Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lab Report XRF 79: S8 Tiger

Caricato da

ASRAR AHMED KHANTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lab Report XRF 79: S8 Tiger

Caricato da

ASRAR AHMED KHANCopyright:

Formati disponibili

Bruker AXS

S8 TIGER

Pressed pellet

Cement plant

Raw material

Result

Lab Report XRF 79

S8 TIGER (((

Process and Quality Control in Cement Production

(ASTM C 114)

Introduction

Instrument

The fast and accurate determination of the elemental

composition of all materials involved in cement production

is vital for successful process control and product quality.

Immediate feedback allows the close control of all process

parameters. Routine analysis demands very short measurement times and this, in turn, frees the same instruments for

additional tasks, such as the analysis of alternative fuels or

non-routine samples like hot meal and filter dust.

The S8 TIGER spectrometer combines ease-of-use through

its unique TouchControlTM and SampleCareTM with superior

analytical performance. SampleCareTM ensures reliable operation and high instrument uptime of the S8 TIGER through

innovative 4x protection of all spectrometer components

against contamination and damage by dust and liquids.

For all these tasks sequential wavelength-dispersive X-ray

fluorescence (WDXRF) spectrometry is today well established.

This report demonstrates the outstanding analytical performance of the S8 TIGER regarding precision, analytical

speed, sample throughput and time-to-result, offering also

analytical flexibility for todays and future tasks.

The S8 TIGER is equipped with the high intensity 4 kW Rhodium X-ray tube, two collimators (0.23 and 0.46) and five

analyzer crystals. The system offers the most flexible and

compact beampath. In combination with the high performance X-ray tube and advanced analyzer crystals, this compact beampath gives highest intensity and analytical speed.

The analysis of sodium and magnesium benefits from the

use of the intensity-optimized XS-55 crystal. The curved

germanium crystal XS-GE-C provides 20-40% more

intensity for the elements P, S and Cl. Unrivalled long term

stability for the elements Al and Si are guaranteed by the

multilayer XS-CEM crystal.

Process Control Chart for CaO

Sample Preparation

10 g of raw meal were finely ground with three grinding aid

tablets and pressed with a pressure of 20 tons. This procedure reproducibly formed very stable samples and could be

used either for manual or automated sample preparation.

Measurement

Measurements were performed on the S8 TIGER with 4 kW

Rh excitation. The total time-to result was 113s, including

loading, evacuation, analysis and reporting of the results.

Two samples were measured alternatively, each sample

50times to demonstrate the analytical performance under

real conditions.

Figure 1:

Process control chart from two non-consecuitve days for

CaO

Process Control Chart for SiO2

The elements Na, Mg, Al, Si, P, S, K, Ca, Mn and Fe were

measured and the concentrations were calculated as

oxides. This test was set up to demonstrate that there is no

compromise regarding quality of analytical data or reproducibility under real conditions. The precision test was repeated

20 times a second day to show the analytical stability.

Results

The summary of the calibration data and the maximum difference between certified and measured data are shown in

Table 1.

Figure 2:

Process control chart from two non-consecuitve days for

SiO2

Process Control Chart for Al2O3

Precision data for CaO, Al2O3 and SiO2 are shown as an

example in the process control chart (Figures 1-3) and summarized for all elements in Tables 2 and 3. Both precision

and accuracy of the S8 TIGER clearly exceed the requirements of ASTM C114, even with short measurement times

since the instrument provides enough countrate. The counting statistical error is reduced to a minimum, making sample

preparation the critical factor for succesful process control.

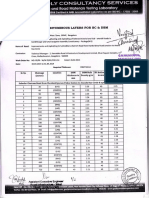

Table 1: Summary of calibration details for ASTM C114

Element

Figure 3:

Process control chart from two non-consecuitve days for

Al2O3

Concentration

Range [%]

ASTM

Max. Diff

S8 TIGER

Max. Diff

Na2O

0.08 - 0.45

0.05

0.02

MgO

1.2 - 4.2

0.2

0.1

Al2O3

3.1 - 5.8

0.2

0.1

Si02

17.6 - 25.2

0.2

0.1

P 2 O5

0.02 - 0.2

0.03

0.03

SO3

1.9 - 3.2

0.1

0.1

K 2O

0.1 - 1.5

0.05

0.04

CaO

61.5 - 68.2

0.3

0.15

Mn3O4

0.08 - 0.6

0.03

0.01

Fe2O3

0.3 - 4.4

0.10

0.03

Conclusions

Authors

The excellent precision achieved within the test period demonstrates the S8 TIGERs superior analytical performance.

The design of the S8 TIGER beampath provides the best

intensity for each element. Specific analyzer crystals e.g.

the XS-CEM are optimized for a maximum of intensity and

stability guarantee long-term precision. Immediate feedback

on the process ensures best product quality. The high analytical speed and shortest time-to-result frees the S8TIGER

also for additional tasks.

Dr. Dominique Porta

Dr. Kai Behrens

Bruker AXS GmbH, Karlsruhe

Table 2: Summary of 50 measurements of one cement sample (Day one)

Time

Na2O

[%]

MgO

[%]

Al2O3

[%]

SiO2

[%]

P 2 O5

[%]

SO3

[%]

K 2O

[%]

CaO

[%]

18:35:36

0.141

2.188

6.300

22.72

0.121

4.075

1.021

60.80

0.130

2.248

18:40:41

0.144

2.189

6.320

22.73

0.120

4.082

1.020

60.77

0.128

2.246

20:37:23

0.143

2.192

6.300

22.77

0.119

4.094

1.015

60.87

0.128

2.248

20:42:28

0.144

2.191

6.290

22.79

0.120

4.087

1.018

60.76

0.129

2.245

22:39:09

0.144

2.191

6.280

22.77

0.120

4.088

1.024

60.87

0.129

2.249

22:44:13

0.144

2.186

6.300

22.79

0.121

4.092

1.019

60.80

0.129

2.254

Mean

Value

0.143

2.189

6.300

22.77

0.120

4.084

1.021

60.78

0.128

2.248

Std.Dev.

0.001

0.006

0.016

0.02

0.001

0.006

0.002

0.05

0.001

0.004

RSD.

1.03

0.27

0.25

0.10

0.62

0.14

0.22

0.08

0.74

0.19

Mn3O4 [%]

Fe2O3

[%]

Table 3: Summary of 20 measurements of the same cement sample (Day three)

Time

Na2O

[%]

MgO

[%]

Al2O3

[%]

SiO2

[%]

P 2 O5

[%]

SO3

[%]

K 2O

[%]

CaO

[%]

Mn3O4 [%]

Fe2O3

[%]

08:42:25

0.140

2.164

6.310

22.77

0.120

4.076

1.014

60.78

0.123

2.228

08:47:29

0.143

2.179

6.330

22.83

0.120

4.078

1.014

60.73

0.129

2.224

10:13:45

0.142

2.199

6.310

22.79

0.121

4.095

1.018

60.76

0.129

2.243

10:18:49

0.141

2.181

6.310

22.81

0.121

4.089

1.017

60.76

0.126

2.239

Mean

Value

0.141

2.187

6.303

22.78

0.121

4.085

1.017

60.79

0.128

2.240

Std.Dev.

0.001

0.009

0.018

0.02

0.001

0.007

0.002

0.04

0.001

0.007

RSD.

0.94

0.39

0.28

0.10

0.67

0.17

0.23

0.07

1.15

0.33

All configurations and specifications are subject to

change without notice. Order No. DOC-L80-E00079.

2007 Bruker AXS. Printed in Germany.

Bruker AXS GmbH

Bruker AXS Inc.

Karlsruhe, Germany

Phone +49 (7 21) 5 95-28 88

Fax +49 (7 21) 5 95-45 87

info@bruker-axs.de

www.bruker-axs.de

Madison, WI, USA

Phone +1 (800) 234-XRAY

Phone +1 (608) 276-3000

Fax +1 (608) 276-3006

info@bruker-axs.com

www.bruker-axs.com

Potrebbero piacerti anche

- Vol II PDFDocumento138 pagineVol II PDFASRAR AHMED KHANNessuna valutazione finora

- DRDOTendernotice 2 PDFDocumento220 pagineDRDOTendernotice 2 PDFASRAR AHMED KHANNessuna valutazione finora

- Percentage Boq: Validate Print HelpDocumento18 paginePercentage Boq: Validate Print HelpASRAR AHMED KHANNessuna valutazione finora

- Tech 87 SPPPDocumento114 pagineTech 87 SPPPASRAR AHMED KHANNessuna valutazione finora

- Preamble To Price ScheduleDocumento3 paginePreamble To Price ScheduleASRAR AHMED KHANNessuna valutazione finora

- CICO Plast Super P-190ADocumento3 pagineCICO Plast Super P-190AASRAR AHMED KHANNessuna valutazione finora

- Vol IDocumento136 pagineVol IASRAR AHMED KHANNessuna valutazione finora

- TD Palanatanki PDFDocumento214 pagineTD Palanatanki PDFASRAR AHMED KHANNessuna valutazione finora

- DBM Report PDFDocumento4 pagineDBM Report PDFASRAR AHMED KHANNessuna valutazione finora

- CICO Plast N PDFDocumento2 pagineCICO Plast N PDFASRAR AHMED KHANNessuna valutazione finora

- CICO Plast Super P-190ADocumento3 pagineCICO Plast Super P-190AASRAR AHMED KHANNessuna valutazione finora

- Government of Rajasthan Public Health Engineering DepartmentDocumento3 pagineGovernment of Rajasthan Public Health Engineering DepartmentASRAR AHMED KHANNessuna valutazione finora

- Cico Plast Super C804Documento2 pagineCico Plast Super C804ASRAR AHMED KHANNessuna valutazione finora

- Cico Plast-N: Normal Water Reducing Admixture / Plasticiser For ConcreteDocumento2 pagineCico Plast-N: Normal Water Reducing Admixture / Plasticiser For ConcreteASRAR AHMED KHANNessuna valutazione finora

- Cico Plast Super C804Documento2 pagineCico Plast Super C804ASRAR AHMED KHANNessuna valutazione finora

- Indian Standard: Methods of Test For Determination of Strength Properties of Natural Building StonesDocumento8 pagineIndian Standard: Methods of Test For Determination of Strength Properties of Natural Building StonesASRAR AHMED KHANNessuna valutazione finora

- TD Palanatanki PDFDocumento214 pagineTD Palanatanki PDFASRAR AHMED KHANNessuna valutazione finora

- Is 10500 SpecificationDocumento10 pagineIs 10500 SpecificationbrahmishtanNessuna valutazione finora

- 1121 1Documento8 pagine1121 1Bhaskar Jyoti DasNessuna valutazione finora

- Ce742lec 25&26Documento83 pagineCe742lec 25&26Anshul SoniNessuna valutazione finora

- Comparison of Core and Cube Compressive Strength of Hardened ConcreteDocumento5 pagineComparison of Core and Cube Compressive Strength of Hardened ConcreteRajmonda RamaNessuna valutazione finora

- ELCODocumento4 pagineELCOASRAR AHMED KHANNessuna valutazione finora

- Appc Soil Properties 718Documento5 pagineAppc Soil Properties 718pinkuru100% (1)

- BTech Civil Scheme and Syllabi Subject To Approval of AcademDocumento47 pagineBTech Civil Scheme and Syllabi Subject To Approval of Academdinesh_nitu2007Nessuna valutazione finora

- Panchat FormDocumento3 paginePanchat FormASRAR AHMED KHANNessuna valutazione finora

- LR XRF 129 s2 Puma Iron Ore As Fused Beads Doc-l80-Exs129 HighDocumento4 pagineLR XRF 129 s2 Puma Iron Ore As Fused Beads Doc-l80-Exs129 HighASRAR AHMED KHANNessuna valutazione finora

- S2R XRF 82 Main Limestone ComponentsDocumento4 pagineS2R XRF 82 Main Limestone ComponentsASRAR AHMED KHANNessuna valutazione finora

- Hussain ProjectDocumento1 paginaHussain ProjectASRAR AHMED KHANNessuna valutazione finora

- SpecDocumento1 paginaSpecASRAR AHMED KHANNessuna valutazione finora

- Govt. College of Engg. & Technology, Bikaner: Civil Engg. Department Fees Details AMICE & TMICE StudentsDocumento4 pagineGovt. College of Engg. & Technology, Bikaner: Civil Engg. Department Fees Details AMICE & TMICE StudentsASRAR AHMED KHANNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- How Hydraulic Valve Lifters WorkDocumento1 paginaHow Hydraulic Valve Lifters WorkSanket Sabale100% (1)

- English 1 Reading (CVC)Documento27 pagineEnglish 1 Reading (CVC)Angelica ArcangelNessuna valutazione finora

- Liquid Fertilizer PresentationDocumento17 pagineLiquid Fertilizer PresentationAnna RothNessuna valutazione finora

- Savage Inequalities Reading ReflectionDocumento2 pagineSavage Inequalities Reading Reflectionapi-367127133Nessuna valutazione finora

- Reishi MushroomDocumento5 pagineReishi Mushroomjunver100% (4)

- Total Parenteral NutritionDocumento8 pagineTotal Parenteral NutritionTemiloluwa AdeyemiNessuna valutazione finora

- Full Download Book Microbiome Immunity Digestive Health and Nutrition Epidemiology Pathophysiology Prevention and Treatment PDFDocumento41 pagineFull Download Book Microbiome Immunity Digestive Health and Nutrition Epidemiology Pathophysiology Prevention and Treatment PDFmildred.walker324100% (15)

- CMO Historical Data MonthlyDocumento117 pagineCMO Historical Data MonthlyHoàng Minh ChuNessuna valutazione finora

- Big BazaarDocumento6 pagineBig BazaaraniketsangodcarNessuna valutazione finora

- MSW TACSOP v.3.3Documento59 pagineMSW TACSOP v.3.3Mira BellaNessuna valutazione finora

- SurveyDocumento1 paginaSurveyJainne Ann BetchaidaNessuna valutazione finora

- 10.4324 9781315717289 PreviewpdfDocumento179 pagine10.4324 9781315717289 PreviewpdfMahdi GargouriNessuna valutazione finora

- Eastman Methyl N-Amyl Ketone (MAK) and Eastman Methyl Isoamyl Ketone (MIAK)Documento4 pagineEastman Methyl N-Amyl Ketone (MAK) and Eastman Methyl Isoamyl Ketone (MIAK)Chemtools Chemtools100% (1)

- DICGC - For Depositors - A Guide To Deposit InsuranceDocumento10 pagineDICGC - For Depositors - A Guide To Deposit InsuranceSachinNessuna valutazione finora

- Material Safety Data Sheet Roto-Inject FluidDocumento5 pagineMaterial Safety Data Sheet Roto-Inject FluidQuintana JoseNessuna valutazione finora

- Dingenen 2017Documento14 pagineDingenen 2017pedro.coleffNessuna valutazione finora

- TD-XT-D004-003 V2.00 20131204 XG1.UCD-135M185M300M Operation Manual PDFDocumento47 pagineTD-XT-D004-003 V2.00 20131204 XG1.UCD-135M185M300M Operation Manual PDFStan TC100% (1)

- One Hour ImproversDocumento1 paginaOne Hour ImproverssathishrajsNessuna valutazione finora

- IFAD Vietnam RIMS Training Workshop 2011 (1 of 7)Documento18 pagineIFAD Vietnam RIMS Training Workshop 2011 (1 of 7)IFAD VietnamNessuna valutazione finora

- Human Nutritional RequirementsDocumento3 pagineHuman Nutritional RequirementsAgnesMagadiaNessuna valutazione finora

- Fitting in and Fighting Back: Stigma Management Strategies Among Homeless KidsDocumento24 pagineFitting in and Fighting Back: Stigma Management Strategies Among Homeless KidsIrisha AnandNessuna valutazione finora

- The Well (Version 2.4)Documento3 pagineThe Well (Version 2.4)Thaís EspinosaNessuna valutazione finora

- VW Golf 8 Variant WD EngDocumento664 pagineVW Golf 8 Variant WD EngLakhdar BouchenakNessuna valutazione finora

- 6 Instrumentation PDFDocumento144 pagine6 Instrumentation PDFWanderley MandruzatoNessuna valutazione finora

- Leonard Peikoff-Introduction To LogicDocumento20 pagineLeonard Peikoff-Introduction To Logicbursa07Nessuna valutazione finora

- Endovascular Skills CourseDocumento20 pagineEndovascular Skills CourseAbdullah JibawiNessuna valutazione finora

- Qualification Handbook v1-1Documento92 pagineQualification Handbook v1-1rafael espinosa semperNessuna valutazione finora

- Premium Connections Catalogue ENGDocumento134 paginePremium Connections Catalogue ENGsubzwarijNessuna valutazione finora

- Types of ProcurementDocumento7 pagineTypes of ProcurementrahulNessuna valutazione finora

- Tibia Bone Segmentation in X-Ray Images - A Comparative AnalysisDocumento8 pagineTibia Bone Segmentation in X-Ray Images - A Comparative AnalysisSuzanaPetrovicNessuna valutazione finora