Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

E 521064

Caricato da

hadiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

E 521064

Caricato da

hadiCopyright:

Formati disponibili

Mitsubishi Heavy Industries Technical Review Vol. 52 No.

1 (March 2015)

64

Development of High-efficiency Gas Engine

with Two-stage Turbocharging System

YUTA FURUKAWA*1

MINORU ICHIHARA*2

KAZUO OGURA*2

AKIHIRO YUKI*3

KAZURO HOTTA*4

DAISUKE TAKEMOTO*4

A new G16NB gas engine for generator use adopting a two-stage turbocharging system was

developed for the improvement of electrical efficiency and output. Two-stage turbocharging, intake

valve close timing and expansion ratio optimization, as well as an increased peak firing pressure,

were adopted to achieve the development target of 10% (4% points) or higher efficiency

improvement. The test engine operated by city gas (13A) displayed the results below: (1)

Turbocharger efficiency was improved by 14% points compared with that of conventional models.

In addition, the pressure ratio of compressor was increased by 1.5 contrasted with that of

conventional models at the rated output. (2) The electrical efficiency of the engine was increased

by 4% points, and attained the worlds top level efficiency of 44.7% or higher. Additionally, the

break mean effective pressure (BMEP) was raised by 0.5 MPa in contrast to that of the current

model.

|1. Introduction

Recently, gas engines for generator use are required to have both high efficiency and high

power. The Miller cycle is well known as one of the means to achieve high efficiency while

avoiding abnormal combustion conditions such as knocking. However, the Miller cycle inherently

lowers the volumetric efficiency, and the output power is lowered at the same boost pressure. A

turbocharger is required to ensure a higher pressure ratio and higher efficiency to compensate for

the disadvantages of the Miller cycle.

Contrarily, a turbocharger tends to lower the turbocharging efficiency in proportion to the

rise of the pressure ratio at a certain pressure ratio and above, and so a high pressure ratio and high

turbocharging efficiency are a trade-off. One solution to achieve both a high pressure ratio and high

turbocharger efficiency is two-stage turbocharging with intermediate cooling. In a two-stage

turbocharging system, each pressure ratio at the lower and higher stages can be designed to be

relatively low, and the high pressure ratio can be attained at the high-efficiency operational point of

each stage. Moreover, the effect of intermediate cooling improves turbocharger efficiency.

In two-stage turbocharging, the pressure ratio of each stage can be set to be relatively low, as

can the compression temperature after the compressor becomes low compared with that of

single-stage turbocharger. This is advantageous in designing the compressor strength.

This report describes the development of the new G16NB high-efficiency gas engine

adopting a two-stage turbocharging system. The development target of this engine is a higher

efficiency of 10% (4% points) or higher than that of conventional models. In this development,

two-stage turbocharging, the optimization of the inlet valve closing timing (IVC) and expansion

ratio, and a higher peak firing pressure (higher Pmax) are adopted to achieve the desired results.

The development of the two-stage turbocharging system and the design of the component parts of

the combustion chamber are detailed in this report.

*1 Engine Engineering Department, Engine Division, Machinery, Equipment & Infrastructure

*2 Chief Staff Manager, Engine Engineering Department, Engine Division, Machinery, Equipment & Infrastructure

*3 Chief Staff Manager, Yokohama Resarch & Development Center, Technology & Innovation Headquarters

*4 Yokohama Resarch & Development Center, Technology & Innovation Headquarters

Mitsubishi Heavy Industries Technical Review Vol. 52 No. 1 (March 2015)

65

|2. Development of G16NB gas engine design

The main specifications of the G16NB engine are shown in Table 1. The output is increased

from 1500kW to 2000kW with the same cylinder bore, stroke length, rated speed and cylinder

numbers. The break mean effective pressure (BMEP), which refers to the load per cycle and unit

displacement volume, is raised by 0.5MPa.

With these specifications, one dimensional performance simulation was conducted using the

IVC, target turbocharger efficiency, the target compressor pressure ratio and the target peak firing

pressure as parameters to clarify the conditions to achieve the target of efficiency improvement.

GT-Power V7.2 calculation software (Gamma Technologies Inc.) was used for the

calculation investigation. Single-stage turbocharging with a turbocharger efficiency equivalent to

two-stage turbocharging was calculated, although the actual engine uses two-stage turbocharging.

In the calculation, the engine output, expansion ratio and excess-air ratio were set to be constant,

and the ignition timing was adjusted to the knocking limit. BMEP was set to the increase target

value by 0.5 MPa. The heat-receiving rate was estimated by extrapolation by conducting a

sensitivity analysis of BMEP from the test results of the current model.

Table 1

Cylinder bore

Stroke

Rated engine speed

Cylinder number

Rated output (at generator end)

Break mean effective pressure

Combustion type

Ignition system

2.1

G16NB main specifications

mm

mm

min-1

kW

MPa

Conventional engine Developmental engine

GS16R2

G16NB

170

170

220

220

1500

1500

16

16

1500

2000

1.6

2.1

Pre-chamber

Pre-chamber

Spark ignition

Spark ignition

Determination of inlet valve close timing, target turbocharger efficiency and

target peak firing pressure

The calculation results of thermal efficiency, compressor pressure ratio and peak firing

pressure (Pmax) to IVC are shown in Figure 1.

Figure 1

One-dimensional performance simulation

As the thermal efficiency calculation shown in the left upper position of Figure 1, the

electrical efficiency improvement cannot be attained by advancing IVC in the case of current

turbocharger efficiency ().

The advancement of IVC by 20 deg, the improvement of target turbocharger efficiency by

Mitsubishi Heavy Industries Technical Review Vol. 52 No. 1 (March 2015)

66

10% points from that of the current turbocharger, the increase of the compressor pressure ratio by

1.5 from the current model, and the increase of Pmax by 5MPa from that of the current model are

required to achieve the target electrical efficiency.

2.2

Design of two-stage turbocharging system

The two-stage turbocharging system was selected to attain the target turbocharger efficiency

and required pressure ratio clarified in the previous section, and the specifications were

investigated.

2.2.1 Determination of parameters

In the target 10% points increase of turbocharger efficiency, 5% points were allotted to

the improvement of single-stage turbocharger efficiency, and the remaining 5% points to the

two-stage turbocharging system. An outline drawing of the two-stage turbocharging system is

shown in Figure 2.

The parameters below are required to design the two-stage turbocharger system.

Loading ratio of high-pressure compressor

Intermediate cooling temperature

Allowable pressure loss of intermediate cooling

Figure 3 shows the results of the parameter study to determine the items above.

The loading ratio of the high-pressure compressor was defined as the required loading

ratio of the high-pressure compressor in the total required compressor loading. In the

calculation, the total compressor pressure ratio including the low and high pressure stages was

constant, and the single-stage compressor efficiency, turbine efficiency and mechanical

efficiency were constant regardless of the condition.

Figure 2

Outline drawing of two-stage turbocharging system

Figure 3 Parameter case study of two-stage turbocharger system

Mitsubishi Heavy Industries Technical Review Vol. 52 No. 1 (March 2015)

67

Figure 3 shows the results below.

The optimum point of the loading ratio of the high pressure compressor differs

depending on the intermediate cooling temperature. The approximate value of 0.5

shows the maximum turbocharger efficiency.

Turbocharger efficiency change is almost linear to the intermediate cooling temperature,

and is approximately 0.1% point/K.

Turbocharger efficiency change is almost linear to the intermediate cooling pressure

loss, and is approximately 0.2% point/KPa.

From the results above, the verification calculation was carried out with the design values

below, and the prospect of satisfying the target turbocharger efficiency was achieved.

High pressure compressor loading ratio: Approximately 0.5

Intermediate cooling temperature: Lower than the baseline by 30C or less

Intermediate cooling pressure loss: Less than 10kPa

2.2.2 Determination of parameters

The ratio of the equivalent area was determined to satisfy the loading ratio of the high

pressure compressor investigated in the previous section.

In addition, the high-pressure compressor pressure ratio and volumetric flow rate were

calculated, and the high- and low-pressure stage compressors were designed. The compressor

was designed to have the maximum efficiency near the operating pressure ratio when

considering the low pressure ratio of each single stage. The turbocharger efficiency of a single

stage was expected to rise by 5 % points contrasted with the current model averaging the lowand high-pressure stage compressors.

A design study of the intermediate cooler layout was conducted to satisfy the target

temperatures of the high- and low-pressure stage turbochargers and the intermediate cooler.

Figure 4 shows the results of the pressure loss calculation.

The intermediate cooler pressure loss calculation was made in several layouts, and finally

a layout which could satisfy the target value of less than 10kPa was determined.

Figure 4 Pressure loss calculation

2.3

Design of combustion chamber

The flow analysis and flame propagation simulation in the pre-chamber was conducted to

optimize the pre- and main combustion chambers. In addition, thermal structure analysis was

carried out to design a combustion chamber that can be realized considering the mechanical

strength under the high Pmax and BMEP conditions.

2.3.1 Flow analysis and flame propagation simulation in pre-chamber

The flow analysis in the pre-chamber was conducted to stabilize the combustion in the

pre-chamber. Figure 5 shows the methane concentration distribution at the timings of 180 deg

and 90 deg before compression top dead center, and the ignition timing. Figure 5 shows the

dilution of the supplied fuel gas by lean mixture flowing from the main chamber, and a uniform

mixture formed at the ignition timing. The optimization of the pre-chamber shape was

conducted using the gas trap rate (fuel gas amount remaining in the pre-chamber at the timing

of ignition to the supplied fuel gas) and the flow speed around the ignition plug as the

evaluation indicator.

The flame propagation simulation was carried out using the three-dimensional

combustion analysis code for the design of the main chamber shape, and the heat-receiving rate,

the gas temperature in the combustion chamber and the heat transfer coefficient were

Mitsubishi Heavy Industries Technical Review Vol. 52 No. 1 (March 2015)

68

calculated. For the three-dimensional combustion analysis code, KIVA was used to solve 42

chemical species and 213 elementary reactions.

Figure 5

Flow analysis in the pre-chamber

The calculated heat-receiving rate and isothermal surface in the analysis are shown in

Figure 6. The figure shows the isothermal surface of 1500C from 5 deg before to 25 deg after

the compression top dead center. The torch flame discharged from the pre-chamber and the

flame surface propagation from the torch are shown.

The heat-receiving rate calculated in the analysis was fed back to the one dimensional

performance simulation in section 2.1 to improve the accuracy of performance calculation, and

the gas temperature in the combustion chamber and the heat transfer coefficient calculated in

the three-dimensional combustion analysis were used as the thermal boundary conditions in the

strength analysis of the piston, cylinder liner, and cylinder head.

Figure 6

2.3.2

Flame propagation simulation

Thermal structure analysis of combustion chamber component parts

For the strength analysis of the combustion chamber component parts, the thermal

boundary conditions in the combustion chamber were determined by the combustion analysis in

the previous section, and the thermal boundary conditions on the cooling face were determined

by the one dimensional flow network analysis. The MHI flow network analysis code was used

for the flow network analysis of cooling system.

The flow channel cross section, flow channel circumferential length, and flow channel

length were used as parameters, and the cooling water channel of the whole engine was

calculated as a one dimensional model for the flow network analysis.

The flow network analysis can calculate the heat transfer coefficient on the main parts

such as the cylinder liner and cylinder head, in addition to the flow speed calculation at each

channel. As an example, the developed view of the heat transfer coefficient distribution around

the cylinder liner and one dimensional model are shown in Figure 7.

The cooling water passage was designed to equalize the heat transfer coefficient in the

circumferential direction at the upper part of the cylinder liner using the results of the analysis.

FEM analysis was conducted using the determined thermal boundary conditions on the

combustion chamber side and cooling water side, and the cylinder was designed to have

sufficient fatigue strength.

Mitsubishi Heavy Industries Technical Review Vol. 52 No. 1 (March 2015)

69

Figure 7

Flow network analysis of cooling system

|3. Test results

A test engine equipped with a two-stage turbocharging system was built, and a performance

test was conducted. The main measurement results are shown in Table 2 and Figure 8. city gas

(13A) was used for the fuel.

The results were sufficient to attain the target values of intermediate cooling temperature and

pressure loss in the two-stage turbocharging system. Then, the target values were satisfied by

improving the turbocharger efficiency by 14% points and the compressor pressure ratio by 1.5 in

contrast to those of the current model at the rated operational point.

In addition, the relationship of the compressor pressure ratio and turbocharger efficiency at

engine partial load was compared. As a result, it was found that the boost pressure rate of increase

at engine starting is advantageous, and the startability is free from problems with the improvement

of turbocharger efficiency from the low pressure ratio condition that is used during engine starting.

The electrical efficiency and BMEP of the G16NB engine were increased by 4% points and

0.5 MPa, respectively, compared with conventional models with a single stage turbocharger of the

same cylinder bore, stroke length, and engine speed. As a result, the worlds top level electrical

efficiency of 44.7% or higher was achieved.

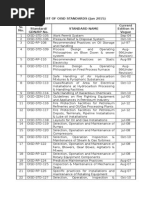

Table 2 Test results

Intermediate cooling temperature

Pressure loss of intermediate cooling

Pressure ratio of compressor

Turbocharger efficiency

Break mean effective pressure

Generation efficiency

Figure 8

kPa

% points

MPa

% points

Target

Baseline-30

10

Current model1.5

10

0.5

4

Measured

Baseline35

5

Current model1.5

14

0.5

4

Test results

|4. Conclusion

The new G16NB generator gas engine was designed, and the test engine displayed the test

results below:

(1) The optimization of the two-stage turbocharging system was conducted. Turbocharger

efficiency was raised by 14% points, and the pressure ratio was raised by 1.5 contrasted with

those of conventional engine models.

Mitsubishi Heavy Industries Technical Review Vol. 52 No. 1 (March 2015)

70

(2)

A two-stage turbocharging system was installed on the engine, and the engine electrical

efficiency of the worlds top level of 44.7% or higher was attained with an efficiency

increase of 4% points. Furthermore, the BMEP was raised by 0.5 MPa in contrast to that of

conventional models using city gas (13A) fuel.

This development was conducted with the aid of the fiscal 2012 Program for Strategic

Innovative Energy Saving Technology of the New Energy and Industrial Technology

Development Organization (NEDO).

Endurance testing using the verification facilities of our company shown in Figure 9 will be

conducted. In addition, plans call for the engine to be launched on the market after evaluating

engine reliability including the two-stage turbocharging system.

Figure 9 Verification facilities

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- KNX EXAM - Question and Answers - No1 - SYSTEM ARGUMENTS - DigitalworldzDocumento2 pagineKNX EXAM - Question and Answers - No1 - SYSTEM ARGUMENTS - Digitalworldzhadi100% (1)

- KNX EXAM - Question and Answers - No2 - BUS DEVICES - DigitalworldzDocumento2 pagineKNX EXAM - Question and Answers - No2 - BUS DEVICES - Digitalworldzhadi50% (2)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- KNX EXAM - Question and Answers - No8 - COMMISSIONING - DigitalworldzDocumento2 pagineKNX EXAM - Question and Answers - No8 - COMMISSIONING - Digitalworldzhadi33% (3)

- KNX EXAM - Question and Answers - No5 - TELEGRAMS - DigitalworldzDocumento2 pagineKNX EXAM - Question and Answers - No5 - TELEGRAMS - DigitalworldzhadiNessuna valutazione finora

- From The Steam Table: Table 3 PT 1@ 540 C & 8mpa H 3496.7 KJ/KG & S 6.8481 PT 2 at 0.0035 Mpa & S S 6.8481 by InterpolationDocumento5 pagineFrom The Steam Table: Table 3 PT 1@ 540 C & 8mpa H 3496.7 KJ/KG & S 6.8481 PT 2 at 0.0035 Mpa & S S 6.8481 by InterpolationMark AgusNessuna valutazione finora

- Ferro ResonanceDocumento30 pagineFerro ResonanceAlex GeorgescuNessuna valutazione finora

- Document ListDocumento2 pagineDocument ListhadiNessuna valutazione finora

- Akuvox E11R Datasheet - 20200220 - V2.2Documento2 pagineAkuvox E11R Datasheet - 20200220 - V2.2hadiNessuna valutazione finora

- 463152ijsetr1597 559Documento5 pagine463152ijsetr1597 559michyimNessuna valutazione finora

- Advance ExamDocumento1 paginaAdvance ExamhadiNessuna valutazione finora

- راهنمای جامعDocumento146 pagineراهنمای جامعhadiNessuna valutazione finora

- Product Data Sheet: 2-Gang Push-Button Insert 1-Pole, 1-Way (NO)Documento1 paginaProduct Data Sheet: 2-Gang Push-Button Insert 1-Pole, 1-Way (NO)hadiNessuna valutazione finora

- Product Documentation: Fan Coil Actuator 2-Gang Art.-No.: FCA 2 REGHEDocumento126 pagineProduct Documentation: Fan Coil Actuator 2-Gang Art.-No.: FCA 2 REGHEhadiNessuna valutazione finora

- En 230xxSR 20200422 TDDocumento301 pagineEn 230xxSR 20200422 TDhadiNessuna valutazione finora

- Product Data Sheet: Switch Actuator, 24-Gang / Blinds Actuator, 12-GangDocumento2 pagineProduct Data Sheet: Switch Actuator, 24-Gang / Blinds Actuator, 12-GanghadiNessuna valutazione finora

- Ieeetran HowtoDocumento28 pagineIeeetran HowtoTeksen AksunNessuna valutazione finora

- Product Data Sheet: Fan Coil Actuator 2-GangDocumento2 pagineProduct Data Sheet: Fan Coil Actuator 2-GanghadiNessuna valutazione finora

- My Boot Camp Printed Document-6Documento1 paginaMy Boot Camp Printed Document-6hadiNessuna valutazione finora

- PI734G - Winding 312: Technical Data SheetDocumento9 paginePI734G - Winding 312: Technical Data SheethadiNessuna valutazione finora

- شیفتDocumento1 paginaشیفتhadiNessuna valutazione finora

- BITCOIN, Do You Like Butterflies? For COINBASE:BTCUSD by Yuriy - Bishko - TradingViewDocumento3 pagineBITCOIN, Do You Like Butterflies? For COINBASE:BTCUSD by Yuriy - Bishko - TradingViewhadiNessuna valutazione finora

- Technical Language of Electrical EngineeringDocumento11 pagineTechnical Language of Electrical EngineeringhadiNessuna valutazione finora

- Kang 2014Documento10 pagineKang 2014hadiNessuna valutazione finora

- +J Procs 2014 05 450 PDFDocumento8 pagine+J Procs 2014 05 450 PDFhadiNessuna valutazione finora

- Technical - Info MTU 20V4000L62Documento7 pagineTechnical - Info MTU 20V4000L62Marvin Tejerina Garfias100% (1)

- Fundamental of Non Directional Overcurrent PDFDocumento56 pagineFundamental of Non Directional Overcurrent PDFAkinbode Sunday OluwagbengaNessuna valutazione finora

- OE Spec GN 400 400V 50Hz 1 16Documento2 pagineOE Spec GN 400 400V 50Hz 1 16hadiNessuna valutazione finora

- 10.1109 JIOT.2015.2452960 A Real Time Dynamic Pricing Algorithm For Smart Grid With Unstable Energy Providers and Malicious UsersDocumento8 pagine10.1109 JIOT.2015.2452960 A Real Time Dynamic Pricing Algorithm For Smart Grid With Unstable Energy Providers and Malicious UsershadiNessuna valutazione finora

- Lujano-Rojas2012 PDFDocumento9 pagineLujano-Rojas2012 PDFhadiNessuna valutazione finora

- +optimal Residential Load Control With Price Prediction in Real-Time Electricity Pricing EnvironmentsDocumento14 pagine+optimal Residential Load Control With Price Prediction in Real-Time Electricity Pricing EnvironmentshadiNessuna valutazione finora

- (1941) R.T Knapp, Pasadena, Calif - Centrifugal-Pump Performance As A Ffected by Design F EaturesDocumento10 pagine(1941) R.T Knapp, Pasadena, Calif - Centrifugal-Pump Performance As A Ffected by Design F Eaturesm.mijajlovicNessuna valutazione finora

- Genset Weifang 60 Kva - Kent PowerDocumento2 pagineGenset Weifang 60 Kva - Kent Poweryusuf berjayaNessuna valutazione finora

- SOP-Blackout Restoration R3Documento10 pagineSOP-Blackout Restoration R3Siddhant SatpathyNessuna valutazione finora

- WiloDocumento270 pagineWiloMaricris MendozaNessuna valutazione finora

- L1 Series Hybrid Inverter User Manual (Neutral) V1.3-20211125142830Documento23 pagineL1 Series Hybrid Inverter User Manual (Neutral) V1.3-20211125142830Ed Ruel RacomaNessuna valutazione finora

- GE Cycles Lecture Info 2009Documento18 pagineGE Cycles Lecture Info 2009Sayantan Datta Gupta100% (1)

- BurnerDocumento3 pagineBurnerRavi sharmaNessuna valutazione finora

- Tanjung Kidurong Monitoring & MitigationsDocumento4 pagineTanjung Kidurong Monitoring & MitigationsMuhammad Redzwan Bin IsmailNessuna valutazione finora

- DPL Ensayo de Penetracion Ligera Mecanica de SuelosDocumento60 pagineDPL Ensayo de Penetracion Ligera Mecanica de SuelosErnesto Guillermo Dobbertin SaldañaNessuna valutazione finora

- Flow Meter Selection ChartDocumento4 pagineFlow Meter Selection ChartharisNessuna valutazione finora

- IAEA Desalination Economic Evaluation Programme (DEEP) To Estimate The Water Desalination Cost in Terms of Water Production and Energy ConsumptionDocumento12 pagineIAEA Desalination Economic Evaluation Programme (DEEP) To Estimate The Water Desalination Cost in Terms of Water Production and Energy ConsumptionTaimoor MazharNessuna valutazione finora

- OISD StandardsDocumento6 pagineOISD Standardskakababa117Nessuna valutazione finora

- JMP Company Profile 2020Documento20 pagineJMP Company Profile 2020Jay MarkNessuna valutazione finora

- Boiler Control Process OverviewDocumento27 pagineBoiler Control Process OverviewSandeep Kumar Krishnaraj100% (1)

- Amg ResumeDocumento3 pagineAmg ResumeSivashankar DhanarajNessuna valutazione finora

- SF-0012.4 SOFC Solutions ENDocumento8 pagineSF-0012.4 SOFC Solutions ENMorgen GumpNessuna valutazione finora

- S-Fuelcell Brochure EN 2020 v1Documento8 pagineS-Fuelcell Brochure EN 2020 v1Cesar ZamudioNessuna valutazione finora

- BENONI Catalogo de Produtos - 2023Documento20 pagineBENONI Catalogo de Produtos - 2023Eduardo LucenaNessuna valutazione finora

- Ohp (2171912)Documento8 pagineOhp (2171912)rajushamla9927Nessuna valutazione finora

- 2c ECOTHERM Shower Water ChillerDocumento8 pagine2c ECOTHERM Shower Water ChillerVocansonNessuna valutazione finora

- Lesson 11 - Steam Power CyclesDocumento12 pagineLesson 11 - Steam Power CyclesabinmwangiNessuna valutazione finora

- Design of Solar Panel / Battery Bank / InvertorDocumento9 pagineDesign of Solar Panel / Battery Bank / Invertornaveen_86Nessuna valutazione finora

- Allpumps Southern Cross 4 Inch Technical Data Sheet BrochureDocumento2 pagineAllpumps Southern Cross 4 Inch Technical Data Sheet BrochureAgus Setia BudiNessuna valutazione finora

- Catalytic Reforming ProcessesDocumento3 pagineCatalytic Reforming Processeskmoualek5872Nessuna valutazione finora

- Presentasi Produk Roda Nurmala NFPA-20 (2020)Documento11 paginePresentasi Produk Roda Nurmala NFPA-20 (2020)dwi apriyantoNessuna valutazione finora

- GE 6FA TurbineDocumento1 paginaGE 6FA TurbinehenriquezrsNessuna valutazione finora

- Chapter 11 Types of PumpsDocumento45 pagineChapter 11 Types of Pumpssuraj7266Nessuna valutazione finora

- Gas Turbine TechnologiesDocumento35 pagineGas Turbine TechnologiesEmin Çelik100% (1)

- Rab Mekanikal Block D - 1Documento21 pagineRab Mekanikal Block D - 1Setyo Tyas JarwantoNessuna valutazione finora