Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MSDS PanaOIL Goslide 46

Caricato da

D Wahyu BawonoDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MSDS PanaOIL Goslide 46

Caricato da

D Wahyu BawonoCopyright:

Formati disponibili

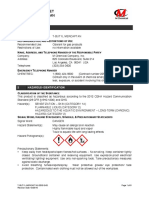

PT Pana Oil Indonesia

MATERIAL SAFETY DATA SHEET

1. LUBRICATING PRODUCT AND COMPANY IDENTIFICATION

PRODUCT NUMBER (S) : NPM MT 002

Coverage : PanaOIL Goslide 46

COMPANY IDENTIFICATION

EMERGENCY TELEPHONE NUMBERS

PT Pana Oil Indonesia

Ruko Renata Sutera, Kav.18A

Jl. Jalur Sutera Timur blok 3B, No.2

Alam Sutera, Tangerang 15144

Health (24 h)

Office hours

Attention

:+(62)254 310 715

:+(62) 21 29 211 784

: Health & Safety Dept.

PRODUCT INFORMATION

MSDS Requests : +(62) 21 29 211 784

Technical Info : +(62) 21 29 211 783

2. COMPOSITION / INFORMATION ON INGREDIENTS

100.00 % Slideways Oil

CONTAINING

COMPONENTS

AMOUNT

Coconut Fatty Amine

0.1-0.2 % wt

61788-46-3

Alkyl Phosphite

< 0.4 % wt

Alkyl Diaryl Amine

< 0.5 % wt

Highly refined mineral oil

98.9 - 99 % wt

3. HAZARDS

LIMIT/QTY

CAS No.

IDENTIFICATION

EYE :

Contact with the eyes causes irritation. If this material is heated, thermal burns may result from eye

contact.

SKIN

Contact with the skin may cause irritation. Contact with the skin may cause an allergic skin reaction. Not

expected to be harmful to internal organs if absorbed through the skin. If this material is heated,

thermal burns may result from skin contact.

INGESTION :

Not expected to be harmful is swallowed.

-1-

PT Pana Oil Indonesia

MATERIAL SAFETY DATA SHEET

INHALATION :

Contains a petroleum-based mineral oil. May cause respiratory irritation or other pulmonary effects

following prolonged or repeated inhalation of oil mist at airborne levels above the recommended mineral

oil mist exposure limit.

SIGNS AND SYMPTOMS OF EXPOSURE :

Eye irritation : may include pain, tearing, reddening, swelling, and impaired vision.

Thermal burns to the eye : may include pain, tearing, reddening, swelling, and impaired vision.

Symptoms of skin irritation or skin allergies may include pain, itching, reddening, swelling, and

blistering.

Thermal burns to the skin : may include pain or feeling of heat, discoloration, swelling, and blistering.

Respiratory irritation : may include coughing and difficulty breathing.

4. FIRST AID MEASURES

EYE

:

Flush eyes with water immediately while holding the eyelids open. Remove contact lenses, if worn, after

initial flushing, and continue flushing for at least 15 minutes. Get medical attention if irritation persists.

If heated material should splash into eyes, flush eyes immediately with fresh water for 15 minutes while

holding the eyelids open. Remove contact lenses, if worn. Get immediate medical attention.

SKIN

Wash with soup and water. Get medical attention if rash or irritation develops. Launder contaminated

clothing before reuse.

If heated material gets on the skin, quickly cool with water or physiological saline. Apply mineral oil or

petroleum jelly after the skin is cooled to facilitate removal of the solidified material. Do not try to peel

the solidified material from the skin or use solvents or thinners to dissolve it. Get medical treatment for

extensive burns.

INGESTION :

DO NOT INDUCE VOMITING. No specific first aid measures are required because this material is not

expected to be harmful if swallowed. As a precaution and if conscious, give the person a glass of water or

milk to drink and get medical advice.

INHALATION :

Removed exposed person to fresh air if adverse effects are observed.

ADDITIONAL INFORMATION :

Note to physician : Treat Symptomatically

-2-

PT Pana Oil Indonesia

MATERIAL SAFETY DATA SHEET

5. FIRE FIGHTING MEASURES

FLAMMABLE PROPERTIES :

Flash Point : (COC) 220 oC

Auto ignition : NDA

Flammability Limits (% by volume in air) : Lower : NDA

Extinguishing Media :

CO2, dry chemical, and foam.

Upper : NDA

FIRE FIGHTING INSTRUCTIONS :

For fires involving this material, do not enter any enclosed or confined fire space without proper

protective equipment, including self-contained breathing apparatus.

UNUSUAL FIRE AND EXPLOSION HAZARDS :

Normal combustion forms carbon dioxide and water vapor and may produce oxides of Ca, P, N, S, B, Mo,

Zn. Incomplete combustion can produce carbon monoxide which is considered toxic as oxygen

insufficiency may occur.

6. ACCIDENTAL RELEASE MEASURES

ACCIDENTAL RELEASE MEASURES :

If heated material is spilled, allow it to cool before proceeding with disposal methods.

Personal Protective Equipment must be worn. Stop the source of the leak or release. Clean up releases as

soon as possible, observing precautions in Exposure Control /Personal Protection. Contain liquid to

prevent further contamination of soil, sewer and waterways. Clean up small spills using appropriate

techniques such as sorbent materials or pumping. Where feasible and appropriate, remove contaminated

soil. Follow prescribed procedures for reporting and responding to larger releases.

Check under Transportation and Labelling (DOT/CERLA) and Other Regulatory Information Section.

7. HANDLING AND STORAGE

Store in a dry place at room temperature. The protective measures as usual in the mineral oil industry

have to be observed. Adequate ventilation in working area. Protective glove must be worn. Anticipation

of splash to eyes should be taken.

Do not breathe vapor or fumes.

Avoid contaminating soil or releasing this material into sewage and drainage systems and bodies of

water.

Do not litter oil container to the environment as it containers retain product residue.

-3-

PT Pana Oil Indonesia

MATERIAL SAFETY DATA SHEET

8. EXPOSURE CONTROLS / PERSONAL PROTECTION

GENERAL CONSIDERATIONS :

Respiratory protection : avoid inhaling vapors

Eye protection : goggles

Hand protection : Chemical-resistant protective gloves according to DIN/EN 374 are recommended. Only

suitable for brief exposure. In the event of contamination, change protective gloves immediately. Avoid

skin contact with the wetted surfaces of the protective gloves

Wear suitable protective clothing

Keep away from foodstuffs and drinks. Wash hand before break and at the end of work. Keep working

clothes separate. Change contaminated or soaked clothing. When handling observe the usual

precautionary measures for chemicals.

9. PHYSICAL AND CHEMICAL PROPERTIES

PHYSICAL DESCRIPTION :

Dark Brown viscous liquid with petroleum odor.

pH

: NA

Vapor pressure

: NDA

Vapor density (AIR =1) : NDA

Boiling Point

: NDA

Freezing Point

: NDA

Melting Point

: NA

Pour Point

: -18 oC

Solubility

: Insoluble in water

Density

: 8657 Kg/L @ 60F

Viscosity

: 45.4 cSt @ 40oC

10. STABILITY AND REACTIVITY

DECOMPOSITION PRODUCTS :

Smoke, Carbon monoxide, Carbon dioxide, Aldehydes, and other products of incomplete combustion

PRODUCT STABILITY :

Stable at room temperature and pressure

INCOMPATIBILITY WITH OTHER MATERIALS :

Halogen, halogenated compounds, strong oxidizing agent of peroxide, Nitrates, peroxides, etc.

POLYMERIZATION :

Will not occur

-4-

PT Pana Oil Indonesia

MATERIAL SAFETY DATA SHEET

11. TOXICOLOGICAL INFORMATION

EYE EFFECTS :

Light to moderate eye irritation. Based on data from components and similar materials.

SKIN EFFECTS :

Light to moderate skin irritation.

ACUTE ORAL EFFECTS :

The LD 50 in rats is from 500 - 2000 mg/kg to > 5000 mg/kg. Based on data from components or similar

materials.

ADDITIONAL TOXICOLOGY INFORMATION :

No data available to indicate products or components may be a skin sensitizer.

No data available to indicate products or components may be respiratory sensitizer.

12. DISPOSAL CONSIDERATIONS

Place contaminated materials in disposable containers and dispose of in a manner consistent with

applicable regulations. Contact local environmental or health authorities for approved disposal of this

materials.

13. TRANSPORTATION INFORMATION

The description shown may not apply to all shipping situations.

DOT SHIPPING NAME

: NOT DESIGNATED AS A HAZARDOUS MATERIAL BY THE FEDERAL DOT

DOT HAZARD CLASS

: NOT APPLICABLE

DOT IDENTIFICATION NUMBER : NOT APPLICABLE

DOT PACKING GROUP : NOT APPLICABLE

14. REGULATORY INFORMATION

SARA 311 CATEGORIES :

1. Immediate (Acute) Health Effects

2. Delayed (Chronic) Health Effects

3. Fire Hazard

4. Sudden Release of pressure Hazard

5. Reactivity Hazard

:

:

:

:

:

YES

NO

NO

NO

NO

-5-

PT Pana Oil Indonesia

MATERIAL SAFETY DATA SHEET

ABBREVIATIONS THAT MAY HAVE BEEN USED IN THIS DOCUMENT :

TLV

: Threshold Limit Value

TWA

: Time Weighted Average

STEL

: Short-term Exposure Limit

TPQ

: Threshold Planning Company

RQ

: Reportable Quantity

PEL

: Permissible Exposure Limit

C

: Ceiling Limit

CAS

: Chemical Abstract Service Number

A1-5

: Appendix A Categories

()

: Change has been proposed

NDA

: No Data Available

NA

: Not Applicable

15. OTHER INFORMATION

The above information is based on the data of which we are aware and is believed to be correct as of the

date hereof. Since this information may be applied under conditions beyond our control and with which

we may be unfamiliar and since data made available subsequent to the date hereof may suggest

modification of the information, we do not assume any responsibility for the results of its use. This

information is furnished upon condition that the person receiving it shall make his own determination of

the suitability of the material for his particular purpose.

THIS IS THE LAST PAGE OF THIS MSDS

-6-

Potrebbero piacerti anche

- Ac-921 Foam Coil CleanerDocumento6 pagineAc-921 Foam Coil CleanerPaul Daniel TharmarajNessuna valutazione finora

- Safety Data Sheet: Chevron (Singapore) Diesel Gas OilDocumento8 pagineSafety Data Sheet: Chevron (Singapore) Diesel Gas OilMaza LufiasNessuna valutazione finora

- Safety Data Sheet: Chevron (Singapore) Diesel Gas OilDocumento8 pagineSafety Data Sheet: Chevron (Singapore) Diesel Gas OilWalter NativoNessuna valutazione finora

- Minimum Oil Circuit BreakerDocumento4 pagineMinimum Oil Circuit BreakergshdavidNessuna valutazione finora

- ZIC ATF-3 Material Safety Data SheetDocumento9 pagineZIC ATF-3 Material Safety Data SheetJose Angel MalumbresNessuna valutazione finora

- 04 - DNF-TiCl4 (Eng) v1.2 MSDS PDFDocumento9 pagine04 - DNF-TiCl4 (Eng) v1.2 MSDS PDFAlfrets Marade SianiparNessuna valutazione finora

- Safety Data Sheet: Section 2: Hazards IdentificationDocumento5 pagineSafety Data Sheet: Section 2: Hazards IdentificationaldiNessuna valutazione finora

- MSDS - Truck Wash No2Documento6 pagineMSDS - Truck Wash No2killischNessuna valutazione finora

- Safety Data Sheet: Chevron (Philippines) Diesel Fuel OilDocumento8 pagineSafety Data Sheet: Chevron (Philippines) Diesel Fuel OilRenalyn TorioNessuna valutazione finora

- Aquatower 170Documento6 pagineAquatower 170Diego y MagelaNessuna valutazione finora

- MSDS TELLUS S2 M68aDocumento5 pagineMSDS TELLUS S2 M68amflorian69Nessuna valutazione finora

- Paraxylene Safety Data Sheet CPChemDocumento14 pagineParaxylene Safety Data Sheet CPChemscribd405Nessuna valutazione finora

- Ficha de Datos de Seguridad Bitzer-BSE-170-OilDocumento7 pagineFicha de Datos de Seguridad Bitzer-BSE-170-OilMONTAJES IND VELANDIANessuna valutazione finora

- SDS Calcium PeroxideDocumento6 pagineSDS Calcium PeroxideMuhammad Iqbal ChandioNessuna valutazione finora

- Fleetguard DCA-4 Liquid - CumminsDocumento12 pagineFleetguard DCA-4 Liquid - CumminsYasser JaviNessuna valutazione finora

- Material Safety Data Sheet: Section 1: Product IdentificationDocumento7 pagineMaterial Safety Data Sheet: Section 1: Product Identificationcvolkan1Nessuna valutazione finora

- Heavy Duty Liquid Lanolin - LanotecDocumento3 pagineHeavy Duty Liquid Lanolin - LanotecBiju_PottayilNessuna valutazione finora

- IXOM Caustic Soda Pearls MSDSDocumento7 pagineIXOM Caustic Soda Pearls MSDSStariunNessuna valutazione finora

- SKF MSDS LGHP 2 PDFDocumento5 pagineSKF MSDS LGHP 2 PDFMunkhnasan MonaNessuna valutazione finora

- V-Clean 66 SDSDocumento11 pagineV-Clean 66 SDSIkhwanHasbullahNessuna valutazione finora

- MSDS of Matpers PH 991Documento4 pagineMSDS of Matpers PH 991jvd prasadNessuna valutazione finora

- MSDS Isothiazolinone - KRIDocumento6 pagineMSDS Isothiazolinone - KRIhsep3.kinruiNessuna valutazione finora

- 209 Flexo Wash SDSDocumento8 pagine209 Flexo Wash SDSNabil NnNessuna valutazione finora

- All Purpose Thinner Sep11Documento4 pagineAll Purpose Thinner Sep11Paul De ChaufepieNessuna valutazione finora

- Dettol Floor Cleaner NZ-V4.1-D8103889Documento7 pagineDettol Floor Cleaner NZ-V4.1-D8103889Hana AlghamdiNessuna valutazione finora

- Titan Electrical Contact CleanerDocumento8 pagineTitan Electrical Contact Cleanerhan-cong.thanhNessuna valutazione finora

- Eng Msds SHL Edm 32 (Re11)Documento6 pagineEng Msds SHL Edm 32 (Re11)duyvuNessuna valutazione finora

- MSDS Lube OilDocumento4 pagineMSDS Lube OilMohamed Sayed AbdoNessuna valutazione finora

- Exxsol D95Documento9 pagineExxsol D95Elisa Arroyo RodriguezNessuna valutazione finora

- Material Safety Data Sheet: 1. IdentificationDocumento10 pagineMaterial Safety Data Sheet: 1. IdentificationMai PhuongNessuna valutazione finora

- MSDS Kyoso Cutting OilDocumento4 pagineMSDS Kyoso Cutting Oilachwan febriantoNessuna valutazione finora

- Premalube Red MsdsDocumento3 paginePremalube Red Msdsfreddy william montalban palaciosNessuna valutazione finora

- Volvo Super Wet Brake Transaxle Oil-SDSDocumento7 pagineVolvo Super Wet Brake Transaxle Oil-SDSLaura Duran0% (1)

- MSDS 15W40Documento4 pagineMSDS 15W40Sukhjeet SinghNessuna valutazione finora

- Safety Data Sheet (SDS) : Nippon Grease Co., Ltd. E4377005 Date:June 1, 2016 Page.1/5Documento5 pagineSafety Data Sheet (SDS) : Nippon Grease Co., Ltd. E4377005 Date:June 1, 2016 Page.1/5Chanchai PrugpadeeNessuna valutazione finora

- Isopar HDocumento11 pagineIsopar Hwaxim26322Nessuna valutazione finora

- Material Safety Data Sheet: 1. IdentificationDocumento9 pagineMaterial Safety Data Sheet: 1. IdentificationsandeepNessuna valutazione finora

- Sodium Met A Period AteDocumento6 pagineSodium Met A Period AteFina Mustika SimanjuntakNessuna valutazione finora

- Aquatrol 362: Safety Data SheetDocumento6 pagineAquatrol 362: Safety Data SheetsitimaezyarohNessuna valutazione finora

- Material Safety Data Sheet: Coupling GreaseDocumento6 pagineMaterial Safety Data Sheet: Coupling GreaserefeiNessuna valutazione finora

- Safety Data Sheet: 1. Identification of The Material and Supplier Ixosurf LabsDocumento7 pagineSafety Data Sheet: 1. Identification of The Material and Supplier Ixosurf LabsJoseNessuna valutazione finora

- Corena Oil PDocumento5 pagineCorena Oil Pmingyu parkNessuna valutazione finora

- Dettol Antiseptic Wound Wash Spray-V4.1-D0258761Documento6 pagineDettol Antiseptic Wound Wash Spray-V4.1-D0258761Hana AlghamdiNessuna valutazione finora

- MSDS Petropath LimeDocumento8 pagineMSDS Petropath LimeAlok SinghNessuna valutazione finora

- Trichloroacetic AcidDocumento10 pagineTrichloroacetic Acidwillyvh99Nessuna valutazione finora

- MSDS - Unol7Documento8 pagineMSDS - Unol7mhaeducationNessuna valutazione finora

- Nitric AcidDocumento10 pagineNitric AcidCahyo ArdoyoNessuna valutazione finora

- Safety Data Sheet: Tokyo Chemical Industry Co., LTDDocumento5 pagineSafety Data Sheet: Tokyo Chemical Industry Co., LTDJonny DenNessuna valutazione finora

- Corena S3 R 46Documento7 pagineCorena S3 R 46Beryl FernandesNessuna valutazione finora

- Kerosene PDFDocumento9 pagineKerosene PDFishnafathonahNessuna valutazione finora

- Havoline Super 2T SDS 31899 21 Feb 2012Documento7 pagineHavoline Super 2T SDS 31899 21 Feb 2012Miguel TorresNessuna valutazione finora

- Material Safety Data Sheet: CrotonaldehydeDocumento6 pagineMaterial Safety Data Sheet: Crotonaldehydeharsh421Nessuna valutazione finora

- Safety Data Sheet T-Butyl Mercaptan: 1 IdentificationDocumento9 pagineSafety Data Sheet T-Butyl Mercaptan: 1 IdentificationJeremíasNessuna valutazione finora

- Havoline Super 2T: Safety Data SheetDocumento8 pagineHavoline Super 2T: Safety Data SheetMiguel TorresNessuna valutazione finora

- ZIC Royal Grease 3Documento10 pagineZIC Royal Grease 3UtkarshNessuna valutazione finora

- Y&X MSDS of SAXDocumento7 pagineY&X MSDS of SAXmishaNessuna valutazione finora

- Lsfo MSDS 2021Documento8 pagineLsfo MSDS 2021jayson lacuestaNessuna valutazione finora

- After a Disaster: Information to Help You and Your Family RecoverDa EverandAfter a Disaster: Information to Help You and Your Family RecoverNessuna valutazione finora

- TDS (Compressor) Amon SHCDocumento1 paginaTDS (Compressor) Amon SHCD Wahyu BawonoNessuna valutazione finora

- Cummins EnglishDocumento1 paginaCummins EnglishD Wahyu BawonoNessuna valutazione finora

- HTO Inspection Form - 030Documento1 paginaHTO Inspection Form - 030D Wahyu BawonoNessuna valutazione finora

- Monthly TS Activity Report - 029Documento1 paginaMonthly TS Activity Report - 029D Wahyu BawonoNessuna valutazione finora

- Msds Panaoil Lorent Z68Documento5 pagineMsds Panaoil Lorent Z68D Wahyu BawonoNessuna valutazione finora

- Laporan Hasil Analisa Pelumas - 015Documento1 paginaLaporan Hasil Analisa Pelumas - 015D Wahyu BawonoNessuna valutazione finora

- TDS (Transmission) Gotra DEX-IIIDocumento1 paginaTDS (Transmission) Gotra DEX-IIID Wahyu BawonoNessuna valutazione finora

- TDS (Specialties) Clean88Documento1 paginaTDS (Specialties) Clean88D Wahyu BawonoNessuna valutazione finora

- TDS (Marine) Neptun TP XTDocumento1 paginaTDS (Marine) Neptun TP XTD Wahyu BawonoNessuna valutazione finora

- Product CatalogueDocumento8 pagineProduct CatalogueD Wahyu BawonoNessuna valutazione finora

- Tds (Grease) Fett Chs-3Documento1 paginaTds (Grease) Fett Chs-3D Wahyu BawonoNessuna valutazione finora

- MSDS PanaOIL Amon SH 32 PDFDocumento5 pagineMSDS PanaOIL Amon SH 32 PDFD Wahyu BawonoNessuna valutazione finora

- TDS (Gas Engine) Natgas LA 40Documento1 paginaTDS (Gas Engine) Natgas LA 40D Wahyu BawonoNessuna valutazione finora

- HDC 40 Plus TDSDocumento1 paginaHDC 40 Plus TDSD Wahyu BawonoNessuna valutazione finora

- TDS (Marine) Neptun TP XTDocumento1 paginaTDS (Marine) Neptun TP XTD Wahyu BawonoNessuna valutazione finora

- TDS (Specialties) SolcutDocumento1 paginaTDS (Specialties) SolcutD Wahyu BawonoNessuna valutazione finora

- Tds (Grease) Fett Lm-2Documento1 paginaTds (Grease) Fett Lm-2D Wahyu BawonoNessuna valutazione finora

- Msds Panaoil Cruiser 15w-40Documento5 pagineMsds Panaoil Cruiser 15w-40D Wahyu BawonoNessuna valutazione finora

- Company ProfileDocumento8 pagineCompany ProfileD Wahyu Bawono0% (1)

- TDS (Igo) Pmo SynDocumento1 paginaTDS (Igo) Pmo SynD Wahyu BawonoNessuna valutazione finora

- MSDS PanaOIL Amon SH 32 PDFDocumento5 pagineMSDS PanaOIL Amon SH 32 PDFD Wahyu BawonoNessuna valutazione finora

- Msds Panaoil Circo 220Documento5 pagineMsds Panaoil Circo 220D Wahyu BawonoNessuna valutazione finora

- TDS (Igo) Igo SG 6000Documento1 paginaTDS (Igo) Igo SG 6000D Wahyu BawonoNessuna valutazione finora

- Tds (Igo) Medvac EpDocumento1 paginaTds (Igo) Medvac EpD Wahyu BawonoNessuna valutazione finora

- TDS (Hydraulic) Lorent ZNFDocumento2 pagineTDS (Hydraulic) Lorent ZNFD Wahyu BawonoNessuna valutazione finora

- TDS (Hydraulic) Lorent ZNFDocumento2 pagineTDS (Hydraulic) Lorent ZNFD Wahyu BawonoNessuna valutazione finora

- TDS (Diesel) Cruiser Advance PlusDocumento2 pagineTDS (Diesel) Cruiser Advance PlusD Wahyu BawonoNessuna valutazione finora

- TDS (Hydraulic) Lorent ZDocumento1 paginaTDS (Hydraulic) Lorent ZD Wahyu BawonoNessuna valutazione finora

- TDS (Diesel) Cruiser HDADocumento1 paginaTDS (Diesel) Cruiser HDAD Wahyu BawonoNessuna valutazione finora

- 2022 Audi e Tron 22Documento318 pagine2022 Audi e Tron 22Alejandro Alberto Robalino MendezNessuna valutazione finora

- Drilling & GroutingDocumento18 pagineDrilling & GroutingSantosh Laxman PatilNessuna valutazione finora

- Inverse of One-To-One FunctionDocumento4 pagineInverse of One-To-One FunctionKathFaye EdaNessuna valutazione finora

- 4 Force & ExtensionDocumento13 pagine4 Force & ExtensionSelwah Hj AkipNessuna valutazione finora

- DOC-20161226-WA0009 DiagramaDocumento61 pagineDOC-20161226-WA0009 DiagramaPedroNessuna valutazione finora

- June 2021 QP - Paper 1 (H) Edexcel Chemistry GCSEDocumento28 pagineJune 2021 QP - Paper 1 (H) Edexcel Chemistry GCSEmiapoppycollinsNessuna valutazione finora

- FRP Handrail Fittings CatalogDocumento6 pagineFRP Handrail Fittings CatalogAl Adel MorenoNessuna valutazione finora

- Contemporary Philippine Arts From The Regions: Quarter 2 - Module 9 Different Contemporary Art Techniques and PerformanceDocumento25 pagineContemporary Philippine Arts From The Regions: Quarter 2 - Module 9 Different Contemporary Art Techniques and PerformanceGrace06 Labin100% (7)

- S TR GEN ID (Component Marking) (Rev 3 2009) - AN Marked UpDocumento6 pagineS TR GEN ID (Component Marking) (Rev 3 2009) - AN Marked UpsnclgsraoNessuna valutazione finora

- tGr12OM CheResoBookU78910Documento110 paginetGr12OM CheResoBookU78910Jamunanantha PranavanNessuna valutazione finora

- Implicit Explicit SignalsDocumento8 pagineImplicit Explicit SignalsVersoza Nel100% (2)

- Electric ScootorDocumento40 pagineElectric Scootor01fe19bme079Nessuna valutazione finora

- Mean Variance Portfolio TheoryDocumento85 pagineMean Variance Portfolio TheoryEbenezerNessuna valutazione finora

- Dawn of Solar PV CookingDocumento5 pagineDawn of Solar PV CookingAbhinav AgrawalNessuna valutazione finora

- Course Syllabus: Course Code Course Title ECTS CreditsDocumento3 pagineCourse Syllabus: Course Code Course Title ECTS CreditsHanaa HamadallahNessuna valutazione finora

- Gemh 108Documento20 pagineGemh 108YuvrajNessuna valutazione finora

- Fundamentals of Pain Medicine: Jianguo Cheng Richard W. RosenquistDocumento346 pagineFundamentals of Pain Medicine: Jianguo Cheng Richard W. RosenquistMayNessuna valutazione finora

- Updated Factory Profile of Aleya Apparels LTDDocumento25 pagineUpdated Factory Profile of Aleya Apparels LTDJahangir Hosen0% (1)

- Awakened Citizen Programme-Report-class VII-2014Documento4 pagineAwakened Citizen Programme-Report-class VII-2014bhsgeneral r m saraswathi50% (4)

- Middle Range Theory Ellen D. Schulzt: Modeling and Role Modeling Katharine Kolcaba: Comfort TheoryDocumento22 pagineMiddle Range Theory Ellen D. Schulzt: Modeling and Role Modeling Katharine Kolcaba: Comfort TheoryMerlinNessuna valutazione finora

- Schneider Pressure Switch XMLDocumento2 pagineSchneider Pressure Switch XMLhaoNessuna valutazione finora

- 外贸专业术语Documento13 pagine外贸专业术语邱建华Nessuna valutazione finora

- Kinematics in One DimensionDocumento4 pagineKinematics in One DimensionAldrin VillanuevaNessuna valutazione finora

- ZF-FreedomLine TransmissionDocumento21 pagineZF-FreedomLine TransmissionHerbert M. Zayco100% (1)

- Anxiety Disorders - Causes, Types, Symptoms, & TreatmentsDocumento5 pagineAnxiety Disorders - Causes, Types, Symptoms, & Treatmentsrehaan662Nessuna valutazione finora

- AoS Soulbound - Pregens - Skyrigger Malgra DainssonDocumento2 pagineAoS Soulbound - Pregens - Skyrigger Malgra DainssonAdrien DeschampsNessuna valutazione finora

- EPCC Hydrocarbon Downstream L&T 09.01.2014Documento49 pagineEPCC Hydrocarbon Downstream L&T 09.01.2014shyaminannnaNessuna valutazione finora

- Dusta ManaDocumento16 pagineDusta ManamahaphalaNessuna valutazione finora

- MTH100Documento3 pagineMTH100Syed Abdul Mussaver ShahNessuna valutazione finora

- Prestige Institute of Management & Research: Guided By:-Submitted By: - Prof. Arpit Loya Sumeet RattanDocumento21 paginePrestige Institute of Management & Research: Guided By:-Submitted By: - Prof. Arpit Loya Sumeet RattanSumeet700005Nessuna valutazione finora