Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TBG616K PDF

Caricato da

Tyler GoodwinTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TBG616K PDF

Caricato da

Tyler GoodwinCopyright:

Formati disponibili

TBG 616 K.

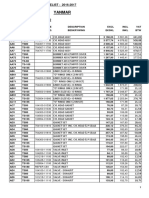

u Dimensions 50 Hz

323-700 kW at 1500

Genset

Length

Width

Height

TBG 616 V8 K

mm

3100

1300

2100

TBG 616 V12 K

mm

4000

1400

2100

TBG 616 V16 K

mm

4400

1400

2200

min-1

The gas engine.

( 50 Hz )

Hz

63

125

250

500

1000

2000

4000

8000

Engine type TBG 616 V8 K

Exhaust noise

120 dB (A )

dB (lin)

108

125

123

116

114

112

107

103

Air-borne noise

97 dB (A)

dB (lin)

85

85

91

93

87

88

92

91

122 dB (A )

dB (lin)

105

126

118

120

115

113

112

105

98 dB (A )

dB (lin)

82

87

91

93

93

90

88

93

125 dB (A )

dB (lin)

108

119

123

120

119

118

115

107

99 dB (A )

dB (lin)

85

93

92

94

93

91

89

92

Engine type TBG 616 V12 K

Exhaust noise

Air-borne noise

Engine type TBG 616 V16 K

Exhaust noise

Air-borne noise

Order-No.

Noise frequency band

0031 1910 / 03 / 2003 / VM-V

u Noise emissions* 50 Hz

These are the characteristics of the TBG 616 K:

State-of-the art 8, 12 and 16 cylinder V-engines.

Exhaust noise at 1 m, b45 , 2.5 dB (A)

Air-borne noise at 1 m from the side, 1 dB (A )

Air-fuel turbocharging and two-stage intercooling.

Single cylinder heads with four-valve technology.

Centrally arranged industrial spark plug with intensive plug seat cooling.

Microprocessor-controlled high-voltage ignition system.

* Values apply to natural gas applications, measured as noise pressure level.

One ignition coil per cylinder.

Electronic control and monitoring of genset operation through TEM.

Exhaust emissions controlled according to combustion chamber temperature.

Your benefits:

Carl-Benz-Strae 5

u

u

u

u

u

D-68167 Mannheim

Phone: + 49 ( 0 ) 6 21- 3 84- 86 10

u Reliable control and monitoring with high safety standards ensure optimum

DEUTZ AG

DEUTZ ENERGY

Fax: + 49 ( 0 ) 6 21- 3 84- 86 12

Internet: www.deutz.de

We move your world.

eMail: deutzenergy.v@ deutz.de

Package of favourable investment and low operating costs.

Low energy consumption thanks to maximum primary energy utilization.

Long service intervals and ease of service guarantee additional cost savings.

Efficient energy conversion with outstanding efficiencies.

Intercooling permits maximum power even when using gases with

low methane numbers.

combustion and maximum engine protection.

u All governing, service, control and monitoring functions are easy and

comfortable to operate.

u Technical data 50 Hz

NOX < = 500 mg /m n3

Naturalgas applications

TBG 616 V8 K

TBG 616 V12 K

TBG 616 V16 K

Engine type

kW

min-1

bar

approx. C

approx. kg / h

approx. kg / h

350

1500

16.0

375

1 940

1 872

525

1500

16.0

411

2 888

2 789

700

1500

16.0

417

3 788

3 655

20/25

9 753

20/25

14 252

20/25

18 461

Engine power 2)

Speed

Mean effective pressure

Exhaust temperature

Exhaust mass flow wet

Combustion air mass flow 2)

Combustion air temperature

minimum/design

Ventilation air flow 3)

approx. kg / h

Minimum heating value (LHV) = 5.0 kWh /m n3

wet exhaust manifold without inliner

TBG 616 V8 K

TBG 616 V12 K

TBG 616 V16 K

kW

min-1

bar

approx. C

approx. kg / h

approx. kg / h

323

1500

14.8

380

1802

1595

485

1500

14.8

403

2 655

2 353

647

1500

14.8

400

3 485

3 081

C

approx. kg / h

20/25

9 237

20/25

13 338

20/25

17 648

96.4

96.6

96.8

kW

8 % kW

8 % kW

8 % kW

8 %kW

kW

kW

+ 5 % kW

+ 5 % kWh/kWh

%

%

%

311

307

21

135

119

20

12

878

2.72

35.4

50.3

85.7

469

412

29

217

194

30

16

1 282

2.64

36.6

49.1

85.7

626

564

36

283

253

40

21

1 711

2.64

36.6

49.5

86.1

m 3/ h

m 3/ h

m 3/ h

m 3/ h

dm 3

dm 3

C

C

C

mbar

mbar

16/30

30.8

8

18.8

28

3

78/90

(78/90)

40/

30/50

5

22/36

37.1

10

18.8

40

3

78/90

(78/90)

40/

30/50

5

30/45

40.2

10

18.8

53

3

78/90

(78/90)

40/

30/50

5

mbar

Ah

kg

kg

20... 100

143

1 810

3 750

20... 100

143

2 380

4 890

20... 100

286

2 880

5 510

Generator

Generator

Efficiency

NOX < = 500 mg /m n3

Sewage gas application (65 % CH4 /35 % CO2 )

Landfill gas application (50 % CH4 /27 % CO2 , rest N2 )

Minimum methane number MN: 70

wet exhaust manifold with inliner

Engine type

Engine power 2)

Speed

Mean effective pressure

Exhaust temperature

Exhaust mass flow wet

Combustion air mass flow 2)

Combustion air temperature

minimum/design

Ventilation air flow 3)

u Technical data 50 Hz

1)

4)

96.4

96.6

96.9

Energy balance

Energy balance

4)

Electrical power

Jacket water heat

Intercooler LT heat 5)

Exhaust cooled to 120 C

Exhaust cooled to 150 C

Engine radiation heat

Generator radiation heat

Fuel consumption 6)

Specific fuel consumption 6)

Electrical efficiency

Thermal efficiency

Total efficiency

kW

8 % kW

8 % kW

8 % kW

8 % kW

kW

kW

+ 5 % kW

+ 5 % kWh/kWh

%

%

%

337

290

21

152

134

20

13

914

2.61

36.9

48.4

85.3

507

382

29

260

233

30

18

1 346

2.56

37.7

47.7

85.4

678

509

41

348

313

40

22

1 795

2.56

37.8

47.7

85.5

m 3/ h

m 3/ h

m 3/ h

m 3/ h

dm 3

dm 3

C

C

C

mbar

mbar

16/30

30.8

8

18.8

28

3

78/90

(74/86)

40/

30 / 50

5

22/36

37.1

10

18.8

40

3

78/90

(74/86)

40/

30 / 50

5

30/45

40.2

10

18.8

53

3

78/90

(74/86)

40/

30 / 50

5

mbar

Ah

kg

kg

20... 100

143

1 810

3 750

20... 100

143

2 380

4 890

20... 100

286

2 880

5 510

TBG 616 V8 K

TBG 616 V12 K

TBG 616 V16 K

132/160

17.5

12 : 1

8.0

70

0.3

132/160

26.3

12 : 1

8.0

100

0.3

132/160

35.0

12 : 1

8.0

135

0.3

Engine type

Bore/stroke

Displacement

Compression ratio

Mean piston speed

Lube oil content 9)

Lube oil consumption mineral oil 10)

Electrical power 4)

Jacket water heat

Intercooler LT heat 5)

Exhaust cooled to 120 C

Exhaust cooled to 150 C

Engine radiation heat

Generator radiation heat

Fuel consumption 6)

Specific fuel consumption 6)

Electrical efficiency

Thermal efficiency

Total efficiency

System parameters

System parameters

Engine jacket water flow rate min./max.

Engine KVS-value 7)

Intercooler coolant flow rate

Intercooler KVS-value 7)

Engine jacket water volume

Intercooler coolant volume

Engine jacket water temperature max.8)

with glycol 8)

Intercooler coolant temperature 8)

Exhaust backpressure min./max.

Maximum pressure loss infront of air cleaner

Gas flow pressure, fixed between

(pressure variation +/ 10 %)

Starter battery 24 V, capacity required

Dry weight engine

Dry weight genset

Efficiency 4)

mm

dm 3

m /s

dm 3

+ 20 % g / kWh

Engine jacket water flow rate min./max.

Engine KVS-value 7)

Intercooler coolant flow rate

Intercooler KVS-value 7)

Engine jacket water volume

Intercooler coolant volume

Engine jacket water temperature max.8)

with glycol 8)

Intercooler coolant temperature 8)

Exhaust backpressure min./max.

Maximum pressure loss infront of air cleaner

Gas flow pressure, fixed between

(pressure variation +/ 10 %)

Starter battery 24 V, capacity required

Dry weight engine

Dry weight genset

1) Exhaust emissions with oxidizing catalyst:

NO X < 0.50 g NO 2 /m n3 dry exhaust gas at 5 % O 2

CO < 0.3 g CO/m n3 dry exhaust gas at 5 % O 2

Formaldehyde < 0.06 g /m n3 dry exhaust gas at 5 % O 2

7) The K VS -value is the parameter for the pressure

loss in the cooling system (= flowrate for 1 bar

pressure loss).

8) Inlet /outlet.

2) Engine power ratings and combustion air volume

flows acc. to ISO 3046/1.

10 ) At full load.

3) Intake air flow at delta T = 15 K including combustion air.

Data for special gas and dual gas operation on request.

4) At 50 Hz, U = 0.4 kV, power factor = 1.

5) At 40 C water inlet.

6) With a tolerance of + 5 %.

9) Including pipes and heat exchangers.

The values given in this data sheet are for information

purposes only and not binding.

The information given in the offer is decisive.

u Technical data 50 Hz

NOX < = 500 mg /m n3

Naturalgas applications

TBG 616 V8 K

TBG 616 V12 K

TBG 616 V16 K

Engine type

kW

min-1

bar

approx. C

approx. kg / h

approx. kg / h

350

1500

16.0

375

1 940

1 872

525

1500

16.0

411

2 888

2 789

700

1500

16.0

417

3 788

3 655

20/25

9 753

20/25

14 252

20/25

18 461

Engine power 2)

Speed

Mean effective pressure

Exhaust temperature

Exhaust mass flow wet

Combustion air mass flow 2)

Combustion air temperature

minimum/design

Ventilation air flow 3)

approx. kg / h

Minimum heating value (LHV) = 5.0 kWh /m n3

wet exhaust manifold without inliner

TBG 616 V8 K

TBG 616 V12 K

TBG 616 V16 K

kW

min-1

bar

approx. C

approx. kg / h

approx. kg / h

323

1500

14.8

380

1802

1595

485

1500

14.8

403

2 655

2 353

647

1500

14.8

400

3 485

3 081

C

approx. kg / h

20/25

9 237

20/25

13 338

20/25

17 648

96.4

96.6

96.8

kW

8 % kW

8 % kW

8 % kW

8 %kW

kW

kW

+ 5 % kW

+ 5 % kWh/kWh

%

%

%

311

307

21

135

119

20

12

878

2.72

35.4

50.3

85.7

469

412

29

217

194

30

16

1 282

2.64

36.6

49.1

85.7

626

564

36

283

253

40

21

1 711

2.64

36.6

49.5

86.1

m 3/ h

m 3/ h

m 3/ h

m 3/ h

dm 3

dm 3

C

C

C

mbar

mbar

16/30

30.8

8

18.8

28

3

78/90

(78/90)

40/

30/50

5

22/36

37.1

10

18.8

40

3

78/90

(78/90)

40/

30/50

5

30/45

40.2

10

18.8

53

3

78/90

(78/90)

40/

30/50

5

mbar

Ah

kg

kg

20... 100

143

1 810

3 750

20... 100

143

2 380

4 890

20... 100

286

2 880

5 510

Generator

Generator

Efficiency

NOX < = 500 mg /m n3

Sewage gas application (65 % CH4 /35 % CO2 )

Landfill gas application (50 % CH4 /27 % CO2 , rest N2 )

Minimum methane number MN: 70

wet exhaust manifold with inliner

Engine type

Engine power 2)

Speed

Mean effective pressure

Exhaust temperature

Exhaust mass flow wet

Combustion air mass flow 2)

Combustion air temperature

minimum/design

Ventilation air flow 3)

u Technical data 50 Hz

1)

4)

96.4

96.6

96.9

Energy balance

Energy balance

4)

Electrical power

Jacket water heat

Intercooler LT heat 5)

Exhaust cooled to 120 C

Exhaust cooled to 150 C

Engine radiation heat

Generator radiation heat

Fuel consumption 6)

Specific fuel consumption 6)

Electrical efficiency

Thermal efficiency

Total efficiency

kW

8 % kW

8 % kW

8 % kW

8 % kW

kW

kW

+ 5 % kW

+ 5 % kWh/kWh

%

%

%

337

290

21

152

134

20

13

914

2.61

36.9

48.4

85.3

507

382

29

260

233

30

18

1 346

2.56

37.7

47.7

85.4

678

509

41

348

313

40

22

1 795

2.56

37.8

47.7

85.5

m 3/ h

m 3/ h

m 3/ h

m 3/ h

dm 3

dm 3

C

C

C

mbar

mbar

16/30

30.8

8

18.8

28

3

78/90

(74/86)

40/

30 / 50

5

22/36

37.1

10

18.8

40

3

78/90

(74/86)

40/

30 / 50

5

30/45

40.2

10

18.8

53

3

78/90

(74/86)

40/

30 / 50

5

mbar

Ah

kg

kg

20... 100

143

1 810

3 750

20... 100

143

2 380

4 890

20... 100

286

2 880

5 510

TBG 616 V8 K

TBG 616 V12 K

TBG 616 V16 K

132/160

17.5

12 : 1

8.0

70

0.3

132/160

26.3

12 : 1

8.0

100

0.3

132/160

35.0

12 : 1

8.0

135

0.3

Engine type

Bore/stroke

Displacement

Compression ratio

Mean piston speed

Lube oil content 9)

Lube oil consumption mineral oil 10)

Electrical power 4)

Jacket water heat

Intercooler LT heat 5)

Exhaust cooled to 120 C

Exhaust cooled to 150 C

Engine radiation heat

Generator radiation heat

Fuel consumption 6)

Specific fuel consumption 6)

Electrical efficiency

Thermal efficiency

Total efficiency

System parameters

System parameters

Engine jacket water flow rate min./max.

Engine KVS-value 7)

Intercooler coolant flow rate

Intercooler KVS-value 7)

Engine jacket water volume

Intercooler coolant volume

Engine jacket water temperature max.8)

with glycol 8)

Intercooler coolant temperature 8)

Exhaust backpressure min./max.

Maximum pressure loss infront of air cleaner

Gas flow pressure, fixed between

(pressure variation +/ 10 %)

Starter battery 24 V, capacity required

Dry weight engine

Dry weight genset

Efficiency 4)

mm

dm 3

m /s

dm 3

+ 20 % g / kWh

Engine jacket water flow rate min./max.

Engine KVS-value 7)

Intercooler coolant flow rate

Intercooler KVS-value 7)

Engine jacket water volume

Intercooler coolant volume

Engine jacket water temperature max.8)

with glycol 8)

Intercooler coolant temperature 8)

Exhaust backpressure min./max.

Maximum pressure loss infront of air cleaner

Gas flow pressure, fixed between

(pressure variation +/ 10 %)

Starter battery 24 V, capacity required

Dry weight engine

Dry weight genset

1) Exhaust emissions with oxidizing catalyst:

NO X < 0.50 g NO 2 /m n3 dry exhaust gas at 5 % O 2

CO < 0.3 g CO/m n3 dry exhaust gas at 5 % O 2

Formaldehyde < 0.06 g /m n3 dry exhaust gas at 5 % O 2

7) The K VS -value is the parameter for the pressure

loss in the cooling system (= flowrate for 1 bar

pressure loss).

8) Inlet /outlet.

2) Engine power ratings and combustion air volume

flows acc. to ISO 3046/1.

10 ) At full load.

3) Intake air flow at delta T = 15 K including combustion air.

Data for special gas and dual gas operation on request.

4) At 50 Hz, U = 0.4 kV, power factor = 1.

5) At 40 C water inlet.

6) With a tolerance of + 5 %.

9) Including pipes and heat exchangers.

The values given in this data sheet are for information

purposes only and not binding.

The information given in the offer is decisive.

TBG 616 K.

u Dimensions 50 Hz

323-700 kW at 1500

Genset

Length

Width

Height

TBG 616 V8 K

mm

3100

1300

2100

TBG 616 V12 K

mm

4000

1400

2100

TBG 616 V16 K

mm

4400

1400

2200

min-1

The gas engine.

( 50 Hz )

Hz

63

125

250

500

1000

2000

4000

8000

Engine type TBG 616 V8 K

Exhaust noise

120 dB (A )

dB (lin)

108

125

123

116

114

112

107

103

Air-borne noise

97 dB (A)

dB (lin)

85

85

91

93

87

88

92

91

122 dB (A )

dB (lin)

105

126

118

120

115

113

112

105

98 dB (A )

dB (lin)

82

87

91

93

93

90

88

93

125 dB (A )

dB (lin)

108

119

123

120

119

118

115

107

99 dB (A )

dB (lin)

85

93

92

94

93

91

89

92

Engine type TBG 616 V12 K

Exhaust noise

Air-borne noise

Engine type TBG 616 V16 K

Exhaust noise

Air-borne noise

Order-No.

Noise frequency band

0031 1910 / 03 / 2003 / VM-V

u Noise emissions* 50 Hz

These are the characteristics of the TBG 616 K:

State-of-the art 8, 12 and 16 cylinder V-engines.

Exhaust noise at 1 m, b45 , 2.5 dB (A)

Air-borne noise at 1 m from the side, 1 dB (A )

Air-fuel turbocharging and two-stage intercooling.

Single cylinder heads with four-valve technology.

Centrally arranged industrial spark plug with intensive plug seat cooling.

Microprocessor-controlled high-voltage ignition system.

* Values apply to natural gas applications, measured as noise pressure level.

One ignition coil per cylinder.

Electronic control and monitoring of genset operation through TEM.

Exhaust emissions controlled according to combustion chamber temperature.

Your benefits:

Carl-Benz-Strae 5

u

u

u

u

u

D-68167 Mannheim

Phone: + 49 ( 0 ) 6 21- 3 84- 86 10

u Reliable control and monitoring with high safety standards ensure optimum

DEUTZ AG

DEUTZ ENERGY

Fax: + 49 ( 0 ) 6 21- 3 84- 86 12

Internet: www.deutz.de

We move your world.

eMail: deutzenergy.v@ deutz.de

Package of favourable investment and low operating costs.

Low energy consumption thanks to maximum primary energy utilization.

Long service intervals and ease of service guarantee additional cost savings.

Efficient energy conversion with outstanding efficiencies.

Intercooling permits maximum power even when using gases with

low methane numbers.

combustion and maximum engine protection.

u All governing, service, control and monitoring functions are easy and

comfortable to operate.

Potrebbero piacerti anche

- TBG 616Documento4 pagineTBG 616sdiaman50% (2)

- GasEngines&Gensets PDFDocumento4 pagineGasEngines&Gensets PDFShakhowath Chowdhury100% (1)

- TCG2032Documento4 pagineTCG2032sdiamanNessuna valutazione finora

- Catalogue TCG2032V16 4Documento4 pagineCatalogue TCG2032V16 4Mizan SarkarNessuna valutazione finora

- J320V21 enDocumento4 pagineJ320V21 enMartin KratkyNessuna valutazione finora

- Stand-By Aggregate Deutz MWM TBG 616 V12: Technical DetailsDocumento1 paginaStand-By Aggregate Deutz MWM TBG 616 V12: Technical DetailsKamieshiNessuna valutazione finora

- J312V02 enDocumento4 pagineJ312V02 enMartin KratkyNessuna valutazione finora

- GE - 200802 - Technical Specs Jenbacher Type 6 PDFDocumento2 pagineGE - 200802 - Technical Specs Jenbacher Type 6 PDFsakthivelNessuna valutazione finora

- Jenbacher JMS 616 GS-N.L Natural Gas Module Technical SpecsDocumento4 pagineJenbacher JMS 616 GS-N.L Natural Gas Module Technical SpecsMartin KratkyNessuna valutazione finora

- Schedle Maintenance JenbacherDocumento3 pagineSchedle Maintenance JenbacherEnrique Garcia0% (1)

- Jenbacher Engine DetailsDocumento2 pagineJenbacher Engine DetailsAmin HunzaiNessuna valutazione finora

- GE Type 3 Technical Instructions 07-30-2012 - Isolated OperationDocumento224 pagineGE Type 3 Technical Instructions 07-30-2012 - Isolated OperationSerg MarushkoNessuna valutazione finora

- Jenbacher 616 GS-N.L Gas Engine Specs & 2.433kW OutputDocumento4 pagineJenbacher 616 GS-N.L Gas Engine Specs & 2.433kW OutputMartin KratkyNessuna valutazione finora

- GE Power Retrofitting Sensor Modules to Improve Engine MonitoringDocumento38 pagineGE Power Retrofitting Sensor Modules to Improve Engine MonitoringPopa MihaiNessuna valutazione finora

- Tedom Handbook For Designers 2008Documento57 pagineTedom Handbook For Designers 2008ManretyNessuna valutazione finora

- MBH Conversion References - Deutz-MWM TBD 6M 628Documento1 paginaMBH Conversion References - Deutz-MWM TBD 6M 628Marbun Benny100% (1)

- Cylinder Head: Maintenance InstructionDocumento12 pagineCylinder Head: Maintenance InstructionReny NapitupuluNessuna valutazione finora

- ManualDocumento4 pagineManualmuhammad arif67% (3)

- Component OverviewDocumento20 pagineComponent OverviewAndronic Cosmin0% (1)

- QSK60 G6 PDFDocumento2 pagineQSK60 G6 PDFShahzad Ali100% (2)

- 1 X Jgs 420-Bl-BopDocumento25 pagine1 X Jgs 420-Bl-Bophaji atinNessuna valutazione finora

- Wartsila W28SG 1Documento5 pagineWartsila W28SG 1hadNessuna valutazione finora

- GE Type 3 TECHNICAL SPECIFICATION OF THE CONTROLDocumento24 pagineGE Type 3 TECHNICAL SPECIFICATION OF THE CONTROLSerg MarushkoNessuna valutazione finora

- 1400-0100 enDocumento3 pagine1400-0100 enKopi BrisbaneNessuna valutazione finora

- Jenbacher Type 6 Fs en Metric 2016Documento2 pagineJenbacher Type 6 Fs en Metric 2016laiquz zamanNessuna valutazione finora

- Extended DIA - Ne XT - AccessDocumento2 pagineExtended DIA - Ne XT - Accesslaiquz zaman33% (3)

- 1000-1109 - Index 17 GE Jenbacher Gas EnginesDocumento14 pagine1000-1109 - Index 17 GE Jenbacher Gas EnginesDavid PomaNessuna valutazione finora

- MWM Interface400VContainerTCG2016CDocumento3 pagineMWM Interface400VContainerTCG2016Cgabinetedeiniciativa100% (1)

- Expt 6 The Split Phase MotorDocumento4 pagineExpt 6 The Split Phase MotorCapalar KyleNessuna valutazione finora

- 0606 - TD - E2842 LE312 - Nat - EngDocumento8 pagine0606 - TD - E2842 LE312 - Nat - EngfaridNessuna valutazione finora

- Reference Cable Schedule - JGS 320 - Non-Grid SynchronizationDocumento2 pagineReference Cable Schedule - JGS 320 - Non-Grid SynchronizationfaisalnadimNessuna valutazione finora

- Ficha Motor Gas Natural Jenbacher JMS 612 GSNL PDFDocumento4 pagineFicha Motor Gas Natural Jenbacher JMS 612 GSNL PDFJuan Jose RuedaNessuna valutazione finora

- Iil C249Documento206 pagineIil C249Khalid RafiqNessuna valutazione finora

- Jenbacher: 1. Key To Module Diagrams and Technical Schema: - 1Documento14 pagineJenbacher: 1. Key To Module Diagrams and Technical Schema: - 1Jamil Ahmed100% (1)

- GE Jenbacher High Efficiency ConceptDocumento9 pagineGE Jenbacher High Efficiency Conceptjulihardo parulian simarmataNessuna valutazione finora

- J624 G01 6300VDocumento5 pagineJ624 G01 6300VJajap TanudjajaNessuna valutazione finora

- G3306Documento4 pagineG3306carlucido247970100% (1)

- J420V06 enDocumento4 pagineJ420V06 enMarianoNessuna valutazione finora

- DEUTZ Gas Engine Limit - Oil AnalysisDocumento13 pagineDEUTZ Gas Engine Limit - Oil Analysisgilar herliana putraNessuna valutazione finora

- ST-108 Lenox Seting PDFDocumento4 pagineST-108 Lenox Seting PDFPopa MihaiNessuna valutazione finora

- J612V22 enDocumento4 pagineJ612V22 enMartin Kratky100% (1)

- TBG 632 Limit Values ListDocumento23 pagineTBG 632 Limit Values ListMizan SarkarNessuna valutazione finora

- 320Documento61 pagine320Rashid Mahmood JaatNessuna valutazione finora

- Jenbacher Gasm BHKW enDocumento28 pagineJenbacher Gasm BHKW ensaniterm100% (1)

- Jenbacher 1.946kW Biogas Engine Module Technical SpecsDocumento4 pagineJenbacher 1.946kW Biogas Engine Module Technical SpecsMartin KratkyNessuna valutazione finora

- ST-124 New Gear Train PDFDocumento21 pagineST-124 New Gear Train PDFPopa MihaiNessuna valutazione finora

- JGS 420 B05 - 1500 KW (Nox - 500)Documento11 pagineJGS 420 B05 - 1500 KW (Nox - 500)Ibrahim Ahmed FarrukhNessuna valutazione finora

- JGS 420 GS-S.L: Low Methane - Coal Mine MethaneDocumento34 pagineJGS 420 GS-S.L: Low Methane - Coal Mine MethaneDexterous EngineeringNessuna valutazione finora

- GTG 1636FPC PWFT4 50HzDocumento24 pagineGTG 1636FPC PWFT4 50HzEmanuel CondeNessuna valutazione finora

- W 0700m6 - Gas Mixer PDFDocumento5 pagineW 0700m6 - Gas Mixer PDFPopa MihaiNessuna valutazione finora

- 1560 kWel gas generator technical dataDocumento1 pagina1560 kWel gas generator technical dataabsahkahNessuna valutazione finora

- QSK19G PerformanceDocumento5 pagineQSK19G PerformancetroyNessuna valutazione finora

- GE Power & Water - Gas Engines: Grupos de Cogeneración Con Motor A Gas Jenbacher para España y Portugal (2013)Documento1 paginaGE Power & Water - Gas Engines: Grupos de Cogeneración Con Motor A Gas Jenbacher para España y Portugal (2013)bintoitoNessuna valutazione finora

- Technical Data Sheet For Avk-Alternators: Unsaturated Saturated Unsaturated SaturatedDocumento9 pagineTechnical Data Sheet For Avk-Alternators: Unsaturated Saturated Unsaturated SaturatedTariqMaqsoodNessuna valutazione finora

- Map GuascorDocumento36 pagineMap GuascorMuhammad SyaqirinNessuna valutazione finora

- 05-07-02-03-01 - Dezentrale Peripherie 01 PDFDocumento17 pagine05-07-02-03-01 - Dezentrale Peripherie 01 PDFTariqMaqsoodNessuna valutazione finora

- ST-135 Steel Pistons, Cylinder Liners, Scraper Rings, Cylinder Head Gaskets PDFDocumento5 pagineST-135 Steel Pistons, Cylinder Liners, Scraper Rings, Cylinder Head Gaskets PDFPopa MihaiNessuna valutazione finora

- PandarosDocumento9 paginePandarosTempest_LNessuna valutazione finora

- Integrated Renewable Energy for Rural Communities: Planning Guidelines, Technologies and ApplicationsDa EverandIntegrated Renewable Energy for Rural Communities: Planning Guidelines, Technologies and ApplicationsNessuna valutazione finora

- Tbg620k 50hz enDocumento4 pagineTbg620k 50hz enEhsanur RahmanNessuna valutazione finora

- Update Unit Ready 21062022Documento1 paginaUpdate Unit Ready 21062022Tyler GoodwinNessuna valutazione finora

- Spare Parts and Lubricants ListingDocumento46 pagineSpare Parts and Lubricants ListingTyler GoodwinNessuna valutazione finora

- Makenda Sales Yanmar Price ListDocumento14 pagineMakenda Sales Yanmar Price ListTyler GoodwinNessuna valutazione finora

- NOMAT Description Part Number PriceDocumento3 pagineNOMAT Description Part Number PriceTyler GoodwinNessuna valutazione finora

- 5 1 Icsc2010 032Documento14 pagine5 1 Icsc2010 032Tyler GoodwinNessuna valutazione finora

- Material No Keterangan Satuan Plant Max Stock LevelDocumento1 paginaMaterial No Keterangan Satuan Plant Max Stock LevelTyler GoodwinNessuna valutazione finora

- PDFDocumento2 paginePDFairsys7projecNessuna valutazione finora

- Modifiable Skills MatrixDocumento84 pagineModifiable Skills MatrixTyler GoodwinNessuna valutazione finora

- Form Monthly Report Redo1Documento2 pagineForm Monthly Report Redo1Tyler GoodwinNessuna valutazione finora

- Ubah Harga NanaDocumento2 pagineUbah Harga NanaTyler GoodwinNessuna valutazione finora

- 87 11qqqDocumento10 pagine87 11qqqTyler GoodwinNessuna valutazione finora

- D85ess P2uDocumento1 paginaD85ess P2uTyler GoodwinNessuna valutazione finora

- Crane Graple AnggaDocumento1 paginaCrane Graple AnggaTyler GoodwinNessuna valutazione finora

- WQ 2Documento2 pagineWQ 2Tyler GoodwinNessuna valutazione finora

- Form Permintaan BarangDocumento148 pagineForm Permintaan BarangTyler GoodwinNessuna valutazione finora

- Book 1Documento4 pagineBook 1Tyler GoodwinNessuna valutazione finora

- Safety Alert From Sangatta - Truck RD3138 Reversed Into An RD3351 Which Was Moving Forward at Dumping PointDocumento2 pagineSafety Alert From Sangatta - Truck RD3138 Reversed Into An RD3351 Which Was Moving Forward at Dumping PointTyler Goodwin100% (1)

- Maintain Nomat Parts Antika-1Documento2 pagineMaintain Nomat Parts Antika-1Tyler GoodwinNessuna valutazione finora

- Shutdown Task Komatsu 530M - UpDate 1Documento3 pagineShutdown Task Komatsu 530M - UpDate 1Tyler GoodwinNessuna valutazione finora

- List of SAP T-CodesDocumento18 pagineList of SAP T-CodesastinetNessuna valutazione finora

- TSR Inta ATVV40035Documento18 pagineTSR Inta ATVV40035Tyler GoodwinNessuna valutazione finora

- Plan Cycle Invest Tools Equip 2011Documento12 paginePlan Cycle Invest Tools Equip 2011Tyler GoodwinNessuna valutazione finora

- Epsilon Manual PDFDocumento32 pagineEpsilon Manual PDFarturo91Nessuna valutazione finora

- Daily equipment maintenance reportDocumento4 pagineDaily equipment maintenance reportTyler GoodwinNessuna valutazione finora

- SAP Inventory Management TcodesDocumento26 pagineSAP Inventory Management TcodesTyler GoodwinNessuna valutazione finora

- Maintenance Schedule WorksheetDocumento2 pagineMaintenance Schedule WorksheetRanu JanuarNessuna valutazione finora

- Bolt Double Wheel SJNWDocumento6 pagineBolt Double Wheel SJNWTyler GoodwinNessuna valutazione finora

- Modifiable Skills MatrixDocumento82 pagineModifiable Skills MatrixRichard Thodé JrNessuna valutazione finora

- AGCO InstallDocumento10 pagineAGCO InstallTyler GoodwinNessuna valutazione finora

- TCODESDocumento3 pagineTCODESTyler GoodwinNessuna valutazione finora

- Facility Process Parameters GuideDocumento58 pagineFacility Process Parameters GuideHandyNessuna valutazione finora

- Eni E&P Casing Design PresentationDocumento87 pagineEni E&P Casing Design PresentationLeon ZidaneNessuna valutazione finora

- Electrical Cable Heads: ApplicationsDocumento3 pagineElectrical Cable Heads: ApplicationsDiego Cordero100% (1)

- Distillation ColumnsDocumento40 pagineDistillation ColumnsSantiagoOrtizLdsNessuna valutazione finora

- Structural Design of Tunnel Lining: Presented By: Mahesh Raj Bhatt M.E. in Structural Engineering Kathmandu UniversityDocumento42 pagineStructural Design of Tunnel Lining: Presented By: Mahesh Raj Bhatt M.E. in Structural Engineering Kathmandu UniversityyadavniranjanNessuna valutazione finora

- Mechanics of Deformable Bodies: Mapúa Institute of TechnologyDocumento16 pagineMechanics of Deformable Bodies: Mapúa Institute of TechnologyAhsan AliNessuna valutazione finora

- Co2 AshraeDocumento62 pagineCo2 Ashraegreerush100% (1)

- Question Bank For Experimental Stress AnalysisDocumento3 pagineQuestion Bank For Experimental Stress AnalysishamdanforaeroNessuna valutazione finora

- 2016 FSAE Electric Vehicle Pedal Assembly Design PDFDocumento40 pagine2016 FSAE Electric Vehicle Pedal Assembly Design PDFCarlos LLivisacaNessuna valutazione finora

- Mackay Flex Isolators CatalogueDocumento142 pagineMackay Flex Isolators Cataloguemuss21Nessuna valutazione finora

- YTH18 General InformationDocumento18 pagineYTH18 General InformationJuan David Orjuela FrancoNessuna valutazione finora

- Parker Solenoid ValveDocumento9 pagineParker Solenoid ValveHamza BayatNessuna valutazione finora

- Intro to material & geometric nonlinearity in engineeringDocumento4 pagineIntro to material & geometric nonlinearity in engineeringchaNessuna valutazione finora

- Seminar ReportDocumento15 pagineSeminar ReportRushikesh PatilNessuna valutazione finora

- Reinforced Concrete Water Tank Design RequirementsDocumento10 pagineReinforced Concrete Water Tank Design Requirementshmd rasikaNessuna valutazione finora

- Equipment Upload FormatDocumento80 pagineEquipment Upload FormatPankaj PandeyNessuna valutazione finora

- API RP 585 Pressure Equipment Integrity Incident InvestigationDocumento43 pagineAPI RP 585 Pressure Equipment Integrity Incident InvestigationKYAW100% (1)

- Nest Total InfoDocumento6 pagineNest Total Infobharat laserNessuna valutazione finora

- Centriflow Fan FlaktDocumento4 pagineCentriflow Fan FlakttalabiraNessuna valutazione finora

- Module 5 Extrusion Lecture 1Documento10 pagineModule 5 Extrusion Lecture 1Ashrav GuptaNessuna valutazione finora

- Inverter Multy Air Conditioner Agyf09lacDocumento25 pagineInverter Multy Air Conditioner Agyf09lacIGNFONessuna valutazione finora

- Spelter SocketDocumento1 paginaSpelter SocketarslanahmedkhawajaNessuna valutazione finora

- Quality Gear Inspection Part I Focuses on Diagnostic TechniquesDocumento7 pagineQuality Gear Inspection Part I Focuses on Diagnostic Techniquessurawutwijarn100% (1)

- On Air ConditioningDocumento26 pagineOn Air ConditioningTej KalyanNessuna valutazione finora

- SCHWING TrainingManualDocumento303 pagineSCHWING TrainingManualHarlinton descalzi86% (100)

- 6N330WDocumento1 pagina6N330WJoginder SinghNessuna valutazione finora

- 2019 Africa Twin DCT Specifications : EngineDocumento1 pagina2019 Africa Twin DCT Specifications : EngineBlahNessuna valutazione finora

- PDF Din 5480 1pdfDocumento10 paginePDF Din 5480 1pdfAKSHAY MAHAJANNessuna valutazione finora

- Switched Reluctance MotorDocumento12 pagineSwitched Reluctance MotorSUMAN CNessuna valutazione finora

- TECHNOLOGY New Program Sizes Pressure-Relief Drums: CloseDocumento7 pagineTECHNOLOGY New Program Sizes Pressure-Relief Drums: CloseCalcetinNessuna valutazione finora