water quality and methods

of treatment (see address below).

NSW Department of Primary Industries, July 2014

Desalination of Bore Water

Table 2. Stock water requirements

Stock type

Consumption (l) per da per head

SHEEP

Weaners

24

Adult dry sheep:

Grassland

26

Saltbush

412

Ewes with lambs

410

CATTLE

Lactating cows:

Grassland

40100

Saltbush

40140

Young stock

2550

Dry stock (400kg)

3580

HORSES

4050

Domestic water

When considering your household water consumption, a base level would be 200 litres per day per

person.

Desalination units are designed to deliver a product of potable drinking water of very high quality. It is

important to check that this is the case when scoping a suitable product for your situation.

In some instances you may require an ultra violet steriliser to ensure that microbial content is treated,

eliminating health risks posed by microbes present in the water.

Desalination units

Reverse osmosis desalination units can broadly be classified into three categories:

1. The first is for low salinity source water of TDS of 0 to 4000 mg/L. These operate under a

pressure of around 1200 kPa and require minimal power, ranging from 0.2 kW to 3 kW, depending

on how much water is processed.

2. The second is for brackish water with TDS of 4000 to 15 000 mg/L. These units operate with a

required pressure of around 3000 kPa. Their energy requirements depend again on how much

water is to be processed and range from 1.5 to 5 kW either single phase or three phase.

3. The third is for seawater, of TDS from 15 000 to 35 000 mg/L. Pressure for operation is much

higher, around 6000 kPa because of the high concentration of salts in the water. Power

requirements are also considerably higher, 1.5 kW to 5.5 kW in single phase or three phase.

NSW Department of Primary Industries, July 2014

Desalination of Bore Water

Running Costs

The running costs of desalination will vary according to the salinity of the water you are wishing to

desalinate, and the amount of water you are treating.

The larger the desalination unit, the cheaper per litre of water treated, but the more expensive it is

overall to run.

You can calculate the cost of desalination by the following method:

What is the power usage per day for each powered component of your system, including the energy cost

of pumping the salty water from the bore, desalination energy costs, and further pumping energy

requirements?

Once you have these in kilowatt hours, you simply multiply this by the cost per unit of energy that you pay

for power from your power supplier.

When watering stock, you may be able to keep costs down, by using a shandying valve which will

enable you to mix the potable water with the untreated bore water, to a concentration suitable to

your stock type. If you are using the water for domestic purposes, then shandying of the water will

not be an option.

The use of pipelines, troughs and tanks will optimise the efficiency of a watering system, making the water

being treated go further. Evaporation losses will be minimised, and friction losses in the pipeline system

can be incorporated into the design of your system.

Waste

There will be a certain amount of waste product as a result of desalination. This waste product is called

brine, and it is simply extra-concentrated bore water. The concentration of this brine will depend on the

initial salinity of the water you are treating.

As a general guide, you can expect the following conversions:

Low salinity desalination units (04000 mg/L TDS) will produce 50% potable water, 50% reject water,

which will be around 50% saltier than the original bore water.

With brackish desalination units (400015 000 mg/L TDS) you could expect around 30% potable water,

70% reject water, which will be around 25% saltier than the original bore water.

In seawater desalination units, (15 00035 000 mg/L TDS) you should expect around 15% potable water,

85% reject water, which will be 35% saltier than the original bore water.

On low salinity and some brackish water units recycle valves may be built to improve recovery rates. This

will decrease the amount of waste product for disposal.

On medium to large capacity plants, a chemical anti-scale treatment will improve recovery rates. This will

decrease the amount of waste produced. The waste will therefore be higher in salinity.

Waste disposal

Disposal of waste product is an important issue which should be a significant part of the planning process

of undertaking a desalination project. It is important to plan the waste disposal carefully, so as to ensure

that you comply with all relevant legislation.

NSW Planning, Environment & Heritage may require your waste disposal site to be licensed because of

the volume of waste produced or if the location is near environmentally sensitive areas.

Section 120 of the Protection of Environment Operations Act 1997 states that you cannot pollute

waterways, or bury solid waste product (in this case it would be salt produced by evaporation) from this

process. Given this, a lined evaporation pond is most appropriate. Bearing in mind your obligations to

contain this waste site, you should consider all issues such as pond size, banks to prevent natural runoff

from entering the area, lining material quality.

Using the figures quoted in this Primefact, you should be able to calculate the amount of water to be

treated, and then the amount of brine that will be produced in the desalination process. Simply multiply

this by the number of days the system will be running, and take into account an evaporation factor to

determine the surface area of the pond.

NSW Department of Primary Industries, July 2014

Desalination of Bore Water

Contact an irrigation/stock and domestic system designer who will be able to ensure that the pond is

adequately designed to meet all of your requirements and obligations.

You should also contact your local council to check that your evaporation pond complies with the local

environment plan. They will also be able to advise of any health issues and regulations should you be

intending using the desalinated water for household use.

Working out some figures

If you are watering 1000 ewes with lambs per day, you will require up to 10 000 litres of water for them to

drink, at 10 litres per head per day.

If your source water is 10 000 mg/L TDS, you will require a brackish water desalination unit.

Given that for brackish desalination units you can expect a reject component of 70%, you will require 33

333 litres of source water per day to produce 10 000 litres of potable water per day.

You will require storage for waste of 23 333 litres per day. In 43 days you will have produced 1 megalitre

of waste!) This is the same volume as an olympic pool every 6 weeks!

If you have a shandying valve, you could make the 10 000 litres go further; sheep will still do well on 5000

mg/L TDS, so your 10 000 litres of potable water once shandied will last for two days.

To supply 10 000 litres of potable water per day, if you have low salinity water, the cost could be around

$21 000.

If you have brackish water, for the same amount of potable water you could expect a desalination system

to cost about $25 000.

If you have high salinity water then the cost could be in the order of about $57 000.

These figures are intended as a guide only, and include some installation and all component costs.

Different suppliers will have different costs associated with their systems. As the technology becomes

more readily available, costs may change. You will need to factor installation and running costs into your

plan.

Your waste water may also be useful in watering salt tolerant species including saltbush and puccinellia,

both of which will grow well in moderately drained soils with high levels of salt present, up to 6400 TDS. If

you are considering utilising this method of waste disposal, you will find further information regarding

suitable species, soil types and water quality on the DPI website under salinity (see address below).

Figure 2. A typical desalination layout for rural areas

NSW Department of Primary Industries, July 2014

Desalination of Bore Water

Acknowledgements

The authors wish to acknowledge:

Edward Joshua, Development Officer Irrigation Broadacre Central NSW;

Eddie Parr, former Industry Leader Irrigation Development, Extensive Industries Development;

Megan Rogers, former Livestock Officer Sheep & Wool, Extensive Industries Development;

Lindsay Evans, NSW DPI; Elizabeth Madden, NSW DPI; Norman Wise NSW Department of Water and

Energy; for their input into this Primefact.

Thanks also to Kingsley Hansen CITOR P/L for review of technical content.

Further reading

Primefact 326 Water requirements for sheep and cattle

Primefact 269, Stock water a limited resource

NSW Department of Primary Industries, July 2014

Desalination of Bore Water

Primefact 1337 Farm Water Quality and Treatment

http://www.environment.gov.au/system/files/resources/53cda9ea-7ec2-49d4-af29d1dde09e96ef/files/nwqms-guidelines-4-vol1.pdf

These publications and other NSW DPI factsheets are available from the NSW DPI website at:

www.dpi.nsw.gov.au/primefacts

Salinity page on the NSW DPI website: http://www.dpi.nsw.gov.au/salinity

(ISSN) 1832-6668

For updates go to www.dpi.nsw.gov.au/factsheets

State of New South Wales through the Department of Trade and Investment, Regional Infrastructure and Services 2014. You may copy, distribute

and otherwise freely deal with this publication for any purpose, provided that you attribute the NSW Department of Primary Industries as the owner.

Disclaimer: The information contained in this publication is based on knowledge and understanding at the time of writing (July 2014). However, because

of advances in knowledge, users are reminded of the need to ensure that information upon which they rely is up to date and to check currency of the

information with the appropriate officer of the Department of Primary Industries or the users independent adviser.

Published by the NSW Department of Primary Industries.

INT 14/42327

NSW Department of Primary Industries, July 2014

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- "Quality Comes First Before Our Name Goes Out.": Motech MindanaoDocumento15 pagine"Quality Comes First Before Our Name Goes Out.": Motech Mindanaoadalcayde2514Nessuna valutazione finora

- D&C PGA EMP Att B - Project ComponentsDocumento9 pagineD&C PGA EMP Att B - Project Componentsadalcayde2514Nessuna valutazione finora

- Desalination Plant ConstructionDocumento104 pagineDesalination Plant Constructionadalcayde2514Nessuna valutazione finora

- D&C PGA EMP Att B - Project ComponentsDocumento9 pagineD&C PGA EMP Att B - Project Componentsadalcayde2514Nessuna valutazione finora

- Construction Method StatementDocumento9 pagineConstruction Method Statementadalcayde2514100% (2)

- Instruction Manual: Downloaded From Manuals Search EngineDocumento36 pagineInstruction Manual: Downloaded From Manuals Search Engineadalcayde2514Nessuna valutazione finora

- Mega DaltanDocumento1 paginaMega Daltanadalcayde2514Nessuna valutazione finora

- A Case Study: Industrial Water Treatment Plant - Maáden Waád Al Shamal Phosphate Project-Turaif, KSADocumento2 pagineA Case Study: Industrial Water Treatment Plant - Maáden Waád Al Shamal Phosphate Project-Turaif, KSAadalcayde2514Nessuna valutazione finora

- Microtunneling Pipe Jacking Construction Specification PDFDocumento16 pagineMicrotunneling Pipe Jacking Construction Specification PDFadalcayde2514Nessuna valutazione finora

- Hydrotest FormulaDocumento17 pagineHydrotest FormulaEarnest007100% (2)

- Api Oil Water Separators 2013Documento6 pagineApi Oil Water Separators 2013adalcayde2514Nessuna valutazione finora

- MBR Vs SBR Vs Conventional Treatment PDFDocumento9 pagineMBR Vs SBR Vs Conventional Treatment PDFadalcayde2514Nessuna valutazione finora

- Environmental Issues in Seawater Reverse Osmosis Desalination: Intakes and OutfallsDocumento18 pagineEnvironmental Issues in Seawater Reverse Osmosis Desalination: Intakes and OutfallsEnrique MartinezNessuna valutazione finora

- Bulk Water Supply CodeDocumento38 pagineBulk Water Supply Codeadalcayde2514Nessuna valutazione finora

- Meter ClassDocumento4 pagineMeter Classadalcayde2514Nessuna valutazione finora

- Deq WB Dwehs Gwwfwim Section7 - 183032 - 7 PDFDocumento20 pagineDeq WB Dwehs Gwwfwim Section7 - 183032 - 7 PDFHari RamNessuna valutazione finora

- Produced Water Costs PDFDocumento40 pagineProduced Water Costs PDFcmegmhiNessuna valutazione finora

- 1Documento43 pagine1Tariq WahidNessuna valutazione finora

- DR900 Multiparameter Portable Colorimeter: Fastest and Simplest Water Testing For The Most Demanding Field EnvironmentsDocumento2 pagineDR900 Multiparameter Portable Colorimeter: Fastest and Simplest Water Testing For The Most Demanding Field Environmentsadalcayde2514Nessuna valutazione finora

- Product Water CostsDocumento26 pagineProduct Water Costsadalcayde2514Nessuna valutazione finora

- Escalante Water District: 2 Escalante City, Negros Occidental Telefax (034) 454-0563Documento4 pagineEscalante Water District: 2 Escalante City, Negros Occidental Telefax (034) 454-0563adalcayde2514Nessuna valutazione finora

- 75525OP8136 - Trade Waste PolicyDocumento4 pagine75525OP8136 - Trade Waste Policyadalcayde2514Nessuna valutazione finora

- Water Meter Size CalculationsDocumento3 pagineWater Meter Size Calculationsadalcayde2514Nessuna valutazione finora

- Eaton Eaton Basket Screen DataDocumento2 pagineEaton Eaton Basket Screen Dataadalcayde2514Nessuna valutazione finora

- Pumps 2Documento2 paginePumps 2Meetoo SharvamNessuna valutazione finora

- Calculation of Design Exa of HDPE PenstockDocumento29 pagineCalculation of Design Exa of HDPE PenstockZainNessuna valutazione finora

- Tornado - FLuence - AeromixDocumento2 pagineTornado - FLuence - Aeromixadalcayde2514Nessuna valutazione finora

- Taco Pump - VT Series - Vertical Turbine PumpsDocumento8 pagineTaco Pump - VT Series - Vertical Turbine Pumpsadalcayde2514Nessuna valutazione finora

- 13Documento6 pagine13adalcayde2514Nessuna valutazione finora

- Maximum Dissolved Oxygen Concentration Saturation TableDocumento3 pagineMaximum Dissolved Oxygen Concentration Saturation Tableadalcayde2514Nessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Storage ReservoirDocumento6 pagineStorage Reservoirmaaz hussainNessuna valutazione finora

- Wind Driven Ocean Circulation: 11.1 Sverdrup's Theory of The Oceanic CirculationDocumento17 pagineWind Driven Ocean Circulation: 11.1 Sverdrup's Theory of The Oceanic CirculationnvanthaoNessuna valutazione finora

- Karvena-Head SluiceDocumento9 pagineKarvena-Head Sluicevaranasirk1Nessuna valutazione finora

- Detention Pond Design Using MASMADocumento72 pagineDetention Pond Design Using MASMAezarul fitri50% (2)

- Indiana Administrative CodeDocumento176 pagineIndiana Administrative CodeMd Mamunur RashidNessuna valutazione finora

- Poster 4 Sedimentation (A2)Documento1 paginaPoster 4 Sedimentation (A2)Ramco33Nessuna valutazione finora

- Kelani Right Bank Water Treatment Plant Sri LankaDocumento11 pagineKelani Right Bank Water Treatment Plant Sri LankaSudeepa SumanasekaraNessuna valutazione finora

- EIA Write-UpDocumento3 pagineEIA Write-UpRoy MarechaNessuna valutazione finora

- Correction Factors For Calculating Oxygen-Transfer Rates of Pond AeratorsDocumento5 pagineCorrection Factors For Calculating Oxygen-Transfer Rates of Pond AeratorsAnonymous CMS3dL1TNessuna valutazione finora

- Waters of The EarthDocumento40 pagineWaters of The EarthTan JelynNessuna valutazione finora

- Water SupplyDocumento10 pagineWater SupplyAr Apurva SharmaNessuna valutazione finora

- NIH - SW - Hydrological Assessment of Ungauged CatchmentsDocumento452 pagineNIH - SW - Hydrological Assessment of Ungauged CatchmentsBalaji AngamuthuNessuna valutazione finora

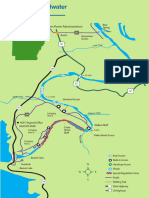

- Arkansas Trout Fishing Guidebook - Beaver Lake TailwaterDocumento1 paginaArkansas Trout Fishing Guidebook - Beaver Lake TailwaterhighmountainbearNessuna valutazione finora

- Dinamik KTADocumento6 pagineDinamik KTAFerdina RahmaNessuna valutazione finora

- Domestic Wastewater Treatment Chap8Documento6 pagineDomestic Wastewater Treatment Chap8nermeen ahmedNessuna valutazione finora

- CBSE Class 11 English Sample Paper Set 1Documento6 pagineCBSE Class 11 English Sample Paper Set 1Swara ParulekarNessuna valutazione finora

- Brine Calculator User ManualDocumento20 pagineBrine Calculator User Manualankitsaxena123100% (2)

- Manual SatrepsDocumento106 pagineManual SatrepsTungish UpretyNessuna valutazione finora

- 11 PH CITYNET Ecotanks SF Project Case StudyDocumento9 pagine11 PH CITYNET Ecotanks SF Project Case StudyVhan PerezNessuna valutazione finora

- Water Balance Industrial ParkDocumento5 pagineWater Balance Industrial Parkmuhammad.civilNessuna valutazione finora

- RORB Worked ExampleDocumento16 pagineRORB Worked Examplerotciv132709Nessuna valutazione finora

- Cooling TowerDocumento12 pagineCooling Towernhalieza1067Nessuna valutazione finora

- Ocean Currents Final SpeechDocumento4 pagineOcean Currents Final SpeechKarla AraujoNessuna valutazione finora

- Famous Landforms and Waterforms in The PhilippinesDocumento19 pagineFamous Landforms and Waterforms in The PhilippinesSotnei Oli100% (1)

- Gec Exam Lyka 3bDocumento5 pagineGec Exam Lyka 3bJan Lemuel Fortaleza RefuncionNessuna valutazione finora

- Success Criteria Grids The Water CycleDocumento1 paginaSuccess Criteria Grids The Water CycleĐặng Thái NhậtNessuna valutazione finora

- Cropwat SoftwareDocumento9 pagineCropwat SoftwareBuocahgendenk ToekankngapusiNessuna valutazione finora

- Gr5 Wk23 Water Water Everywhere PDFDocumento2 pagineGr5 Wk23 Water Water Everywhere PDFJhester de leonNessuna valutazione finora

- Assessment of Rainwater Harvesting Potential of NSTU CampusDocumento5 pagineAssessment of Rainwater Harvesting Potential of NSTU CampusFahim SiddikiNessuna valutazione finora

- Mohana DocumentationDocumento9 pagineMohana DocumentationArshi KhanNessuna valutazione finora