Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Survey Report 1

Caricato da

Slamat Parulian Simamora0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

11 visualizzazioni15 pagineSurveying

Copyright

© © All Rights Reserved

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoSurveying

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

11 visualizzazioni15 pagineSurvey Report 1

Caricato da

Slamat Parulian SimamoraSurveying

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 15

TEBODIN

Client (Order number 35664-00

- Document number: 1113001

Project: Project

Revision: A

Author: J. van Wier

Telephone: ++ 31 0)40 265.21 11,

Fax + 31 (040 266 22 00,

E-mail vanwier@tebodin

Date: 29 march 2006

Site survey Hall no. 2

— Bergen op Zoom

oder runber 366400

Docurert raer 1800

fevson A

TEBODIN | ae: 25rcn2000

moth boo | pecae

a | aenszone | seca Nan AAP vancen oe

2.02006 [rst sue Jomnvier | AAP. an den

ex. [ote Descipton autor | onc s]

© copight Toon

{tis sre. No pat fh pubeton my be raredhced er ransmited any fe or by ony means wit peas o the

pole

Ste survey Hall no, 2 TE >t TE - seen op zor

uf

TEBODIN

(Order number: 35684.00,

Document number: 1113001

Revision: A

Date: 29 march 2006

Page: 3 0f15|

1

14

12

13

2

24

22

23

24

3

34

32

33

4

44

42

43

44

6

54

52

53

54

55

56

6

61

62

7

7A

72

73

74

78

78

Table of contents

‘Summary

General

Introduction

Key figures

History

Outdoor facilities

‘Accass to main road

Green field

Parking

Security

Foundation

Pile foundation

Foundation beams

Foundation blocks

Floor structure

Documentation

Visual appearance

Structural behavior of the floor

Mezzanine floor

Stoo! structures

Documentation

Structure

Extra loads

Documentation

Elevations

Fire wall

Roof

Documentation

Renovation

Building services and utilities

Heating

Domestic water

Sprinkler installation

Sewage

Electricity

Utilities

Page

"

"

"1

"

"1

12

13

13

13

4

14

14

14

14

14

15

Stesuvey Heino, 2 TE >. TE - serge op Zoom a

Cxder number 35664-00

Document number: 1113001

Revion: A

TEBODIN | oxe-20macnzo0e

Constants treats | Powe earae

Drawings Revision

20.2.0.0.110.1 — Architectural lay out Groundfloor hall 2 9

site

External enclosures

1113002 — Photo annex Site survey Hall no. 2~ il

West site

Date

27-01-2006

° 03-03-2006

Stesiney Halo? TE °-: TE sce o» 2-1

Order number: 35664-00

‘Becumeat number: 1119001

Revision:

TEBODIN | cate:29 aren 2008

CConsatanis& Enuineer

Page: 5 of 15

Summary

As part ofthe feasibility study to be provided by Tebodin for Il Engineering, a site survey was made of Hall no.

2 on MEE site in Bergen op Zoom, the Netherlands,

This hal is part of a building complex that was originally constructed in 1962 and acquired by lin 1993. After

that ID renovated Hall no. 2. The elevations were changed and provided with closed facades of modern

cladding, On the roof the orignal bitumen sheet was removed for a new one with adkition of an extra layer of

thermal insuaton

‘The superstructure of the hall is based on foundation beams on top of foundation piles. These piles are most

likely of concrete and are hammered into the ground to a depth of about 10 to 11 m below ground level. The steel

structure that bears the superstructure of the building is left intact and seems to be in rather good shape,

although a good judgment of the coating can only be made after cleaning the steel structure. Unknown is to what

extend extra live loads (others than from climate) can be accepted to act on the trusses of the steel structure,

‘The floor structure of the hall is in very bad shape and in fact only acceptable for basic needs such as the one

related fo warehouse activities. The surface of the floor is cracked all over the hall. Another striking view is the

Unequal deformation of the floor. Cracking and deformations are most likely due to the low modulus of subgrade

reaction of the soil layers that bear the floor slab. Furthermore spots of spoils and dirt can be found on many

places on the floor surface.

‘The hall has @ heating installation for basic heating, Furthermore a new sprinkler-net was installed after 1993

Other building services are also avaliable on basic levels such as lighting (200 lux) and domestic water (used

only for supply of fre extinguisher hoses). The central equipment for these services are shared with other parts of

the building and are situated outside Hall no. 2. Other utilities than these are unknown.

Stesuney Hallo, 2 TE ct TE - seen 0 20r

Order number: 5864-00

Document rumber: 1113001

Revision: A

TEBODIN | cate:20 merch 2008

Consultants & Engineers

Page: 6 of 15,

14

12

13

General

Introduction

In week 08/2006 Tebodin received an assignment to determine the feasibility of Hall no. 2 ~ II site in

Bergen op Zoom the Netherlands, for installation of a new flavor manufacturing center

‘An initial site survey was carried out by Tebodin, based on site survey forms of fl Engineering. After the full

scope of the assignment got clear, a more detailed survey was carried out. Since the above mentioned site

survey forms give oniy a brief and rather superficial impression of the building, a need for a more substantial

format came about. Furthermore civil and architectural drawings were placed at Tebodins disposal, which give

detailed information about the way the building was constructed

Hence this document was established, to inform [il in detail about the civil and architectural condition of the

building, meant to accommodate the new flavor manufacturing center. The following chapters of this report

describe the status quo of the building: foundation, floor structure, steel structure, wall cladding and inner walls,

the roof and building services and utiities.

Key figures

Hall no. 2s situated on [INI site in Bergen op Zoom, The area of the Ill site is about 6.5 Ha, The front

elevation of the building (towards the entrance) faces north-west direction.

The hall has the simple geometry of a rectangular box. The inside area of Hall no. 2 is 30 x 120 = 3,600 m?. The

fee height (under trusses) is 6.0 m, The total height ofthe building indoor is 8.9 to 9.2. This makes an indoor

Volume of 32,600 m*, The outdoor height ofthe building is approximately 9.3 m.

History

The avaliable land architectural erevings show tat Han. 2 was constuctd in 1862 as par ofa bulsng

complex consisting of three in line halls. Hall no. 2 was used as production facility for wooden doors and closets

ot MIMI corgon cp Zoom Inter year the buldngcompior wee itera extended in he

Panag ees Ut

After the building complex was acquired by Il in 1993, Hall no, 2 was renovated and made suitable for use as

‘a warehouse for tobacco raw materials and finished goods.

Ste suney Hel no, 2 TE °c: TE - secen 0 zo aT

‘Order umber 3664-00

Document number: 1113001

Revision: A

TEBODIN | ose: 28 aren 2008

24

2.2

23

24

age: 7 of 15

Outdoor facilities

Access to main road

‘The bulking complet which Halo. 218 apa, he most western tof fllln Been op Zoom. The ste

's tcctoreramea ll ste On the cast de of tare wo oer ses ll te:

The ste re dhided by a publ roe The buldingcomplox hae det access to the puble

road MMMM, as part o ne oct road newor of Bergen op Zoom and les approximately km om the

highway ASB Enchover- Mkdelbur/Vssinen. The lliflaes es slong the ral road Roosendaa ~ Middl

burgissingen hich is connected IN te in Bergen ep 200m

Halo. 2 fe onthe ont side towards th road at approximately 100 m fom the canal gate. Besides an

entrance wth overhead doos (8x 8m} on the font ie, thee fs enaher one withthe seme ize on the rear

tide of te buldng, Bath etrances are connected othe road neta he ste. Roads have awh of 5 o 6m

and ee paved wth bce and concepts

Green field

(On the front side of the building complex, the major part of the site which is not yet build over (by buildings), Is

green field, The total area of green field on the front side of the building is approximately 1.9 Ha. Directly in front

of Hall no. 2 (up to the pavement) lies a green field with an area of approximately 2,500 m*

Parking

‘The logistical organization of traffic is rather basic (not organized). Trucks with incoming goods that have to wait

for unloading, are parked on the available space on roads on site, Since nowadays warehousing activities of

on the [IBM site require only little personnel, there is stil litle capacity of parking places available for

private cars of personnel

Security

The I site is professionally guarded and can only be regularly entered via a gate house, because the site is

completely fenced (towards public road, sites of ther companies and il so calcd IEEE biting)

Stesuvey Halo, 2 TE °c: TE - seen 0» 200

‘Onder number: 5664-00

Document umber 1113001

Revision: A

TEBODIN | os: 29:acen2000

34

3.2

3.3

Page: 8 of 15

Foundation

foundation

The superstructure of Hall no, 2 is based on foundation beams which are placed on top of foundation piles.

‘These foundation piles are positioned under the columns of the steel structure. Although the available drawings

give no definite clue, most likely foundation piles are made of concrete and were hammered into the ground to a

depth of about 10 to 11m subgrade.

From the drawings no definite conclusion can be derived for what reason in every third axis (truss) double piles

are used. It could be that these piles are placed under a slope in the direction of the axis but drawings do not

support this vision. Further investigation of the structural behavior of the concrete structure should give more

definite information,

Foundation beams

‘The foundation beams of the building rum along the elevation and the inner (fire) wall as well under the columns

of the mezzanine floor on the south-west side of the hall,

‘The foundation beams under the elevations have a multiple use:

‘= connect the foundation piles in order to resist horizontal forces along the elevation

‘= create a foot for the elevation on which facade elements (e.g. cladding) can be based

«form a barrier against incoming water

‘form a structural barrier against mechanical forces such as from fork lift trucks

“The appearance of the foundation beams show that the concrete has become of age. On the outside of the upper

part of foundation beams organism are growing into the less compacted parts of the concrete. On the inner side

the cast in steel parts (L-profiles) have corroded and affected the concrete in a minor way. Furthermore cracks

have appeared on some locations, however not on a large scale.

Foundation blocks

To support equipment for door and closet production, four foundation blocks have originally been constructed in

Hall no. 2. The information on these foundation blocks is rather poor. The area and position is known: twice 765 x

245 cm? and twice $50 x 250 om? on the north-east side of the hall, where they were found indeed. The thickness

Cr height is unknown, The surface of the foundation blocks can hardly be distinguished from the surrounding

floor. The surface of the foundation blocks is cracked just as the floor is, but in a different pattern.

Stesuney Holo 2 TE >.<: TE - 32:20 o, 27

(der number: 38864-00

Document number: 1113001

Rovsion: A

TEBODIN | pate:20:marcr2008

44

42

43

Page: 8 of 15

Floor structure

Documentation

‘The available drawings indicate that a floor slab of concrete (most likely reinforced concrete) was to be

established, in between the rectangle of foundation beams, Furthermore two foundation blocks for equipment are

part of the floor structure since the top of these top lies equal with the surface of the floor. The drawings show

that the thickness of the concrete floor siab was foreseen at 1 cm. There is no information available of the steel

reinforcement of the concrete of the floor stab,

Visual appearance

The floor structure is only visible on the surface of the floor slab. The surface of the slab shows cracks all over

the hall, wherever the floor was clear from stored goods (at least 40 % of the floor visible). These cracks form

different patterns. The floor surface shows patterns of circular cracked parts of about @ 10-120 em and with a

‘width of 0.5 -1 mm, in some parts cracks in patterns of about @ 75 cm and with a width of 1-3 mm (sometimes.

combined with the smaller pattems and widths). Larger divisions of the floor wit cracks of several meters and a

‘width of 2 to 5 and sometimes even more are also visible.

‘The floor slab is not separated in parts in order to reduce tensile stresses. This is for certain a cause of crackling

(see 5.3). The upper layer of the floor slab, when not cracked, is smooth in general. The floor surface looks to be

covered with some kind of coating that prevents erosion and freeing mineral dust from the concrete surface.

Besides smooth, the floor surface is shiny, probably caused by tire wearing. Another striking vision is the

Uunequality of the floor. Most likely unequal deformations of subgrade soil have caused the floor to sink uneven,

which can be observed easily and felt by walking on the floor as well

Besides cracks the floor is covered with spots of spoils and dirt of various kind and size. These make the floor

ook outdated and give, in combination with cracks, litle confidence in future use of any kind other than

warehousing. The slab is not separated from the foundation beams and neither is the slab separated from the

foundation blocks for equipment, This is another explanation for a part of the crackling (see 5.3).

‘The vertical deformation of the rigid foundation beams and blocks is much less than the elastically supported

floor slab and causes in worst case crackling

Structural behavior of the floor

Although litte is known about the strength conditions of the concrete floor slab, two conclusions can be derived

from the visual appearance. However uncertain these conclusions are, because of poor as built information, they

‘are important for a good judgement of the floor structure,

First of all, the strength of the floor slab itself. Since the floor is cracked all over the area of the hall, it must have

2 poor strength in relation to the (live) loads that acted on it. The following arguments give an explanation

« in the days of construction (1982) the maximum concrete quality to be established on site was different from

today — most likely no better concrete quality could be established than with strength parameters of about 40 %

of nowadays concrete

Sie suvey Hao 2 EE °c TE - 32529 20. aT

Corder number: 3566400

‘Document number: 1139001

Revision: A

TEBODIN | oste:29 mac 2008

44

Page: 10015

+ the steel quality of the reinforcement bars in the concrete slab in 1962 is different from today ~ most likely,

(regular budget) no better steel quality for the floor could be established than with maximum tensile stresses of

of about 45 % of nowadays steel

However, the definite explanation for the cracking of the floor must be the low and varying modulus of sub-grade

reaction (unit kN/m?) that probably was established in 1962. The sub-grade reaction of (the various layers of) soil

provide an elastical support for the concrete floor. The stiffer this support is, the better performance of the

concrete floor. Most likely the upper part of the existing soil was removed because of its rather low modulus of

reaction and replaced by a layer of suitable sand that was compacted on site. At the time of construction the

know-how of slab foundations was not as it is today. Furthermore the means for compacting soil were rather

under-developed compared to nowadays standards. Therefore is should be assumed that the modulus of sub-

grade reaction for the floor slab is significantly lower and varies more than acceptable nowadays ~ a modulus

less than 1.000 kN/m? instead of 10.000 kN/ m=

‘When the modulus of sub-grade reaction has such a low value and varies as well, this gives a negative effect in

two ways, respectively:

* the forces on the floor slab (bending moments) due to the loads that act on it, increase in respect to a regular

(nowadays) modulus ~ when the maximum strength capacity of the floor is overrun, the floor will crack with

minor deformations

+ deformations of the soil will vary and this will cause not foreseen (not calculated) forces ~ when the maximum,

strength capacity of the floor is overrun, the floor will crack and deform (sink) with the deformations of the

subgrade soil layer

The result wll be what is visible today in Hall no, 2: a floor slab completely covered with cracks of various sizes

‘and deformations that are visible and can be felt wnen walking on the floor.

Mezzanine floor

On the south-west side of the hall a mezzanine floor was constructed with a depth of 5 m. The floor rests upon

columns (based on a foundation beam (see 4.) and on the adjacent fire wall. The floor is constructed in

reinforced concrete and can be entered by laddersistairs.

Stesuvey Heir, 2 TE °c: TE - cece op Zoo

Po

Cxder number: 3566400

Document number: 1113001

Rovision: A

TEBODIN | pace 20 macr2000

Constani&frsnees | Doe aa ayag

5 Steel structures.

5.1 Documentation

‘The steel structures of the building were originally constructed as foreseen on the (available) drawings and are

nearly untouched until today.

5.2 Structure

‘The super structure of the building consists of a steel structure of trusses with a span of 30 mon columns. A

truss is placed in an axis successively every 5 m. The height of the trusses varies form 2.8 to 3.1 m. Every truss

was constructed in two sections of 15 m each and is established of L and H steel profiles.

Horizontal loads from both directions (wind loads), are distributed to elevations and inner wall by horizontal

trusses. Thus such horizontal trusses can be seen at the top between the (vertical) trusses at the axis near the

elevation and inner wall on the north-east and south-west side (length 30 m). Furthermore (in the other direction)

horizontal trusses can be seen at the bottom end of the vertical trusses along the elevations (length 120 m). The

steel structure of these trusses is constructed in such a way that a platform was created on which infrastructure

for building services (cables et cetera) could be installed.

‘The coating steel structure is in a relatively good condition. However some parts are corroded. By cleaning the

steel structure, a proper view for judging the status of the coating of the steel structure can be obtained, so that a

decision for renovating the coating can be made,

5.3 Extra loads

‘There Is a drawing of the architect that shows that a load of 2.5 tons (2,600 kg or a weight of 25 KN) should be

taken info account by the structural engineer. Tebodin structural calculations show us that these extra loads are

indeed possible. This means that walkable ceilings in combination with process piping and HVAC loads are

allowed within certain limits. See also: Tebodin report “Capacity check existing trusses Hall no. 2 ; no. 1113003;

dated: 21-03-06",

5.4 Documentation

‘The available drawings show that the original front and rear elevation consisted of steel frames with glass for

lighting, from ground level to roof edge. The roof edge originally consisted of timberwork with a wooden fascia

(elevation strip).

8.5 Elevations

‘The renovation of the elevations, after the building complex was acquired by Ill in 1993, was carried out by

removing the original lighting frames and replacing these by modern cladding. The cladding consists of inner

steel box plates, in which thermal insulation made of glass flber woo! is placed, and outer corugated steel plates.

‘The corrugated steel plates are sendzimir zinced and coated in ll yellow.

Stecuvey Hal ro, 2 TE °c: TE - e900 o Zor a

Stites] eae

‘a usranetas

as

TEBODIN | oy nse

In the front elevation (of 120 m) a new entrance was created with an overhead door of approximately § x 5 m*

Furthermore in this elevation three new emergency exits were made — one of them placed in the overhead door.

In the rear elevation also a new entrance was created with the same size as in the front elevation as well as three

new emergency exits.

On the rear side of the building (south-east side) a ladder is placed from which the roof can be entered, In front of

the elevation of the adjacent hall a stairs with platforms is placed from which the roof of this hall can be entered

and by walking on the roof Hall no. 2 can be reached

The original elevation on the north-east side of Hall no. 2, consisting of masonry, was covered by cladding, Its

not clear whether any insulation was applied. The original entrance was fled by new masonry.

5.6 Fire wall

Between Hall no. 2 and the adjacent hall, a fire wall of approximately 20 cm masonry, including doors, was

constructed. The detail that shows in which way the integrity of the fire wall was to be saved under fire in one of

the halls is not applied. Therefore it is unclear whether the fire wall will properly perform under fire and it is also

unclear to what extend fire development via the roof will not occur.

Sitesunvey Halo, TE >: TE - seen o 2.

(Order number: 35664:00

Document ramoer 1713001

Revision: A

TEBODIN | 5.6: 23marcn 2009

Constants & Engineers

Page: 13 0f15

64

62

Roof

Documentation

The available drawings show that the original roof covering consisted of plates of wood fibers mixed with cement

and reinforced with steel bars. On top of that a waterproof tar-free bitumen sheet was applied which was

probably, according to details from drawings, bitumen-glued on the wood fibers-cement plate,

The drawings do not show serious measurements against calamities due to failing of the rainwater sewerage.

‘Whenever the rainwater sewerage gets out of order (rainwater pipes choked-up by leaves for instance) the water

level on the roof (swimming pool) creates a load that generally is to be avoided by establishing emergency

outlets on the edges of the roof. There are no such emergency outlets

Renovation

After the building complex was acquired by Il in 1983, Hall no. 2 was renovated. Thus the waterproof sheet of

the roof was removed (as can be seen through the left over holes inthe roof plates), layer of thermal insulation

(Glass fiber or mineral wool) was added to the wood fibers-cement plate and on top ofthat a waterproof bitumen

sheet with mineral protection (against UV-radiation) was placed, Most ikely the layer of insulation is fixed to the

\wood fibers-cement plate with mechanical means and the bitumen sheet is bitumen-glued on top of the insulation

layer.

At the roof edges a row of concrete tiles are placed, probably in order to give weight to the roof covering. This is

often necessary to compensate for the extra wind loads that occur on roof edges and for which the regular fixing

of the new roof covering to the fibers-cement plate has probably not enough strength capacity.

Nowadays the roof is prohibited from entrance. The reason is that on a number of spots existing holes are only

covered by thermal insulation and bitumen sheet. This gives a safety risk against which a prohibition measu-

rement was taken,

Site suvey Hal no 2 TE °c! TTT cece op 200

(Onder umber 95664-00

‘Bocument number: 1119001

Revision: &

TEBODIN | gssc:20:arcn2008

Page: 14 0f15|

TA

72

73

74

15

Building services and utilities

Heating

Hall no. 2s stil heated by the system that was originally installed in 1962. Two pipes @ 75 mm rum along the

elevations of 120 m and produce enough heat to give the hall a basic working temperature under winter

conditions of approximately 10 °C. The boiler for this heating system is shared with other parts of the building

complex and is situated outside Hall no. 2.

Domest

water

For sanitary use domestic water is available, however there are no sanitary facities available in Hall no, 2. Most

likely domestic water is used for supply of the fire extinguisher hoses that are installed in Hall no. 2

Sprinkler installation

The building complex was constructed in 1962 with a sprinkler installation. However this installation is no longer

used these days, Instead a new sprinkler was installed after Il acquired the building in 1993. The sprinkler

installation is designed for fire protection of warehouse activities as they are today. The (central) equipment of

the sprinkler installation (pumps and tank) is shared with other parts of the building complex and is situated

outside Hall no. 2. The available pressure of the sprinklemnet is 11 to 12 bar.

Sewage

Besides a sewage system for rainwater from the roof (see 8.), there is no sewage system for waste or process

water in Hall no, 2 avellable.

Electricity

General

The electrical instalation in Hall no. 2 ofl Ste consists of @ minimum requirement for a warehouse.

Mains

‘The electrical power supply for Hall no. 2 is fed from the adjacent Hall 1 of the [lf site. There is no HV

provision in Hall no. 2. A 10 KV Ring Main Unit (RMU) is installed in the central part of Hal 1. This RMU has two

spare cells each for a transformer with a capacity of 630 KVA. The RMU also accommodates an HV switchgear

with 4 switches. The RMU is connected with one 10kV 120mm?, Cu cable and can provide two additional

transformers of 830 KVA or one transformer of 1000 KVA,

Power distribution

Hall no, 2 currently accommodates one LV power distribution board. This board provides electricity to the

florescent lighting in Hall no. 2 and some 400V power sockets. The state of the cabinet is obsolete.

Ste suvey Helo? TE 9. TE - ceoen op 20°

Order number: 35664-00

Document number: 1119001

Revision: A

TEBODIN | pate-251mercn 2008

Consatancs & engineers | oe a oyag

Lighting

Ater Ii acquired the building complex in 1993 new florescent lighting system was installed in Hall no. 2. The

lighting fixtures are installed at the bottom side of the trusses at 6.0 m above the floor. The lighting fixtures have

an open structure. The lighting produces a basic illumination of approximately 200 lux.

Low voltage systems

There are no LV systems such as CCTV, Public Address, Intrusion alarm, Acess Control etc. installed either in or

outside Hall no. 2

Lighting protection

‘There is no lighting protection installed on Hall no. 2.

7.6 Utilities

Other utilities than described above are unknown

Stesuney Helo 2 TE >.<: TE coe 9° zn

Potrebbero piacerti anche

- Syncrhro Pro Data SheetDocumento10 pagineSyncrhro Pro Data SheetSlamat Parulian SimamoraNessuna valutazione finora

- Synchro Pro PDFDocumento115 pagineSynchro Pro PDFSlamat Parulian SimamoraNessuna valutazione finora

- Regression AnalysisDocumento8 pagineRegression AnalysisSlamat Parulian SimamoraNessuna valutazione finora

- Project Control ProcedureDocumento21 pagineProject Control ProcedureSlamat Parulian Simamora100% (5)

- Editing 3D Equipment in SynchroDocumento8 pagineEditing 3D Equipment in SynchroSlamat Parulian SimamoraNessuna valutazione finora

- Sejiram Mill 80 TPH Project: Feasibility Phase Feasibility PhaseDocumento10 pagineSejiram Mill 80 TPH Project: Feasibility Phase Feasibility PhaseSlamat Parulian Simamora100% (1)

- 1, ArmiDocumento5 pagine1, ArmiSlamat Parulian SimamoraNessuna valutazione finora

- Asta Tutorial PDFDocumento10 pagineAsta Tutorial PDFSlamat Parulian SimamoraNessuna valutazione finora

- Level 1 Schedule PDFDocumento5 pagineLevel 1 Schedule PDFSlamat Parulian Simamora100% (1)

- Progress Report: PT. H.B. Fuller IndonesiaDocumento4 pagineProgress Report: PT. H.B. Fuller IndonesiaSlamat Parulian SimamoraNessuna valutazione finora

- Weekly Schedule: Pt. Tenaris - Spij Pt. Tenaris - Spij Pt. Tenaris - Spij Pt. Unilever IndonesiaDocumento6 pagineWeekly Schedule: Pt. Tenaris - Spij Pt. Tenaris - Spij Pt. Tenaris - Spij Pt. Unilever IndonesiaSlamat Parulian Simamora100% (1)

- Personal Development Plan: 1. Key Strengths and Development AreasDocumento4 paginePersonal Development Plan: 1. Key Strengths and Development AreasSlamat Parulian SimamoraNessuna valutazione finora

- Project/Company Logo Title of Itp: Date of Issue: This ITP Accompanies The Method StatementDocumento6 pagineProject/Company Logo Title of Itp: Date of Issue: This ITP Accompanies The Method StatementSlamat Parulian SimamoraNessuna valutazione finora

- Quality Control and Quality AssuranceDocumento22 pagineQuality Control and Quality AssurancejswldeepNessuna valutazione finora

- 3 DayscheduleDocumento1 pagina3 DayscheduleSlamat Parulian Simamora100% (1)

- 14234-3 Eg 14234-3 Egbaoma Gas Processing Plant - New: 14234-3.co 14234-3.contract About ContractDocumento7 pagine14234-3 Eg 14234-3 Egbaoma Gas Processing Plant - New: 14234-3.co 14234-3.contract About ContractSlamat Parulian Simamora100% (2)

- Triple Constraint: ManagingDocumento30 pagineTriple Constraint: ManagingSlamat Parulian SimamoraNessuna valutazione finora

- EVM With Ms Project 2013Documento7 pagineEVM With Ms Project 2013Slamat Parulian SimamoraNessuna valutazione finora

- Jotafloor SL UniversalDocumento4 pagineJotafloor SL UniversalSlamat Parulian SimamoraNessuna valutazione finora

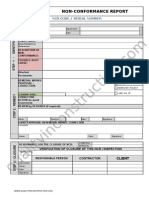

- Non-Conformance Report: NCR Code / Serial NumberDocumento1 paginaNon-Conformance Report: NCR Code / Serial NumberSlamat Parulian SimamoraNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)