Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Coil-Lock ... Hold-in-Device: From Power Quality Solutions Inc

Caricato da

velizarkoDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Coil-Lock ... Hold-in-Device: From Power Quality Solutions Inc

Caricato da

velizarkoCopyright:

Formati disponibili

110613

Coil-Lock ... Hold-in-Device

From Power Quality Solutions Inc.

Coil-Lock Applications Relays, contactors, and motor starters are used

extensively in commercial and industrial facilities to control business

machines and process equipment. These devices often have a low

tolerance to electric service voltage sags, and are diagnosed as weak

links in automated production lines. During common voltage sags, the

solenoid coils in these motor-driven systems may de-energize long

enough to cause the power circuit mechanical contacts to open, and the

connected electrical equipment to shutdown. This situation can disrupt

business operations and impact an entire manufacturing facility. The CoilLock eliminates costly process downtime, installs in minutes, and can

be a cost-effective alternative to other voltage sag protection methods.

The Coil-Lock product is available in different models to be compatible

with most relays, contactors, or solenoid coils, and is ideal for protecting

master control relays, and E-stop circuits.

A typical Coil-Lock weighs approximately 5 oz.

The Coil-Lock is designed to ensure that at any time input voltage is

(0.14kg) and measures 4 x 2 3/8 x 1 3/4.

present (down to ~25% of nominal voltage), the protected AC coil will

maintain enough energy to hold-in the critical process element. When the

input voltage goes below 25% of nominal, the Coil-Lock releases the coil, thereby ensuring that safety is not compromised,

and the on/off state operation of the existing process functions as intended. The key to properly applying Coil-Locks is to

determine the DC resistance of the AC coil of the relay/contactor unit you want to protect from deep voltage sags. Once you

have the AC coils DC resistance value, the next step is to select the appropriate model Coil-Lock listed on this sheet.

Coil-Lock Specifications

PERCENT OF NOMINAL VOLTAGE

Momentary Voltage Sag Range: Provides continuous output voltage to hold-in relay and contactor coils for all IEEE Std.

P1159 defined voltage sags to approximately 25% of nominal

Interruption Ride-Through Range: Designed to act as a discrete on/off device and will turn off the coil voltage if the Coil-Lock

input voltage is interrupted for a few cycles (depending on the relay/contactor rating and vendor model)

Coil Inrush Current: Provides required high inrush coil current during startup

Transient Surge Protection: Provides transient voltage

surge suppression for the relay/contactor coil circuit

Typical Unprotected vs.

Transient Surge Withstand: Designed to survive ANSI/IEEE

PQSI Coil-Lock Protected Devices

C62.41 Category A and Category B defined transient voltage

Voltage Sag Protection Performance

surges to 6kV/500A

Applied Environment: Designed to be compatible with stress

100

and

vibration common to typical commercial and industrial

Unprotected devices will ride

90

applications

through sags here

80

Ambient Temperature Operating Range: -29 C (-20F) to

+55 C (131F)

Steady-State Operating Voltage Range: Designed to

operate normally within 10% of nominal coil voltage

70

60

Devices protected by a Coil-Lock will

continue to keep contacts closed for

voltage sags in this region.

50

40

PQSI Coil-Lock Warranty Unconditional-free Coil-Lock

replacement for one year from date of purchase. Neither PQSI

nor its business associates are responsible for any production

loss or damage caused by a Coil-Lock misapplication or CoilLock failure.

30

20

Coil is de-energized in this region to maintain

safety function for emergency stop circuits.

10

0

0

DURATION IN CYCLES

For Technical Information Contact:

3 Seconds

Beginning at 100% voltage, a typical unprotected device

(yellow area) will trip when voltage sags by 25%. A device

protected with a Coil-Lock (green area) will be protected

when the voltage sags by 75%.

Phone: 865-671-8364 Fax: 800-881-2893

Visit our website at www.pqsi.com

or

e-mail us at customerservice@pqsi.com

040710

Coil-Lock Installation Procedures

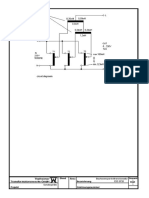

Step #1 Remove wires A and B, shown in Figure 1, from the relay/contactor coil and connect to octal mounting base socket

terminals 1 and 2, shown in Figure 2.

Step #2 Connect new wires from the octal mounting base socket terminals 3 and 4 to the relay/contactor where you removed

the wires in Step #1.

Step #3 Figure 3 below shows the physical orientation, locations, and terminal numbers of the octal mounting base socket

to provide a clearer understanding of terminal connections.

Application Advisories and Notes

[a] Coil-Locks are intended to interface with AC solenoid coil operated devices and may not be compatible with DC coil

operated devices or coils that have integral electronic circuitry as part of their operating strategy.

[b] In some AC coil applications, coil energy discharge devices such as rectifier diodes are pre-wired across the AC

coil. These devices should be removed before installing the Coil-Lock. After the Coil-Lock is installed, the Coil-Lock

provides the required AC coil discharge feature.

[c] For proper Coil-Lock operation, observe conventional isolation and grounding techniques on all Coil-Lock terminal

points and avoid any sneak ground paths.

[d] The Coil-Lock should be installed in an electrical / fire enclosure that complies with the applicable safety standard.

[e]

Safety Caution: Read all instructions thoroughly prior to installation. If this equipment is used in a manner not

specified, the protection provided by this equipment may be impaired.

[f]

Safety Caution: Risk of electric shock if this equipment is not connected in accordance with Figures 2 and 3

below.

[g] On equipment with LEDs to indicate the coil device is energized, while the coil device will operate properly, the LED

may not illuminate. Since the Coil-Lock output voltage is polarized, simply reverse the Coil-Lock connections on the

coil device.

Figure 1. Original Installation

Figure 3. Coil-Lock Octal Mounting Base Socket

Terminal Connection Layout

Start

Stop

OL

Line

Contactor

Coil

A

Control

Power

Supply

CR

Input Vac

CR

Neutral

Figure 2. After Installation of PQSI Coil-Lock

Stop

Line

Start

Control

Power

Supply

OL

A

CR

Input Vac

Neutral

PQSI 3

Coil-Lock

(Refer to

Figure 3)

Contactor

Coil

CR

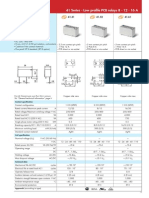

COIL-LOCK ~ 120V and 240V Models* (All Coil-Locks Include Din-Rail Octal Mounting Base Socket)

Model

Number

AC Coil Resistance

Measured w/DC Ohmmeter

Comments

1000-120V

801 to 4.5k Ohms [1]

UL Compliant File E255764

1001-120V

201 to 800 Ohms

[1]

UL Compliant File E255764

1002-120V

8 to 200 Ohms

[1]

UL Compliant File E255764

1002-120V-CE

8 to 200 Ohms

[1]

1003-120V

3 to 7.9 Ohms

[1]

UL Compliant File E255764

1001-240V

601 to 17.5k Ohms [2]

UL Compliant File E255764

1002-240V

155 to 600 Ohms

[2]

UL Compliant File E255764

1003-240V

20 to 154 Ohms

[2]

UL Compliant File E255764

UL & CE Compliant (50 ma no load, 0.4 Amps w/8 Ohm Coil)

[1] For use with 100 to 125 Vac 50/60 Hz relays and contactors only.

[2] For use with 200 to 240 Vac 50/60 Hz relays and contactors only.

*FOR PRICING

Call 865-671-8364

or e-mail customerservice@pqsi.com

Potrebbero piacerti anche

- Stevie Wonder - As (V. George Michael)Documento8 pagineStevie Wonder - As (V. George Michael)rfontanabr100% (1)

- MINI Cooper Service Manual 2002 2006 Table of ContentsDocumento176 pagineMINI Cooper Service Manual 2002 2006 Table of ContentsJoel Victoria100% (1)

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsDa EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsValutazione: 3 su 5 stelle3/5 (2)

- Winrar Password Remover 2015 Crack Plus Activation KeyDocumento15 pagineWinrar Password Remover 2015 Crack Plus Activation Keysiyamsanker722160% (5)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- Service Manual Type MRSU 04 Rotor Earth Fault RelayDocumento24 pagineService Manual Type MRSU 04 Rotor Earth Fault RelayRinda_RaynaNessuna valutazione finora

- Service Manual Type MCSU 01 Sensitive Earth Fault RelayDocumento24 pagineService Manual Type MCSU 01 Sensitive Earth Fault RelayRinda_Rayna100% (1)

- I9-083G Novar 300Documento16 pagineI9-083G Novar 300Rinda_Rayna0% (1)

- Commissioning Instructions Motormaster 200 Motor Protection RelaysDocumento20 pagineCommissioning Instructions Motormaster 200 Motor Protection RelaysRinda_RaynaNessuna valutazione finora

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionNessuna valutazione finora

- Kitz 101 102 User ManualDocumento36 pagineKitz 101 102 User ManualMohd Zulfiqar100% (1)

- KVTR 100Documento114 pagineKVTR 100gutman0464289Nessuna valutazione finora

- R8505 KVTR100Documento88 pagineR8505 KVTR100Rinda_RaynaNessuna valutazione finora

- MCGG Over Current RelayDocumento34 pagineMCGG Over Current Relaysilkwormfrog100% (2)

- Kavr100 DDocumento130 pagineKavr100 DIndra Aryana0% (1)

- KCGG Kceg Service ManualDocumento284 pagineKCGG Kceg Service Manualisola_zhou100% (1)

- HAT Series Air Circuit Breaker Hyundai ElectricDocumento67 pagineHAT Series Air Circuit Breaker Hyundai Electricthanhlangdai67% (6)

- MVTP Manual GB PDFDocumento22 pagineMVTP Manual GB PDFVikash Kumar PrasadNessuna valutazione finora

- VTT11 AlstomDocumento6 pagineVTT11 AlstomShubhasish SarkarNessuna valutazione finora

- ACB ManualDocumento42 pagineACB Manual4usangeetNessuna valutazione finora

- Type MCAG 14, 34: High Stability Circulating Current RelaysDocumento30 pagineType MCAG 14, 34: High Stability Circulating Current Relaysrenjithas2005100% (2)

- R8605B M300 V2Documento268 pagineR8605B M300 V2Rinda_Rayna100% (2)

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- Installation And Maintenance Manual JOSLYN P/N 1455-85-M JOSLYN P/N 1455-85-MN Ac Power Arresters 208/120 VAC, 3φ, 4 WIRE, GROUNDED WYEDocumento8 pagineInstallation And Maintenance Manual JOSLYN P/N 1455-85-M JOSLYN P/N 1455-85-MN Ac Power Arresters 208/120 VAC, 3φ, 4 WIRE, GROUNDED WYEsrogan2323Nessuna valutazione finora

- Hyundai ACB Catalog SP HATDocumento68 pagineHyundai ACB Catalog SP HATtommagne100% (1)

- Nursing Informatics 2018Documento66 pagineNursing Informatics 2018Undher Ground Maker100% (5)

- Scrum: The Art of Doing Twice The Work in Half The TimeDocumento3 pagineScrum: The Art of Doing Twice The Work in Half The TimeSyarifudin Zuhri100% (3)

- R8618a M220Documento68 pagineR8618a M220Rinda_RaynaNessuna valutazione finora

- R8017G MBCHDocumento52 pagineR8017G MBCHmjbriceno@gmail.com100% (1)

- Areva MVTT Relay ManualDocumento42 pagineAreva MVTT Relay ManualjbatoyNessuna valutazione finora

- R5888C Quadramho A4RBDocumento336 pagineR5888C Quadramho A4RBdbeard811100% (1)

- PQSI Coil Lock Model 1003Documento2 paginePQSI Coil Lock Model 1003prabuNessuna valutazione finora

- Coil-Lock ... Hold-in-Device: From Power Quality Solutions IncDocumento2 pagineCoil-Lock ... Hold-in-Device: From Power Quality Solutions IncAUGUSTA WIBI ARDIKTANessuna valutazione finora

- Weidmuller OptocouplersDocumento34 pagineWeidmuller Optocouplersspeedy65Nessuna valutazione finora

- R8501G K1RangeDocumento208 pagineR8501G K1RangeRinda_RaynaNessuna valutazione finora

- Service Manual Type LFCB102 Digital Current Differential RelayDocumento211 pagineService Manual Type LFCB102 Digital Current Differential RelayRinda_RaynaNessuna valutazione finora

- KVGCDocumento46 pagineKVGCLê Văn PhúNessuna valutazione finora

- ABB RCCB F 804Documento12 pagineABB RCCB F 804catalinccNessuna valutazione finora

- 3089-99 RCCB F660Documento16 pagine3089-99 RCCB F660Nguyen SonNessuna valutazione finora

- R8033C MvtiDocumento28 pagineR8033C MvtiRinda_RaynaNessuna valutazione finora

- Cable ConnectionDocumento14 pagineCable Connectionmeeraneela0808Nessuna valutazione finora

- Electric Power Voltage Sag Solutions-The PQSI Coil-LockDocumento18 pagineElectric Power Voltage Sag Solutions-The PQSI Coil-LockKoti Reddy DoddaNessuna valutazione finora

- Service Manual Type MWTU 11 Forward and Reverse Power RelayDocumento32 pagineService Manual Type MWTU 11 Forward and Reverse Power RelaymarkgaloNessuna valutazione finora

- RxtcsDocumento6 pagineRxtcsEr Anoop GuptaNessuna valutazione finora

- KVTLDocumento56 pagineKVTLgj42107Nessuna valutazione finora

- R8005C MvawDocumento20 pagineR8005C MvawRinda_RaynaNessuna valutazione finora

- Samsung TXJ2567 - Chassis K51ADocumento65 pagineSamsung TXJ2567 - Chassis K51AElectronica ReyNessuna valutazione finora

- Instructions For Cutler-Hammer LDB, LD, HLD, HLDB, LDC, LW, HLW, LWC, CLD, CHLD, CLDC Circuit Breakers and L-Frame Series C SwitchesDocumento12 pagineInstructions For Cutler-Hammer LDB, LD, HLD, HLDB, LDC, LW, HLW, LWC, CLD, CHLD, CLDC Circuit Breakers and L-Frame Series C Switchespayolin77Nessuna valutazione finora

- 700W1000W User ManualDocumento19 pagine700W1000W User Manualvanhuong87Nessuna valutazione finora

- Controllogix Voltage/Current Input Module: Installation InstructionsDocumento20 pagineControllogix Voltage/Current Input Module: Installation InstructionsMarco RojasNessuna valutazione finora

- Service Manual Type MHOA 04, MHOB 04, MHOC 04 Translay Feeder Protection SchemesDocumento36 pagineService Manual Type MHOA 04, MHOB 04, MHOC 04 Translay Feeder Protection SchemesRinda_RaynaNessuna valutazione finora

- Manual de UPS Del Mamografo de La PoliciaDocumento30 pagineManual de UPS Del Mamografo de La PoliciaaxsalazarNessuna valutazione finora

- Chap 13 PLC Installation PracticesDocumento38 pagineChap 13 PLC Installation PracticesHasan JomaaNessuna valutazione finora

- Regulador de Voltage KVGC 202Documento168 pagineRegulador de Voltage KVGC 202enriqueunoNessuna valutazione finora

- RFL 9550 Line TrapDocumento12 pagineRFL 9550 Line TrapSINU0607IITEEENessuna valutazione finora

- Samsung Sv5000W-1 PDFDocumento103 pagineSamsung Sv5000W-1 PDFsigi_204Nessuna valutazione finora

- R8124B MJTW01Documento150 pagineR8124B MJTW01Rinda_RaynaNessuna valutazione finora

- MVAJ053Documento38 pagineMVAJ053Yusof BasriNessuna valutazione finora

- Alstom Scs Skd-Ske11Documento4 pagineAlstom Scs Skd-Ske11Nihal K JoshiNessuna valutazione finora

- ULN2004AC-inversor LvadoraDocumento8 pagineULN2004AC-inversor Lvadoraarturo_hernandez_78Nessuna valutazione finora

- Elpa SineDocumento12 pagineElpa SinevelizarkoNessuna valutazione finora

- LPA05Documento2 pagineLPA05velizarkoNessuna valutazione finora

- TLE2061 PrecisionDocumento82 pagineTLE2061 PrecisionvelizarkoNessuna valutazione finora

- TX IrhsDocumento1 paginaTX IrhsvelizarkoNessuna valutazione finora

- SP ESS9720 Transformer DatasheetDocumento1 paginaSP ESS9720 Transformer DatasheetvelizarkoNessuna valutazione finora

- Tsal7200: High Power Infrared Emitting Diode, 950 NM, Gaalas/GaasDocumento6 pagineTsal7200: High Power Infrared Emitting Diode, 950 NM, Gaalas/GaasvelizarkoNessuna valutazione finora

- Avago HLCP j100, HDSP 48xxDocumento7 pagineAvago HLCP j100, HDSP 48xxvelizarkoNessuna valutazione finora

- ADocumento10 pagineAVictor PuglieseNessuna valutazione finora

- Manual QS enDocumento24 pagineManual QS envelizarkoNessuna valutazione finora

- HF Shunts PPA Mar 2012Documento1 paginaHF Shunts PPA Mar 2012velizarkoNessuna valutazione finora

- For Pricing, Delivery, and Ordering Information, Please Contact Maxim/Dallas Direct! atDocumento12 pagineFor Pricing, Delivery, and Ordering Information, Please Contact Maxim/Dallas Direct! atvelizarkoNessuna valutazione finora

- TLC 7628Documento12 pagineTLC 7628velizarkoNessuna valutazione finora

- Finder 16A 12V DC Relay Datasheet.Documento10 pagineFinder 16A 12V DC Relay Datasheet.velizarkoNessuna valutazione finora

- Features: NA555, NE555, SA555, SE555 Precision TimersDocumento24 pagineFeatures: NA555, NE555, SA555, SE555 Precision TimersvelizarkoNessuna valutazione finora

- Single/Dual, Ultra-Fast, Low-Power Precision TTL ComparatorsDocumento11 pagineSingle/Dual, Ultra-Fast, Low-Power Precision TTL ComparatorsvelizarkoNessuna valutazione finora

- HEF4104B: 1. General DescriptionDocumento14 pagineHEF4104B: 1. General DescriptionvelizarkoNessuna valutazione finora

- A Key To Dutch HistoryDocumento115 pagineA Key To Dutch HistoryvelizarkoNessuna valutazione finora

- Ramdump Modem 2023-09-07 07-20-23 PropsDocumento26 pagineRamdump Modem 2023-09-07 07-20-23 PropsIván Carrera YentzenNessuna valutazione finora

- KVT-516 - Owners Manual - EnglishDocumento100 pagineKVT-516 - Owners Manual - EnglishgmwesleyNessuna valutazione finora

- OPM Assignment 1Documento11 pagineOPM Assignment 1Azka FarooquiNessuna valutazione finora

- Regulator Temperatura E5 - C Users ManualDocumento392 pagineRegulator Temperatura E5 - C Users ManualFaulhaber AdrianNessuna valutazione finora

- Benchmark - Big Haul Manual.1733Documento20 pagineBenchmark - Big Haul Manual.1733James GillenwaterNessuna valutazione finora

- 19Documento12 pagine19Bianka MátéNessuna valutazione finora

- Australian Mining 4.0 v15anonymousEDfinal002Documento21 pagineAustralian Mining 4.0 v15anonymousEDfinal002Camila Araya maluendaNessuna valutazione finora

- Coimbatore RegionDocumento195 pagineCoimbatore RegionThiruvengadam CNessuna valutazione finora

- Internet of ThingsDocumento29 pagineInternet of ThingsRochelle SiolaoNessuna valutazione finora

- Digital Logic Design 5th Edition Chap 3 NotesDocumento32 pagineDigital Logic Design 5th Edition Chap 3 NotesHelly BoNessuna valutazione finora

- Eagle Point Tutorial - Cross SectionDocumento9 pagineEagle Point Tutorial - Cross Sectionqadiradnan7177100% (6)

- Netflix 1Documento22 pagineNetflix 1CarmenNessuna valutazione finora

- UMC Series - Driver ReadMe - 2019 04 02 PDFDocumento3 pagineUMC Series - Driver ReadMe - 2019 04 02 PDFLeo Do Monte0% (1)

- Multistage Coil Gun Project ProposalDocumento8 pagineMultistage Coil Gun Project ProposalAbdullah ArifNessuna valutazione finora

- Transformer Monitoring Systems - MRDocumento4 pagineTransformer Monitoring Systems - MRKelly chatingNessuna valutazione finora

- Social Networking The Third Place and The Evolution of CommunicationDocumento11 pagineSocial Networking The Third Place and The Evolution of CommunicationAli Bora AygünNessuna valutazione finora

- A Novel Security Framework Using Trust and Fuzzy Logic in ManetDocumento15 pagineA Novel Security Framework Using Trust and Fuzzy Logic in ManetijdpsNessuna valutazione finora

- ReadmeDocumento60 pagineReadmetimur_okNessuna valutazione finora

- Mobius Industries Marketing CVDocumento2 pagineMobius Industries Marketing CVIssy TurtonNessuna valutazione finora

- HB-2048-001 1099590 QIAgility Unpacking and Installation GuideDocumento4 pagineHB-2048-001 1099590 QIAgility Unpacking and Installation GuideSHOBHANessuna valutazione finora

- Curriculum - RobochampsDocumento16 pagineCurriculum - RobochampsSarimNessuna valutazione finora

- Crash - Log - 2023 04 01 22 36 07Documento2 pagineCrash - Log - 2023 04 01 22 36 07Aizen HamburgerNessuna valutazione finora

- 8-Week SQL Challenge Data Bank. Transaction Data Analysis-Case Study #4 by Chisom Promise MLearning - Ai Apr, 2023 MediumDocumento26 pagine8-Week SQL Challenge Data Bank. Transaction Data Analysis-Case Study #4 by Chisom Promise MLearning - Ai Apr, 2023 Mediumshmasood55Nessuna valutazione finora

- Project Communication PlanDocumento5 pagineProject Communication PlanCraig VanceNessuna valutazione finora

- Accu-Chek Active User Manual PDFDocumento70 pagineAccu-Chek Active User Manual PDFjoseluisblanco69Nessuna valutazione finora

- MECHANICAL - Muhammad Shafiq Bin Roslan - 0139724098Documento3 pagineMECHANICAL - Muhammad Shafiq Bin Roslan - 0139724098philljohnNessuna valutazione finora