Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Us5353871 PDF

Caricato da

mohammadreza91Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Us5353871 PDF

Caricato da

mohammadreza91Copyright:

Formati disponibili

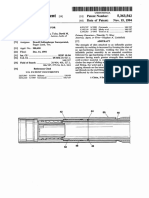

USOO5353871A

United States Patent [19]

[11] Patent Number:

Eslinger et a1.

[45]

[54]

INFLATABLE PACKER WITH PROTECTIVE

4,892,144

RINGS

[75]

Inventors:

David M. Eslinger, Broken Arrow,

Dowell Schlumberger Incorporated,

Sugar Land, Tex.

_

'

[51]

"

1/1990 Coone ........................... .. 166/187 x

P'Tma'y Exammer_Ramn 5- Butts

Assistant Examiner-Frank S. Tsay

Attorney, Agent, or Firm-Stephen A. Little?eld

[57]

[21] Appl NO _ 128 353

[22] Filed:

Oct. 11, 1994

4,979,570 12/1990 Mody ................ .. 166/187 X

5,280,824 1/1994 Eslinger et a1. ................... .. 166/187

_

.

.

Okla; Robert M. Sorem, Sugar Land,

Tex

[73] Assignee:

Date of Patent:

5,353,871

ABSTRACT

An in?atable packer apparatus having an inner elasto

mer sleeve covered by armor such as overlapped, longi

Sep. 28, 1993

tudinal slats that extend between upper and lower col

Int Cl 5 ....................................... .. E21B 33/127

1am The end Pr?m f Such slats Pass thmugh Stress

[52] US. cl. :...:..' ..................... .. 166/187- 166/195

?ngs having madly ?ared 1186 PYtinS1 and thin

[58] Field Of Search .............. .. 166/187 191 179 122

.

[56]

Protector rings "muted inside the R086 Pm'lkms are

employed to distribute very localized contact loads

References Clted

Us. PATENT DOCUMENTS

form the edge of the slats to the stress rings to prevent

the formation of cracks in such rings. The apparatus

X

further includes an elastomeric sleeve member which is

guzcason """"""""""" " 1662:; X

4,082,298 4/1978 salgordof..::::::::::::l 166/187 X

166 1

expanded into sealing contact with a well bore wall by

?uid Pressure applied to the inside f the inner elast"

4,406,461

menc Sleeve member

9/1983 McGill .......................... .. 166/187 X

4,886,117

4,424,861 12/1989

l/l984 Carter,

Patel ..................................

Jr. et al. .

.. 166/187

4 Claims, 1 Drawing Sheet

73 via

27

f

I7

l0

/

,7/15

/

20

/

I

/

22

I

/

l4 --/'

/

US. Patent

5,353,871

Oct. 11, 1994

FIG. 7

V/

/

a

27 25

24

23

30

2725

30

34

FIG. 3

FIG. 4

5,353,871

BRIEF DESCRIPTION OF THE DRAWINGS

The present invention has other objects, features and

advantages which will become more clearly apparent in

connection with the. following detailed description of

preferred embodiments in which:

INFLATABLE PACKER WITH PROTECTIVE

RINGS

FIELD OF THE INVENTION

This invention relates generally to improved in?at

FIG. 1 is a schematic view showing an in?atable

packer disposed in a well bore on a running string;

a well, and particularly to a slat-style in?atable packer

where thin protector rings are attached to the stress 10 FIG. 2 is a fragmentary isometric view of the in?at

able packer shown in FIG. 1;

rings at the ends of the packer element to prevent dam

FIG. 3 is a fragmentary, enlarged sectional view that

age to such rings during operation at high differential

illustrates

one embodiment of a protector ring of the

pressures.

able packers that are used to bridge or isolate a zone in

present invention; and

FIG. 4 is a view similar to FIG. 3 showing another

BACKGROUND OF THE INVENTION

15 embodiment of the invention.

In?atable packers are used in the oil industry during

testing, completion and workover operations to bridge

DETAILED DESCRIPTION OF PREFERRED

a well bore or to isolate a zone therein. A typical in?at

EMBODIMENTS

able packer has a tubular body that carries upper and

Referring initially to FIG. 1, an in?atable packer 10 is

lower retainer rings to which the adjacent ends of an 20 shown suspended in a well bore 21 on a running string

in?atable packer element are attached. In response to

12 of jointed or coil tubing. The packer 10 includes a

the application of ?uid pressure to the inside of the

tubular body 8 that carries upper and lower retainer

packer element, it expands outward into sealing engage

rings 13, 14. A packer element 15 includes an inner

ment with the surrounding well bore well.

elastomer sleeve 16 (FIG. 2) which has its opposite ends

One type of in?atable packer element has an inner 25 secured to collars which are mounted inside the retainer

elastomer sleeve or bladder that is surrounded by an

rings 13, 14, such sleeve being surrounded by an armor

armor assembly which can be a plurality of circumfer

assembly that and includes a plurality of circumferen

entially spaced, overlapped slats, reverse-layed cables,

tially spaced, partially overlapped metal slats 17. The

or a composite of woven materials such as cables or

30 opposite ends of the slats 17 also are secured to inner

wires. An outer elastomer sleeve covers all or a part of

metal rings by welding or the like. Although an over

the armor assembly to provide a leak proof seal with the

well bore wall when the inner sleeve is pressurized and

expanded. The end portions of the armor assembly

extend underneath stress rings to where they are joined 35

to retainer rings by welding. During operation of the

lapped slat-type construction is shown, the armor as

sembly could comprise opposite layed cables, or a com

posite of woven cables or wires. To provide a leak

proof seal against the well bore wall, an outer elastomer

sleeve 20 covers at least a portion of the slats 17 so as to

packer at high differential pressures, each end portion

be pressed against the well wall when internal ?uid

pressure is applied to expand the inner sleeve 16 and the

of the armor has outer .edges that tend to indent the

slats 17.

nose of its associates stress ring which can cause one or

Upper and lower stress ring assemblies 21, 22 are

more small initial cracks to appear therein. Since the 40

mounted adjacent the retainer rings 13, 14 as shown in

stress ring is very highly stressed normal to such inden

FIG. 1. Each stress ring 25 is generally tubular and has

tations, the cracks tend to propagate and cause failure

on the stress ring and thus the packer element. Thus

such indentations can limit the operating differential

an outer cylindrical surface 23 that can be somewhat

vide a new and improved in?atable packer of the type

has an inner surface 33 that ?ares outward, as shown, in

order to distribute the bending of the slat or other armor

portions over a substantial radius when the element 16 is

50 expanded so that such portions do not undergo perma

larger than the o.d. of the back-up ring 24, and an irmer

45 cylindrical surface 28 that ?ts closely around the end

pressure of the packer in an undesirable manner.

portions of the slats 17. The nose 30 of each stress ring

The general object of the present invention is to pro

described having protectors which distribute the local

ized loads and thereby minimize indentations in the

packer stress rings under high differential pressure oper

nent deformation that might otherwise prevent the ele

ment from fully retracting when in?ation pressure is

released.

SUMMARY OF THE INVENTION

As shown in FIG. 2, the slats 17 have outer edges 32

This and other objects of the present invention are

55 that tend to make indentations in the inner surface of the

attained through the provision of an in?atable packer

nose 30 of a stress ring 25 under high differential pres

apparatus which include thin protector rings which are

ations.

'

mounted so as to cover the nose portions of each stress

sure, which can cause small cracks to appear therein.

Such cracks tend to propagate, once formed, which can

ring which surround end portions of the armor. Such

lead to packer failure. In order to prevent such indenta

protector rings closely match the contour of the noses

tions, a thin protector ring 34 is attached inside the nose

of the stress rings, or can initially have a cylindrical

portion 30 of each stress ring 25 as shown in FIG. 3.

cross-section that is formed to the shape of the stress

The ring 34, which can be made of copper, brass, plastic

ring nose by the end portions of the armor during opera

or a similar material, has a pro?le that closely matches

tion of the packer. The rings function to distribute very

the ?ared contour of the stress ring nose portion 30, and

localized slat contact loads, which minimizes indenta 65 thus distributes the very localized contact loads to mini

tions in the stress rings and the formation of cracks.

mize indentations in the stress ring. In this manner the

Thus the operating differential pressure of the in?atable

operating differential pressure of the. packer 10 is sub

packer is substantially improved.

stantially improved.

5,353,871

As shown in FIG. 4, another embodiment of a protec

tor ring 35 initially has a cylindrical cross-section that is

formed to the contour of the inner ?ared surface 33 of

the stress ring nose 30 by outward pressure of the slats

Of course the packer 10 could be permanently set in the

well bore by maintaining the in?ation pressure.

It now will be recognized that a new and improved

in?atable packer apparatus has been provided which

includes thin protection rings which distribute very

17 during operation of the packer 10. Here again the

very localized contact loads are distributed in a manner

localized contact loads on stress rings to prevent or at

that minimizes any indentations in a stress ring, so that

least minimize the formation of cracks in the stress rings

the operating differential pressure of the packer is sub

or collars, thereby improving the operating differential

stantially improved. The ring 35 can be made of the

pressure of the packer. The armoring material which is

same material of the other ring 34.

10 used in the packer assembly can be overlapped slat,

reverse-layed cables, or composite woven cables or

wires. Since certain changes or modi?cations may be

OPERATION

In operation the packer 10 is assembled as shown in

the drawings and is lowered into the well bore 11 on the

made in the disclosed embodiment without departing

from the inventive concepts involved, it is the aim of the

appended claims to cover all such changes and modi?

cations falling within the true spirit and scope of the

running string 12. Although the well bore 11 is shown in

FIG. 1 as being cased at 9, it can be uncased (open hole).

When the packer 10 has been lowered to setting depth,

pressure is applied to the interior of the elastomer sleeve

16 via the running string 12 which causes the packer

present invention.

What is claimed is:

1. An in?atable well packer apparatus comprising: a

tubular body member carrying upper and lower con

nector sleeves; armoring means extending between and

element 15 to expand or balloon outward until the outer

elastomer sleeve 20, as well as the uncovered portions

of the slats 17, engage the well bole wall. The sleeve 20

connected to said connector sleeves; an inner elastomer

prevents ?uid leakage, while the slat portions 17 pro

sleeve member between said body member and said

vide a frictional anchor against longitudinal movement.

armoring means; an outer elastomer sleeve member

The packer 10 provides a bridge in the well bore 11 25 covering at least a portion of said armoring means; an

which enables various service work to be done.

The inner surfaces of the thin protector ring 34

shown in FIG. 3 are engaged by the outer edges 31 of

the overlapped slats 17 so that localized contact loads

upper stress ring mounted adjacent said upper connec

tor sleeve and a lower stress ring mounted adjacent said

lower connector sleeve, each of said stress rings sur

rounding an end portion of said armor means; and pro

are distributed in a manner that minimizes the formation 30 tective ring means positioned inside each of said stress

of indentations in the stress ring and resulting cracks

rings for distributing localized loads applied by said end

that can cause failure thereof. The embodiment shown

portions of said armor means to said stress rings during

in?ation and expansion of said packer apparatus to pre

in FIG. 4 works in a similar manner except that the

sleeve 35, which is initially cylindrical, is formed into

the generally outwardly ?ared shape of the ring surface

vent the formation of cracks in said stress rings in re

35 sponse to said loads.

33 by the outward pressure of the slat portions during

expansion of the in?atable packer element 15. Thus

2. The apparatus of claim 1 wherein each of said

stress rings has a nose portion with an outward ?ared

formed, the rings 34 or 35 distribute loads to the stress

irmer surface, said protective ring means each compris

rings 25 so that the formation of cracks therein is mini

ing a thin member having a pro?le that closely matches

mized.

4-0 the contour of said ?ared irmer surface.

If it is desired to retract the packer element 15 so that

3. The apparatus of claim 1 wherein each of said

the packer assembly 10 can be either removed from the

stress rings has a nose portion with an outwardly ?ared

well, or moved to another setting location, the ?uid

pressure that is being applied to the interior of the inner

inner surface, said protective ring means each compris

ing a thin cylindrical member located within said ?ared

elastomer sleeve 16 is relieved so that it inherently re 45 surface and arranged to be spread outward into confor

tracts to a tubular form on account of its resilience. For

mity with said ?ared inner surface as said packer appa

the same reason, the slats 17 also straighten to their

ratus is in?ated.

original positions. Of course the outer sleeve 20 which

4. The apparatus of claim 1 wherein said armor means

includes circumferentially spaced, overlapped metal

also is made of an elastomeric material, returns to its

original retracted condition. Then the packer assembly

50 slat members.

10 is free to be moved longitudinally in the well bore 11.

55

65

1i

Potrebbero piacerti anche

- Us 20050077053Documento16 pagineUs 20050077053mohammadreza91Nessuna valutazione finora

- Us 5988287Documento14 pagineUs 5988287mohammadreza91Nessuna valutazione finora

- Viii/Ii/Ii": United States Patent (191 (11) Patent Number: 4,708,208Documento9 pagineViii/Ii/Ii": United States Patent (191 (11) Patent Number: 4,708,208mohammadreza91Nessuna valutazione finora

- Ullltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992Documento7 pagineUllltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992mohammadreza91Nessuna valutazione finora

- Us 4406461Documento5 pagineUs 4406461mohammadreza91Nessuna valutazione finora

- Packer Sealing Element With Shape Memory MaterialDocumento8 paginePacker Sealing Element With Shape Memory Materialmohammadreza91Nessuna valutazione finora

- United States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f PatentDocumento10 pagineUnited States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f Patentmohammadreza91Nessuna valutazione finora

- Us 2843208Documento7 pagineUs 2843208mohammadreza91Nessuna valutazione finora

- References Cited Robiatiorlial Movergents. Pat Least One ElaitigallybexaatrlidDocumento7 pagineReferences Cited Robiatiorlial Movergents. Pat Least One Elaitigallybexaatrlidmohammadreza91Nessuna valutazione finora

- Us 4406461Documento5 pagineUs 4406461mohammadreza91Nessuna valutazione finora

- US5439053 Thickness PDFDocumento6 pagineUS5439053 Thickness PDFmohammadreza91Nessuna valutazione finora

- Inflatable Packer Reinforcement MethodDocumento5 pagineInflatable Packer Reinforcement Methodmohammadreza91Nessuna valutazione finora

- 0 - Rank One Convexification Approach For The Modeling of Magnetic Shape Memory Response PDFDocumento2 pagine0 - Rank One Convexification Approach For The Modeling of Magnetic Shape Memory Response PDFmohammadreza91Nessuna valutazione finora

- Method of Increasing Strength of Welded Slat Assembly for Inflatable PackersDocumento6 pagineMethod of Increasing Strength of Welded Slat Assembly for Inflatable Packersmohammadreza91Nessuna valutazione finora

- Ullltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992Documento7 pagineUllltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992mohammadreza91Nessuna valutazione finora

- 1286 - Giant Magnetic-field-Induced Strain in NiMnGa Seven-Layered Martensitic PhaseDocumento3 pagine1286 - Giant Magnetic-field-Induced Strain in NiMnGa Seven-Layered Martensitic Phasemohammadreza91Nessuna valutazione finora

- United States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985Documento5 pagineUnited States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985mohammadreza91Nessuna valutazione finora

- Unlted States Patent (10) Patent No.: US 7,621,322 B2Documento9 pagineUnlted States Patent (10) Patent No.: US 7,621,322 B2mohammadreza91Nessuna valutazione finora

- 79 - Magnetic - Eld-Induced Superelasticity of Ferromagnetic Thermoelastic Martensites Experiment and Modeling PDFDocumento8 pagine79 - Magnetic - Eld-Induced Superelasticity of Ferromagnetic Thermoelastic Martensites Experiment and Modeling PDFmohammadreza91Nessuna valutazione finora

- 268-Giant Field-Induced Reversible Strain in Magnetic Shape Memory NiMnGa Alloy PDFDocumento3 pagine268-Giant Field-Induced Reversible Strain in Magnetic Shape Memory NiMnGa Alloy PDFmohammadreza91Nessuna valutazione finora

- 86 - Voltage Generation Induced by Mechanical Straining in Magnetic Shape Memory Materials PDFDocumento5 pagine86 - Voltage Generation Induced by Mechanical Straining in Magnetic Shape Memory Materials PDFmohammadreza91Nessuna valutazione finora

- 11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555Documento5 pagine11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555mohammadreza91Nessuna valutazione finora

- 55 - Stress-And Magnetic-Field-Induced Variant Rearrangement in Ni-Mn-Ga Single Crystals With Seven-Layered Martensitic Structure PDFDocumento4 pagine55 - Stress-And Magnetic-Field-Induced Variant Rearrangement in Ni-Mn-Ga Single Crystals With Seven-Layered Martensitic Structure PDFmohammadreza91Nessuna valutazione finora

- 75 - Modelling Detwinning of Martensite Platelets Under Magnetic and (Or) Stress Actions On Ni-Mn-Ga Alloys PDFDocumento3 pagine75 - Modelling Detwinning of Martensite Platelets Under Magnetic and (Or) Stress Actions On Ni-Mn-Ga Alloys PDFmohammadreza91Nessuna valutazione finora

- 142 - Quantitative Model of Large Magnetostrain Effect in Ferromagnetic Shape Memory Alloys PDFDocumento10 pagine142 - Quantitative Model of Large Magnetostrain Effect in Ferromagnetic Shape Memory Alloys PDFmohammadreza91Nessuna valutazione finora

- 1577 - Energy Harvesting Vibration Sources For Microsystems ApplicationsDocumento21 pagine1577 - Energy Harvesting Vibration Sources For Microsystems Applicationsmohammadreza91Nessuna valutazione finora

- 18 - A Three Dimensional Phenomenological Model For Magnetic Shape Memory AlloysDocumento7 pagine18 - A Three Dimensional Phenomenological Model For Magnetic Shape Memory Alloysmohammadreza91Nessuna valutazione finora

- 967 - 6% Magnetic-Field-Induced Strain by Twin-Boundary Motion in Ferromagnetic Ni-Mn-GaDocumento4 pagine967 - 6% Magnetic-Field-Induced Strain by Twin-Boundary Motion in Ferromagnetic Ni-Mn-Gamohammadreza91Nessuna valutazione finora

- 1286 - Giant Magnetic-field-Induced Strain in NiMnGa Seven-Layered Martensitic PhaseDocumento3 pagine1286 - Giant Magnetic-field-Induced Strain in NiMnGa Seven-Layered Martensitic Phasemohammadreza91Nessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Honda Pump BrochureDocumento18 pagineHonda Pump Brochurefser04Nessuna valutazione finora

- Synthesis of Copper Oxide Nanoparticles Using Simple Chemical Route PDFDocumento3 pagineSynthesis of Copper Oxide Nanoparticles Using Simple Chemical Route PDFRobinsonNessuna valutazione finora

- 1331 AbDocumento1 pagina1331 AbPreeti BhadkeNessuna valutazione finora

- 07 Tool Wear, Life & MachinabilityDocumento27 pagine07 Tool Wear, Life & MachinabilitySasi ReddyNessuna valutazione finora

- Model Question Paper: Fifth Semester B.E. Degree ExaminationDocumento3 pagineModel Question Paper: Fifth Semester B.E. Degree ExaminationPCT 19AE04 Sivakumar. KNessuna valutazione finora

- Essential Paint and Coating Terms ExplainedDocumento2 pagineEssential Paint and Coating Terms Explainedvincent lemireNessuna valutazione finora

- Toc Analyzer: Anggota: RingganiDocumento10 pagineToc Analyzer: Anggota: RingganiAnty Sintya Ringgani IINessuna valutazione finora

- UPP Piping Install-Small PDFDocumento12 pagineUPP Piping Install-Small PDFsk lukoNessuna valutazione finora

- Lesonal Basecoat SBDocumento5 pagineLesonal Basecoat SBjunot88Nessuna valutazione finora

- SBI Product OverviewDocumento1 paginaSBI Product OverviewSutiyo PrawiroNessuna valutazione finora

- Compound and Mixture - ExperimentDocumento3 pagineCompound and Mixture - Experimentvanshika devadigaNessuna valutazione finora

- Practical Design of Vibro Stone Columns: June 2016Documento15 paginePractical Design of Vibro Stone Columns: June 2016Dr Ganesh Kame (Dr Kame)Nessuna valutazione finora

- Chapter 20-The First Law of Thermodynamics: Multiple ChoiceDocumento13 pagineChapter 20-The First Law of Thermodynamics: Multiple ChoiceJhajha AlboniaNessuna valutazione finora

- Experiment 7: Determination of AshDocumento7 pagineExperiment 7: Determination of AshhasifahNessuna valutazione finora

- Bsi Eof DWG Cs 150 (0) - Lighting Pole 10m HeightDocumento1 paginaBsi Eof DWG Cs 150 (0) - Lighting Pole 10m HeightdharuNessuna valutazione finora

- Frontiers e ManufacturingDocumento9 pagineFrontiers e ManufacturingmartinsandovalandresNessuna valutazione finora

- 11.2 - Ingliskeelne NimekiriDocumento37 pagine11.2 - Ingliskeelne NimekiriMichael MacDonaldNessuna valutazione finora

- Handbook To BS5628-2Documento280 pagineHandbook To BS5628-2Ashwin B S Rao80% (5)

- Properties of Iron AlloysDocumento2 pagineProperties of Iron AlloysAmber ShrivastavaNessuna valutazione finora

- Armacell Armasound Barrier E TDSDocumento4 pagineArmacell Armasound Barrier E TDSPrasad MandavaNessuna valutazione finora

- Chemistry Basics: Elements, Atoms, Bonding and MatterDocumento65 pagineChemistry Basics: Elements, Atoms, Bonding and MatterJohnpaul KondoNessuna valutazione finora

- Product Data Sheet OK Autrod 12.51: G 'Gas-Shielded Metal-Arc Welding'Documento2 pagineProduct Data Sheet OK Autrod 12.51: G 'Gas-Shielded Metal-Arc Welding'Filipe CordeiroNessuna valutazione finora

- 25m Span Superstructure of Bridge DesignDocumento45 pagine25m Span Superstructure of Bridge Designshekhar Nath chapagain75% (4)

- BOD Test Measures Organic Pollution in WaterDocumento6 pagineBOD Test Measures Organic Pollution in WaterAriffi YusofNessuna valutazione finora

- Electrochimica Acta Volume 25 Issue 2 1980 (Doi 10.1016/0013-4686 (80) 80033-8) B. Lillebuen S.A. Ytterdahl R. Huglen K.A. Paulsen - Current Efficiency and Back Reaction in AluminiuDocumento7 pagineElectrochimica Acta Volume 25 Issue 2 1980 (Doi 10.1016/0013-4686 (80) 80033-8) B. Lillebuen S.A. Ytterdahl R. Huglen K.A. Paulsen - Current Efficiency and Back Reaction in AluminiuLisa ArdianaNessuna valutazione finora

- 5 Structures of RocksDocumento6 pagine5 Structures of RocksAhmad ZahidNessuna valutazione finora

- Bihar VAT Rate SchedulesDocumento22 pagineBihar VAT Rate SchedulesNeeraj SinghNessuna valutazione finora

- 1.02-1 Oxygas Welding & Related ProcessDocumento37 pagine1.02-1 Oxygas Welding & Related Processrohit mathankerNessuna valutazione finora

- An Introduction To PVDF Coatings: Product Data SheetDocumento3 pagineAn Introduction To PVDF Coatings: Product Data SheetAnonymous DJrec2Nessuna valutazione finora

- Gas DehydrationDocumento61 pagineGas Dehydrationraja.mtNessuna valutazione finora